-

-

January 4, 2025 at 6:37 pm

javat33489

SubscriberHello everyone.

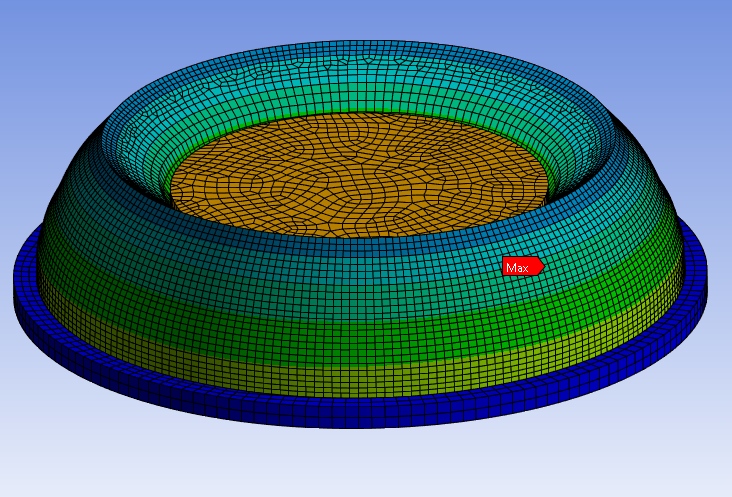

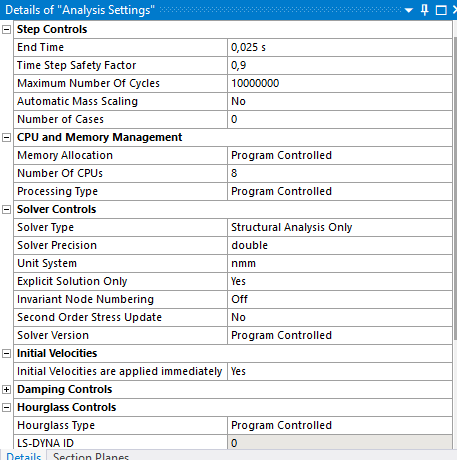

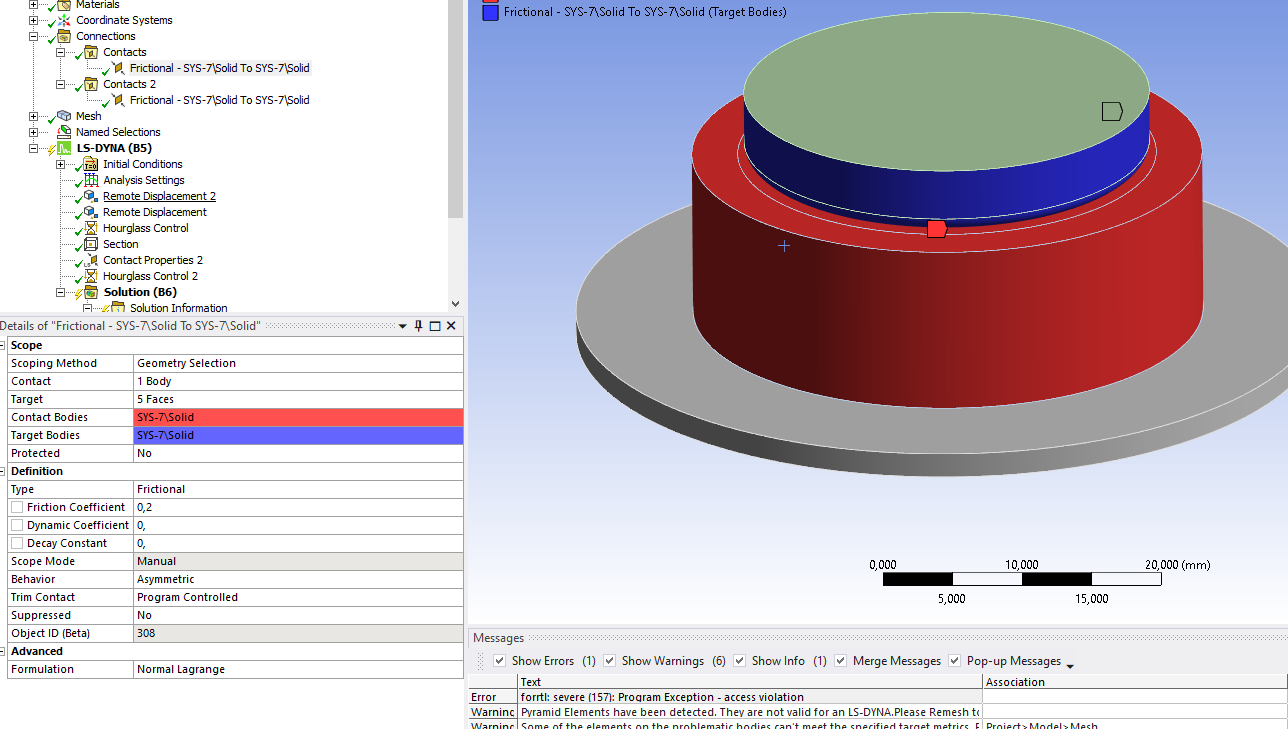

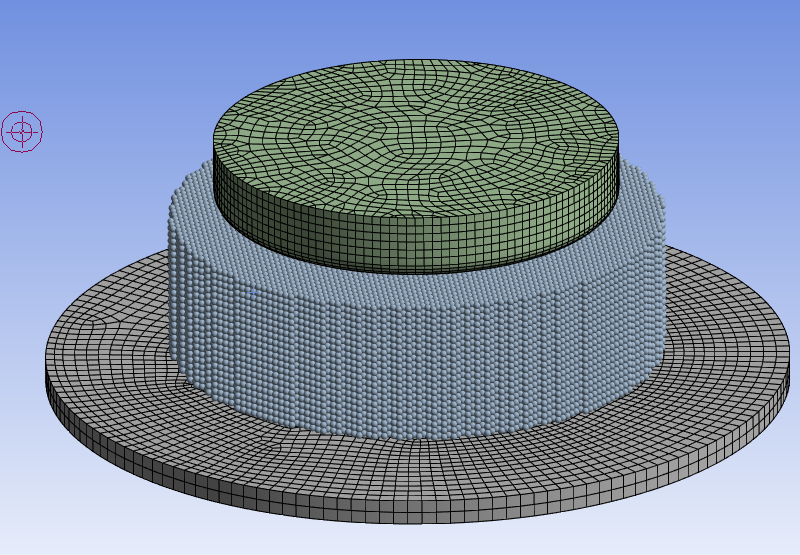

