-

-

September 30, 2024 at 5:16 am

Kinjal

SubscriberI am carrying out flow boiling simulation in fluent to predict DNB. I am starting with heat flux of 0.5Mw/m^2 and increasing it step by step and monitoring temoerature. When the chf is reached wall temperature will increase suddenly and the solution will diverge. At first when I was usimg sauter mean I was able to get the diversgence but at that time it was giving wrong results for WHFP i.e. my evaporative heat flux was going above total heat flux which is not possible. Then I kept the boilig dia. default for the secondary phase and WHFP gave the correct results but now I am not able to predict DNB. What can be the issue?

-

October 1, 2024 at 1:16 pm

Rob

Forum ModeratorLots of things. An overuse of TLAs may play a part, but I'd start by looking at the mesh and other solver settings.

-

October 18, 2024 at 3:40 pm

Kinjal

SubscriberHello the above problem is solved. Now I have got a recalibrated model for nucleation site density, udf for which is given below

#include "udf.h"#define C 42.27#define n 4.67#define delta_T_ref 1DEFINE_BOILING_PROPERTY(nucleation_site_density, f, t, c0, t0, from_index, from_species_index, to_index, to_species_index){real nuc_d, subcool;real T_w=F_T(f,t);real T_SAT = C_STORAGE_R(c0,t0,SV_SAT_TEMPERATURE);/* Subcooling calculation: T_w - T_l */subcool = T_w - T_SAT;/* Calculate nucleation site density using the formula */nuc_d = pow(C,n) * pow((subcool / delta_T_ref), n);return nuc_d;} This seems correct but why is fluent crashing while predicting wall temperature and printing on console bisection method cannot find wall temperature. How can I resolve this issue, Please help -

October 18, 2024 at 3:56 pm

Rob

Forum ModeratorNot sure, does it behave running on a single core?

-

October 18, 2024 at 4:37 pm

Kinjal

SubscriberNo multiple cores. Hello can you please help me.

-

October 18, 2024 at 4:40 pm

Kinjal

SubscriberThe udf is correct right?

Bisection method cannot find wall temperature bounds for the face with ID 557 on the boundary 'heated_wall' centered at ( 0.243575 0.005500 ). Skipping this face.

Bisection method cannot find wall temperature bounds for the face with ID 558 on the boundary 'heated_wall' centered at ( 0.244252 0.005500 ). Skipping this face.

Bisection method cannot find wall temperature bounds for the face with ID 559 on the boundary 'heated_wall' centered at ( 0.244928 0.005500 ). Skipping this face.

Bisection method cannot find wall temperature bounds for the face with ID 560 on the boundary 'heated_wall' centered at ( 0.245604 0.005500 ). Skipping this face.

Bisection method cannot find wall temperature bounds for the face with ID 561 on the boundary 'heated_wall' centered at ( 0.246281 0.005500 ). Skipping this face.This is what it says

-

October 21, 2024 at 8:50 am

Rob

Forum ModeratorBisection looks to be parallel, but could be a red herring. I assume you're retaining all data? Can you try on a single core and post the wall boundary settings that you're using?

-

October 21, 2024 at 11:16 am

Kinjal

SubscriberAs this is a simulation for predicting CHF I am giving 0.5MW/m2 heat flux initially and increasing it in steps of 0.5 after wall tempature is stabilised. This is controlled by udf. I tried on single core. It doen't make any difference.

-

October 21, 2024 at 12:22 pm

Rob

Forum ModeratorAnd is anything else set on the wall bc?

-

October 21, 2024 at 3:32 pm

Kinjal

SubscriberNo nothing

-

October 21, 2024 at 3:33 pm

Rob

Forum ModeratorIs it a thin wall?

-

October 21, 2024 at 4:51 pm

Kinjal

SubscriberThe geometry is a simple 2d rectangle

Axis symmetric BC is used and on the wall heat flux is applied in steps

It is like heat flux is constant until temparture is stabilised and it is increased after that. But while I am monitoring heat flux file it is changed and it drops suddenly when boiling begins. Inout should not change right.

