TAGGED: #thermal-radiation, heat-transfer, transient

-

-

July 16, 2024 at 7:50 pm

Rishi Yadav

SubscriberI am trying to simulate the transient heat analysis, but I am getting an error, 'An error occurred inside the SOLVER module: Enclosure type Perfect was incorrectly chosen in some Surface to Surface Radiation objects'.

The initial temperatures are 1400 C, and 300 C for different parts. Had heat flux as heating source and radiation data. Since inside the chamber is vacuum, so I choose surface to surface radiation and chose enclosure type as perfect. I am not sure, why there is an error. Please guide.

-

July 19, 2024 at 12:14 pm

Sampat Kumar

Ansys EmployeeHi

Will you please try to open the solver output file and let me what is the actual error message there? Is there any shell body in the model?

Best Regards,

Sampat -

July 19, 2024 at 6:15 pm

Rishi Yadav

SubscriberSolver Output

Ansys Mechanical Enterprise Academic Research

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2023 R1 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2023 Ansys, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2023 R1

Point Releases and Patches installed:

ANSYS, Inc. License Manager 2023 R1

Discovery 2023 R1

Ansys Sherlock 2023 R1

SpaceClaim 2023 R1

Autodyn 2023 R1

LS-DYNA 2023 R1

CFD-Post only 2023 R1

CFX (includes CFD-Post) 2023 R1

Chemkin 2023 R1

EnSight 2023 R1

FENSAP-ICE 2023 R1

Fluent (includes CFD-Post) 2023 R1

Polyflow (includes CFD-Post) 2023 R1

Forte (includes EnSight) 2023 R1

TurboGrid 2023 R1

Motion 2023 R1

Aqwa 2023 R1

optiSLang 2023 R1

Additive 2023 R1

Customization Files for User Programmable Features 2023 R1

Mechanical Products 2023 R1

Material Calibration App 2023 R1

Icepak (includes CFD-Post) 2023 R1

Remote Solve Manager Standalone Services 2023 R1

Ansys Sound - SAS 2023 R1

Viewer 2023 R1

ACIS Geometry Interface 2023 R1

AutoCAD Geometry Interface 2023 R1

Catia, Version 4 Geometry Interface 2023 R1

Catia, Version 5 Geometry Interface 2023 R1

Catia, Version 6 Geometry Interface 2023 R1

Creo Elements/Direct Modeling Geometry Interface 2023 R1

Creo Parametric Geometry Interface 2023 R1

Inventor Geometry Interface 2023 R1

JTOpen Geometry Interface 2023 R1

NX Geometry Interface 2023 R1

Parasolid Geometry Interface 2023 R1

Solid Edge Geometry Interface 2023 R1

SOLIDWORKS Geometry Interface 2023 R1

***** MAPDL COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

SHARED MEMORY PARALLEL REQUESTED

SINGLE PROCESS WITH 24 THREADS REQUESTED

TOTAL OF 24 CORES REQUESTED

INPUT FILE NAME = D:\Ansys Rishi\Ansys Simulations\5\_ProjectScratch\ScrD250\dummy.dat

OUTPUT FILE NAME = D:\Ansys Rishi\Ansys Simulations\5\_ProjectScratch\ScrD250\solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

RELEASE= 2023 R1 BUILD= 23.1 UP20221128 VERSION=WINDOWS x64

CURRENT JOBNAME=file 13:22:18 JUL 19, 2024 CP= 0.125

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

DO NOT WRITE ELEMENT RESULTS INTO DATABASE

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 13.3716667

TITLE=

5--Transient Thermal (C5)

ACT Extensions:

LSDYNA, 2023.1

5f463412-bd3e-484b-87e7-cbc0a665e474, wbex

/COM, AdditiveWizard, 2023.1

d670da30-b684-4a76-8cae-363c855c1121, wbex

/COM, ANSYSMotion, 2023.1

20180725-3f81-49eb-9f31-41364844c769, wbex

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = D:\Ansys Rishi\Ansys Simulations\5\_ProjectScratch\ScrD250\

