-

-

January 30, 2023 at 11:51 pm

reza121

SubscriberHello, I hope you are doing well.

I have a question about the particle time step and the number of times the particle equation of motion is solved in a single cell for a single parcel passing through that cell.

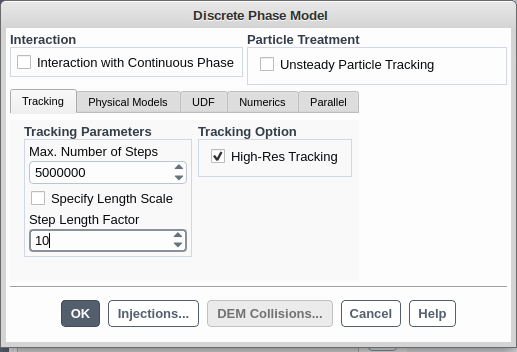

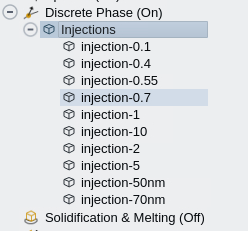

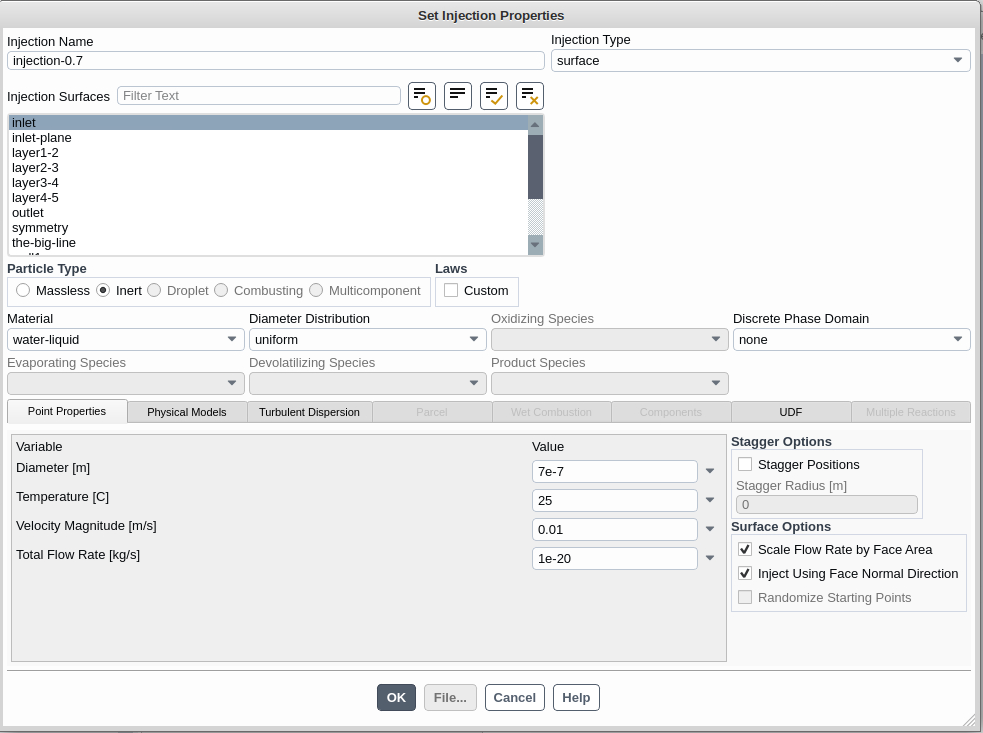

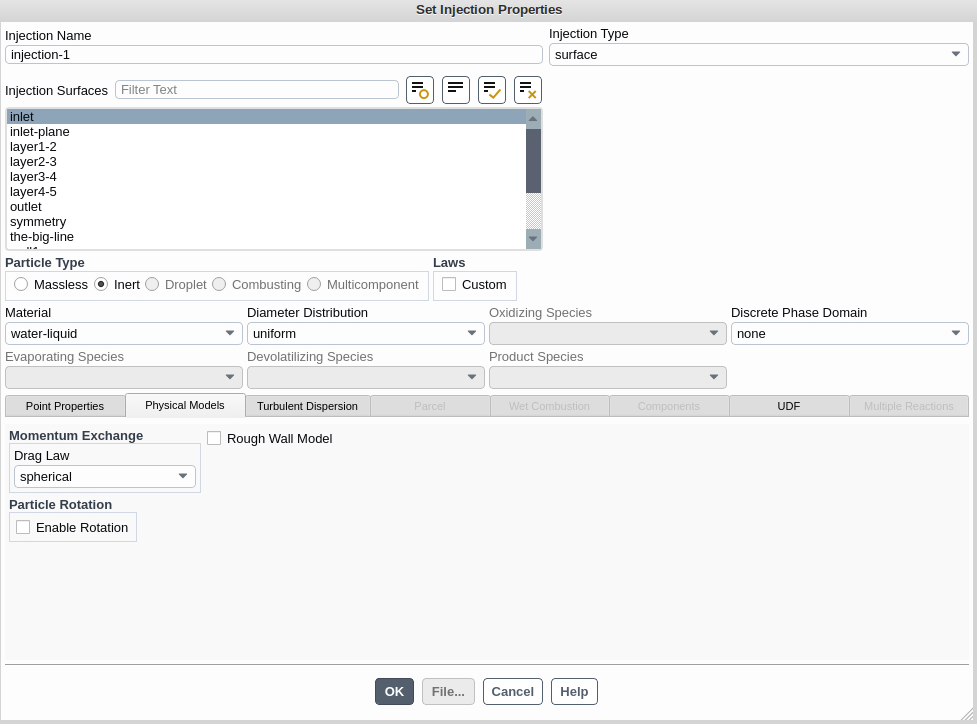

