TAGGED: mechanical, rigid-body-motion, thermal-analysis

-

-

November 12, 2024 at 3:27 pm

fsvensen92

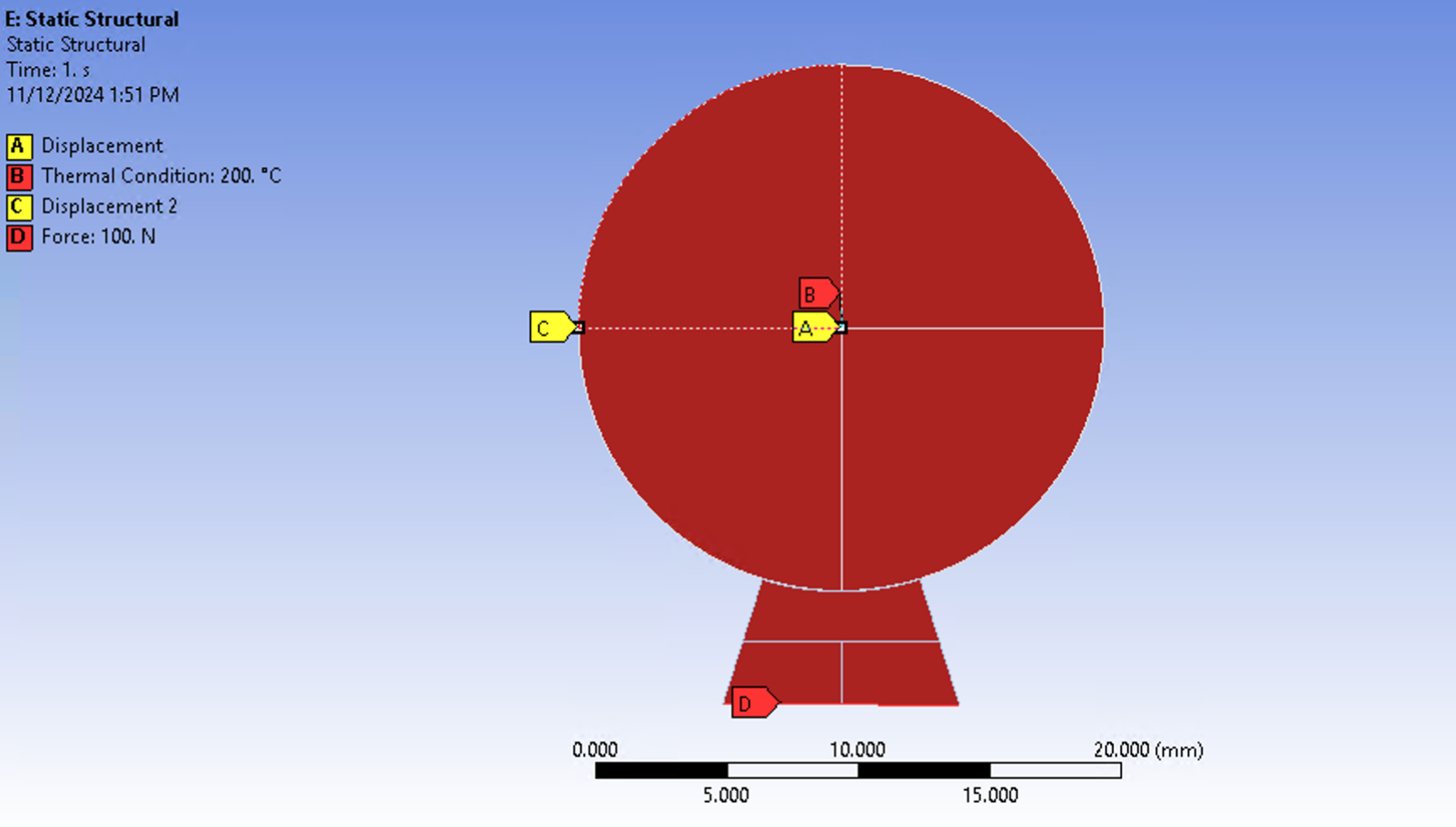

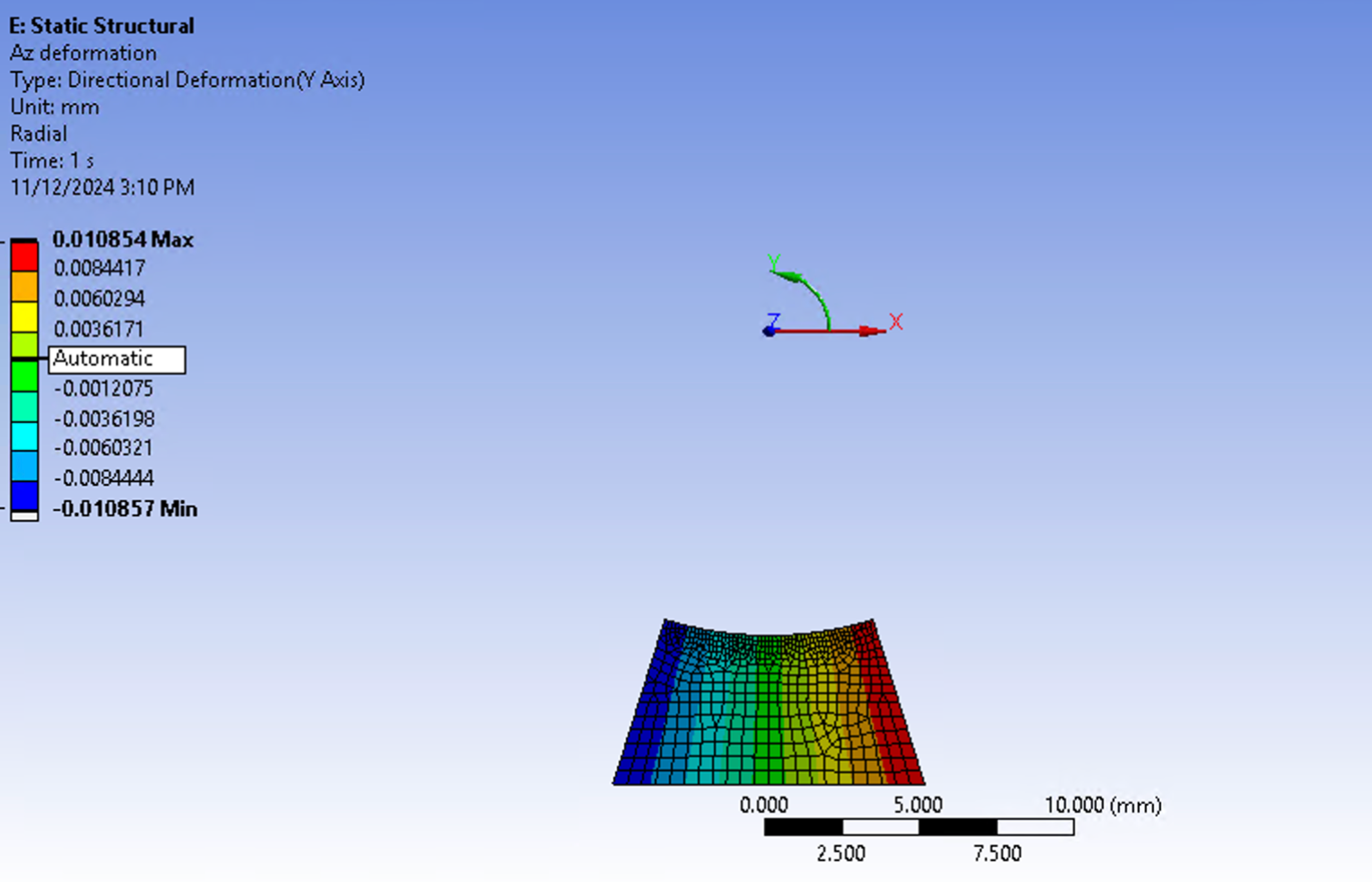

SubscriberI have a geometry of two metal bodies (a circular drum and a wedge) and I want to study the deformation during thermal expansion and a force applied at the bottom edge pointing towards the drum center. I expect to see expansion of the wedge in the azimuth along the circumferance of the drum.

