-

-

February 25, 2021 at 10:52 am

Jacob_22

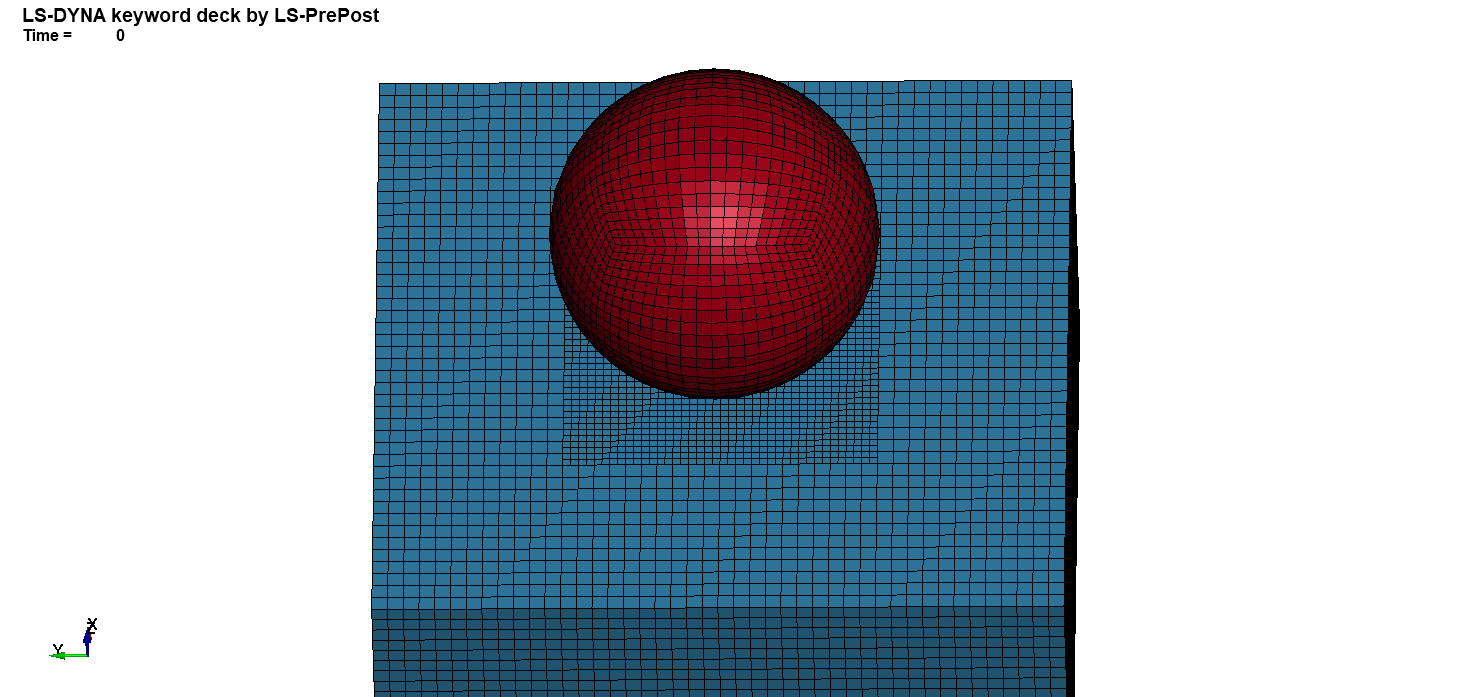

SubscriberI am currently analyzing the simple case of a FEM elastic sphere impacting an FEM rigid, rectangular target. The image below shows the simple geometry and meshing of the problem.

March 3, 2021 at 10:33 pmReno Genest

Ansys Employee,nnHere are my answers:n(i) Yes, you can scale the contact stiffness. See https://ftp.lstc.com/anonymous/outgoing/support/FAQ/contact_stiffness_adjustment for more information. Personally, I like to change the soft option when the contact is not behaving properly (large contact energy when the friction is zero). My go to settings now are soft=2, sbopt=3, depth=35, and pstiff=1. Note that soft and pstiff options will change the method of calculating the contact stiffness. Look at the manual for more information.n(ii) You can output the results d3plot every cycle (with or without a curve) when the contact is being establish. See *DATABASE_BINARY_D3PLOT in the manual for more information. With results at every cycle, you can see in LS-PrePost if the sphere is penetrating too much into the rigid plate. If the penetration is too much, you can increase the contact stiffness; a factor of 10 is a good start. Note that in real life there is no penetration between parts, but with an infinite contact stiffness, we get instabilities in FEA codes. See the link above for more information. I like to change the soft option instead of scaling the contact stiffness. nFor more information on contacts, see https://ftp.lstc.com/anonymous/outgoing/support/FAQ/contact.overview and https://ftp.lstc.com/anonymous/outgoing/support/FAQ_docs/contact.pdf.nTo improve your hourglass problem, you could try solid elform=1 with hourglass type 6 for the sphere. Or solid elform=-1 (fully integrated) which do not have hourglass problem. Here is more information on elements: https://www.dynamore.de/de/download/papers/forum11/entwicklerforum-2011/erhart.pdfnAt last, make sure you model the rigid body with regular material density and Young's modulus using *MAT_RIGID. For soft=0, the bulk modulus of the material in contact is used to calculate the contact stiffness; if you have a very high value of E, then the contact stiffness will be artificially high.Reno.March 6, 2021 at 2:17 pmJacob_22

SubscriberHi Reno,nnThank you for your very thorough answer! It seems that the main takeaway from your response is that you feel changing the SOFT option from 0 to 2 is generally preferred over messing with the contact stiffness. I am aware of the fact that SOFT=1 or 2 is preferred when dissimilar meshes and/or material densities are involved in impact, but in this case, the mesh densities are very similar and the materials are fairly similar in nature (the sphere is aluminum oxide and the target is an aluminum alloy). Do you have any insight into why you feel SOFT=2 might better handle this seemingly basic contact and thus prevent the need to tune the SLSFAC value? Sincerely,nJacobnMarch 8, 2021 at 5:19 pmReno Genest

Ansys EmployeennYes, I prefer modifying the soft option before I mess around with the contact stiffness. The soft option will change the way the contact stiffness is calculated and this changes the contact stiffness.nFor a contact with similar material densities and stiffnesses, soft=0 or 1 should work fine. But, you have a rigid body which can affect the contact. You can try with the base plate as a deformable body instead of rigid. You could remesh the plate with larger elements (just a bit larger than the sphere) so that the bottom plate elements do not affect the time step. This way, the calculation time will not increase by much. This will show you if the rigid body affects the contact or not.nSoft=2 uses segment based contact detection; it looks at slave segments (in other words faces of elements) penetrating master segments (and vice versa for surface to surface contacts) instead of nodes penetrating segments. So, in some situations, soft=2 will be better because of segment based contact detection. For your case, nodal detection should work fine though.nWhich contact are you using? The AUTOMATIC family of contacts are the newer generation and are recommended. They tend to be more robust. I would try *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE. A surface to surface is a two way contact; that is, the contact detection is looking for penetration from slave into the master and also the master into the slave. It takes a bit more time to compute, but is more robust.Also, you have many ways of specifying the slave and master sides. You can use the part ID (option 3). Sometimes, you get better results when specifying segments (option 0) to define the slave and master sides of a surface_to_surface contact. So, you can try that as well.Let me know how it goes.nnReno.nViewing 3 reply threads- The topic ‘Contact Stiffness and Handling Large Contact Energies’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3862

-

1414

-

1221

-

1118

-

1015

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.