TAGGED: #Modal_Analysis, modal, reinforced-concrete

-

-

December 2, 2024 at 1:46 pm

christian.paolini

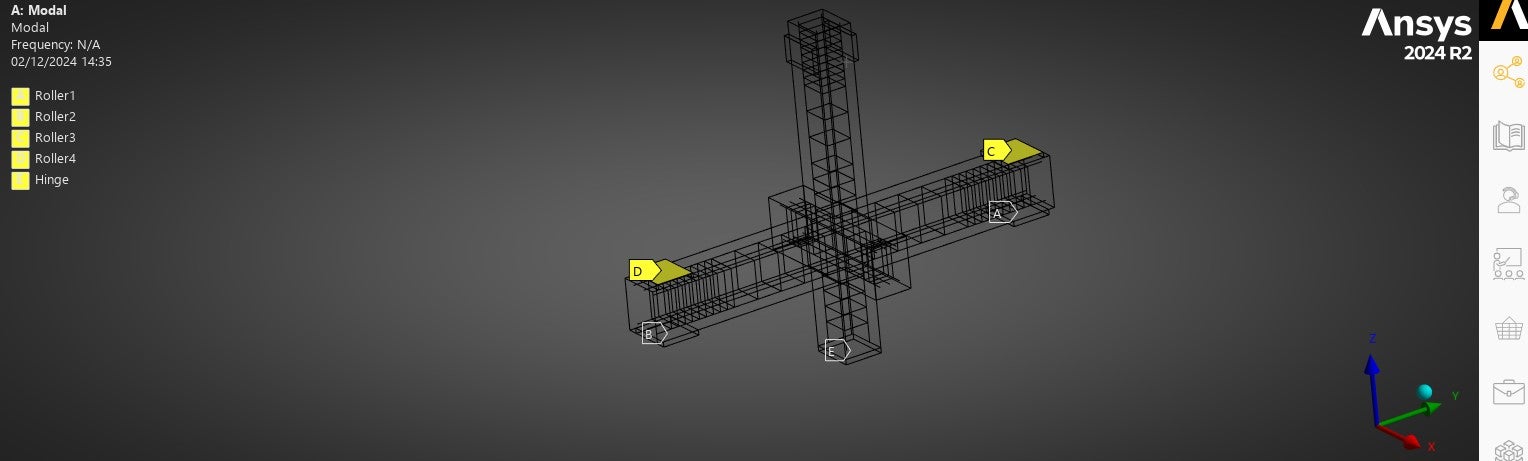

SubscriberGood morning everyone I am working on a reinforced concrete beam-column joint, I have roller constraints and a hinge constraint applied on the main beam and column base respectively. The constraints have been applied to steel plates. Once the analysis is done I find that my frequency is 10Hz higher than what is identified through experimental data, what could be the problems associated with this high value? The materials have the same properties as the experimental model. Thank you all!

-

December 3, 2024 at 2:13 pm

Erik Kostson

Ansys EmployeeHi

Not sure what is the error between exp., and simulation (an absolute value of 10 Hz does not say much).

If you think that the material properties are exactly correct (often we do not them exactly and need to study their effect when changing them), then boundary conditions could be something to look at.

Still one can look at using a design of experiemnts (so look at what par., influence the agreement between the 2), and optimization to tune exp., to simulations.

See here for some ideas on the above (look at: Model Calibration of a railway vehicle):

https://library.dynardo.de/en/library/industries/railway-systems.html

Perhaps other members here can chime in and provide some ideas, but I hope the above

helps

-

December 3, 2024 at 4:20 pm

dlooman

Ansys EmployeeIt's easy for the FEA boundary conditions to over-state the rigidity of the actual supports. For example, if you apply a "roller" constraint to a face you are also preventing rotation of that face.

-

- You must be logged in to reply to this topic.

-

3472

-

1057

-

1051

-

940

-

902

© 2025 Copyright ANSYS, Inc. All rights reserved.