TAGGED: boundary-condition, fluent

-

-

July 12, 2024 at 9:14 am

Zen

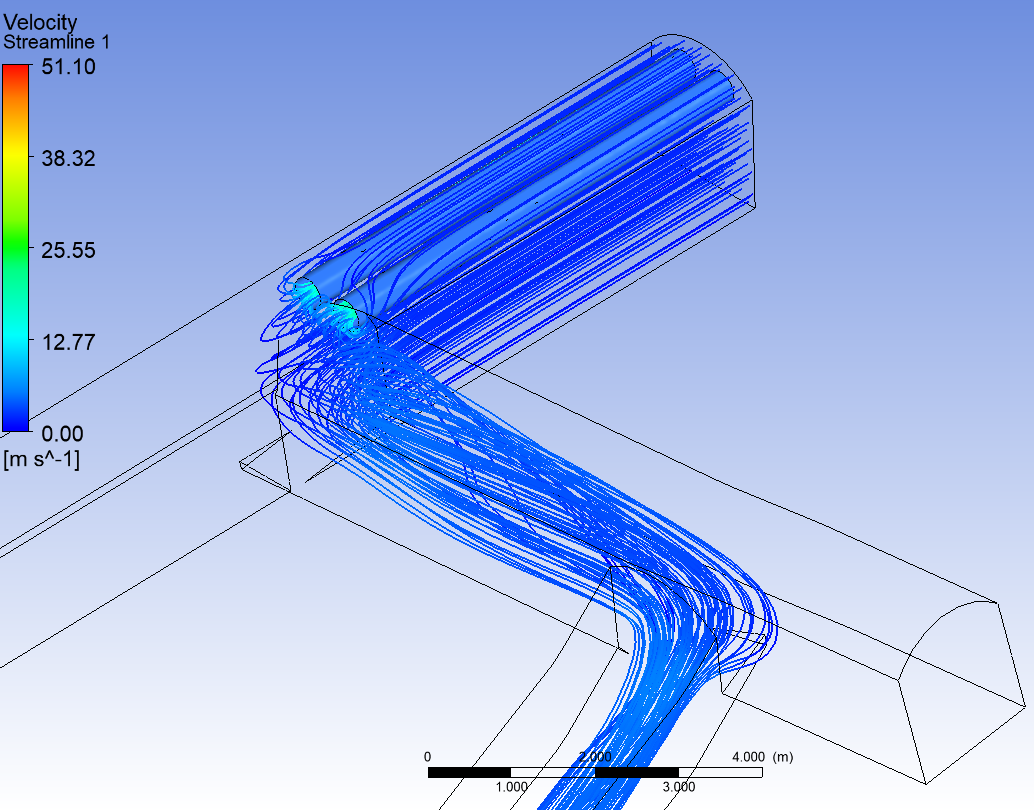

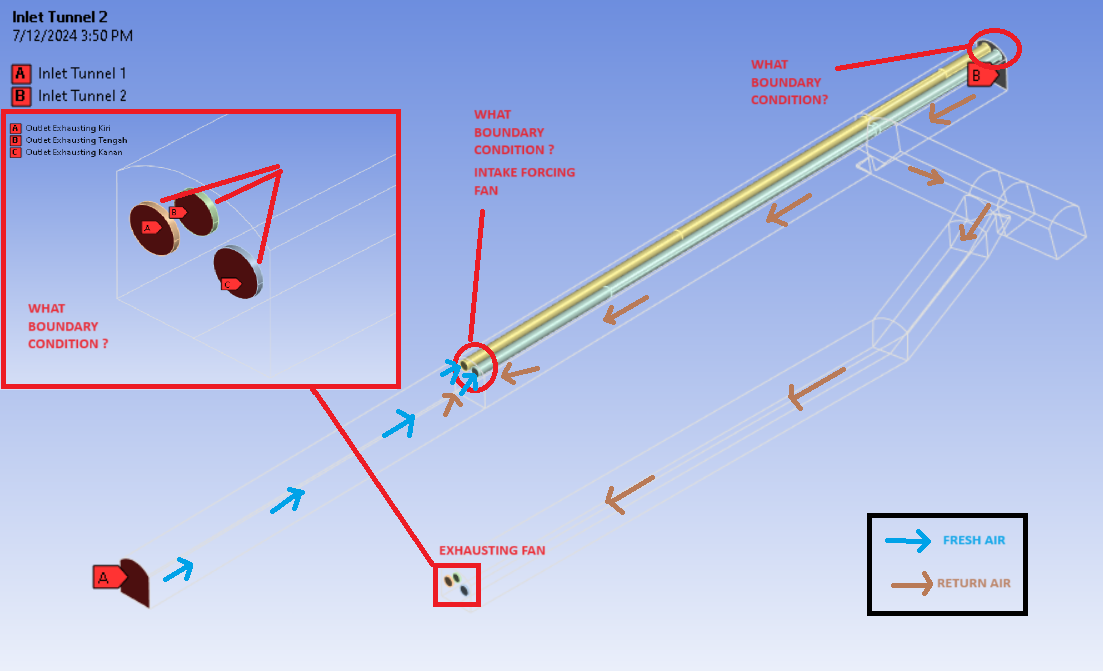

SubscriberHi all, i want to perform an analysis of air recirculation and determine the percentage of dirty air that enters the intake duct (forcing fan system, 2 ducts). I am having difficulty defining the boundary condition for the intake forcing duct so that it can draw air from velocity inlet tunnel 1 and 2 as shown in the picture.