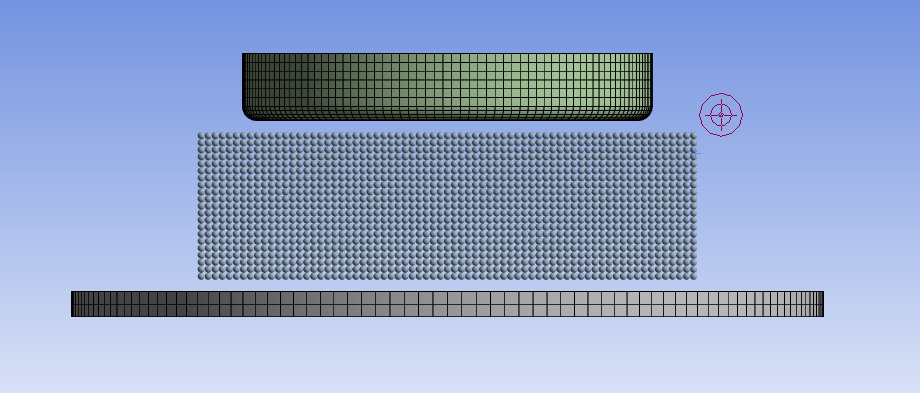

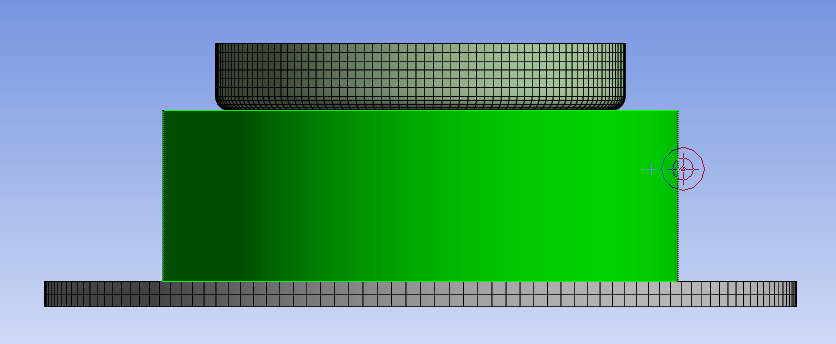

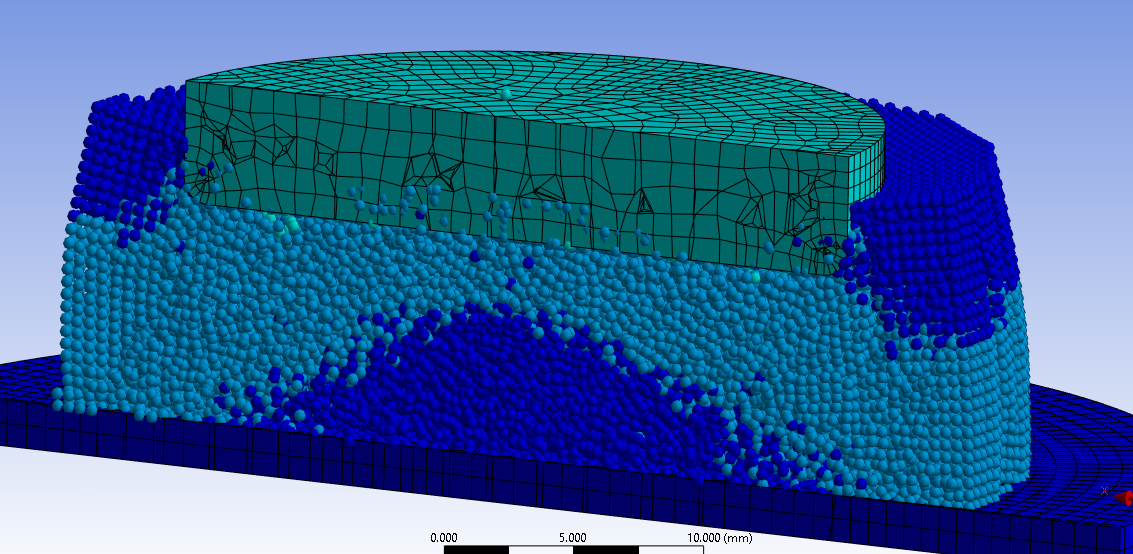

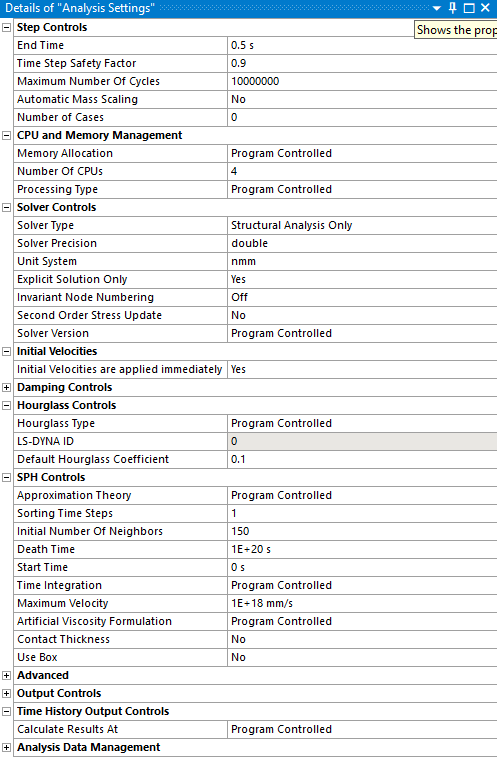

I decided to create a new topic