-

-

December 30, 2025 at 10:03 pm

gwcourtney02

SubscriberI’m working on a dry balloon molding project and am consistently observing a repeatable wall-thickness difference between the proximal and distal ends of the balloon. We're investigating what the issue could be through CFD. The mold geometry and heating are axially symmetric, but the system uses a single internal nitrogen inlet. We have seen that the use of a very small restrictor (0.002 in diameter) is helping with this wall thickness gradient for certain balloon sizes but not all. The theory is that it is restricting the flow in a way that causes the parison tube to inflate/lock in more uniformly. How should I go about modeling this event in CFX, preferably? I'd like to avoid a FSI because I don't have parison tube stress-strain data at molding temperatures. I have also been told to look into the gas interaction between the outer face of the tube and the inner mold wall, but I don’t see how they could produce a prox–dist difference without introducing an explicit asymmetric event. If anyone thinks external cavity pressure can create prox–dist differences in a symmetric setup, I’d appreciate the mechanism.

Other background information can be found in this thread: https://www.reddit.com/r/ANSYS_Mechanical/comments/1prf8wu/comment/nv8rd6c/?%24deep_link=true&context=1&correlation_id=7af1af5a-7836-5efe-a936-6d40457a7799&ref=email_comment_reply&ref_campaign=email_comment_reply&ref_source=email&%243p=e_as&_branch_match_id=1443610646411822155&utm_medium=Email+Amazon+SES&_branch_referrer=H4sIAAAAAAAAA31Oy07EMAz8mu6tLX23K1VoBeIGlz1xitzUaSPSJHJTChe%2BHReWK5Itjccz9swh%2BPWcpoTjqEMC3idG27e08PdRXha%2BRwHriaEjPWkLRmxk%2BvlwRcUlyp%2B49n1Pbn7pFiaI%2B%2FJyfb2KZ5QzWC3BMMXLBW1YGWaeVLtvjLRVBgIMBsUAxjhnhYQwY0ASCoEV9r2lsZbHr4LfVXk5InpxxIyKx0AbRnktnQ34EZjIfiYi5LOar%2BmRyQZUBqqCuGmLOq5QYQwdo3os78qqgabpOvYRKhbjAtqIW1pB6M3n746TLR70ZP8VrW4jiX%2BS0xdzSKTtJAZy%2B4rUP8zkFvwGUsKKCXsBAAA%3D

Thank you! -

January 2, 2026 at 1:37 pm

B D

Ansys EmployeeHello,

If you are looking at modeling inflation of the balloon, this cannot be done just in CFX as CFX does not deal with balloon deformation. You will need to perform FSI where CFX solves the pressure field within balloon and mechanical solves the deformation of balloon because of the pressure inside.

If you are modeling only the final fluid volume after inflation to see the pressure distribution (as you mentioned in the comment: "I'm also not currently modeling the mold in CFX (or future case, Fluent) - just the internal fluid volume of the fully inflated balloon."), you need to model air as compressible fluid with ideal gas formulation if you intend to close the bottom side as wall. This is because we cannot add incompressible fluid into a closed system (physically impossible!).

-

January 2, 2026 at 7:01 pm

jcooper

Ansys EmployeeHi:

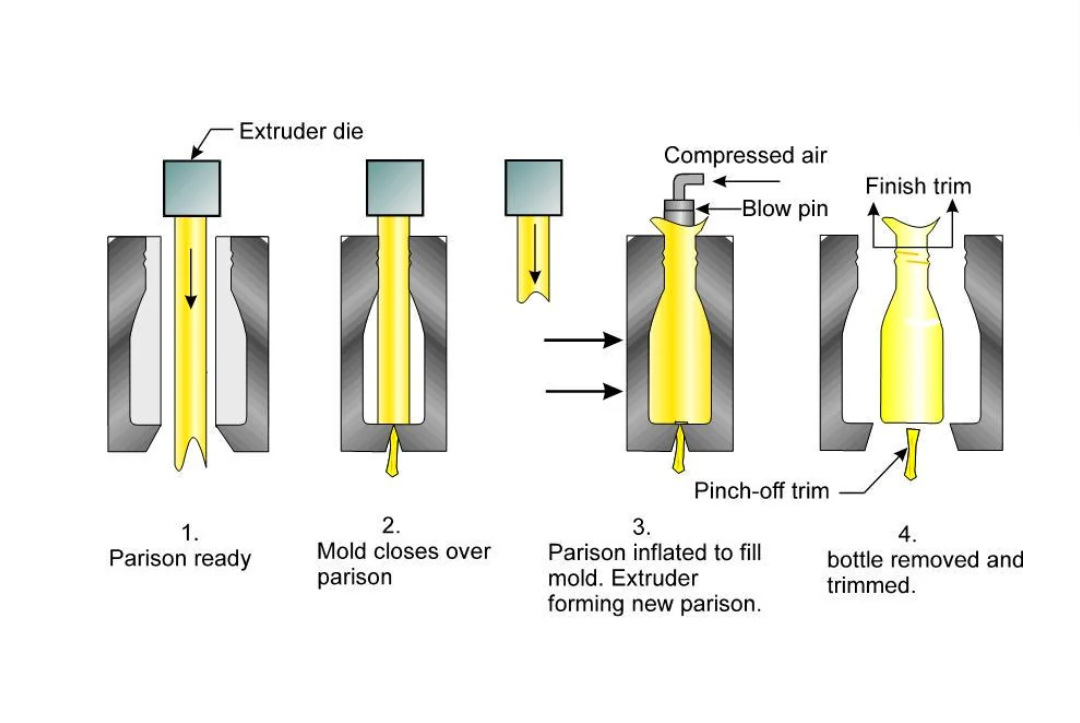

I followed your link above and, from the image below of the process, I agree with BD; this is most definitiely an FSI process, because the mold will push on the entering gas, and the gas will respond to that pressure. Ultimately, a balance establishes itself which determines the shape of the vessel, including wall thickness. Because the moving wall of the vessel changes the internal flow field of the gas, there is not much that can be learned from a simulation that uses a static mold size/shape.

This simulation can probably also be done in Mechanical similar (see video below starting about 8 minutes):

https://www.youtube.com/watch?v=WfGLdlFiFh0

Regards,

Judy

-

- You must be logged in to reply to this topic.

-

4783

-

1566

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.