-

October 22, 2024 at 9:04 am

Rob

Forum ModeratorWhich heat flux? Pictures of panels will help.

-

October 22, 2024 at 1:57 pm

Kinjal

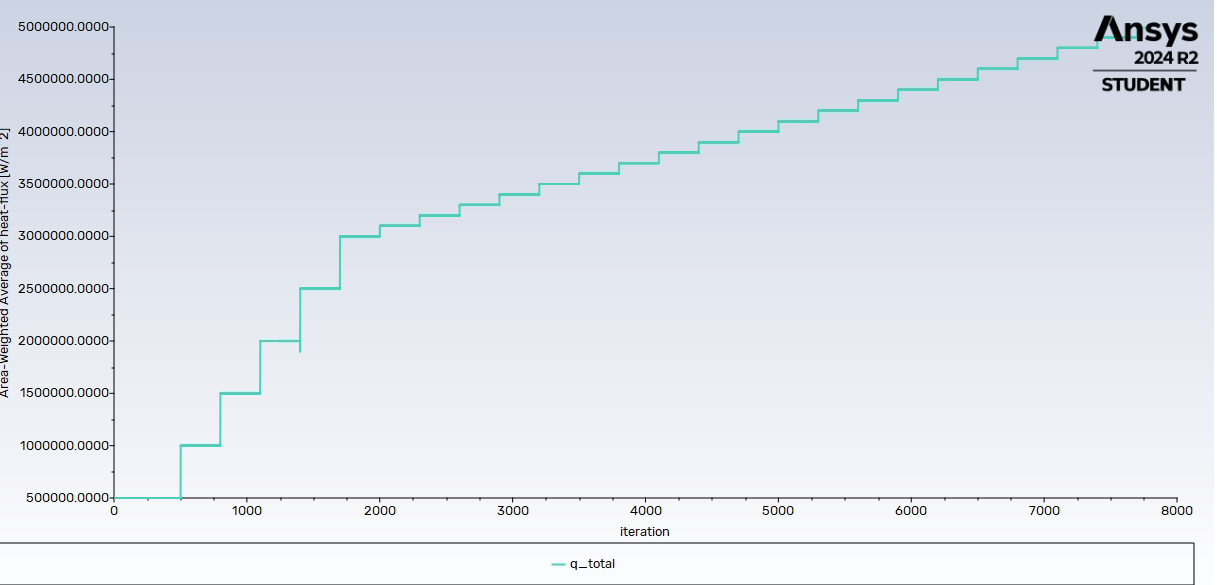

Subscriber#include “udf.h”DEFINE_PROFILE(dynamic_heat_flux, thread, position){int n = N_ITER; // Get the current iteration numberreal q0 = 0.5e6; // Initial heat flux (W/m^2)real q; // Heat flux at the current iterationreal chf = 3e6; // CHF value (W/m^2)// Determine the heat flux based on the iteration numberif (n <= 500){q = q0;}else{int i;q = q0;for (i = 500; i <= n; i += 300){// Check if q approaches 75% of chfif (q >= 0.75 * chf){q += 0.1e6; // Increment by an additional 10% step}else{q += 0.5e6; // Increment the heat flux by 0.5e6}}}// Print the heat flux value after every 300 iterationsif (n % 300 == 0){Message(“Iteration %d: Heat Flux = %g W/m^2\n”, n, q);}face_t f;begin_f_loop(f, thread){F_PROFILE(f, thread, position) = q; // Apply the heat flux}end_f_loop(f, thread)}this is how heat flux is applied