about pressing rubber. Test calculation. LS Dyna ACT Workbench.

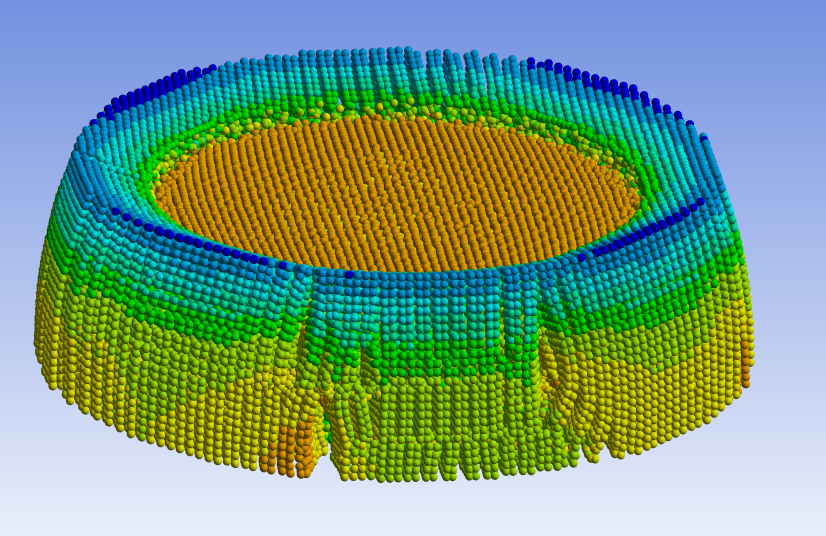

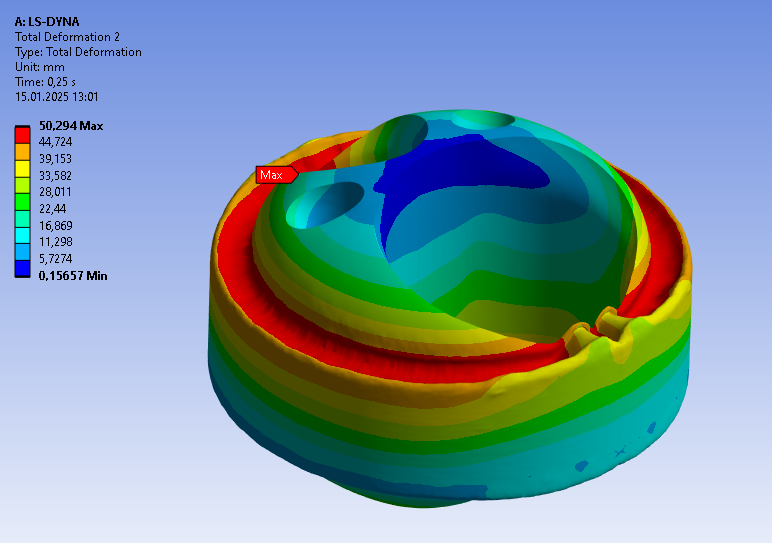

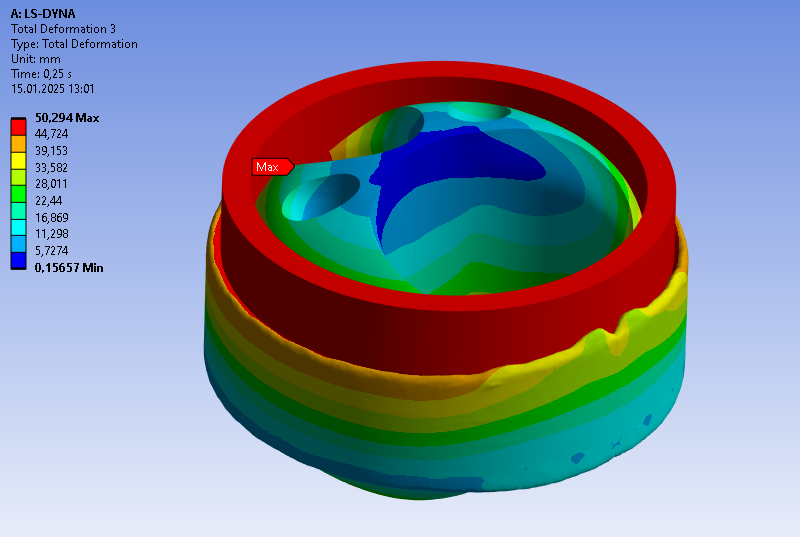

I compress a round rubber plate.