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = D:\Ansys Rishi\Ansys Simulations\5\5_files\dp0\SYS-2\MECH\

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = D:\Ansys Rishi\Ansys Simulations\5\5_files\user_files\

--- Data in consistent NMM units. See Solving Units in the help system for more

MPA UNITS SPECIFIED FOR INTERNAL

LENGTH = MILLIMETERS (mm)

MASS = TONNE (Mg)

TIME = SECONDS (sec)

TEMPERATURE = CELSIUS (C)

TOFFSET = 273.0

FORCE = NEWTON (N)

HEAT = MILLIJOULES (mJ)

INPUT UNITS ARE ALSO SET TO MPA

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***

Ansys Mechanical Enterprise Academic Research

00214406 VERSION=WINDOWS x64 13:22:18 JUL 19, 2024 CP= 0.234

5--Transient Thermal (C5)

***** MAPDL ANALYSIS DEFINITION (PREP7) *****

*********** Nodes for the whole assembly ***********

*********** Elements for Body 1 "Q10_Build_Table_(Rounded corners)" ***********

*********** Elements for Body 2 "Q10_tungsten_Disk" ***********

*********** Elements for Body 3 "powder layer" ***********

*********** Elements for Body 4 "Q10_powder_spread-1" ***********

*********** Elements for Body 5 "Q10_complete heat shield" ***********

*********** Send User Defined Coordinate System(s) ***********

*********** Send Materials ***********

*** WARNING *** CP = 6.922 TIME= 13:22:19

The temperature-dependent secant coefficient of thermal expansion for

material 1 includes a temperature point of reference temperature (with

a tolerance of 1 degree). This data is ignored for the MPAMOD command

operation to avoid a numerical singularity.

*** WARNING *** CP = 6.922 TIME= 13:22:19

The temperature-dependent secant coefficient of thermal expansion for

material 5 includes a temperature point of reference temperature (with

a tolerance of 1 degree). This data is ignored for the MPAMOD command

operation to avoid a numerical singularity.

*********** Create Contact "Contact Region" ***********

Real Constant Set For Above Contact Is 7 & 6

*********** Create Contact "Contact Region 3" ***********

Real Constant Set For Above Contact Is 9 & 8

*********** Create Contact "Contact Region 4" ***********

Real Constant Set For Above Contact Is 11 & 10

*********** Create Contact "Contact Region 5" ***********

Real Constant Set For Above Contact Is 13 & 12

*********** Define Temperature Constraint ***********

*********** Define Temperature Constraint ***********

*********** Define Temperature Constraint ***********

*********** Create "Heat Flux" ***********

*********** Create "ToSurface(Closed)" Radiation ***********

*********** Create "ToSurface(Closed)" Radiation ***********

***************** Define Uniform Initial temperature ***************

***** ROUTINE COMPLETED ***** CP = 8.422

--- Number of total nodes = 104159

--- Number of contact elements = 3805

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 49733

--- Number of condensed parts = 0

--- Number of total elements = 53538

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 13.3719444

****************************************************************************

************************* SOLUTION ********************************

****************************************************************************

***** MAPDL SOLUTION ROUTINE *****

PERFORM A TRANSIENT ANALYSIS

THIS WILL BE A NEW ANALYSIS

STEP BOUNDARY CONDITION KEY= 1

CONTACT INFORMATION PRINTOUT LEVEL 1

DO NOT SAVE ANY RESTART FILES AT ALL

Use Full Nonlinear Thermal Transient Solution

NLHIST: ADDED NODAL RESULTS HISTORY FOR:

NAME = MAX_TEMP

ITEM/COMP = TEMPMAX

NODE = 0

NLHIST: ADDED NODAL RESULTS HISTORY FOR:

