TAGGED: convergence, coupled-field, disc-brake

-

-

April 6, 2025 at 7:16 am

engr.rohan7

SubscriberHello community,

I am trying to run a thermo mechaincal analysis for brake. I have applied convection with film coefficient of 5e-05 W/mm^2 K on to the brake faces of the disc and pads. The initial and reference temperature is 22 deg C for convection. I have also applied the mechanical loads like joint rotational velocity, joint force. Frictional contacts have been defined between contacting faces of pad and disc that are having Pure penalty formulation with detection method as Nodal- normal to target. Normal stiffness defined as 0.075. The load steps for free rotation converge, but at the start of brake application (Brake force applied as joint force in 3rd load step) where the brake force is linearly ramped over a span of 0.1 seconds fails to converge with following errors:

The value of TEMP at node 215974 is 11417734.8. It ia greater than the

current limit of 1000000 (which can be reset on the NCNV command).

This generally indicates that there are no temperature constraints or

convections applied.*** MESSAGE CONTINUATION ---- DIAGNOSTIC INFORMATION ***

If one or more parts of the model are held together only by contact

verify that the contact surfaces are closed. You can check contact

status in the SOLUTION module for the converged solutions using

CNCHECK.

*** ERROR ***

*** MESSAGE CONTINUATION ---- DIAGNOSTIC INFORMATION ***

Rigid body motion can also occur when net section yielding has

occurred resulting in large displacements for small increments of load

or when buckling has occurred. You can plot the time history curve

for node 215974 in the TEMP direction to check for stiffness (slope of

the curve) approaching zero.As per the error, I've previously ran the contact tool and observed the initial status to be closed for all the contacts defined. How to troubleshoot these errors so that the disc can stop rotating after the brake force application.

Regards,

Rohan.

-

April 7, 2025 at 1:39 pm

danielshaw

Ansys EmployeeThat error message indicates that the analysis is numerically unstable. For a structural analysis, it typically means that a load is applied in a direction without any restraint. For a thermal analysis, it often means that heat is being applied into the model, but not dissipated from the model, so the temperature increases to infinity (or at least until it reaches the internal limit and triggers the error message). You need to check your boundary conditions. If it is a transient analysis, you might also consider running it for a very small time step. If it converges, you can review those results to see where the over temperature is occuring. That result might give you a clue as to what boundary conditions need to be added or modified.

-

April 7, 2025 at 2:23 pm

dlooman

Ansys EmployeeA debug technique is to run a short transient and check which body is heating up quickly.

-

April 8, 2025 at 5:00 am

engr.rohan7

SubscriberThank you @danielshaw and @dlooman your feedback. It is a coupled field transient analysis and the total time span for the analysis is 0.5s. I have a query regarding @dlooman's debug technique. Should I run a transient thermal or coupled field transient as usual for debugging. I would also like to know the time span for the analysis.

@danielshaw as you mentioned in your reply, I have applied joint force using translational joint for brakepad. The gap between the brakepad and disc surface is zero. So I haven't applied any displacement constraint and directly applied the ramped joint force. I would like to know whether any modification in application of mechanical load is required.

Regards,

Rohan.

-

April 8, 2025 at 1:29 pm

danielshaw

Ansys EmployeeThe error message indicates that the solutioin is exceeding a TEMP DOF, not a structural DOF. So, the immediate issue is with the temperature boundary conditions. Are you doing a thermal-structural coupled field analysis or are there other physics involved? If it is only thermal-mechanical, how is heat input into the model and how is it dissipated? If internal heat is generated by the brackepads how is that heat dissipated?

There is no majical number for the short time transient. You just need to run it for long enough to capture the improper heat up, but not long enough to numerically crash. I would start by decreasing the inital time step that caused the crashed by a factor of something like 10-100 and see what happens. Also, you might try slowing down how the heat is applied/generated, so the heat up occurs slower. It might not be physical reality, but it may give you some clues about how the model is behaving and which BCs are incorrect.