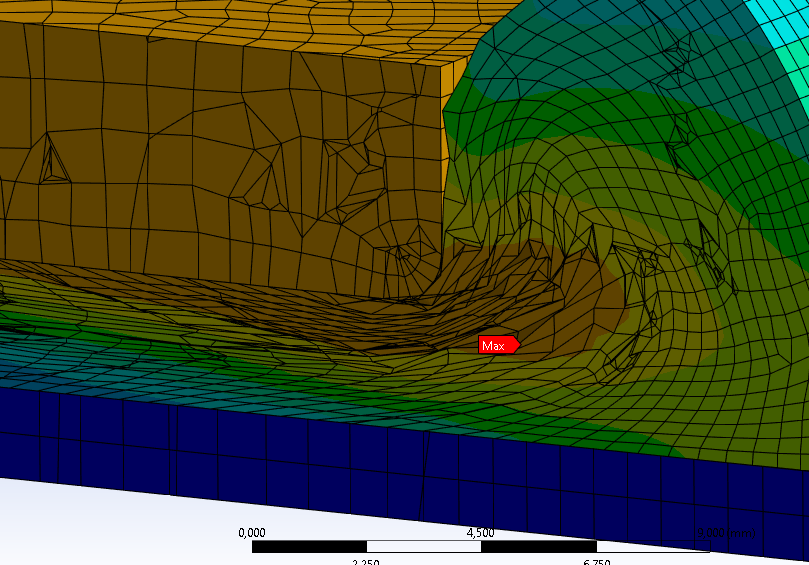

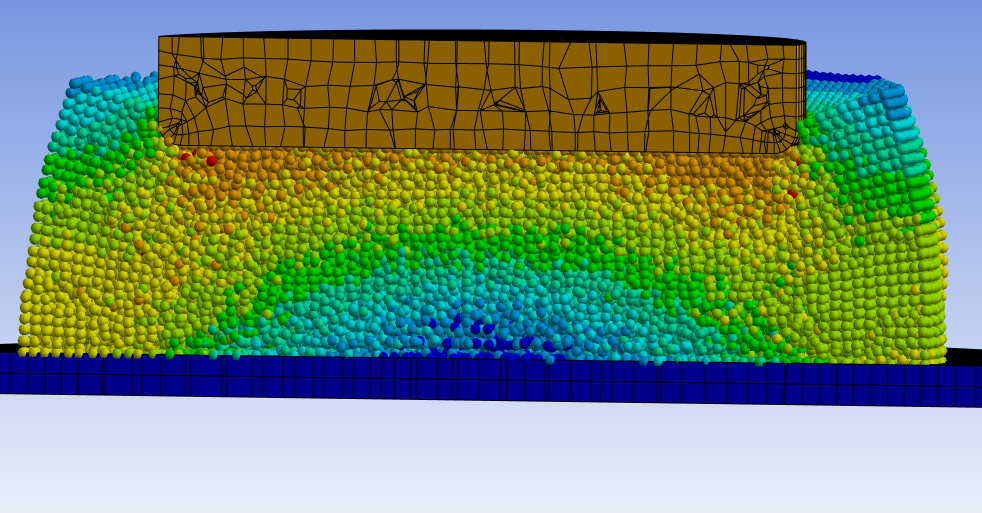

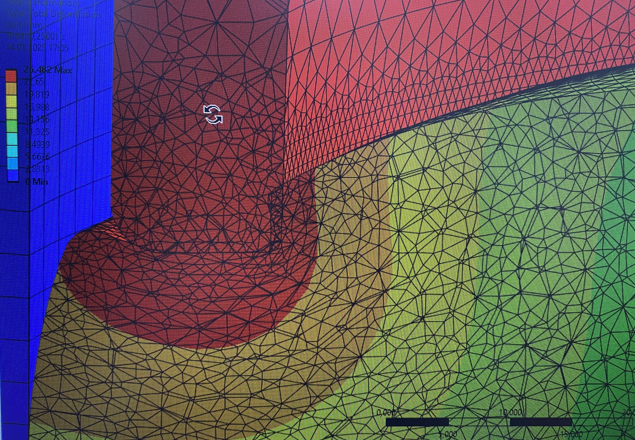

Everything is going well, but when the task is almost solved and the rubber is strongly compressed, the grid begins to penetrate each other:Why is that? And how to fix it?

I also tried:

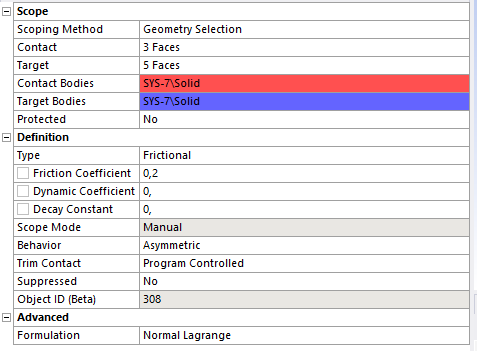

- set Normal Lagrange in contact

- configure the Contact Properties contact

- set General dumping in the solver settings

- applied Horuglass

- made the grid smaller

- and also changed Section to the rubber body.Please give me some advice on how to make the grid not penetrate each other for as long as possible.