NAME = MIN_TEMP

ITEM/COMP = TEMPMIN

NODE = 0

********* Initial Time Increment Check And Fourier Modulus *********

Specified Initial Time Increment: 0.1

Estimated Increment Needed, le*le/alpha, Body 1: 7.4608

Estimated Increment Needed, le*le/alpha, Body 2: 0.543679

Estimated Increment Needed, le*le/alpha, Body 3: 0.0288621

Estimated Increment Needed, le*le/alpha, Body 4: 2.24448

Estimated Increment Needed, le*le/alpha, Body 5: 0.98259

****************************************************

******************* SOLVE FOR LS 1 OF 1 ****************

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

REAL= 1400.00000 IMAG= 0.00000000

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

REAL= 300.000000 IMAG= 0.00000000

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

REAL= 300.000000 IMAG= 0.00000000

SELECT FOR ITEM=TYPE COMPONENT=

IN RANGE 14 TO 14 STEP 1

53 ELEMENTS (OF 53538 DEFINED) SELECTED BY ESEL COMMAND.

SELECT ALL NODES HAVING ANY ELEMENT IN ELEMENT SET.

182 NODES (OF 104159 DEFINED) SELECTED FROM

53 SELECTED ELEMENTS BY NSLE COMMAND.

GENERATE SURFACE LOAD HFLU ON SURFACE DEFINED BY ALL SELECTED NODES

ACCORDING TO TABLE PARAMETER = _LOADVARI75

NUMBER OF HFLU ELEMENT FACE LOADS STORED = 53

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 104159 STEP 1

104159 NODES (OF 104159 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 86886 STEP 1

53538 ELEMENTS (OF 53538 DEFINED) SELECTED BY ESEL COMMAND.

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 6 KVAL = 1

ACCORDING TO TABLE PARAMETER = _RADVARI65

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 6 KVAL = 2

VALUES = 1.0000 1.0000 1.0000 1.0000

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 104159 STEP 1

104159 NODES (OF 104159 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 86886 STEP 1

53538 ELEMENTS (OF 53538 DEFINED) SELECTED BY ESEL COMMAND.

ENCLOSURE= 1 VIEWFACTOR SCALE METHOD = 1

ITERATIONS = 100

TOLERANCE = 1.000000047E-03

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 1 KVAL = 1

ACCORDING TO TABLE PARAMETER = _RADVARI79

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 1 KVAL = 2

VALUES = 1.0000 1.0000 1.0000 1.0000

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 2 KVAL = 1

ACCORDING TO TABLE PARAMETER = _RADVARI79

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 2 KVAL = 2

VALUES = 1.0000 1.0000 1.0000 1.0000

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 3 KVAL = 1

ACCORDING TO TABLE PARAMETER = _RADVARI79

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 3 KVAL = 2

VALUES = 1.0000 1.0000 1.0000 1.0000

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 4 KVAL = 1

ACCORDING TO TABLE PARAMETER = _RADVARI79

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 4 KVAL = 2

VALUES = 1.0000 1.0000 1.0000 1.0000

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 104159 STEP 1

104159 NODES (OF 104159 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 86886 STEP 1

53538 ELEMENTS (OF 53538 DEFINED) SELECTED BY ESEL COMMAND.

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 104159 STEP 1

104159 NODES (OF 104159 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 86886 STEP 1

53538 ELEMENTS (OF 53538 DEFINED) SELECTED BY ESEL COMMAND.

PRINTOUT RESUMED BY /GOP

DO NOT USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE INITIAL TIME STEP SIZE OF 0.1000000 FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 0.1000000 AS THE MINIMUM TIME STEP SIZE

USE 0.1000000 AS THE MAXIMUM TIME STEP SIZE

TIME= 200.00

INCLUDE TRANSIENT EFFECTS FOR ALL DEGREES OF FREEDOM THIS LOAD STEP

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE FFLU ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE MISC ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

CONVERGENCE ON HEAT BASED ON THE NORM OF THE N-R LOAD

WITH A TOLERANCE OF 0.1000E-03 AND A MINIMUM REFERENCE VALUE OF 0.1000E-02

USING THE L2 NORM (CHECK THE SRSS VALUE)

UNDER RELAXATION FOR RADIATION FLUX= 0.10000

TOLERENCE FOR RADIOSITY FLUX= 0.00010

USING JACOBI ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 3D ENCLOSURES.

