-

-

September 22, 2019 at 11:17 pm

vishaish

SubscriberHello Everyone,

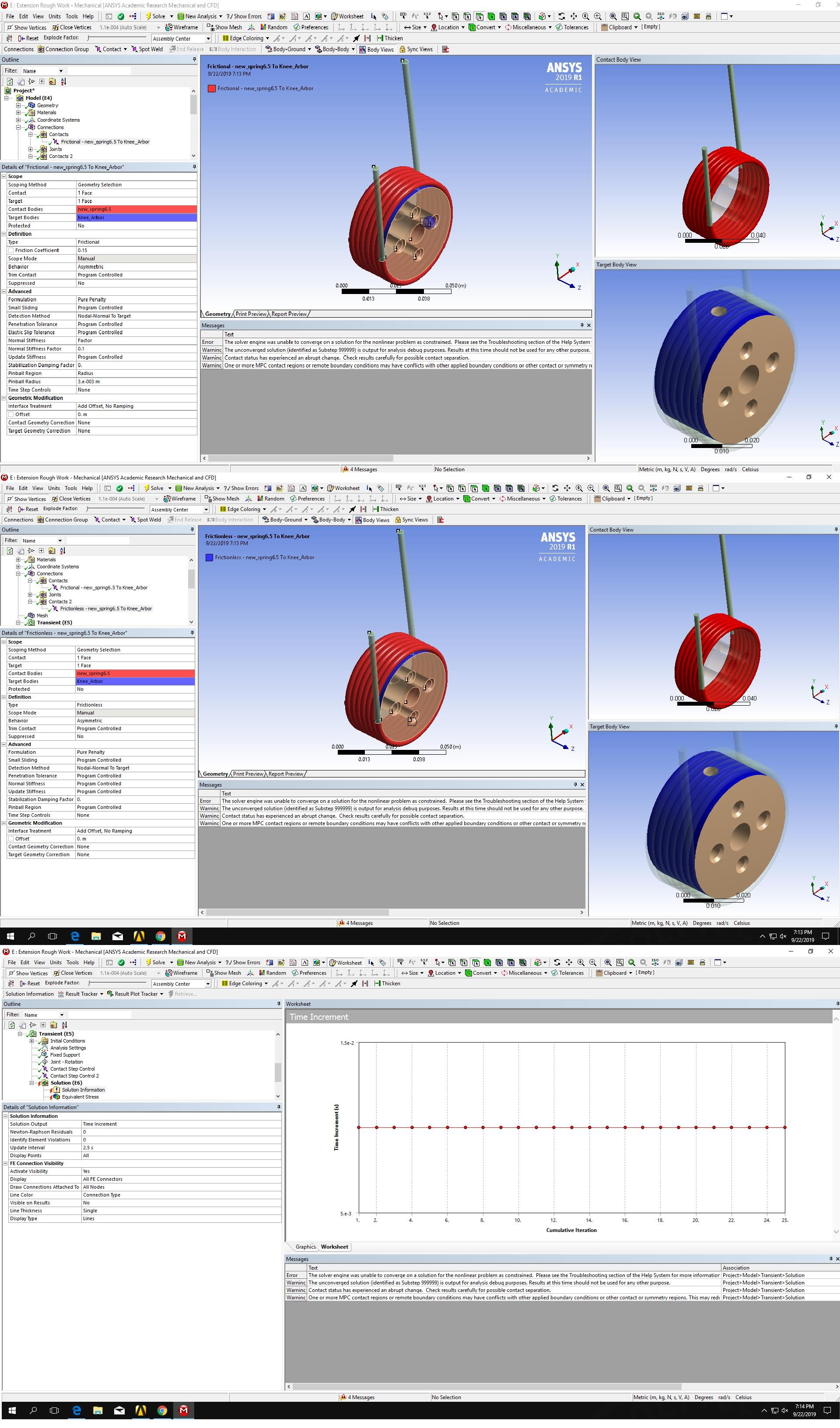

I am trying to simulate a friction driven mechanism.I am trying to simulate a contact step control approach where the contact body has has friction during the first step and they are frictonless during the second step. I have the two contact step control for two different types of contact with status alive/dead based on steps. But I am having warning and errors when i run the simulation. Can someone help me with this.

I referred to this link before but I am not sure if I have to change any parameters on the Analysis Settings. @https://studentcommunity.ansys.com/profile/smedikon/

For your reference I have included pictures about the contacts and error messages on this discussion

-

September 23, 2019 at 2:00 am

peteroznewman

SubscriberWhat questions do you have that you want a simulation to provide answers to?

It looks like you have drawn a spiral in CAD to represent the cable, is that true?

Is the cable meshed with solid elements or beam elements?

What material properties have been assigned to the cable elements?