-

April 8, 2025 at 2:11 pm

engr.rohan7

SubscriberThank you @danielshaw for your feedback. Yes, it is a thermo mechanical analysis of brake. No other physics is involved. Regarding the temperature boundary conditions, I have applied a convection load with film coefficient 5e-05 W/mm^2 K. This film coefficient is applied constant over the entire timespan of 0.5s, i.e free rotation of disc and braking phase. The convection is applied on contacting faces and outer faces of the disc. No other thermal boundary conditions are applied. I haven't applied any additional boundary conditions to dissipate internal heat generated due to frictional heating. As per your suggestions, I will run an iteration to determine the sudden heat up.

If you may suggest a way to address the heat dissipation due to frictional heating I will incorporate that in my simulation as well. Thanks in advance.

Regards,

Rohan.

-

April 8, 2025 at 3:44 pm

danielshaw

Ansys EmployeeSo, it appears that the model internally generates heat due to frictional contact and then attempts to dissipate that heat to the surrounding air using a natural converction film coefficient on some surfaces. I do not know how heat is dissipated from you model, but you may need to reconsider how the BCs are applied. Did you apply a thermal BC to all free surfaces or a limited set? Where did you obtain that film coefficient? Are its units consistent with other model units?

-

April 8, 2025 at 5:59 pm

engr.rohan7

SubscriberHello @danielshaw,

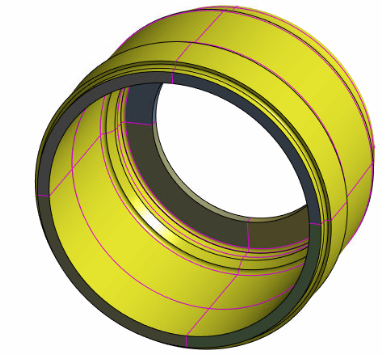

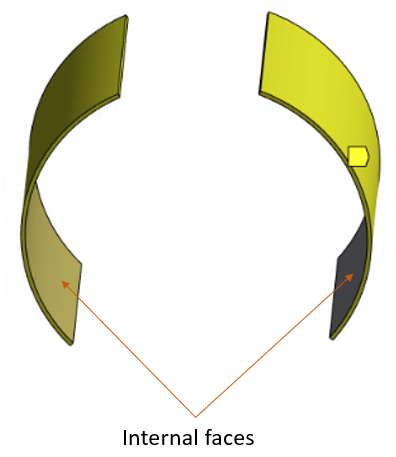

As shown in above image, the yellow marked surfaces are considered for convective heat transfer for brakedrum and brakepads. The annular ring portion of the brakedrum and the internal faces of brakepad on right are not considered for convection. Two elements are maintained across thickness of the pad in mesh. The film coefficient data was not available so standard value was considered of stagnant air. The units are consistent with other model units [Metric (mm, kg, N, s, mV, mA)].

Regards,

Rohan.

-

April 8, 2025 at 8:50 pm

danielshaw

Ansys EmployeeI cannot debug your model's BCs from those images. Does your model rely on contact to transfer heat between bodies? If so, are the contacts engaged? Maybe the model has an open contact pair and heat is input into the body on one side of the contact but cannot be conducted to the body on the other side.. Did you try to run a very short transient and post-process the thermal results? The best debugging approach is probably to obtain a converged solution (even for tiny time step) and review the results to see if the heat is being conducted and dissipated as expected.

-

April 9, 2025 at 6:27 am

engr.rohan7

SubscriberHello @danielshaw,

Yes the pad and the drum are connected through frictional contacts. I generated a contact tool for the contacts and the initial status shows the contacts is closed with penetration for one contact to be 2.38e-02 mm and for second pad- drum contact penetration is 3.7e-04mm. I have also created a command snippet for frictional contacts where I have divided the thermal energy between contact and target and also defined a command for conversion of friction to heat using RMODIF 15 and RMODIF 18 commands. As you have previously mentioned, I have created a setup where during the brake force application load step, I have given a very small time steps, to capture the temperature spike. I will get back with the results.

Regards,

Rohan.