USING GSEIDEL ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 2D ENCLOSURES.

MAXIMUM NUMBER OF ITERATIONS= 1000

TOLERENCE FOR ITERATIVE SOLVER= 0.00010

RELAXATION FOR ITERATIVE SOLVER= 0.10000

HEMICUBE RESOLUTION= 10

MIN NORMALIZED DIST BEFORE AUTO SUBDIVIDE= 1.000000000E-09

SELECT COMPONENT _CM65

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

1018 ELEMENTS (OF 53538 DEFINED) SELECTED FROM

1919 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 670

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 581

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 670

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 581

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 104829 STEP 1

104829 NODES (OF 104829 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 87467 STEP 1

54119 ELEMENTS (OF 54119 DEFINED) SELECTED BY ESEL COMMAND.

SELECT COMPONENT _CM79

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

46561 ELEMENTS (OF 54119 DEFINED) SELECTED FROM

28462 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 7225

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 14013

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 7225

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 14013

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 112054 STEP 1

112054 NODES (OF 112054 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 101480 STEP 1

68132 ELEMENTS (OF 68132 DEFINED) SELECTED BY ESEL COMMAND.

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

***** MAPDL SOLVE COMMAND *****

CALCULATING VIEW FACTORS USING HEMICUBE METHOD

RETRIEVED 1 ENCLOSURES.

TOTAL OF 14594 DEFINED ELEMENT FACES.

# ENCLOSURE = 1 # SURFACES = 14594 # NODES = 7895

******************************************************************************

V I E W F A C T O R S M O O T H I N G

******************************************************************************

Smoothing of viewfactor matrix...

Max iterations = 100

Tolerance = 0.001

Some of the rows in the viewfactor matrix have all zeros

row sum total should be = 14590.0000

row sum total before forcing symmetry = 14587.0815

row sum total after forcing symmetry = 14587.0815

row sum total after smoothing = 14590.0002

Raw rowsum error min = -7.3418e-01

Raw rowsum error max = 2.3842e-07

Raw rowsum error mean = -1.9998e-04 +/- 9.3284e-03

Symmetric rowsum error min = -7.3418e-01

Symmetric rowsum error max = 2.3842e-07

Symmetric rowsum error mean = -1.9998e-04 +/- 5.7435e-08

Smoothed rowsum error min = -1.7881e-07

Smoothed rowsum error max = 3.5763e-07

Smoothed rowsum error mean = 1.4719e-08 +/- 5.1301e-11

number of iterations to smooth = 1

******************************************************************************

E N D O F V I E W F A C T O R S M O O T H I N G

******************************************************************************

TIME OF CALCULATION FOR THIS ENCLOSURE = 74.1875

CHECKING VIEW FACTOR SUM

*** NOTE *** CP = 110.109 TIME= 13:23:42

Some of the rows in the viewfactor matrix have all zeros for enclosure

1.

*** ERROR *** CP = 110.172 TIME= 13:23:42

No Space Temperature or Space Node specified for open Enclosure 1.

ERROR IN VIEW FACTOR CALCULATION

*** WARNING *** CP = 110.172 TIME= 13:23:42

Some radiation enclosures have viewfactor scaling. Use VFSM,STAT

command to check the status. Also note that scaling is ignored if the

viewfactor sum is <= 0.0.

NUMBER OF WARNING MESSAGES ENCOUNTERED= 3

NUMBER OF ERROR MESSAGES ENCOUNTERED= 1

***** PROBLEM TERMINATED BY INDICATED ERROR(S) OR BY END OF INPUT DATA *****

+--------------------- M A P D L S T A T I S T I C S ------------------------+

Release: 2023 R1 Build: 23.1 Update: UP20221128 Platform: WINDOWS x64

Date Run: 07/19/2024 Time: 13:23 Process ID: 19840

Operating System: Windows Server 2019 (Build: 17763)

Processor Model: Intel(R) Xeon(R) CPU E5-2660 v4 @ 2.00GHz

Compiler: Intel(R) Fortran Compiler Version 19.0.5 (Build: 20190815)

