-

-

July 31, 2025 at 1:21 pm

Scott Ormiston

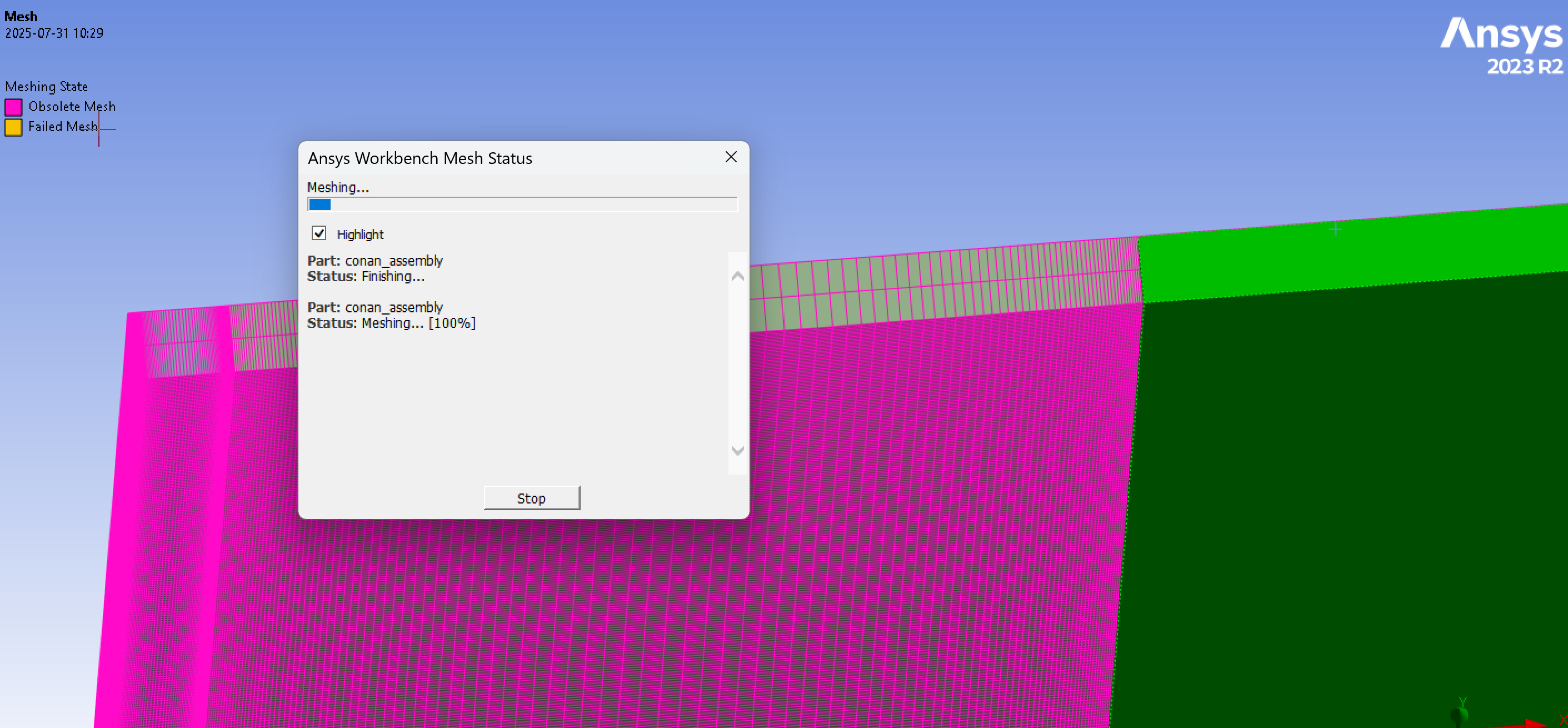

SubscriberI am trying to mesh a rectangular region with three different size bodies in contact. It looks like a wide plate cut in three (one fluid, one solid, and another fluid). I am using edge sizings of number of divisions on all edges (to get a directed Cartesian mesh).

The mesh is quite fine. For example, I am trying to use 74 divisions across 0.0034 m on one edge. If I use no bias, the spacing size is 4.595E-05 m. The problem is that when I try to generate the mesh, it does not respect this number, and just puts 8 divisions (for example). Is it possible that there is a setting somewhere on default spacing that is above 5E-05 m, so that it refuses to go below that number?

It also sometimes stops at 5% Meshing... for hours (literally) without completing. Do you have any idea why that might happen? I have lots of RAM left on the Win11 PC and I asked for 4 cores for parallel for meshing and it seems to be using them.

-

July 31, 2025 at 3:39 pm

-

July 31, 2025 at 6:15 pm

Scott Ormiston

SubscriberUpdate. The issue seems to have been having too small a default element size (1e-06 m) and to small a max size in the mesh sizing was too small. I set them to 1e-03 m and 1 m, respectively, and now at least meshes are being produced with a few minutes.

I would like to know why some of my edge sizing defaulted to a growth rate of 1.2 and no control of the behaviour. I had to redo four edge sizings by duplicating one in order to get them all to have Hard behaviour. I think this also helped.

Thanks.

-

- You must be logged in to reply to this topic.

-

3572

-

1193

-

1076

-

1063

-

952

© 2025 Copyright ANSYS, Inc. All rights reserved.