-

-

August 13, 2024 at 9:12 am

NUR ZUMIRAH AHMAD KAMAL

Subscribergreetings genius,

i'm currently conducting a burst pressure analysis on high carbon steel pipe. the pipe initially having defect size of 20 mm diameter at the centre of 1m pipe. choosen composite laminate was wrapped around defect area to study the pipe and composites performance as pressure was apply internally (up to 45 MPa), using ASTM D1599-99 procedureThe problem arise as the pipe reading exceed pipe ultimate tensile strength (746 MPa) but the composite wrapped around pipe defect area having 5.7386 MPa which to me unacceptable. Am i apply the pressure correctly? if yes does the result correct to you? could you please suggest me anything that make this analysis right?

result of composite only

-

August 16, 2024 at 11:00 pm

Bill Bulat

Ansys EmployeeGreetings!

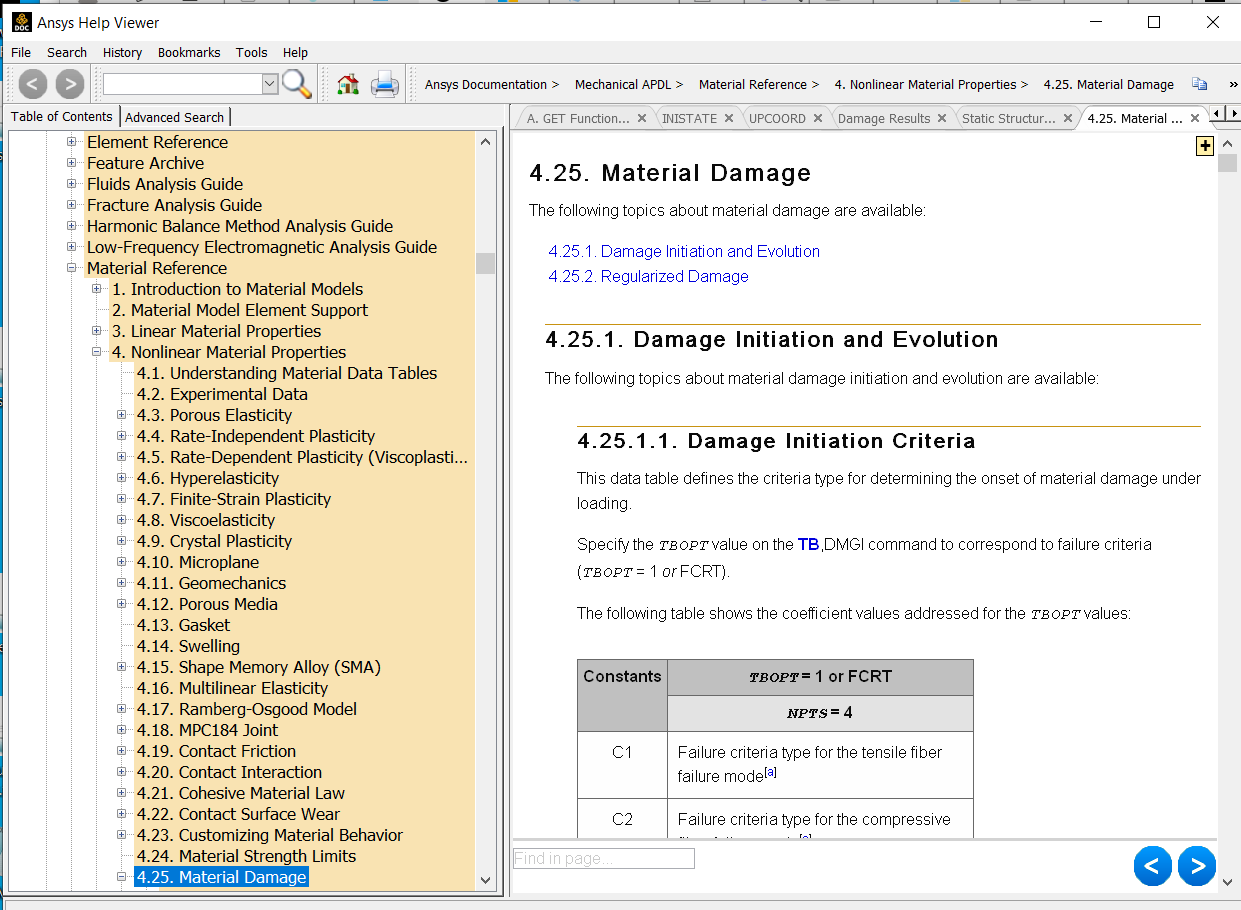

If the 746 MPa ultimate tensile strength of your steel was defined in Engineering Data, I doubt that it alone will predict some material failure in your finite element model when stresses exceed this value. If the pipe material model is linear, then calculated stresses can exceed this value and the material response will continue to be linear. The ultimate tensile stress material "property" defined in Engineering Data a little misleading. To simulate failure, you'd either need to define a damage material model:

It might be easier to make some approximation (e.g. use a bilinear isotropic hardening material model with a very low slope in the plastic part of the curve). Then, when calculated stresses in the pipe exceed the yield stress, the pipe will expand much more easily and the composite sleeve will recieve more of the load.

--Bill

-

- You must be logged in to reply to this topic.

-

2788

-

965

-

851

-

599

-

591

© 2025 Copyright ANSYS, Inc. All rights reserved.

.png)

.png)

.png)