-

April 27, 2025 at 4:37 am

engr.rohan7

SubscriberHello @danielshaw,

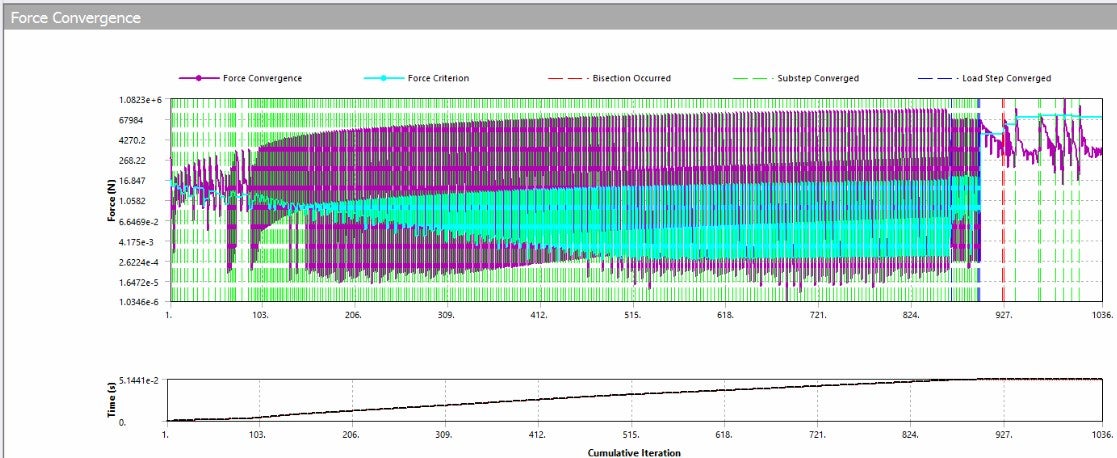

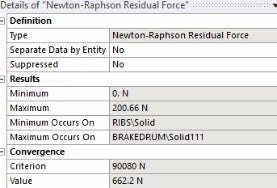

As per the previous discussion I have done the coupled field analysis of the brakedrum and now I don't get the error of TEMP dof since I changed the material assignment (previously the density of the material assigned to the brakepad and brakeshoe was 1kg/m^3 so assigned default material of structural steel). However, when the load step of brake force starts, the solution stops and I have some N-R residuals as shown below,

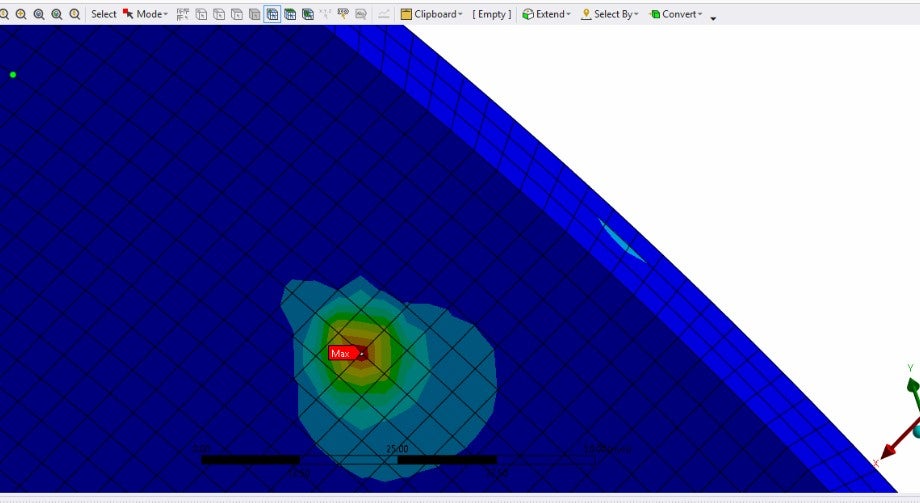

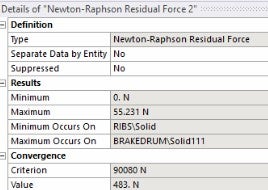

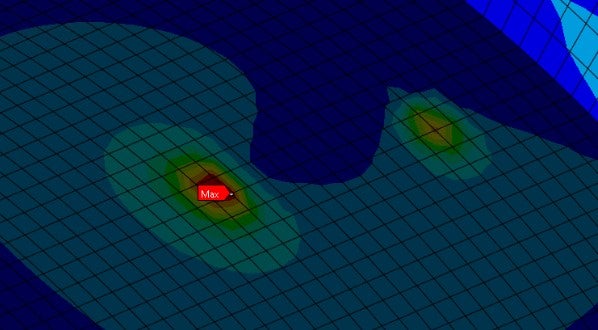

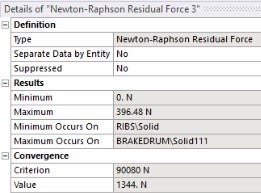

1) Force convergence plot,

2) 1st N-R residual,

3) 2nd N-R residual,

4) 3rd N-R residual,

The force imbalance location for 1st and 3rd N-R residual is same.