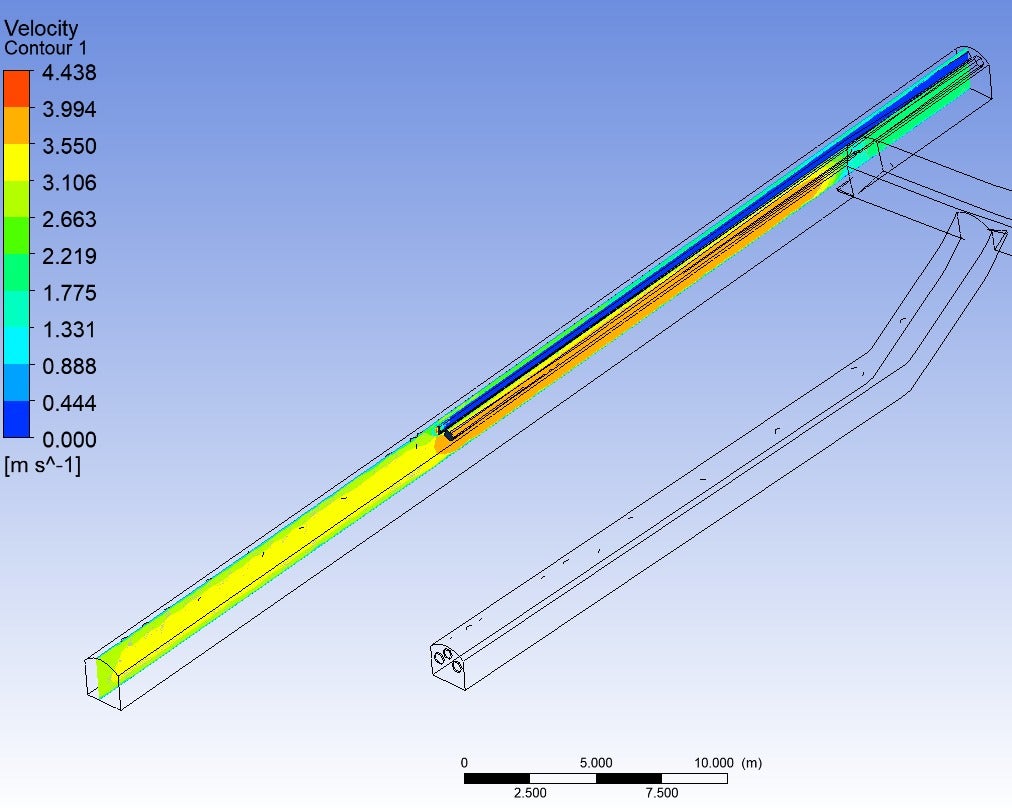

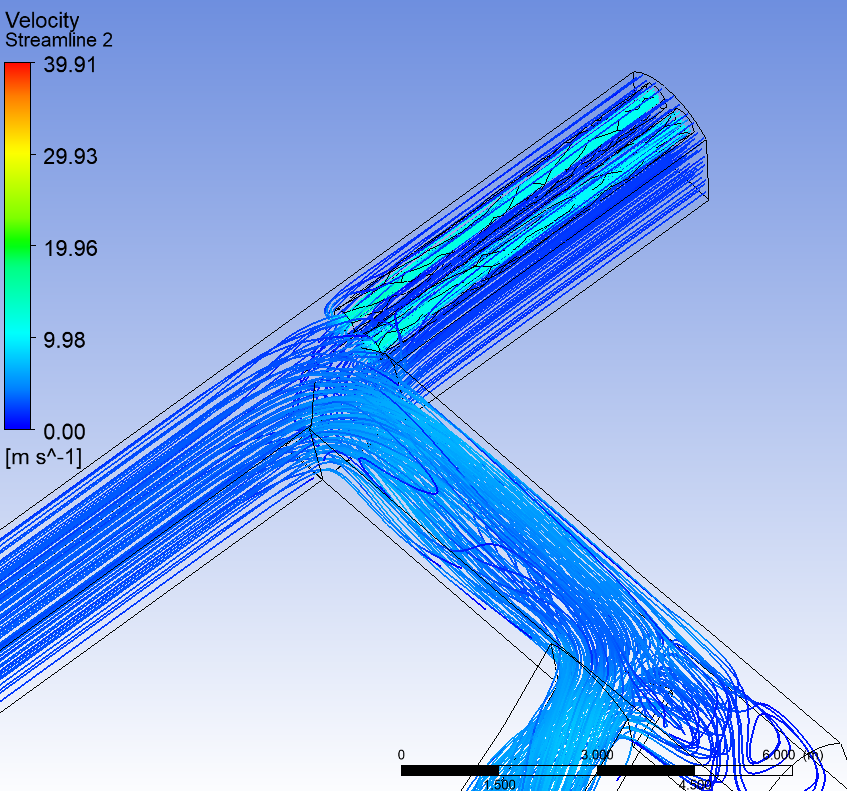

For the time being, I have tried to define the front part of the duct as the "fan" boundary condition and set a constant speed of 19.6 m/s. However, when generating the