Intel(R) C/C++ Compiler Version 19.0.5 (Build: 20190815)

Intel(R) Math Kernel Library Version 2020.0.0 Product Build 20191125

BLAS Library supplied by Intel(R) MKL

Number of machines requested : 1

Total number of cores available : 56

Number of physical cores available : 28

Number of processes requested : 1

Number of threads per process requested : 24

Total number of cores requested : 24 (Shared Memory Parallel)

GPU Acceleration: Not Requested

Job Name: file

Input File: dummy.dat

Working Directory: D:\Ansys Rishi\Ansys Simulations\5\_ProjectScratch\ScrD250

Total CPU time for main thread : 84.1 seconds

Total CPU time summed for all threads : 113.5 seconds

Elapsed time spent obtaining a license : 0.9 seconds

Elapsed time spent pre-processing model (/PREP7) : 0.6 seconds

Elapsed time spent solution - preprocessing : 0.0 seconds

Elapsed time spent computing solution : 0.0 seconds

Elapsed time spent solution - postprocessing : 0.0 seconds

Elapsed time spent post-processing model (/POST1) : 0.0 seconds

Sum of memory used on all processes : 162.0 MB

Sum of memory allocated on all processes : 2112.0 MB

Physical memory available : 64 GB

Total amount of I/O written to disk : 0.0 GB

Total amount of I/O read from disk : 0.0 GB

+------------------ E N D M A P D L S T A T I S T I C S -------------------+

*-----------------------------------------------------------------------------*

| |

| RUN COMPLETED |

| |

|-----------------------------------------------------------------------------|

| |

| Ansys MAPDL 2023 R1 Build 23.1 UP20221128 WINDOWS x64 |

| |

|-----------------------------------------------------------------------------|

| |

| Database Requested(-db) 1024 MB Scratch Memory Requested 1024 MB |

| Maximum Database Used 79 MB Maximum Scratch Memory Used 83 MB |

| |

|-----------------------------------------------------------------------------|

| |

| CP Time (sec) = 113.453 Time = 13:23:42 |

| Elapsed Time (sec) = 86.000 Date = 07/19/2024 |

| |

*-----------------------------------------------------------------------------* -

July 23, 2024 at 2:20 pm

Sampat Kumar

Ansys EmployeeHi

if your model includes a shell body then apply the radiation boundary condition individually for the shell bodies. Try to run with the same enclosure number and the "close" enclosure type. I believe there's a possibility that some bodies are not covered by the radiation boundary condition enclosure, which explains why this error is occurring. Kindly verify this.

Secondly, I believe there is some leakage in the enclosure type, which is the reason you are receiving the error. if you are still unable to solve the problem even after adding all the bodies in the enclosure. The enclosure type assing "open" can be used to run it. When using the "open" enclosure type, there might be a possibility that some heat will seep into the surroundings, however, it will not affect your analysis.