-

October 22, 2024 at 2:06 pm

Kinjal

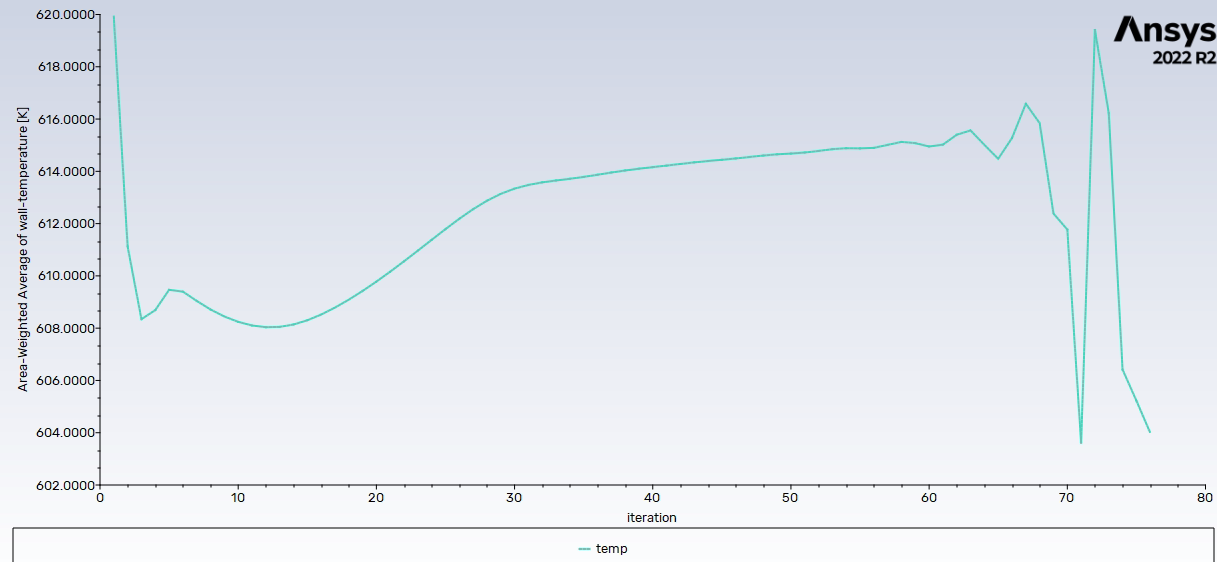

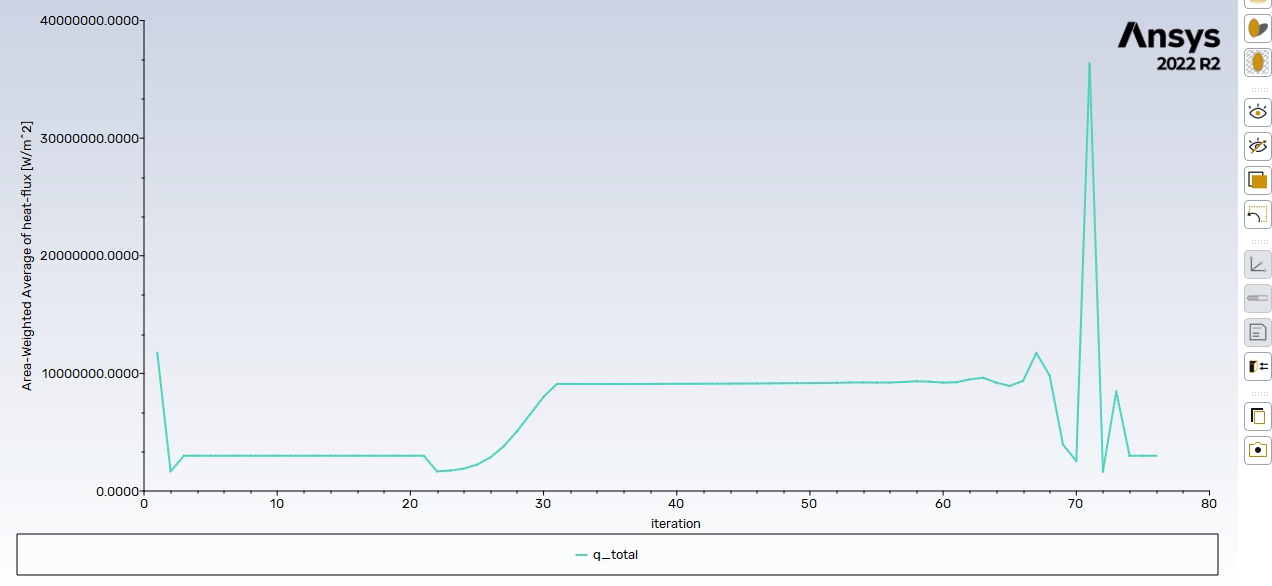

Subscriber -

October 22, 2024 at 2:07 pm

Rob

Forum ModeratorWhy not use a profile or just link flux to iteration number with a limit? Your code isn't monitoring anything in Fluent, it's just checking the iteration number.

-

October 22, 2024 at 2:09 pm

Kinjal

SubscriberBut this works when I am using Lemmert Chawla model from the fluent direcly but when it is given through udf it is causing problem

-

October 22, 2024 at 2:38 pm

Rob

Forum ModeratorAnd how does the UDF differ from the model?

-

October 22, 2024 at 3:10 pm

Kinjal

SubscriberEven if I am making udf same as a model it is not working for me. Also the heat input which I give changes when the udf is activated

-

October 22, 2024 at 3:14 pm

Rob

Forum ModeratorYou have two UDFs. Which one alters the heat flux you're reporting, and what are you reporting?

-

October 22, 2024 at 3:22 pm

Kinjal

SubscriberSo heat flux udf I am using and it works well when lemmert chawla model existing in fluent is selected, but the combination of nucleation site density and heat flux udf is causing heat flux to change a lot and results are unphysical. I want to modify the existing Lemmert Chawla model for my simulation as values need to be different, but this is not working. Can you check if there is issue with my NSD udf which I have posted above.

-

October 22, 2024 at 3:30 pm

Rob

Forum ModeratorWe don't debug UDFs. So, the problem is not with the heat flux it's only when you turn on the nucleation UDF? I'd not use single letter variable/constants and always define a value as 1.0 if it's real just in case you've accidentally tagged something that predefined as an integer: I learnt coding with FORTRAN so have a few old habits.