report, why does the duct not showing any air velocity? As can be seen in velocity contour 1 (blue contour).

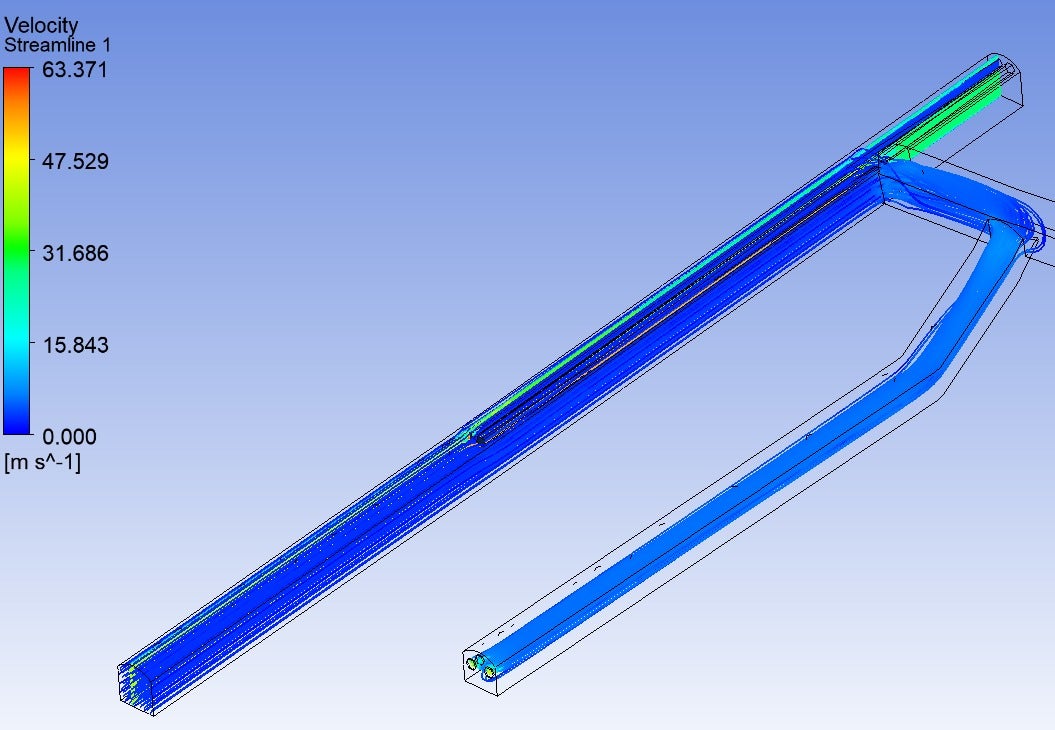

Also in the streamline report, it can be seen that the forcing duct is not drawing any air at all.