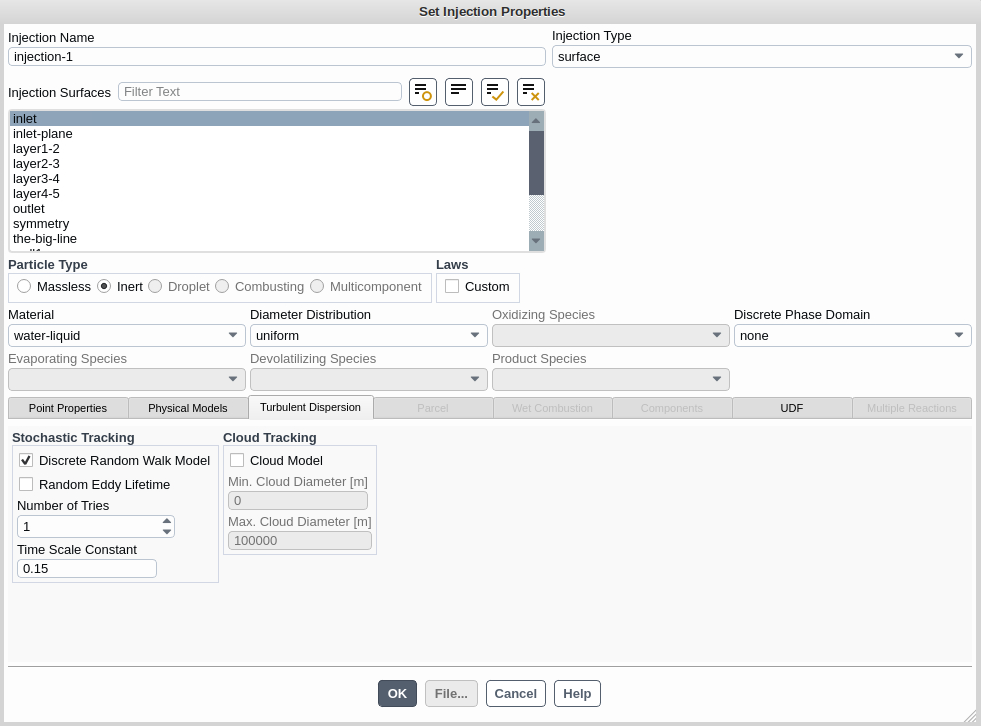

I am simulating particle capture in multi-layer screens in fluent using DPM. K-Omega SST model is used and DRW is added to the DPM model to see the impact of turbulence dispersion on the particle capture. I have defined multiple mono-size injection groups under the specified settings according to the attached photos. size of the smallest under-study particles is 50 nm and the largest size is 10 microns.