-

September 23, 2019 at 2:21 am

vishaish

SubscriberThe coiled structure is a torsion spring. I am simulating a wrap spring brake. The center shaft/arbor can rotate freely in the clockwise direction but when it rotates in the anticlockwise direction the spring wraps around the shaft and clamps the shaft making it difficult to move .

I would like to simulate this mechanism to learn the stress developed in the spring and the shaft.

The material used in the spring is a music wire and has its properties.

density - 7800 kg/m3

Youngs modulus - 1.9e11 Pa

Poisson's ratio - .29

The mesh has default setting.

-

September 23, 2019 at 3:52 am

peteroznewman

SubscriberI recommend you first try a line body and beam elements for the torsion spring.

SpaceClaim can convert the solid torsion spring to beam elements.

This will represent a much simpler contact model and a much smaller number of nodes so the solving will go faster.

-

September 23, 2019 at 4:02 am

vishaish

SubscriberThank you Peter for the help I will give it a try.

The problem is, I was able to simulate the results as close to the expected results, the only problem that I had was when I was trying to switch from one type of contact(frictional) to another(frictionless) using the Contact Step control method. I was wondering if you had any suggestions for that?

-

September 23, 2019 at 12:50 pm

peteroznewman

SubscriberA torsion spring friction clutch does not work by having a switch to turn friction on and off. Don't put that in the model.

A torsion spring friction clutch works by having friction pull the spring wrap tight in one direction and push the spring wrap loose in the other direction. For it to work, there must be some initial interference between the spring and the shaft. Did you include initial interference in the geometry and did you allow contact to resolve that interference and create a contact force between the spring and the shaft before you start rotating the shaft?

-

September 23, 2019 at 3:00 pm

vishaish

SubscriberYou are exactly right. I understand that I cannot turn friction on and off. No I didn't provide the initial interference nor allow the contact to resolve the interference. Sorry I am new to using Ansys. While calculating it mathematically I found the interference and the contact force. But I wasn't sure how to import such details to the software.

Can you give me some additional details/links to your post. Are there any past references that mention about interference, or resolve contact force? And if so am I using the right project schematic to work for such system. I was simulating this using transient structural.

I believe that this is too much to ask but can you give me some details on how to mention interference and resolve contact force?

I was able to find very little references about friction based mechanism and they weren't of much help and I would really appreciate your help.

-

September 23, 2019 at 3:56 pm

peteroznewman

Subscriber1) Use Static Structural, not Transient unless you are concerned about inertia forces due to high accelerations.

2) If you have CAD geometry that has a coil spring tangent to a shaft, you can include a very small interference by entering an offset in the Contact details. A positive value moves the contact closer together (increase penetration/reduce gap) and a negative value moves the contact further apart. The screen shot below is for two sheet bodies, so yours will look slightly different if you have a beam and a face of a solid.

3) Under Analysis Settings, make a three step analysis.

- Step 1 nothing moves, the interference in the contact is resolved, generating a contact force.

- Step 2 set a positive rotation of 5 degrees to the shaft to show slipping in one direction

- Step 3 set the rotation to 2 degrees to the shaft to make it go backward 3 degrees and show gripping.

The ANSYS setting must have Large Deflection On (automatically set in Transient).

4) Insert a Torque Reaction on the rotation boundary condition to show the torque being used to rotate the shaft.

-

September 23, 2019 at 4:52 pm

vishaish

SubscriberThank you so much Peter for helping me out with problem and taking time to give me all the details. I am currently running the simulation with all these properties in place

-

September 23, 2019 at 9:25 pm

vishaish

SubscriberHey Peter I tried it the way you told me with the same values. I was able to see the movement but I am getting an error and few warning messages due to which my solution failed I would really appreciate if you could help me out with this.

I am guessing the problem is in Mesh but can I know your thoughts on it.

-

September 23, 2019 at 10:38 pm

peteroznewman

Subscriber1) The offset of 0.1 mm was just an example. It may be 100 times too large. Set it to 0 for now. Under Connections, insert a Contact Tool and Generate Initial Contact Status. That will tell you if the contact is open or closed and the size of the gap or penetration. Reply with a screen snapshot of that table.

2) In the Solution Information folder Details, one row is Identify Element Violations. Change the 0 to a 1 or higher number and the offending element in the Error message will be available for inspection as a Named Selection making it very easy to find the offending element.

-

September 23, 2019 at 10:55 pm

-

September 24, 2019 at 3:04 am

vishaish

Subscriberhttps://studentcommunity.ansys.com/profile/peteroznewman/ Do you have any suggestions to my previous post?

-

September 25, 2019 at 11:32 pm

vishaish

SubscriberHello Mr. Peter I tried solving the solution as per your saying. I am not able to make it converge. I tried with different sized meshing, different step size but I am not able to make it converge. The Force Convergence and Criterion are not even crossing once I have always been getting Bisection. And it took longer time to simulate .