From the residual plots, we can see the convergence value is well below the convergence criterion but still why the solution does not continue solving and terminates? I had previously applied the initial minimum and maximum substeps to be 1000, 750, 1500 resp., but I changed it to 2000, 1500, 4000 resp, but still the same issue of N-R residuals occurs where criterion > value is seen. How to troubleshoot this issue and make sure the solution doesn't stop even when convergence value is well below criterion.

Regards,

Rohan.

-

April 27, 2025 at 5:03 am

engr.rohan7

SubscriberHello @danielshaw,

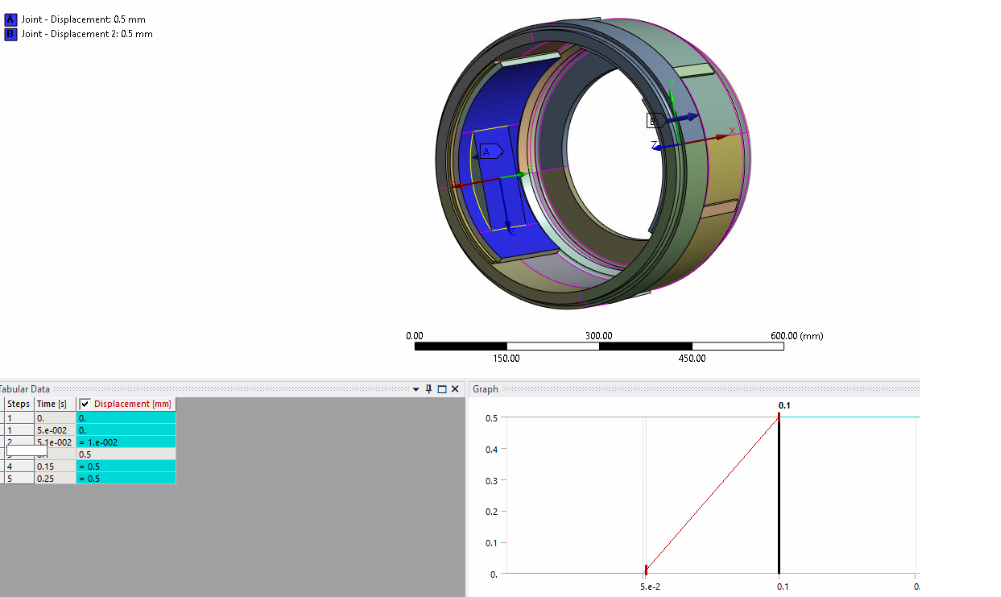

In addition to above post, I forgot to mention that the interface treatment for frictional contacts is Add Offset, no ramping with offset value equal to the gap value mentioned in the initial info of Contact tool. The contact status is closed for the frictional contacts. I have also attached the following image where a joint displacement is applied to move the brakepad into contact with the brakedrum surface during the corresponding loadstep as shown below during which the convergence issue occurs at the start of this load step as mentioned in previous post. In the next load step, the brakeforce is applied. I would like to know whether the load applied is correct or any changes need to be made?

Regards,

Rohan.

-

May 1, 2025 at 9:57 pm

danielshaw

Ansys EmployeeDid you review the solve.out file? Did it issue any error or warning messages indicating why the solution stopped?

-

May 3, 2025 at 11:59 am

engr.rohan7

SubscriberYes I reviewed the solve.out file and one error message of “Solution failed to converge at time… Run terminated” was seen. As mentioned above, the solver plotted the N-R residuals and stopped the solution from proceeding. How to proceed with the solution?

Regards,

Rohan

-

-

- You must be logged in to reply to this topic.

- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- How to model a bimodular material in Mechanical

- APDL, memory, solid

- Meaning of the error

- Simulate a fan on the end of shaft

- Real Life Example of a non-symmetric eigenvalue problem

- Nonlinear load cases combinations

- How can the results of Pressures and Motions for all elements be obtained?

-

3962

-

1415

-

1272

-

1119

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.