What is the problem? can someone help me step by step to fix it?

Thank you,

-

July 15, 2024 at 12:22 pm

Rob

Forum ModeratorGo through all of the boundary settings but also look for wall, and wall & shadow pairs. A lack of flow "somewhere" can be real (there's nothing driving flow), poor choice of boundary conditions (you've got a wall where you didn't expect it) or a post processing hiccup (releasing pathlines from a surface will show where that fluid goes, not that anything is entrained by that boundary).

-

July 17, 2024 at 8:25 am

-

-

July 17, 2024 at 9:11 am

Rob

Forum ModeratorHave a look at the boundary flux reports. Assuming each boundary is unique then you can find the mass in/out.

-

July 17, 2024 at 3:39 pm

Zen

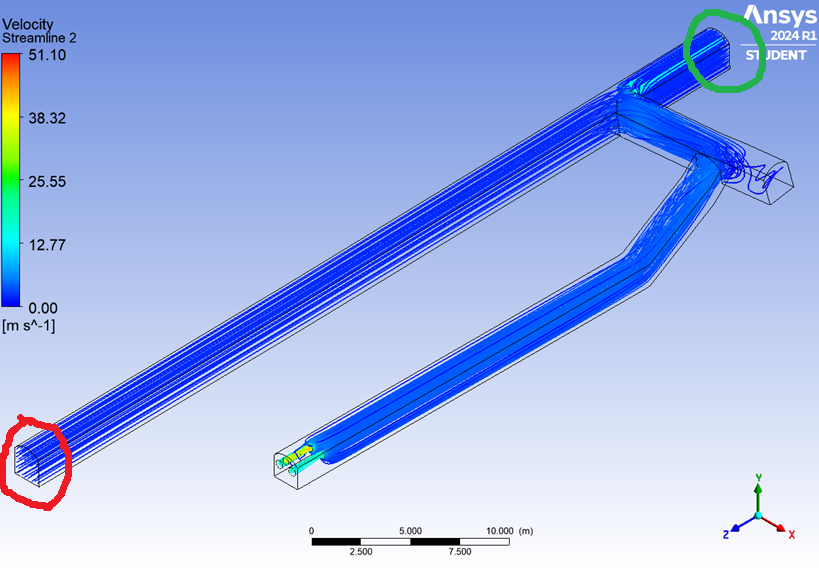

SubscriberGot it, but how can I calculate the mass flow rate of air produced only by the tunnel located at the top right? If I use a flux report, the value will surely include the mass flow rate from both the tunnel at the top right and the tunnel at the bottom left. Please advise on what I should do. Thank you.

-

-

July 19, 2024 at 10:20 am

Rob

Forum ModeratorFlux reports are on a per surface basis so provided you labelled the outlet faces etc you're good to use the Expressions.

-

July 19, 2024 at 2:35 pm

Zen

SubscriberI apologize for any confusion caused by my previous question. Yes, I can perform a flux report by selecting the face in front of the duct that will be traversed by a mass flow rate. When I perform a flux report, the resulting value will surely represents the total mass flow rate passing through the selected area/face, meaning it will be influenced by the mass flow rates from inlet 1 (red) and inlet 2 (green).Is there a way to determine the mass flow rate from the flux report that is influenced only by inlet 2 (green)? I specifically want to know the value of the return air (inlet 2) that re-enters my intake duct while ignoring the mass flow rate from inlet 1. Thank you.

-

July 22, 2024 at 9:43 am

Rob

Forum ModeratorAh, yes, it's for both surfaces. In CFD Post you can probably use a plane near the boundary. In Fluent I'd just separate the boundary to get boundary and boundary:014 (example names) and report there. Other than some very specialised options I'd not use CFD Post with Fluent data.

-

- The topic ‘Boundary Condition Definition’ is closed to new replies.

-

5054

-

1764

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.