Best Regards,

Sampat -

July 24, 2024 at 3:31 am

Rishi Yadav

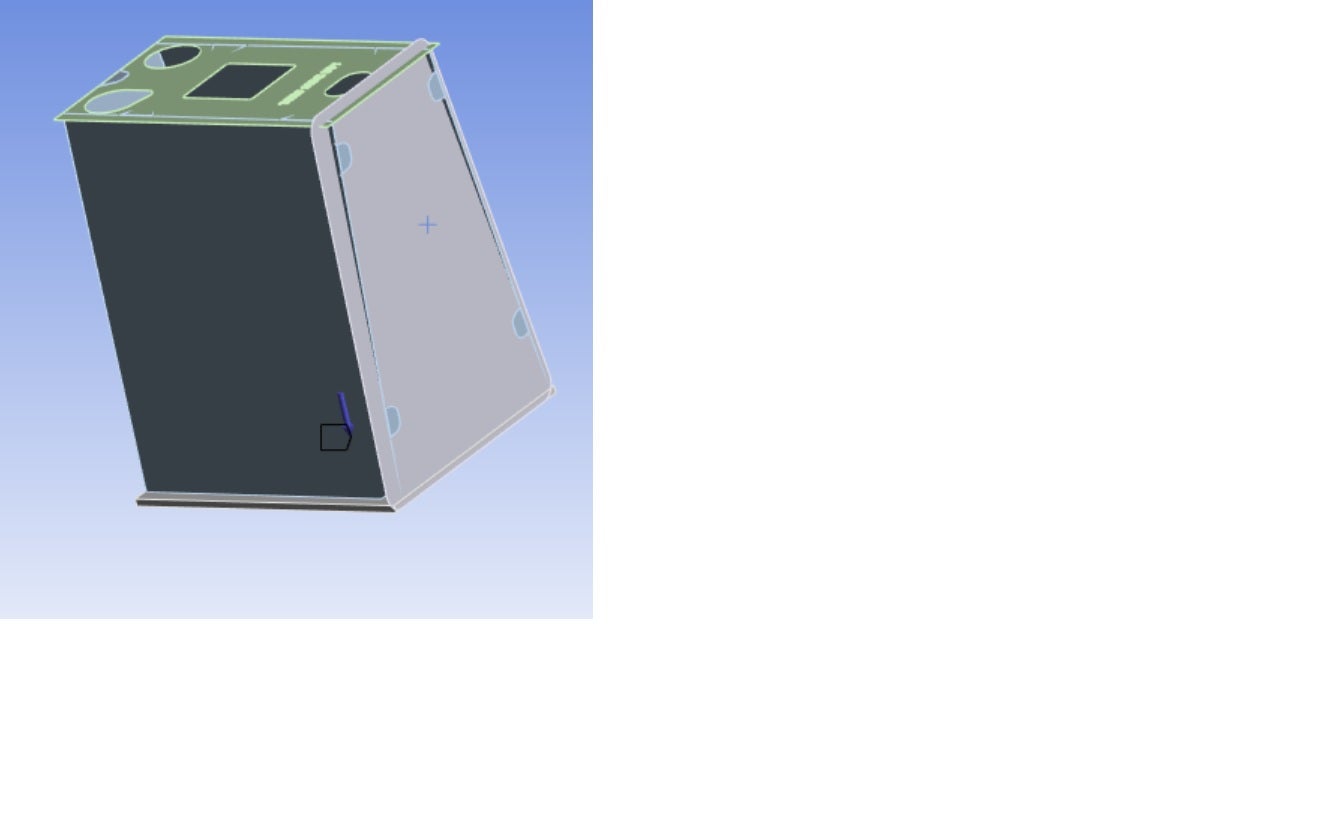

SubscriberThere are no shell bodies. I felt there might be some leakage so I changed the heat shield with no space as shown in image below. I did try to run the simulation with open condition but it is same error. I noticed in the error it is mentionig about, 'no space tempertaure', how can that be specified?

*** ERROR *** CP = 106.672 TIME= 13:52:20

No Space Temperature or Space Node specified for open Enclosure 1.To run with eclosure type as open. Temperature is rising upto ~1450 degree celcius from 1400 degree celcius but starts decreasing after that. It should reach about 3300 degree celcius.

-

August 1, 2024 at 9:54 am

Sampat Kumar

Ansys EmployeeHi Rishi,

Thanks for your patience.As I explained, the issue is due to the lack of a properly defined or captured radiation surface in the boundary conditions. Since there are inclined plates, bodies outside the close enclosure also participate in radiation heat transfer, which might create an issue in the calculation of view factors.

It’s crucial to remember that view factors are used to calculate radiation exchange between surfaces. They represent the fraction of radiation leaving one surface that reaches another.

I would suggest splitting the body that is outside the enclosure which will help you to apply the radiation boundary condition only to the surfaces within the enclosure. I believe this will help you to resolve the issue.

Note:- After following the above procedure, you can refine the mesh.