General conditions:- The center of the drum should be fixed

- The center of the wedge should only move in the radial direction

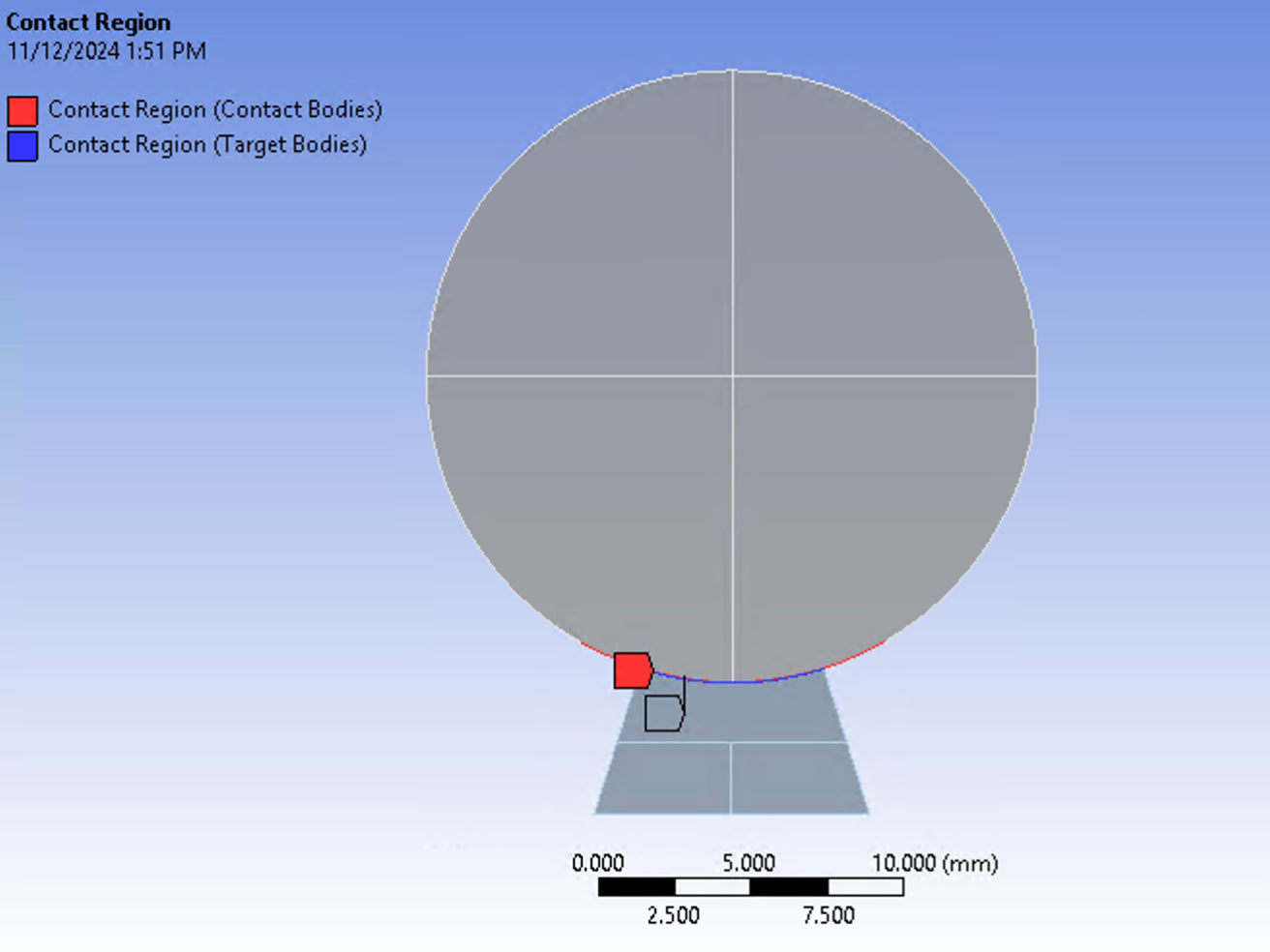

- There is initially a very small gap between the bodies

I am struggeling with applying the correct BCs and contacts. My initial setup was the following:- Bonded contact

- Fix rigid body motion for the drum by constraining both degrees of freedom at the center of mass and in the Y axis at the edg

