TAGGED: ansys-contact, contacts, frictionless-contact

-

-

November 10, 2023 at 1:30 pm

Vasileios Zatagias

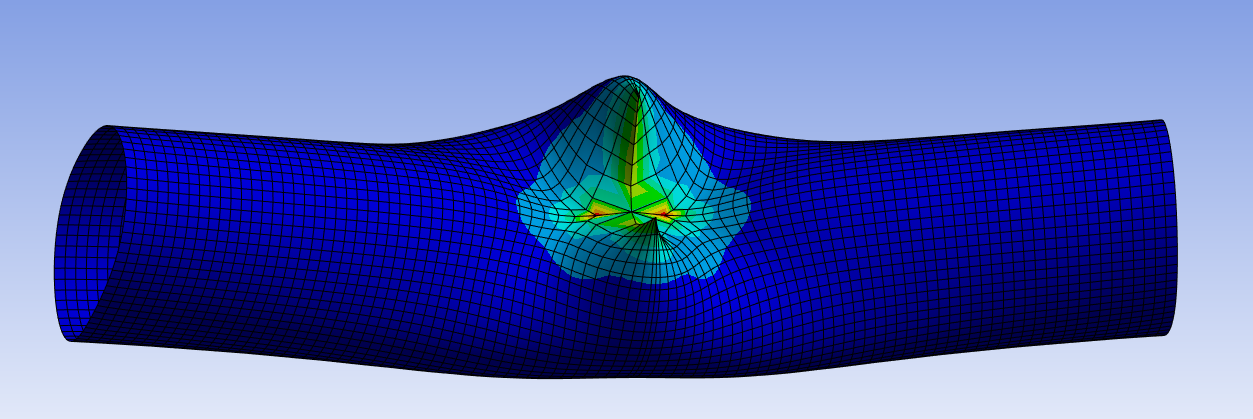

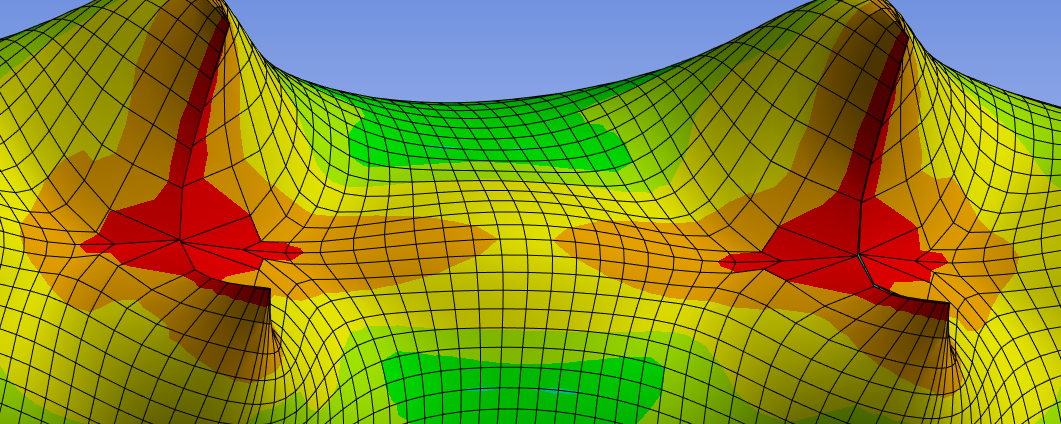

SubscriberHello, I am simulating a problem where a linear cut on a cylindrical shell is closed transversely. There are some partitions to provide vertices, to put a displacement on, to the middle of the cut, so that it can "close". With one cut in the middle of the cylinder shell, everything is okay. But with two cuts, some problems arise and the edges or faces don't touch (and I can't run it using large deformation). What contact should I use or is it another problem? I am uploading some photos for your better understanding. The first image shows the cut in the middle of the cylinder shells' length, the second shows what happens when there are 2 cuts right and left (same distance from the center of the cylindrical shell in z-direction). There is a gap and the faces or edges don't "touch" one another. This happens on the left cut too (not clearly visible in the image). (I am not using large deformation in my analysis here)

-

November 13, 2023 at 3:38 pm

mrife

Ansys EmployeeHi Vasileios

Are the images the 'real' deformations or have they been scaled to better show behavior? When post-processing the contact what is the resultant Gap distance? Why are large deformations not being used?

-

November 14, 2023 at 4:49 pm

Vasileios Zatagias

SubscriberHello,

Yes, the image shows the true scale of the deformation. I do not know what the gap distance is. What I intend to do is for these faces/edges to "touch" one another and not have this gap. When using large deformation, it cannot run at all, it has an error regarding excessive distortion.

I would gladly talk about it with you further, via chat/email if you would like to.

Thanks for your answer and time.

-

- The topic ‘Contacts’ is closed to new replies.

-

3367

-

1050

-

1047

-

886

-

837

© 2025 Copyright ANSYS, Inc. All rights reserved.