The drag law is spherical. It is noteworthy that the "number of tries" will be set to 50 for the capture study but it is set to 1 here for studying the trajectory of one single parcel.

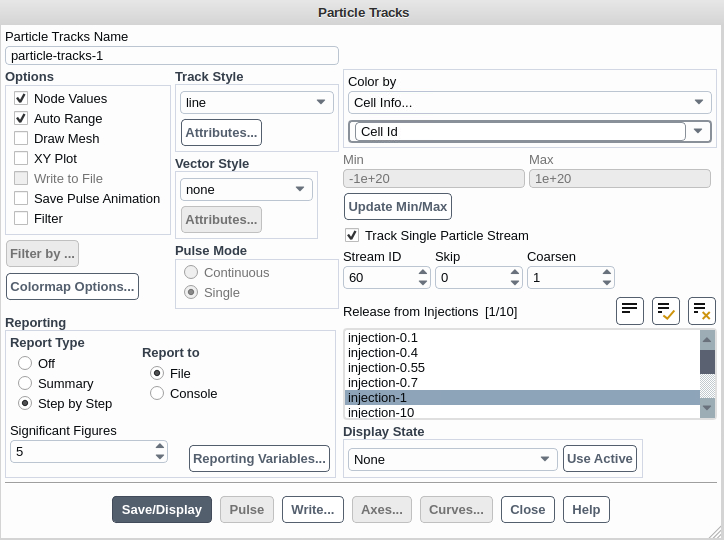

both the flow and particle tracking are calculated in steady-state conditions. I have extracted a "step by step" file report of the particle track for the 1-micron size group while the "track single particle stream" was activated.

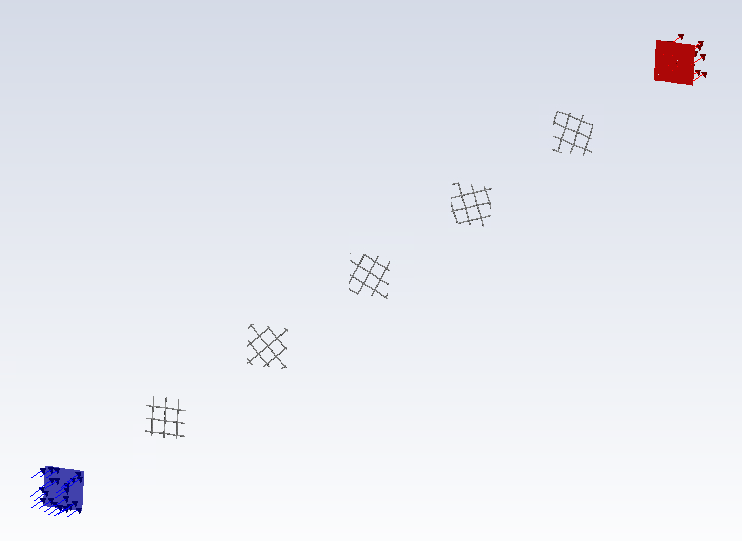

As you can see in the above photo, I set the "color by" as the cell id which is the id of the cell that the particle was commuting through when tracking its motion. When I look into the .dpmrpt file, I notice that even though the "step length factor" was set to 10 under the tracking parameters in the discrete phase model window (please refer to the screenshot above), particle trajectory is updated only once in each cell and not 10 times. This will be the case even if I specify a length scale.

I was expecting fluent to actually solve the equation of motion 10 times in each cell and interpolate the flow properties like velocity based on the position of the particle in that cell according to its distance from the adjacent cells. However, this is not the case apparently and the particle path is updated only once in each cell. The problem with that is that the relaxation time of some of my small particles is below 1e-6s while the particle time step in this report is around 1e-5 - 1e-6s.

The question is, how can I reduce the particle time step without having to refine my grid size? I would appreciate if you could give me any complimentary information on how the tracking works and whether my above conclusion is correct.