I went through your conversation and tutorial with Han yu " HOW TO SIMULATE TWO CONNECTOR MOTION". I observed a few things like Newton Raphson method and imported into mysystem to learn where the issue was. But the results that I was getting was inside the last three coils of the torsion spring. So I increased the mesh size and ran but still no convergence.

Can you help me out with this.

For your reference I have included the file too.

In the Project Schematic the simulation was carried out in the Flat (Static Structural) Model.

I am not sure how to proceed further and I am stuck at this point.

Sorry I had to delete the mesh because the file was too big. I am including a picture of the error message and the contact tool in this post.

-

September 26, 2019 at 1:58 am

peteroznewman

SubscriberHello vishaish,

I am travelling with a laptop with the Student license on it so I will not be able to run your model because it has 248,000 nodes and the Student license limit is 32,000 nodes. I suggested more than once to convert the torsion spring to a beam model. That I can run on the Student license.

You will want to define a beam to surface contact using contact elements CONTA177 and you want to set KEYOP(11) = 1 to allow you to input the radius of the beam profile 1.463 mm as a Real Constant.

Unfortunately, I have done this in 2019 R2 which means you can't open my file in 19.1 so try to do the conversion. Step 1 is to open the geometry in SpaceClaim and Fill the flats on one end of the torsion spring. Then on the Prepare Tab, use the Extract button.

Kind regards,

Peter -

September 26, 2019 at 3:05 am

vishaish

SubscriberHello Mr Peter thank you for getting back to me. I wasn't sure how to create a beam for the spring that's the reason I didn't go for it and I apologize for causing you trouble. I will follow the instructions as you have mentioned above.

I am working on my college system where I have 2019 R2 version. So I would really appreciate if I you could send me the file for reference.

Thank you for taking time to create the model and helping me out with the issues.

-

September 26, 2019 at 5:05 am

peteroznewman

SubscriberI don't claim that my attached model is in any way finished or what you wanted, it was made to show a beam model. There is a lot more work to be done. One idea I have is to rotate the ends of the spring to open up the diameter of the coils, then insert the shaft, then rotate the ends of the spring back so that the coils come to rest on the shaft. That is how you put a torsion spring on a shaft to make a clutch. I have not implemented that in the attached model. That is what I would try next.

Here is my question to the community to find out how to improve this model.

Attached is an ANSYS 2019 R2 model that has a large offset.

-

September 26, 2019 at 11:31 am

vishaish

SubscriberThank you so much for sending me the file. In practice I did the same too.I have a physical model of the set up where I had to open up the coil by rotating the ends of the spring to insert the shaft and then it sprung back to rest on the shaft. Thank you for the question to the community. I will work on the beam model to implement the clutching technique.

-

September 26, 2019 at 9:09 pm

vishaish

SubscriberHello Mr. Peter. I started simulating the design using the beam as my spring. I was able to download your file and have it as a reference but I was not able to find any APDL commands.I was trying to recreate the simulation which included CONTA177 and KEYOPT(11) to learn about the APDL commands. I had small doubts regarding these commands on how to import and work on commands. I referred a few articles where they have mentioned that CONTA177 is used to represent contact and sliding between 3d surfaces and deformable line segements and KEYOPT(11) is to refer the dimensions and shape of the beams.

I was wondering if you had any prior examples or videos that I could refer to get a better understanding of how to use the commands.

-

October 11, 2019 at 4:51 am

peteroznewman

SubscriberThe attached model has four steps. In step 1, a moment is applied to open up the coils, but also, there is a contact step control where the contact between the coil and the shaft is set to dead for step 1. Then in step 2, the contact between the now opened coil and the shaft is set to alive. In step 3, the moment that opened the coils is ramped back to zero and the coil cinches onto the shaft. Finally, in step 4, the shaft is rotated.

There are two models in the attached archive, system A has the shaft rotate by 5 degrees, while system B has the shaft rotate by -0.15 degrees. The result was that rotating by -0.15 degrees had a constant 430 N-mm of torque, while rotating by 5 degrees had a constantly increasing torque. Look at the graph between 3 and 4 s.

System B

System A

We can see that in system A, the torque to rotate the shaft increases with the rotation angle up to a very large value, indicating the clutch is gripping.

We can see that in system B, the torque to rotate the shaft is small and constant, indicating the clutch is slipping.

-

November 13, 2019 at 9:50 am

saifali

Subscriber+

-

November 13, 2019 at 9:12 pm

vishaish

SubscriberThank you so much for helping me with the simulation. I am currently looking at the results. Thank you for your time..

-

- The topic ‘Contact Step Control’ is closed to new replies.

- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- How to model a bimodular material in Mechanical

- Meaning of the error

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

-

3932

-

1414

-

1272

-

1119

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.