TAGGED: uniaxial-tensile-test

-

-

November 6, 2025 at 3:43 pm

tarek.azzouni

SubscriberDear community,

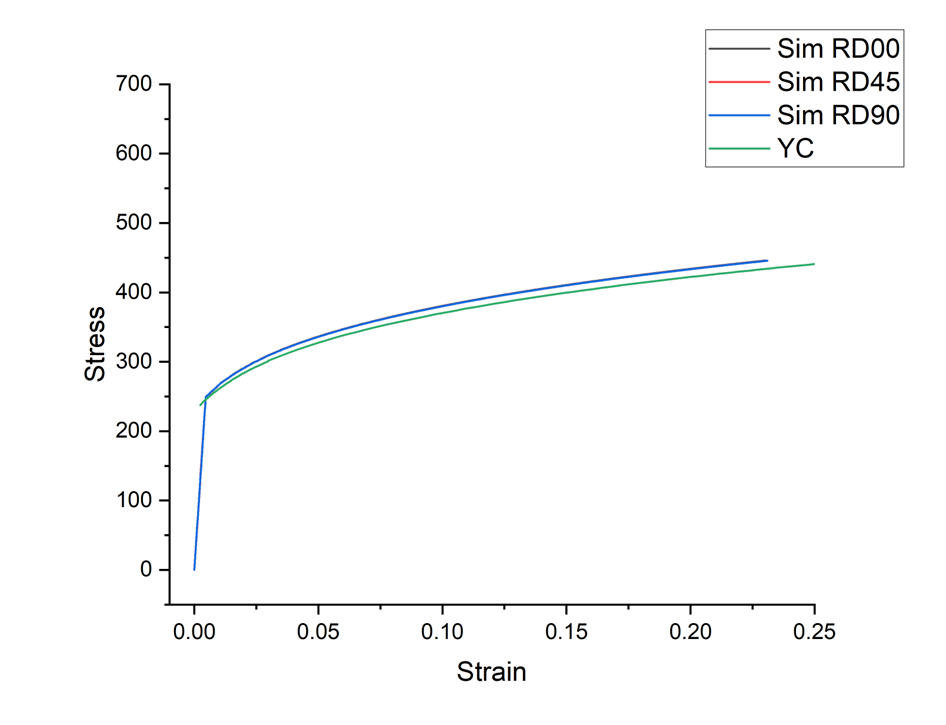

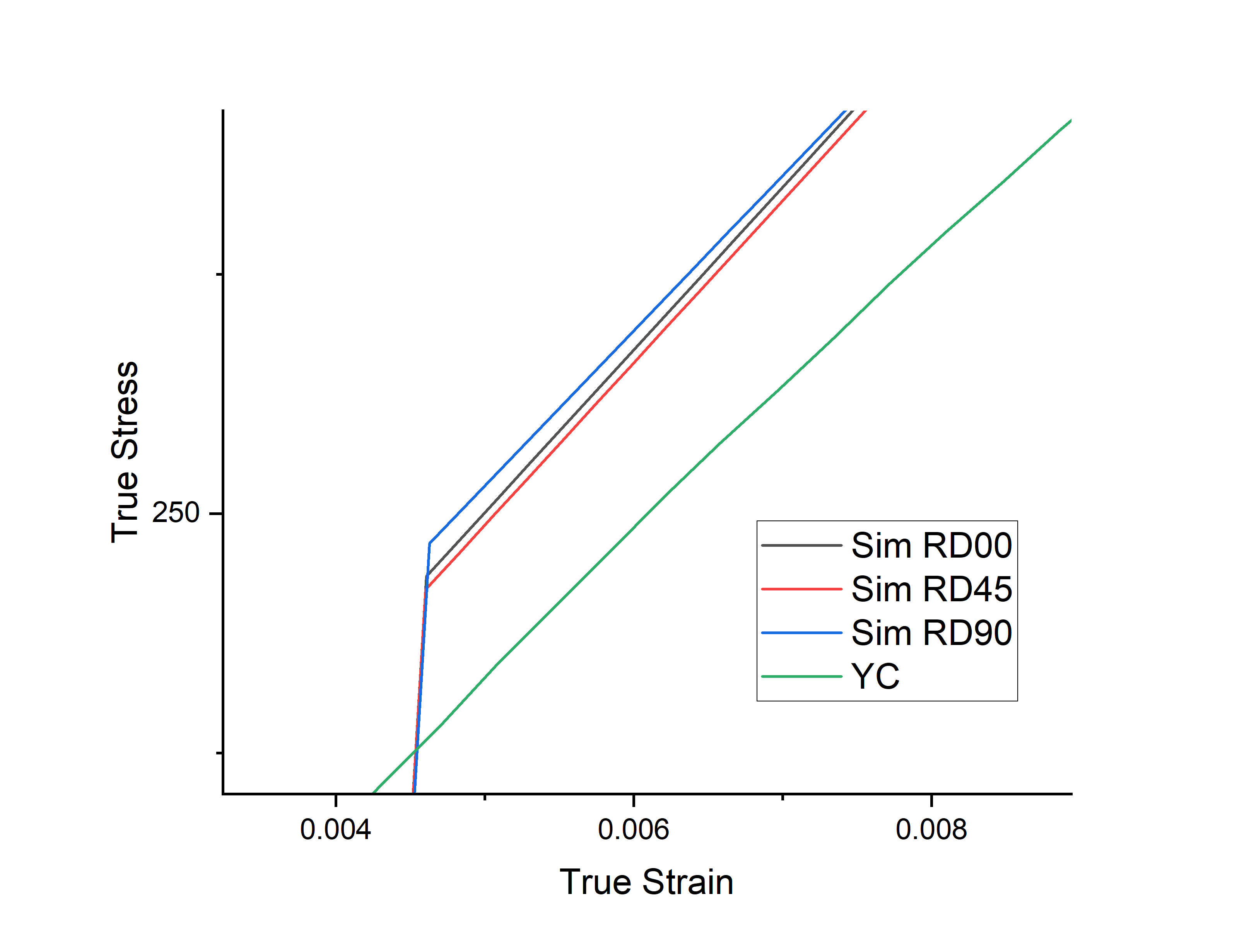

I would like to know how we could validate a simple one-element test and a tensile test. I have now generated everything, but I am a bit confused, as my stress-strain curve are all the same with the 3 Rolling direction (0, 45 and 90), the difference is small at a scale of 0.1-0.01. THe material model im using is the MAT133 Barlat Yield 2000-2d.

In case you have any idea please let me know.

Best, -

November 6, 2025 at 5:49 pm

Armin

Ansys EmployeeHi Tarek, Do you have any pictures comparing the stress-strain curves of the one-element model versus the experimental data in all three directions? Please remember that the comparison between the one-element model and the experiment is only valid up to the onset of necking in the actual tensile test. -

November 7, 2025 at 10:45 am

tarek.azzouni

Subscriber-

November 7, 2025 at 3:11 pm

Armin

Ansys EmployeeThank you. Assuming that RD is your reference direction, it should yield the same response as the input hardening curve. Here are a few suggestions:

Try running the *MAT_133 with all the Barlat anisotropic coefficients (ALPHAi) set to 1 and the exponent (A) set to 2. This verificiation step will essentially simplify the model to isotropic von Mises, and it should provide identical stress-strain results in different directions, all matching the input hardening curve.

Once the step above is verified, implement the anisotropy coefficients that you calibrated using experimental data.

Ensure that the material axes are selected properly (AOPT variable) to indicate that the single-element test is pulled in the RD. Compare your RD results with the input hardening curve.