-

January 31, 2023 at 12:02 pm

Rob

Forum ModeratorI suspect the flow isn't doing much so the Accuracy Controls are kicking in to save cpu https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v231/en/flu_ug/flu_ug_sec_discrete_use_oview.html%23flu_ug_sec_pt_numerics

Note, 1 micron particles will probably follow the flow so may well miss the screens. How big are the holes, and how large is the near wall cell?

-

February 1, 2023 at 1:54 am

reza121

SubscriberThank you so much for your reply, Rob.

You are absolutely right. After disabling the accuracy control, the total number of tracking steps for a single parcel was increased from about 2300 to about 40000 (still, the path is updated only once in some of the cells which I am not sure why? Maybe the parcel passes through a very small part of those cells and doesn't traverse through the whole cell, i.e. doesn't go from one end to another end of the cell)

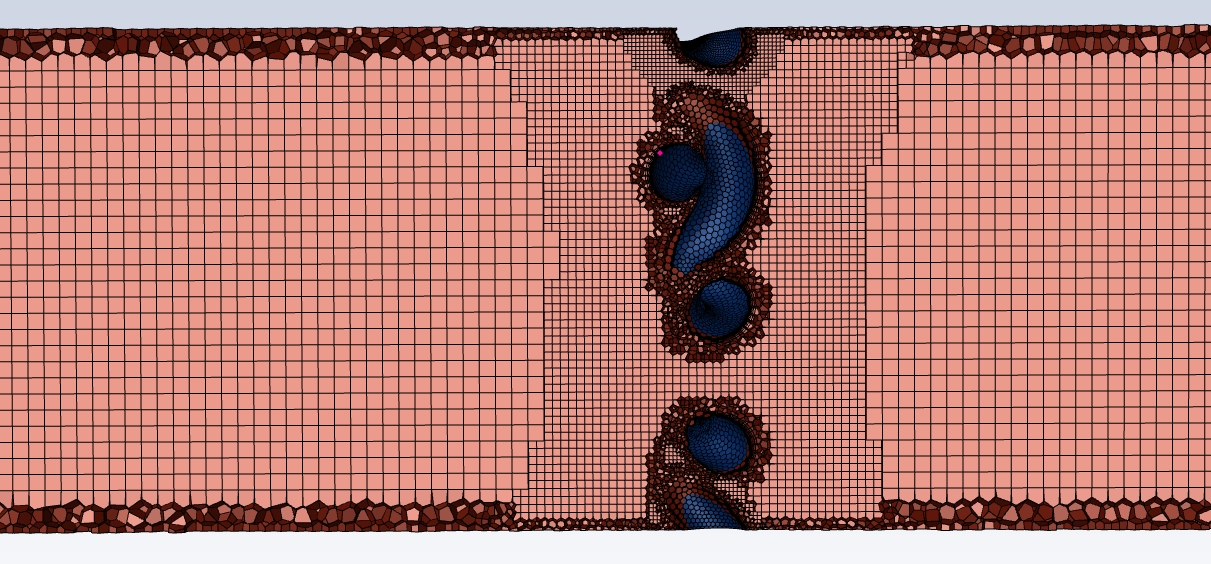

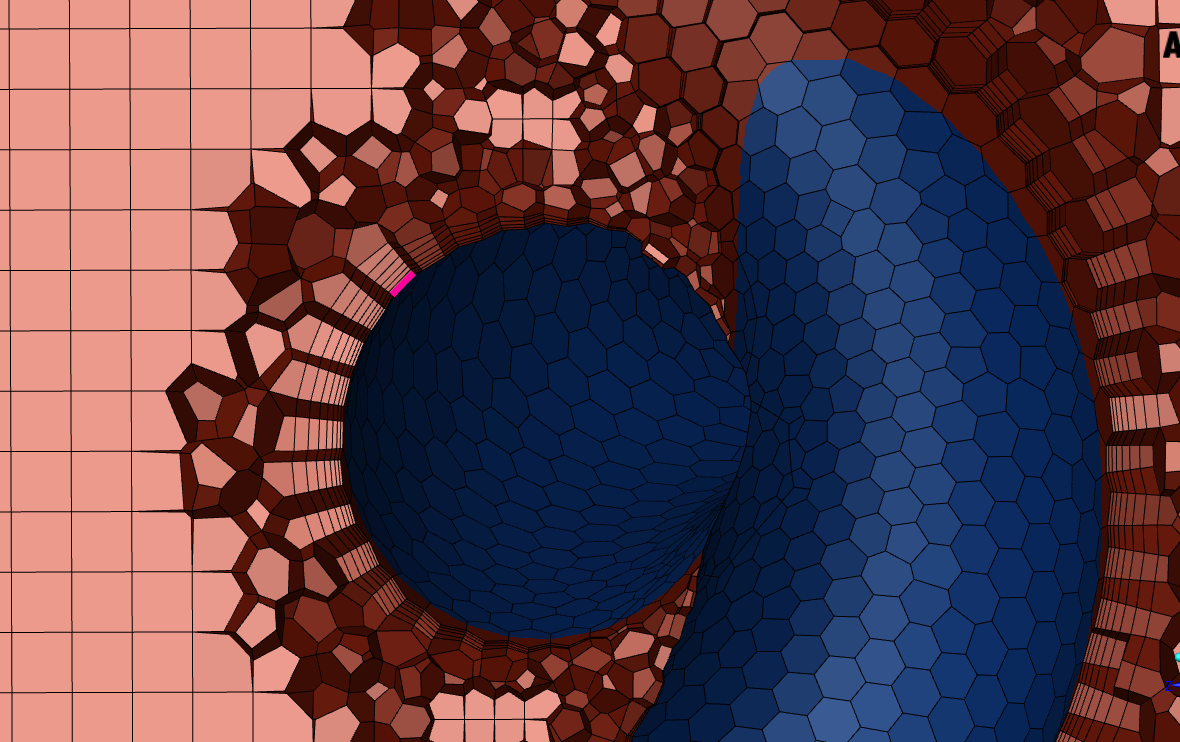

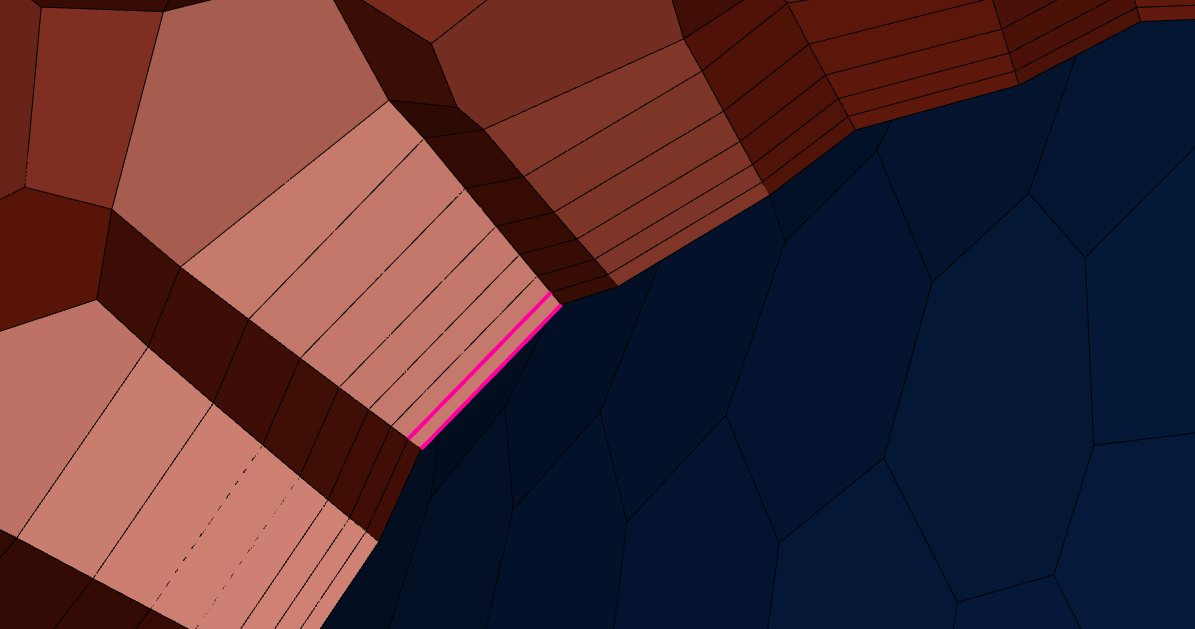

These are 3 different zooms of my mesh. The height of the first layer of mesh, right above the walls, is about 3e-7m according to the third photo in the following.

