-

-

July 31, 2024 at 7:30 pm

manuel.pacherres

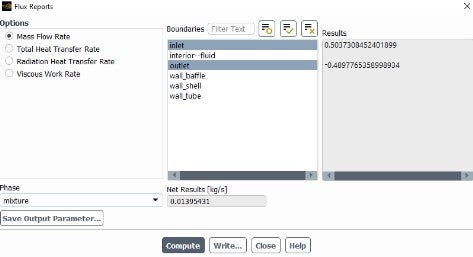

SubscriberHola a todos,Estoy intentando simular un intercambiador de calor de tubos y coraza con nanofluidos. Sucede que cuando realizo la simulación con solo agua pura, mi balance de masa me da alrededor de 1.0254617e-07 y la tasa de transferencia de calor está dentro de lo esperado. Sin embargo, cuando utilizo nanofluidos, mi balance de masa empeora (con un valor de 0.1395431), creo yo que aun sigue siendo despreciable, pero nosé si es aceptable. Cabe resaltar que la calidad mínima ortogonal de mi malla es de 0.20 -

July 31, 2024 at 7:56 pm

Federico

Ansys EmployeeHello Manuel,

how do your residuals look like for the nanofluids case? 2.5% mass imbalance is not bad, but you might want to run this case further and see if you get better precision.

-

August 1, 2024 at 6:43 am

NickFL

SubscriberHola Manuel,

No puedo escribir en español, espero que el inglés esta bien.

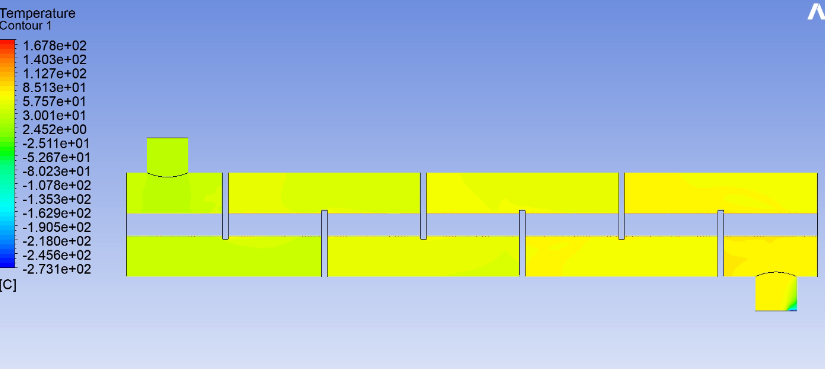

I assume that the lower tube is defined as the flow outlet? It appears you have flow that is flowing back into the domain that has a very cold temperature -273C or 0K! That is because of the backflow conditions you have specified at this boundary condition. There are two things to consider, one is to change that to something more appropriate like the 50C that the rest of the outlet is. A better solution, the one I would chose, is to extend the outlet further “down” so that there is no backflow. This approach might also help with your mass imbalance problem in that, with backflow it is allowing water back into the domain. Look at the velocity vectors across the outlet and see if they make physical sense.

If that is not clear, please let me know and I will try and explain it better.

-

August 1, 2024 at 12:33 pm

manuel.pacherres

SubscriberHi Federico, the residuals for all cases are below 10e-07 more or less, only for continuity it is around 10e-04. However, I tried to reduce the convergence criteria to get lower residuals (and thus perform more iterations) and the result is the same.

Regarding the mass imbalance, if my mass flow at the inlet is 0.5 kg/s and the mass balance given by ansys is 0.01395431 kg/s, my mass imbalance in percentage would be 2.79% right? Would that be correct? -

August 1, 2024 at 12:40 pm

manuel.pacherres

SubscriberHi Nick FL,

Thanks a lot for the reply.

When I simulated only water, in the output condition I activated the "Prevent reverse flow" option, for some reflux cases, that way my mass balance gives good results. However, when I use the multiphase model to deal with nanofluids I am not presented with that option.

So if I extend the tube at the outlet, would that improve my temperature gradient and my mass balance? I will try it!

I will also check the velocity vectors at the outlet to see if they are consistent.

Thanks again.-

August 2, 2024 at 6:47 am

NickFL

SubscriberYes with the multiphase model the outlet boundary condition is more complex. Extending the outlet will prevent fluid from trying to re-enter at this boundary.

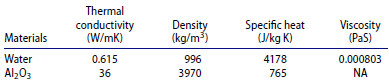

You wrote that you have a nanofluid in this heat exchanger. Is the second phase that you are trying to model the nanoparticles? If so, what are your problem dimensions? Typically, when we model nanofluids we will adjust the fluid properties of a single phase simulation. Modeling the particles themselves is a computationally intensive problem and done only for very simple geometries. Your HEx looks a bit more complex than what is typically considered.

Yes look at the velocity vectors and temperature contours at the exit. It would also be good to look closely at the condition you defined at the outlet. When the solution builds a wall at the outlet it can lead to the convergence not being good, especially if the mesh is coarse.

-

-

August 2, 2024 at 1:19 pm

manuel.pacherres

SubscriberHola Nick FL,

Efectivamente, extendí un poco el tubo de la salida del intercambiador de calor y el balance de masa mejoró (siendo totalmente despreciables), así también, el gradiente de temperatura es coherente. Anexo dos imágenes sobre lo comentado.

Los resultados que mostré en el inicio de este hilo de preguntas era justamente con respecto a los nanofluidos, pues cuando simulé mi intercambiador de calor con solo agua, no tuve dicho problema, ya que como comenté, para solo modelar una fase tenía esa opción de activar la prevención de reflujo. Esta opción no me es posible activar cuando utilizo un modelo multifásico, sin embargo, extender un poco mas la salida del tubo de mi intercambiador de calor funcionó. Las nanopartículas que estoy simulando es de óxido de aluminio de mas o menos 25 nm de diámetro. La propiedades térmicas de esta nanopartículas estoy considerando las mostradas abajo en la imagen anexada.

A que se refiere con ajustar las propiedades del fluido de una simulación de una fase?. No entendí bien. Se refiere a modelar al nanofluido como monofásico o bifásico?. O se refiere a las propiedades térmicas que en este caso tendría que ajustar de acuerdo a la nanopartícula utilizada? -

August 5, 2024 at 10:04 am

NickFL

SubscriberExcellent! Notice that the seperation bubble at the exit reattaches to the wall and thus we are much more confident in our solution here.

What I meant by adjusting the properties of a single phase flow is just changing the properties of water to account for the Al nanoparticles. I would direct your attention to the article: Assessment of Single Phase Model of a Nanofluid for Numerical Prediction of Forced Convection Heat Transfer, Journal of Nanofluids 2016. https://doi.org/10.1166/jon.2016.1199 There are likely many other studies that have done something similar. You have done well by adding complexity to your model in small steps. This might be one more small step to take before moving to the two-phase solution. You would have to also determine if the parameters are appropriate for your case.

You are making good progress. Congrats!!!

-

August 16, 2024 at 5:05 pm

manuel.pacherres

SubscriberHola Nick FL,

Disculpa por la respuesta tardía, intenté entrar a la web de Ansys en dos ocasiones y creo que estaba en mantenimiento.

Entiendo aquello que mencionas en que puedo tratar al nanofluido como monofásico, sin necesidad de utilizar un modelo multifásico. Muchas gracias por el artículo que enviaste, lo revisaré.

Y muchas gracias por la informacion y la idea brindad para poder solucionar el problema del balance de masa, fue muy valioso!!!.

-

- The topic ‘Balance de masa’ is closed to new replies.

-

5059

-

1765

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.