-

-

November 9, 2025 at 3:55 pm

tarek.azzouni

SubscriberDear Armin,

Thank you very much for your input. I will give it a try.

I have another question: what is the best way to validate a simulation in terms of extracting data from LS-DYNA? My colleagues use nodout and secforc, but I’ve found that the results can be highly dependent on the node ID. Currently, I am selecting an area of elements, extracting the strain and stress, averaging the results, and then comparing them to experimental data. What would you recommend?

Thank you!

-

November 10, 2025 at 2:43 pm

Armin

Ansys EmployeeHi Tarek,

No problem at all.

What variables are you going to compare in the simulation with respect to the experiment? If you are focusing on local values (such as local strains obtained from DIC measurements), you can select the same surface area in your model as in the experiment and average the results of all elements over that area. You may find the following paper helpful in this regard.

https://www.sciencedirect.com/science/article/pii/S2666359722000208

-

-

November 10, 2025 at 2:48 pm

tarek.azzouni

SubscriberDear Armin,

I'm mostly checking the strain and the stress compared to the flow curve that i get from my experiment. some of my colleagues advised me to select nodes and then compare but i find this very tricking as something you get very weird behaviour.

Best regards-

November 10, 2025 at 4:30 pm

Armin

Ansys EmployeeI see your point. Since you're dealing with single-element simulations for validation purposes, I would suggest to use a simple element formulation and then directly extract the elemental stress and strain of the single-element and compare with the experiment.

-

-

- You must be logged in to reply to this topic.

-

4512

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.