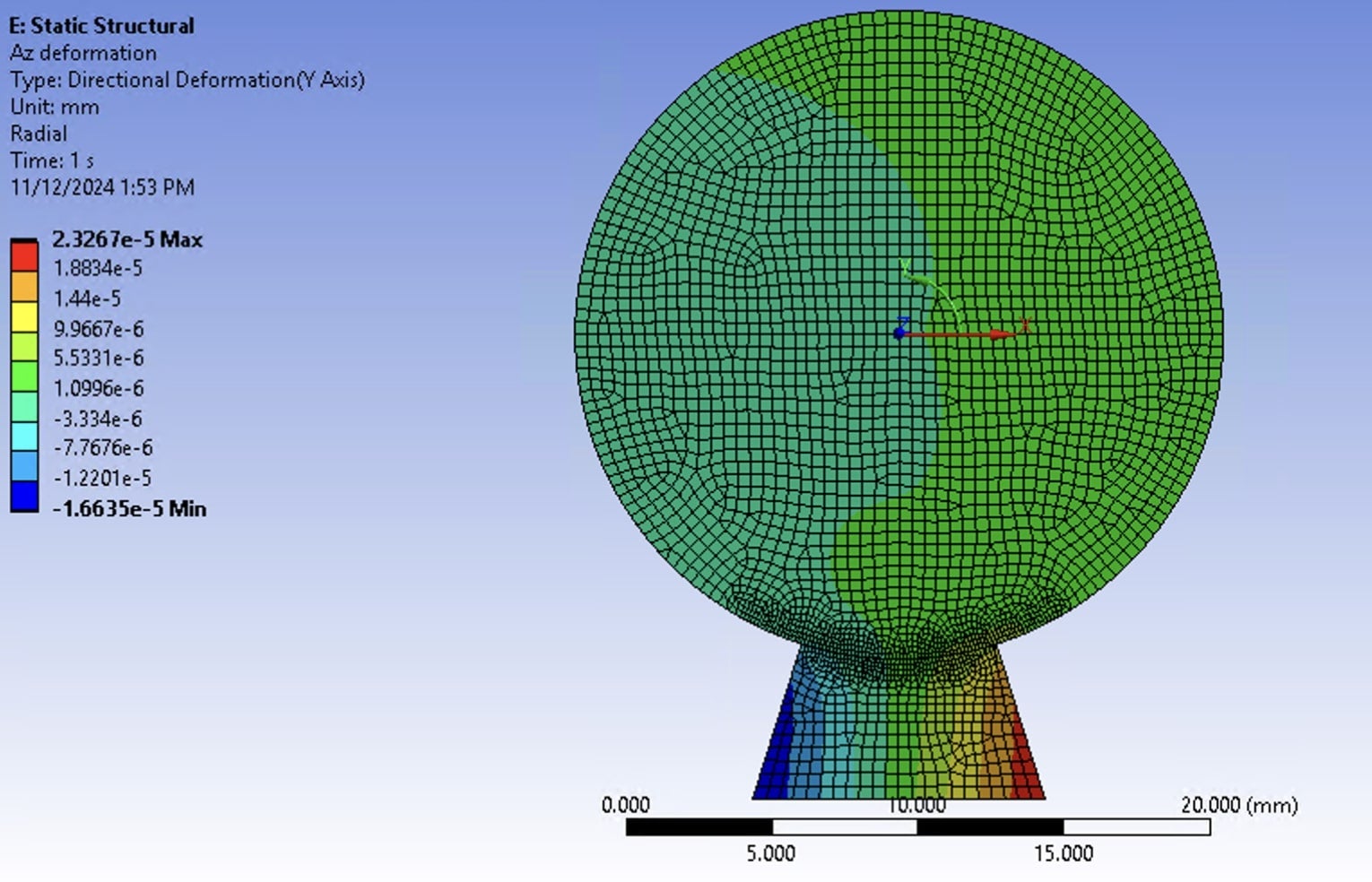

The expansion in the wedge along the azimuth is much lower than I would expect from both analytical estimates and simulating only the wedge while allowing free thermal expansion.

My understanding of thermal expansion is that in the bonded contact setup, every node will expand away from the center of the circular drum, leading to these results.