Best Regards,

Sampat -

August 10, 2024 at 5:07 am

Rishi Yadav

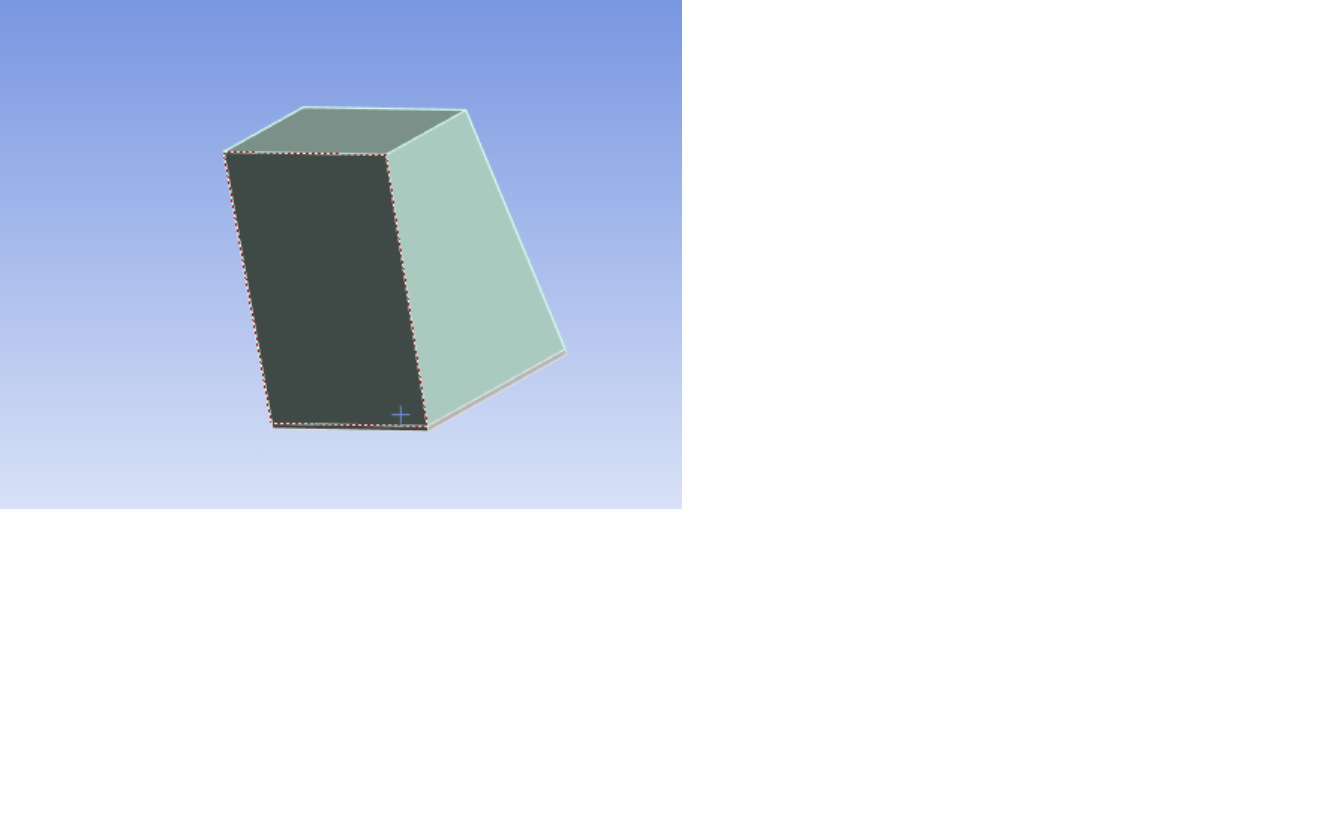

SubscriberI am getting an error with body split (image attached), and when I tried the face split, the face splitted into 4 parts. There is no body outside the enclosure. There is a build tray, on which a plate is placed on and on that plate there is a layer, which is getting heated. The process is in the vaccum. The heat shield is there (top structure) to prevent the heat loss. Radiation from heat shield is also playing a role in heating the layer. Can we connect over zoom?

-

- The topic ‘An error occurred inside the SOLVER module: Enclosure type’ is closed to new replies.

-

3472

-

1057

-

1051

-

940

-

902

© 2025 Copyright ANSYS, Inc. All rights reserved.