-

January 6, 2025 at 2:37 pm

Ram Gopisetti

Ansys EmployeeHi Javat,

You have not touched the necessary parameters to avoid penetration in your model: contact/target penalty scale factor, using higher values may crash the solver so you need fine balance here. Also, do you need an Asymmetric behavior here as it creates _NODES_TO_SURFACE keyword and is unnecessary in your model.

For softer materials such as rubber, you can try tet element as they have some elemental stiffness and are less prone to hourglassing start with tet 13 ( also need to set tet13v for accuracy ) and use tet10 for a bit more stiffness response.

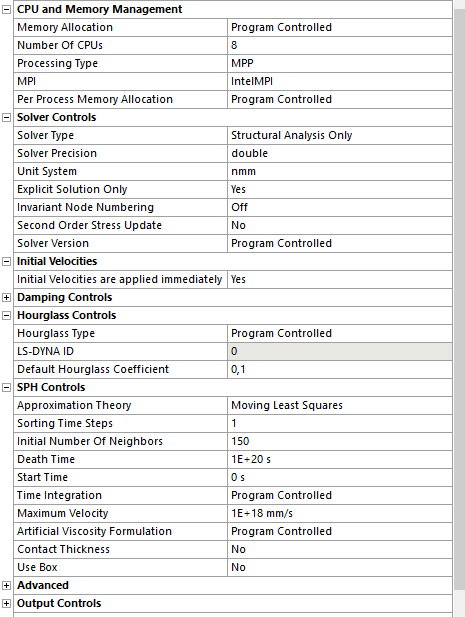

You can try SPH for rubber and see if it has improved response but use MLS approximation theory on MPP.

Cheers, Ram

-

January 6, 2025 at 4:07 pm

javat33489

SubscriberThanks for the reply sir.

Also, do you need an Asymmetric behavior here as it creates _NODES_TO_SURFACE keyword and is unnecessary in your model.

I didn't understand, should I use asymmetric contact or not? -

January 6, 2025 at 6:38 pm

-

January 6, 2025 at 7:25 pm

-

-

January 8, 2025 at 4:06 pm

Ram Gopisetti

Ansys EmployeeHi,

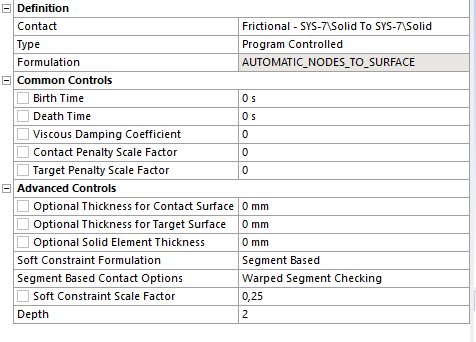

Set the contacts behaviour to program controlled but for SPH it automatically scopes it as node_to_surface contact.

Navigate to the solution directory, and please review d3hsp for more information on the errors and post it here for further recommendations.

Also, ensure you are taking care of higher-order elements like pyramids in your model.

Cheers, Ram

-

January 8, 2025 at 7:35 pm

-

January 13, 2025 at 5:28 pm

javat33489

SubscriberWhat do you say sir?

-

January 14, 2025 at 4:01 pm

javat33489

SubscriberSir. I figured out the gap.

But SPH still doesn't work. Also my grid doesn't work completely.

I will tell you everything in detail in a separate comment below. I need help.

-

-

January 8, 2025 at 7:11 pm

javat33489

SubscriberThanks for the reply sir.

Set the contacts behaviour to program controlled but for SPH it automatically scopes it as node_to_surface contact.

It doesn't help.

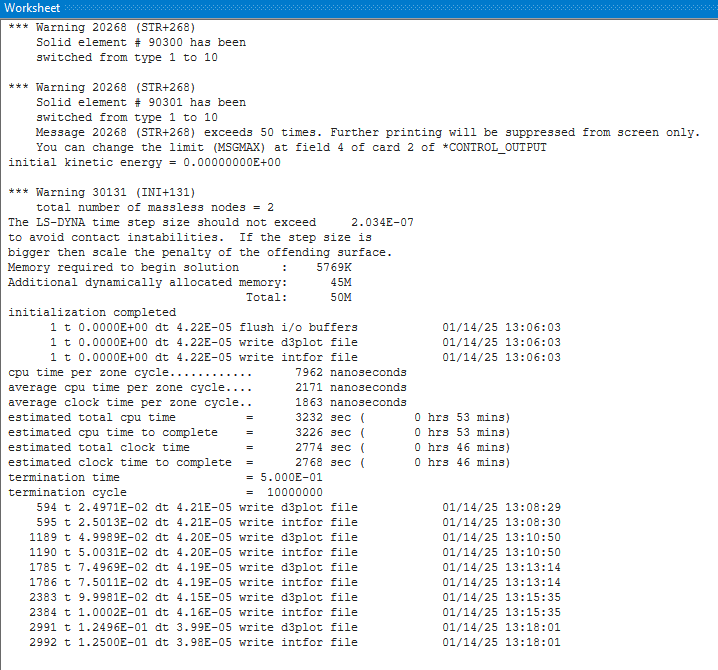

Navigate to the solution directory, and please review d3hsp for more information on the errors and post it here for further recommendations.

