-

-

April 30, 2025 at 5:53 pm

javat33489

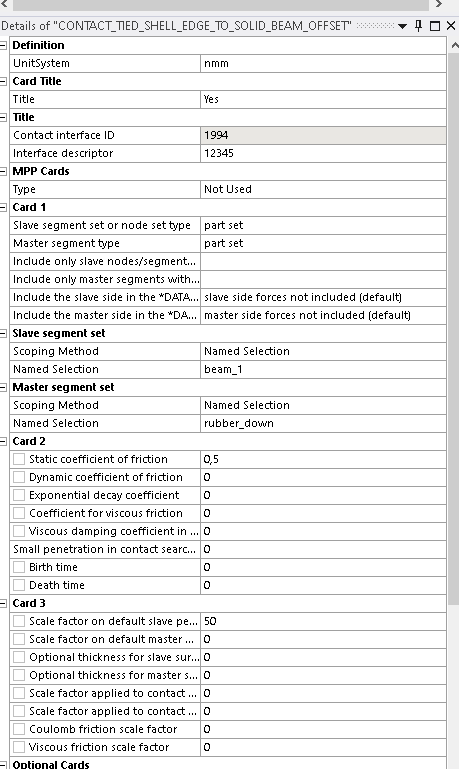

SubscriberHello everyone. I modeled a tied contact between rubber and beam elements (wire). Beam elements under the rubber and create a strong frame.

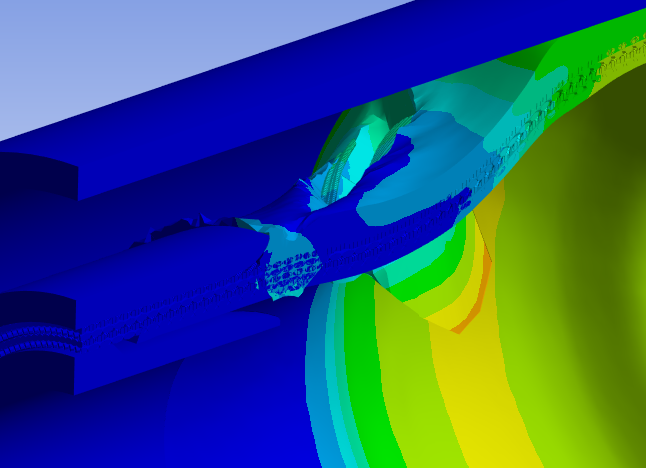

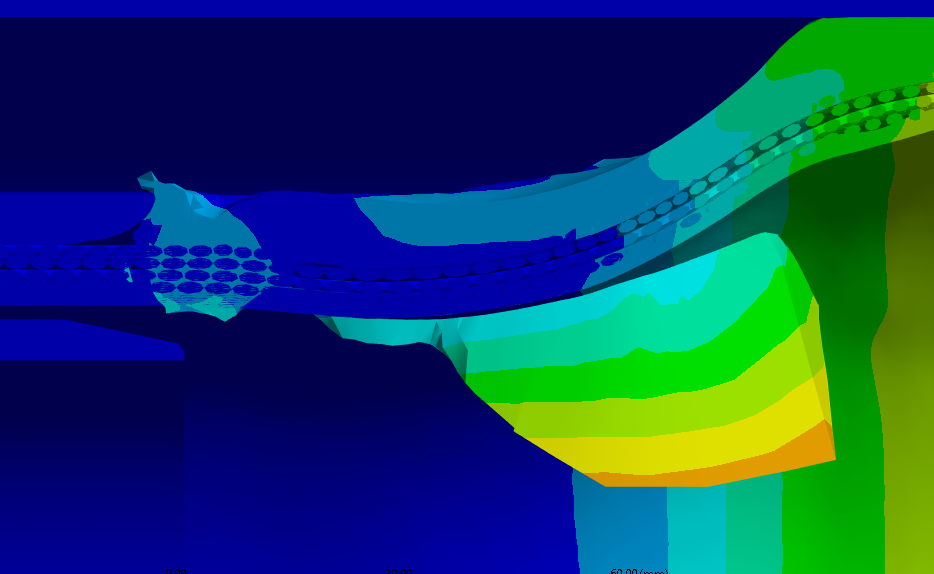

When I apply pressure to the rubber it starts to inflate and the wire (beam elements) do not allow it to break but allow it to inflate.

At first everything goes well but at some point the rubber starts to penetrate through the beam elements.

How to fix this? I have attached the contact settings. What other settings can I set to avoid my problem?

I use Section =2 for the rubber, section= beam for the beam elements. -

May 5, 2025 at 11:43 am

Ram Gopisetti

Ansys EmployeeHi,

I’m unsure of the exact outcome, but BEAM_OFFSET applies exclusively to tied_shell_edge ( I don't see any shell edge here ) and spotweld.

TIED_SHELL_EDGE_TO_SOLID is relevant only when solids use formulations with nodal rotational degrees of freedom (such as ELFORMs 3, 4, 20, or 22) or when the solid part is rigid.

I recommend that you do a small patch test with beams and solid elements and tune the SFSA, SFSB, SAST, SBST ( in negative value), and then use that learning in your main model, or use shared nodes between the entities; selective node sharing can be made in LSPP or SpaceClaim.

Cheers, Ram

-

May 8, 2025 at 2:12 am

Dennis Chen

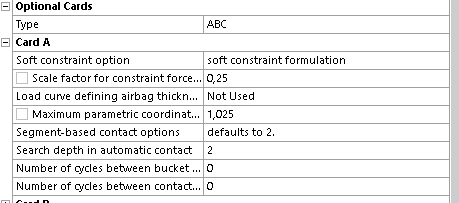

Subscribera couple things to just try out to see if it helps

1) increase SAST and SBST to some negative value way larger (absolute value) than what you are using to see if it fixes the problem. negative values will cause determination of whether a node is tied or not based on separation distance. Since you like to use workbench keyword manager, you probably use mechanical.. (a pure dyna user would never use this keyword manager because it’s a nightmare), this is like the pinball radius in mechanical

2) try the soft =1, see R15 documentation page 1164/4084. can also change depth from 2 to 5 to try as well. I may not be correct in thinking this but for a beam –> surface contact, a segment baesd approach may not be best. A segment based contact calculates contact forces (what prevents penetration) based on the reference segments’ normal vector but you have a situation in which your master/target side is deforming a lot so I can see how that force vector on a node-segment pair bases would do weird stuffs. Again, not 100% sure I am thinking about this properly, but it is worth trying to use soft=1 for a pure penalty based tied contact with a much higher contact stiffness.

3) I don’t know your exact setup, but if it’s truly supposed to be a tied contact between the wire mesh and the very soft material in real life, you can just merge the nodes, it is the most convenient way to do this. There’s a lot of ways to merge nodes properly (outside spaceclaim with the shared topology) by making sure you have the proper edge defined in the rubber material side and then you define the same # of division on the edge so the node merge would work without moving the nodes inside workbench preprocessor.

I hope this helps and Ram won’t disapprove! :)

-

- You must be logged in to reply to this topic.

-

3597

-

1283

-

1107

-

1068

-

978

© 2025 Copyright ANSYS, Inc. All rights reserved.