-

October 22, 2024 at 3:33 pm

Kinjal

SubscriberI don’t know what exactly is the problem. How can I modify the existing model in fluent then. By using default model I am getting very high wall superheat values which are unphysical, hence I am recalibrating. But problem is surely not with the heat flux as it works well for default.

-

October 22, 2024 at 3:46 pm

Rob

Forum ModeratorNor do I as you haven't shared what you're monitoring to see why you think it's not working. What is the Heat Flux Report that Fluent is reporting? NOT the surface integral.

-

October 22, 2024 at 4:56 pm

-

October 23, 2024 at 10:19 am

Rob

Forum ModeratorWhich is the SURFACE INTEGRAL. Please check the value from the FLUX REPORT.

-

November 12, 2024 at 6:36 am

Kinjal

SubscriberBut why to check surface integral? Here the problem is with the udf. Am I calling wall temperature in a correct way. Can you please confirm on that?

-

November 12, 2024 at 2:15 pm

Rob

Forum ModeratorWhat temperature call?

-

November 12, 2024 at 2:38 pm

Kinjal

Subscriberin udf which I have shared above

-

November 12, 2024 at 2:41 pm

Kinjal

SubscriberI amusing same model as that default model in fluent for nucleation site density byt through udf. The reason for this is I want to change the values of constants in the default model. But the udf doesn't give same results as that of default model. Why is it happening.

-

November 12, 2024 at 2:53 pm

Rob

Forum ModeratorAh, the first UDF. You're calling the wall facet temperature, what does the documentation show? Note, UDFs are not fully supported - you need to check documentation carefully.

-

- You must be logged in to reply to this topic.

-

5274

-

1859

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.