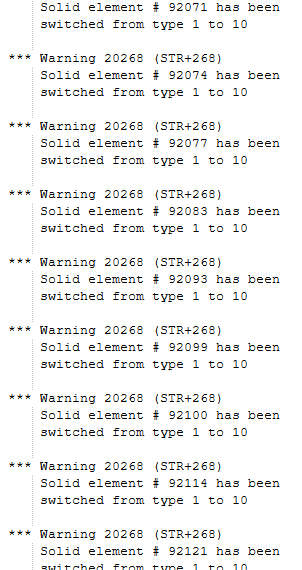

Yes sir, but there are no errors except warnings:

-

January 14, 2025 at 4:09 pm

javat33489

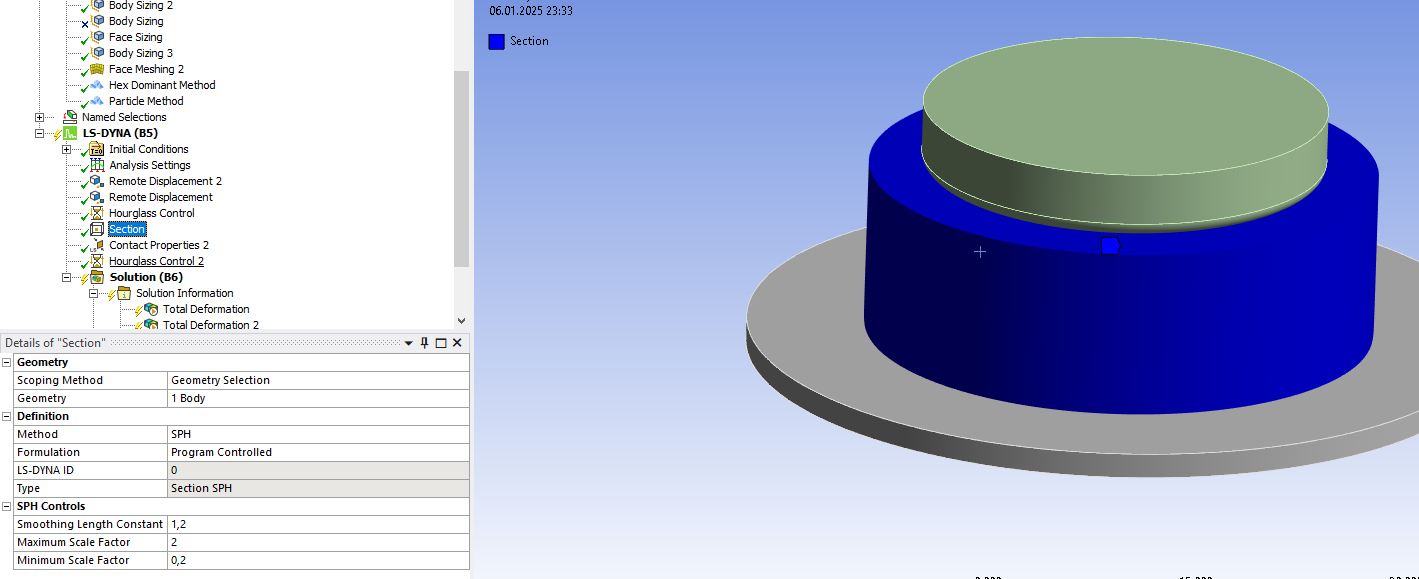

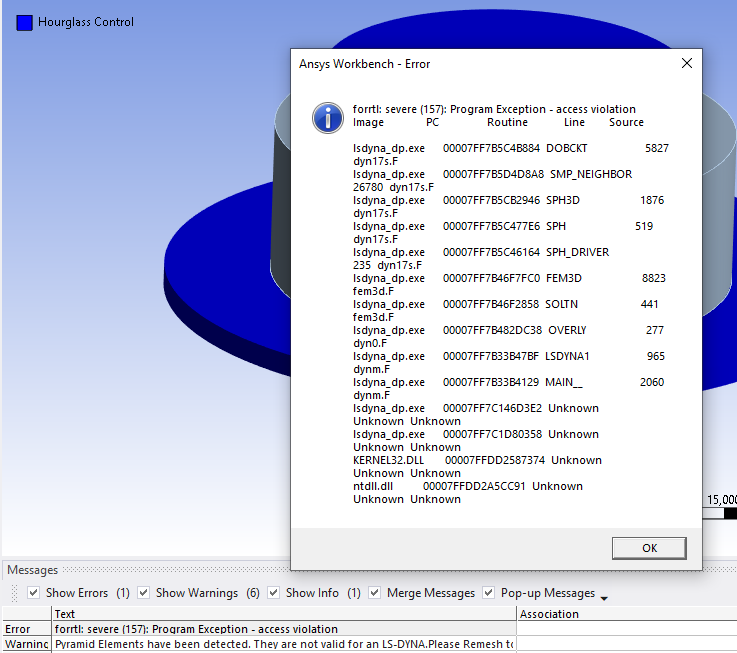

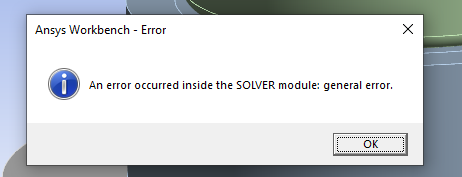

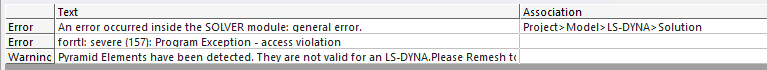

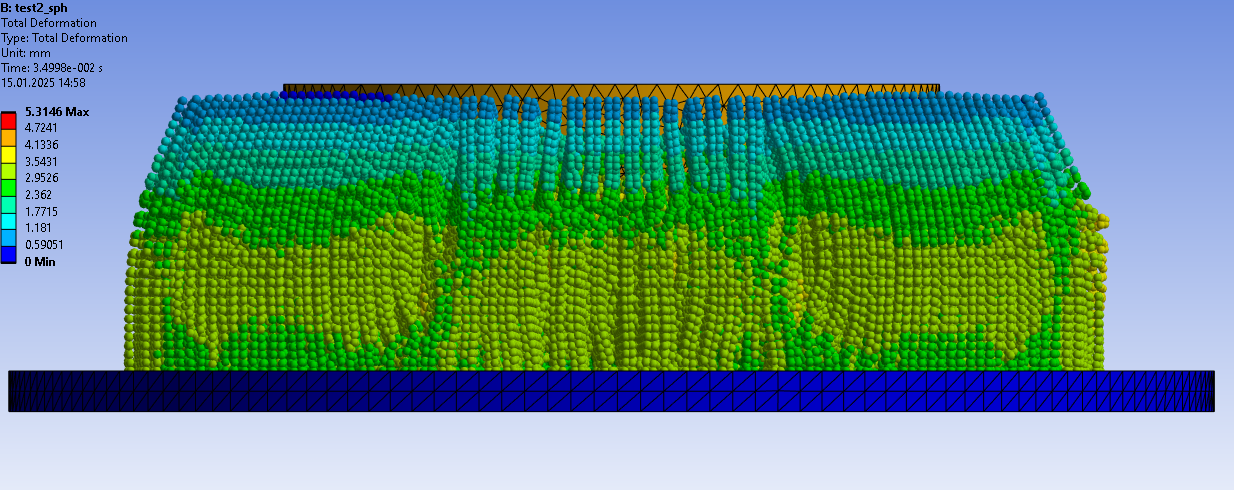

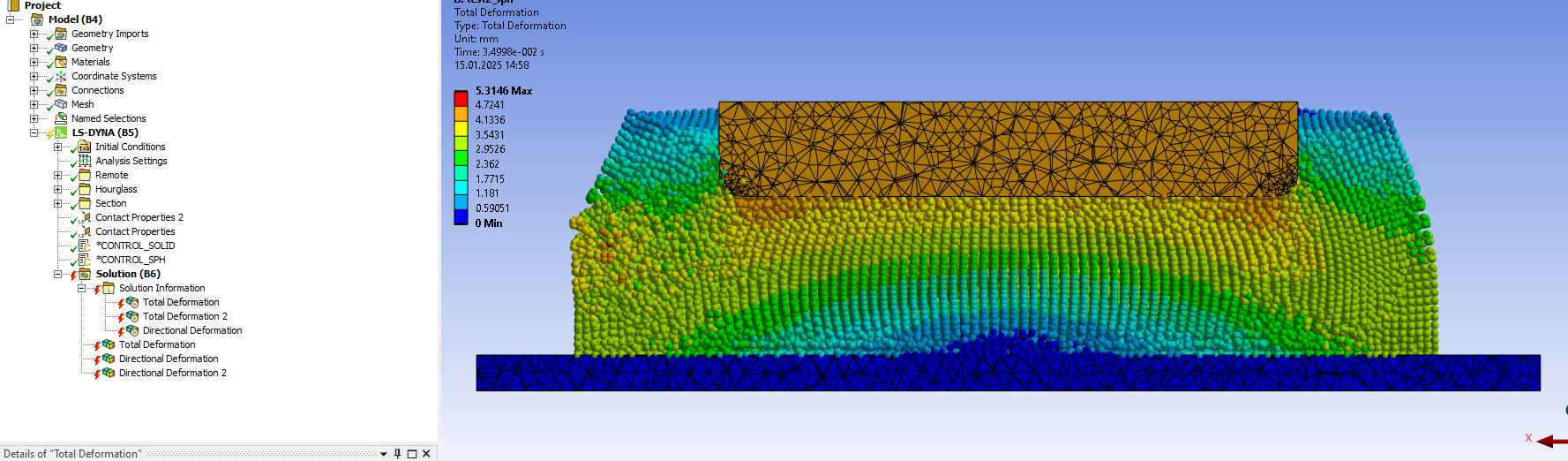

Subscriber1. SPH. Sir, the particle method does not work if I turn on MLS. I immediately get an error, the solution does not even start.

When I turn off MLS, the calculation starts, but after a while it stops because of errors. Errors are not indicated in the logs. I attach several pictures: solution, settings and errors:Perhaps the problem is in the contacts.

