-

-

March 10, 2020 at 7:31 pm

Rajasekhar

SubscriberHello all,

we are simulating a multi species setup in our case. we have a room where the Supply volume flow rate is 10360 L/S. our extract volume flow rate is 9320 L/S. so we have a difference of 1040 l/s, which is accumulating in the fluid domain. for now we are using velocity inlet boundary condition at inlets and velocity inlet boundary condition with negative velocity at outlets.

in the current case we have to maintain a positive pressure in the fluid domain. so, we are supplying more inflow compared to outflow.

our simulation is running with not very great convergence of continuity but we are able to achieve some simulation contours.

will anyone please suggest what are the other boundary conditions if the above conditions are not correct.

Also will any one please suggest is there any possible way to maintain positive pressure with mass imbalance in our current simulation.

Thankyou,

Reddy.

-

March 10, 2020 at 9:18 pm

Rahul Kumar

Ansys EmployeeHello,

What is the method that you are using to solve the problem?

Regards,

Rahul

-

March 10, 2020 at 10:29 pm

Karthik Remella

AdministratorHello Reddy,

If I understand correctly, your continuity equation will never converge because of the mass-imbalance you are trying to maintain. Are you treating the gas as compressible or incompressible?

Ideally, I would recommend a velocity inlet (or pressure inlet) and pressure outlet boundary condition. This should ensure a positive pressure in the room as long as the flow is unidirectional. With one value of velocity inlet and a different velocity outlet, you will always run into convergence issues.

Please share some details (and plots) related to your model and maybe we can better help you answer the question.

Thank you.

Best Regards,

Karthik

-

March 11, 2020 at 6:36 am

Rajasekhar

SubscriberHello Karthik,

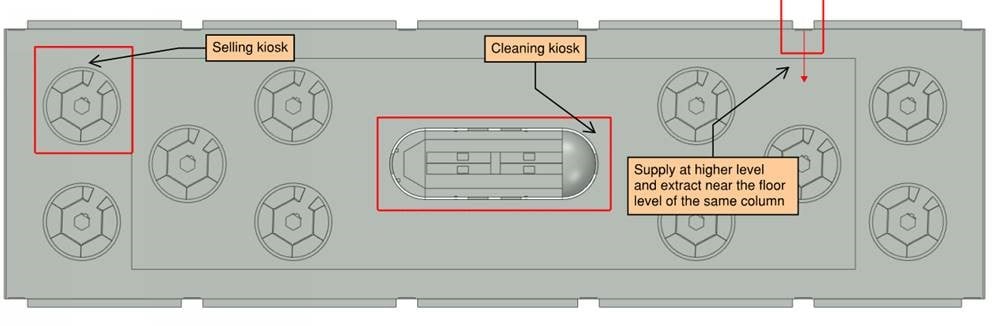

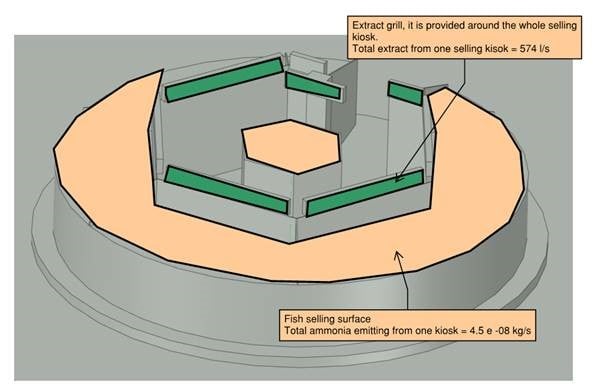

thanks for your prompt reply. we are solving in compressible flow with k epsilon model. we are enabling species transport with ammonia mass fraction from certain source generation surfaces. these source generation surfaces are not our volumetric flow inlets. our volumetric flow inlets are defined separately with only fresh air coming into the domain. attaching an image for better understanding.

see the simulation procedure we are following in our case.

Steps for Meshing :

- Import Geometry unit in mm

- No local sizing

- Compute Surface mesh: Min size: 20 mm and Max Size: 200 mm

- Define boundary layers at the extract, inlet, surface-emitting surfaces

- Compute Volume Mesh size: Max size: 800 mm, number of the buffer layer 3, number of peer layer = 2

Solver

- Ammonia emitting surface = mass flow inlet with total emission from one selling kiosk = 4.5 e-08 kg/s or 5.02 e-09 kg/sm2

- Number of selling kiosk =10

- Ammonia emitting surface = mass flow inlet from cleaning kiosk = 4.4 e08 kg/s or 1.8 e-09 kg/sm2

- Extract points along the entire selling kiosk (total extracat from 10 selling kiosk = 5740 l/s)

- Supply and extract points within the cleaning kiosk (Total supply within the cleaning kiosk =1000 l/s and total extract within cleaning = 1236 l/s)

- Supply and extract points located at the column of the market (total supply from column = 9360 l/s, total extract from column = 2344 l/s)

I hope the above data helps.

i have one more doubt. if we try to match the inlet flow rate with extract flow rate, is it possible to use velocity inlet at both boundary conditions.

Thankyou,

Reddy.

-

March 12, 2020 at 6:59 pm

Karthik Remella

AdministratorHello,

Since you are solving an incompressible flow problem, your extraction flow rate will match your inlet flow rate automatically. Using a velocity inlet and outlet condition for your boundaries is not a robust way of setting up the problem. You should be using either of the three combinations (in the following order):

1. Velocity inlet (or mass flow inlet) and pressure outlet

2. Pressure inlet and pressure outlet

3. Pressure inlet and velocity outlet or mass flow outlet (I would not use this unless you are unable to absolutely pin down your boundary conditions and use options 1 and 2).

I hope this helps.

Best Regards,

Karthik

-

March 14, 2020 at 3:47 am

Rajasekhar

SubscriberThanks a lot for your support. i got the idea.

have a great day.

-

- The topic ‘ANSYS FLUENT BOUNDARY CONDITION HELP’ is closed to new replies.

-

4823

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.