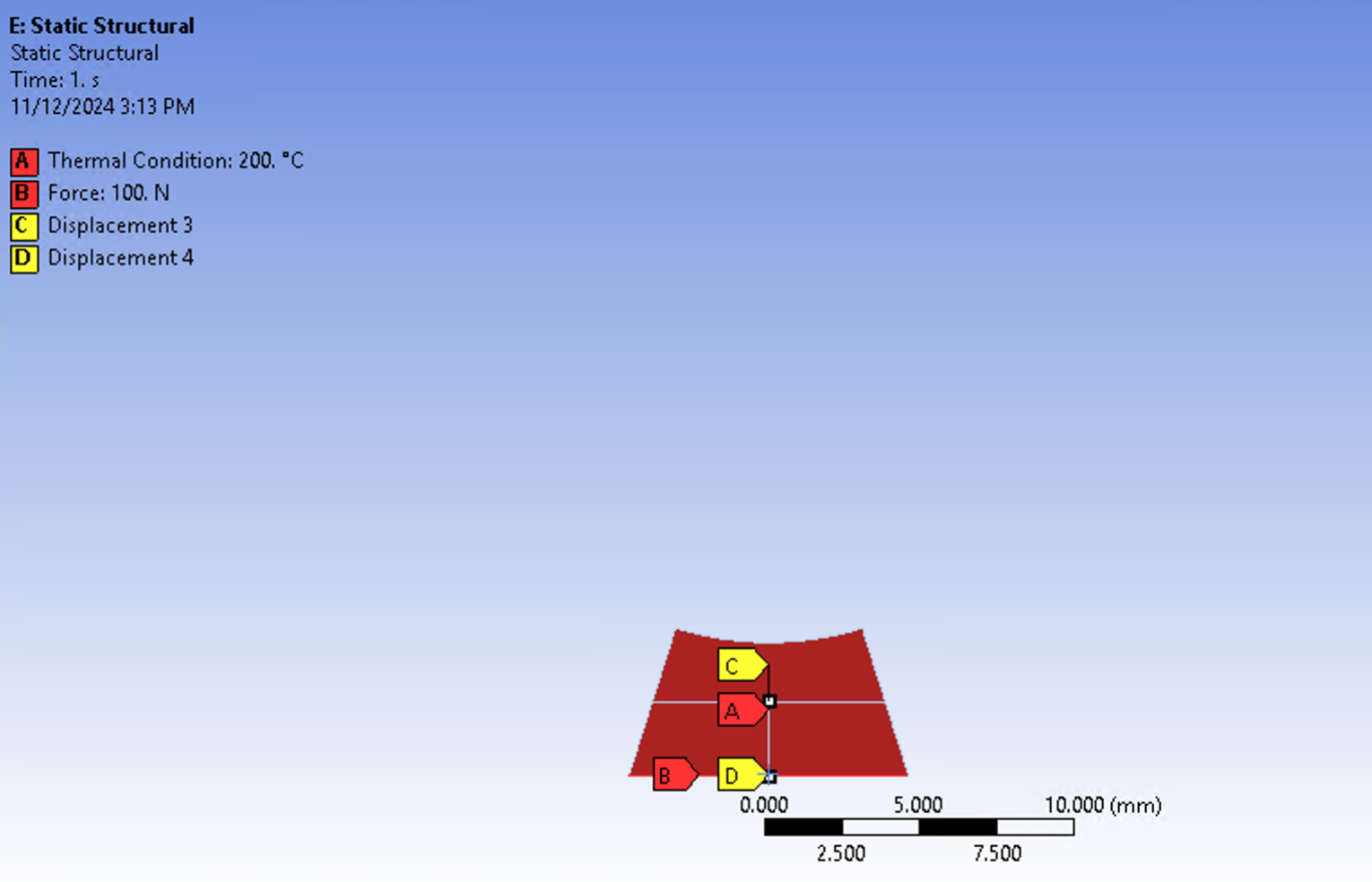

This lead me to change the contact from bonded to frictional and add an additional radial only displacement in the wedge center to allow the wedge to expand freely independent of the drum, but now I am getting convergence issues and rigid body motion warnings due to the wedge beeing underconstrained.

Any tips or suggestions?This is simplified version of the real geometry, so looking for general tips for how to approach this problem. In reality the geometry is more compelex (additional bodies) and without symmetry.

-

November 12, 2024 at 9:48 pm

peteroznewman

SubscriberWhat features prevent the drum center from moving? It is better to model the features that keep the center of the drum from moving such as three blade flexures arranged around the diameter of the drum.

Same question and suggestion for the wedge. What features allow the wedge to move only radially? It is better to model the features that allow a small motion such as two blade flexures on the wedge.

If there is a radial force on the wedge and there is a small gap between the wedge and the drum, the gap will be closed by the force. Since you know this, it would be much easier to solve if you put the wedge in initial contact with the drum.

-

- You must be logged in to reply to this topic.

-

3442

-

1057

-

1051

-

918

-

896

© 2025 Copyright ANSYS, Inc. All rights reserved.