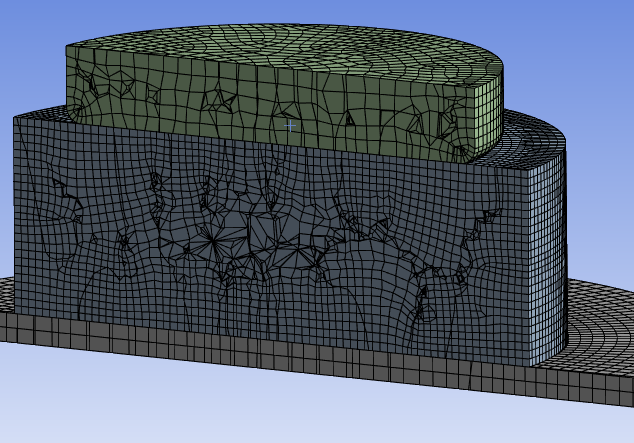

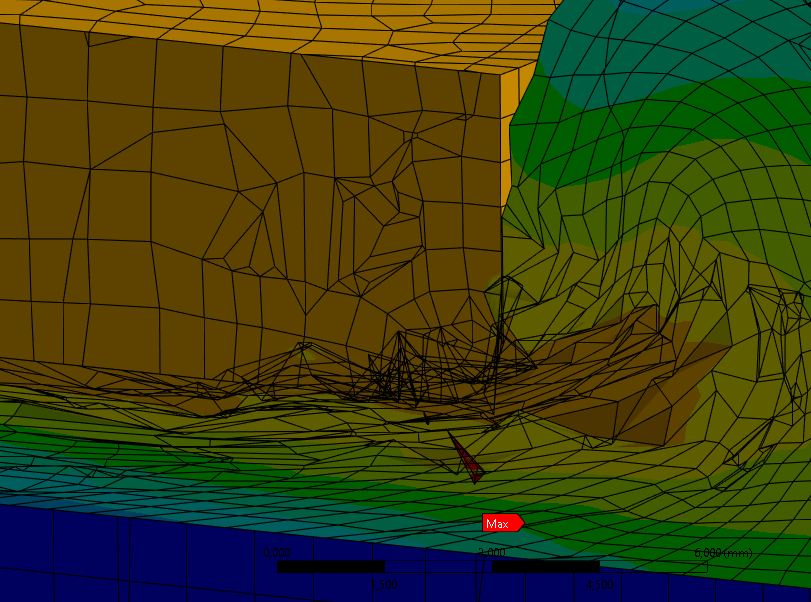

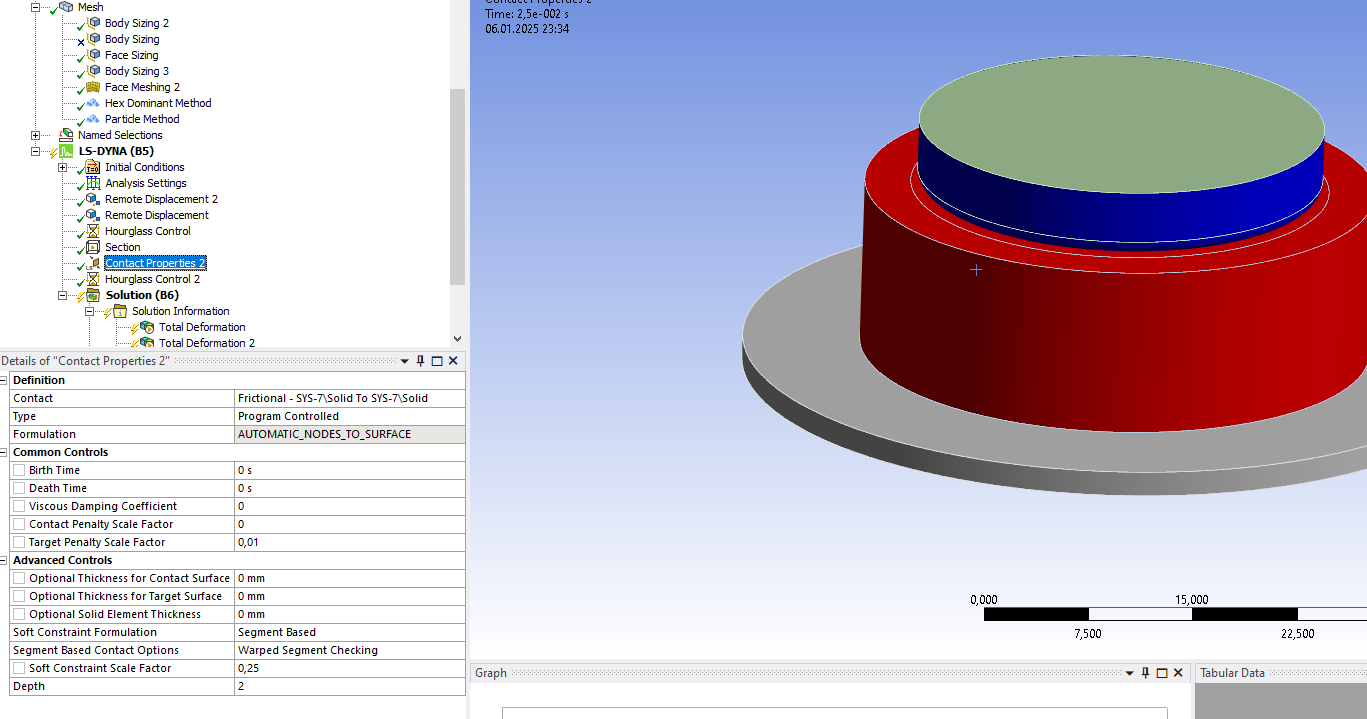

2. I used your advice and configured contacts. Now everything works. But when I started working with a real model (its geometry is more complex) I still see strong penetrations, I attach some pictures of the settings:

By the way, sir, I set these parameters to 0, and then the penetration is the least:

If I set any value, there is a very strong penetration, as if there is no contact.

_________________________

Please help and advice sir.

-

January 16, 2025 at 5:38 pm

javat33489

Subscriber1. Sir I used the tet13 setting incorrectly. Now I did it correctly.

Sir the result on the real model became better, but there are such local penetrations, how to make the result better?2. I managed to run the SPH calculation with MLS but the result is absolutely the same, always at about the same place I get an error, I tried all the settings and contacts. Sir, I need help.

-

- You must be logged in to reply to this topic.

-

3367

-

1050

-

1047

-

886

-

831

© 2025 Copyright ANSYS, Inc. All rights reserved.