-

-

May 23, 2024 at 9:29 am

Jana Rittelmann

SubscriberHi there!

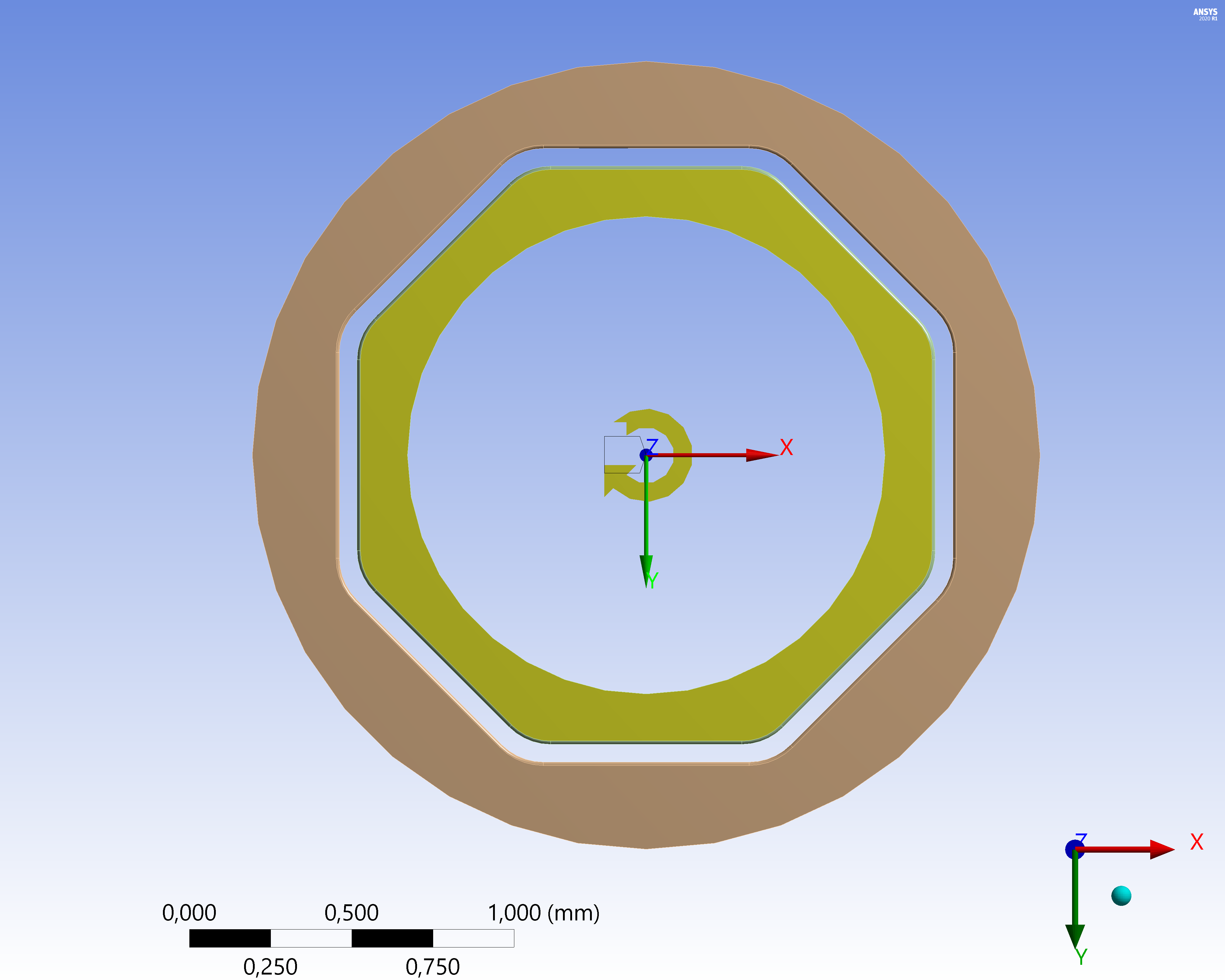

I did a simulation of two octagonal tubes where one is supposed to rotate inside of the other, see the first screenshot.

First, I used Polyamide (Nylon 6.6) as material for both parts and after mesh refinement in some regions my solutions converged in the regions of interest. Mesh refinement was needed for stresses to converge, but this wasn't the case for rotations and moment reactions which stayed quite close to each other no matter the refinement.

Now that I switched to Nitinol as material, I am seeing some behavior I cannot quite explain.

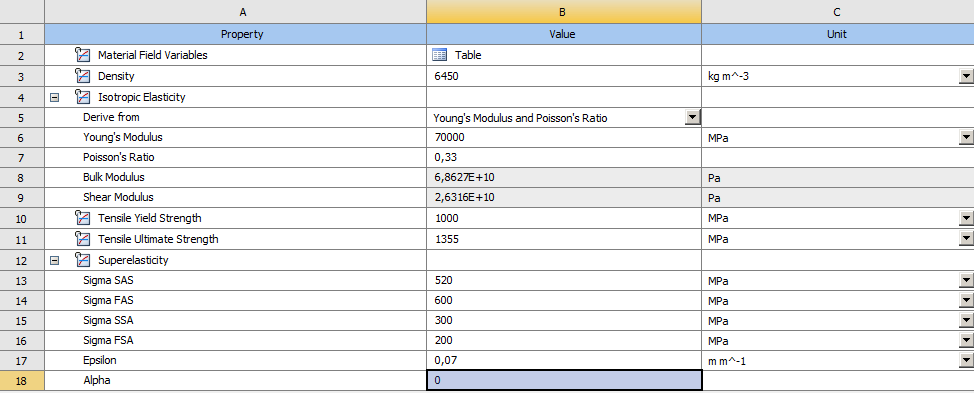

This is how I defined my Nitinol material:

I did the exact same simulation as with PA66 before, the mesh sizing parameters are the same too (the ones for which I achieved mesh convergence in the ROI in the PA66 simulation).