At high velocities (above 1m/s) because of the higher inertia of the particles, they cannot follow the sudden change of streamlines close to the wires well enough and hit the walls and get captured (filtration by impaction mechanism). My wire diameter is 0.05mm (50 microns) and the wire distance (i.e. aperture size) is 0.1mm (100 microns). the porosity of the screen (ratio of the area covered by the wires to the total area) is about 60%.

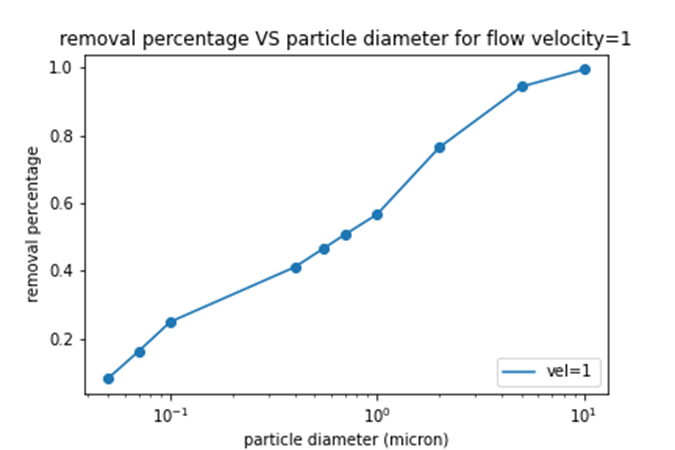

I currently observe about 60% removal of the 1-micron particles at 1m/s.

-

February 1, 2023 at 10:04 am

Rob

Forum ModeratorOK, you may want to revise the first cell height. DPM won't check wall collision unless it's in the near wall cell, at one micron diameter at the point the parcel enters the cell it should have hit the wall.

It's a common discussion here when introducing aero engineers to multiphase. They're very familiar with y+ from their academic CFD courses but not so much with how the more complex models behave. It's also why I have very little to do with modelling cars and aeroplanes....

-

February 1, 2023 at 4:07 pm

reza121

SubscriberThank you so much for your reply, Rob.

yes, now I remember that I read somewhere that fluent doesn't consider the particle diameter size when tracking them, and the particles are studied as point-particles which is actually the center of my particle (is that true? please correct me if I am wrong)

Based on what you said, I guess my first mesh layer height must be larger that my particle diameter(please correct me if I'm wrong). I am studying a range of particle sizes from 50nm to 10 microns. Do you think that it will be ok for tracking of those tiny particles if I generate a mesh with the first mesh layer height larger than 10 microns? (my hypothesis is that it should be fine and the trajectory of those small particles will be updated in more steps as they are passing through that mesh layer above the wall). Or do I have to generate different meshes for each of my particles? Of course, I should be mindful of the flow characterization limitations like y+ as well.

Now that we are talking about this issue, just to make sure, would you also please tell me, which one of these two is fluent's criterion for marking a particle as trapped on a wall:

1- the particle hitting the wall surface (this must be the correct one I think)

2- the particle entering the first mesh layer, right above the wall surface (the particle is marked as trapped as soon as it enters that mesh cell and no trajectory update happens in that cell)

Thank you so much for your time

-

February 1, 2023 at 4:39 pm

Rob

Forum ModeratorThe trajectory is checked in the near wall cell, so depending on the angles etc the particle can still miss the wall. The position relative to the wall (ie if it'll hit it) is NOT checked until you're in the near wall cell. So, if the cell height (remember Fluent reports cell centre height, Meshing returns cell height) is over the radius you should be OK.

-

- The topic ‘a question on DRW in DPM fluent’ is closed to new replies.

-

4723

-

1565

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.