Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Applying Pressure › Reply To: Applying Pressure

Greetings!

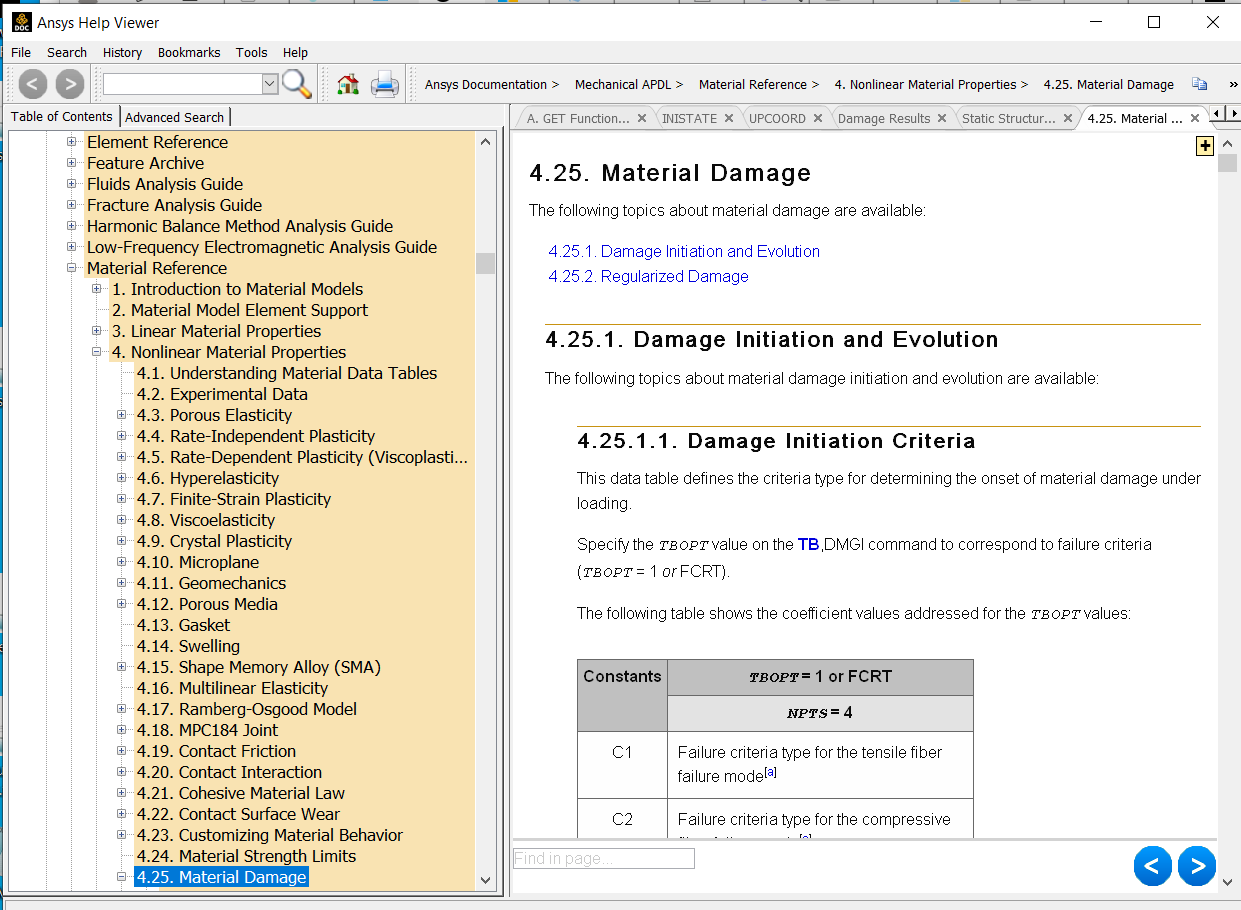

If the 746 MPa ultimate tensile strength of your steel was defined in Engineering Data, I doubt that it alone will predict some material failure in your finite element model when stresses exceed this value. If the pipe material model is linear, then calculated stresses can exceed this value and the material response will continue to be linear. The ultimate tensile stress material "property" defined in Engineering Data a little misleading. To simulate failure, you'd either need to define a damage material model:

It might be easier to make some approximation (e.g. use a bilinear isotropic hardening material model with a very low slope in the plastic part of the curve). Then, when calculated stresses in the pipe exceed the yield stress, the pipe will expand much more easily and the composite sleeve will recieve more of the load.

--Bill