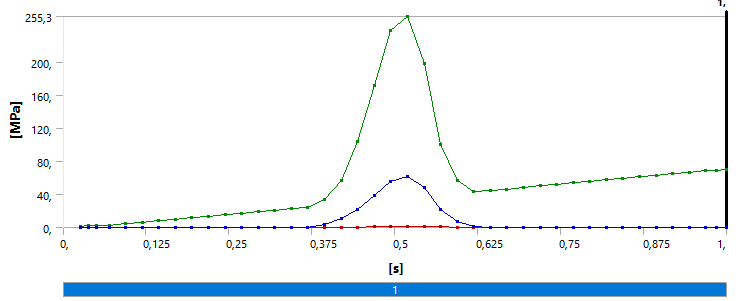

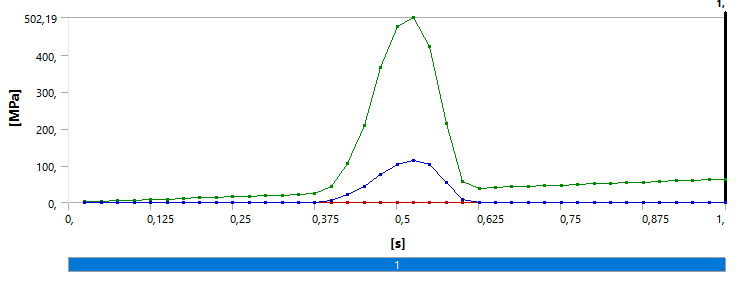

However, the refined mesh shows results which are almost exactly twice as high as the results for the inital mesh (which was already refined at critical points/ROI, so I didn't start with the default mesh or anything). This is the case for ALL results. Stresses, rotations, moment reactions... I would have expected this for the stress results as before, if the mesh wouldn't have been fine enough but not for ALL results:

- equivalent stresses over both bodies (in ROI) --> maximum and average results are affected, too, so it's not like it's a local stress riser or anything

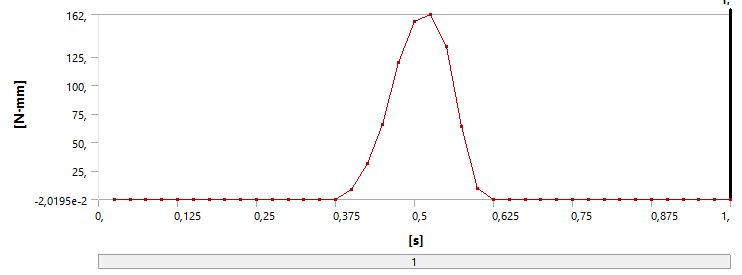

2. Moment reaction on one side of the inner part (where I applied a remote displacement rotation)

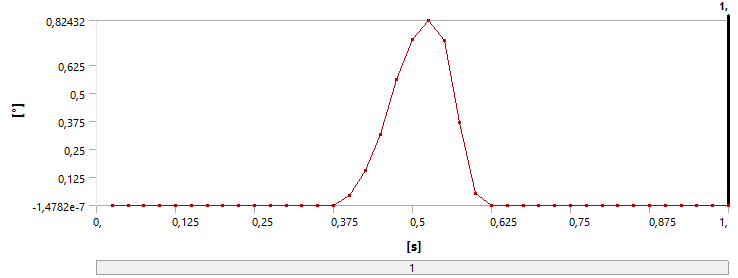

3. Rotation at the opposite end of the outer part (where it is free to rotate and does so to a certain extent while both parts are in contact during the rotation of the inner part)

Can anyone maybe explain what is happening here or has maybe had some similar experiences?

Is my understanding reasonable that I find it weird that all the results almost exactly double?

Could it be because of the nonlinear material properties of Nitinol?

Thanks in advance!

-

May 23, 2024 at 11:19 am

peteroznewman

SubscriberWhat is the Young's Modulus for the PA66?

In the elastic region, stress is proportional to Young's Modulus for an equal amount of strain.

-

May 23, 2024 at 11:25 am

Jana Rittelmann

SubscriberThe Young’s Modulus for the PA66 I used is 1480 MPa.

The diagrams are all for the Nitinol simulation – once not refined (as much) and once refined. Like, the only thing changing between the pairs of diagrams is the mesh size. I don’t know if maybe that didn’t come across clearly.

I am not trying to compare the PA66 results with the Nitinol results - I of course did expect a difference in stress values for that.

I hope my problem now is described a little better.

-

-

- The topic ‘All results (almost exactly) double after mesh refinement in Nitinol simulation’ is closed to new replies.

-

3472

-

1057

-

1051

-

934

-

897

© 2025 Copyright ANSYS, Inc. All rights reserved.