-

-

June 4, 2024 at 12:21 pm

Andres Mayorga

SubscriberHello all,

I am trying to replicate a double lap shear tensile test we did on a composite coupon to check for adhesive failure but I am having issues setting up the bonded interactions between the composite shell and adhesive body.

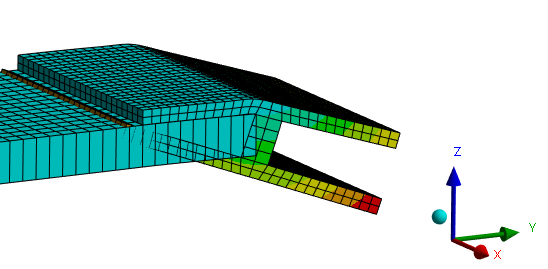

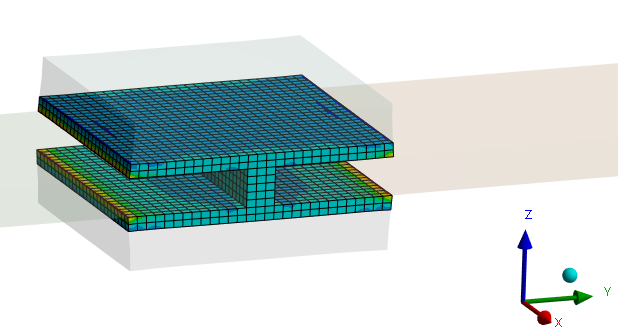

I set my composite coupon as a surface and did a solid body for the adhesive, as shown below:

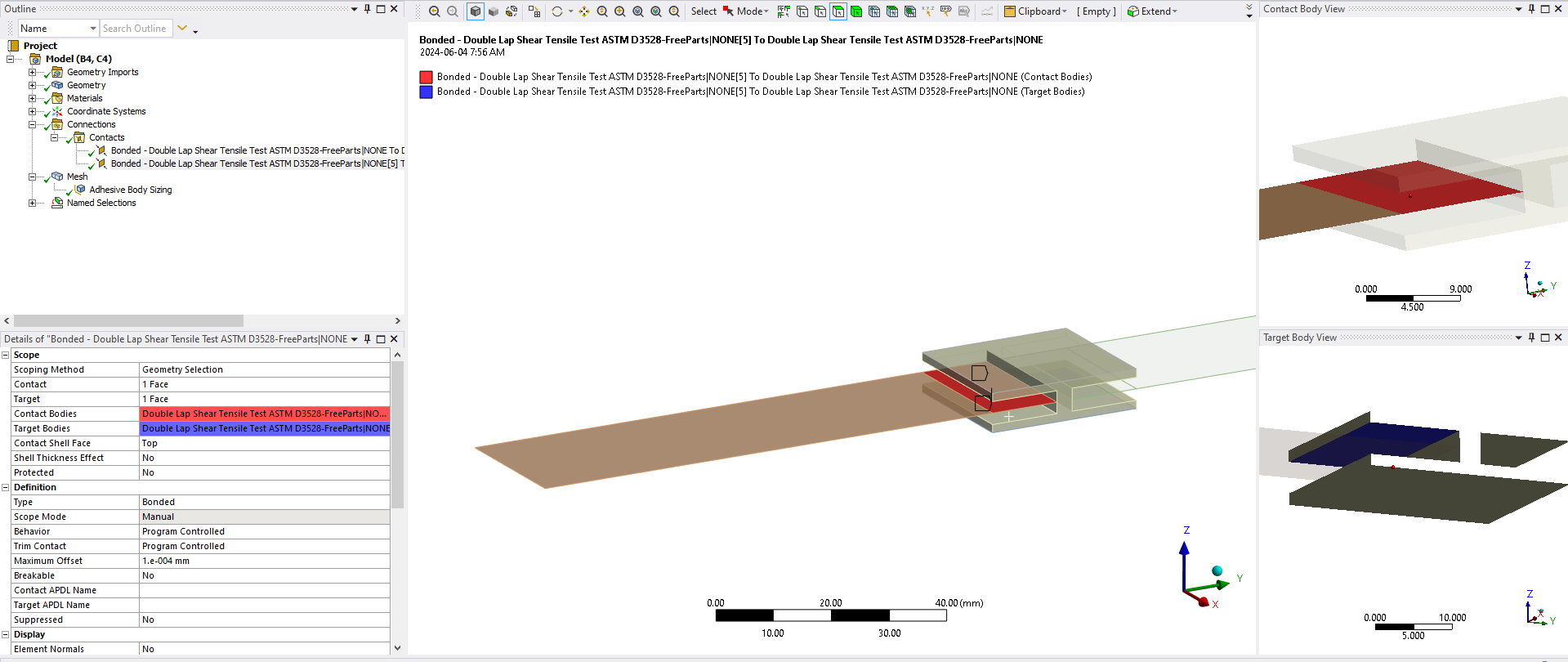

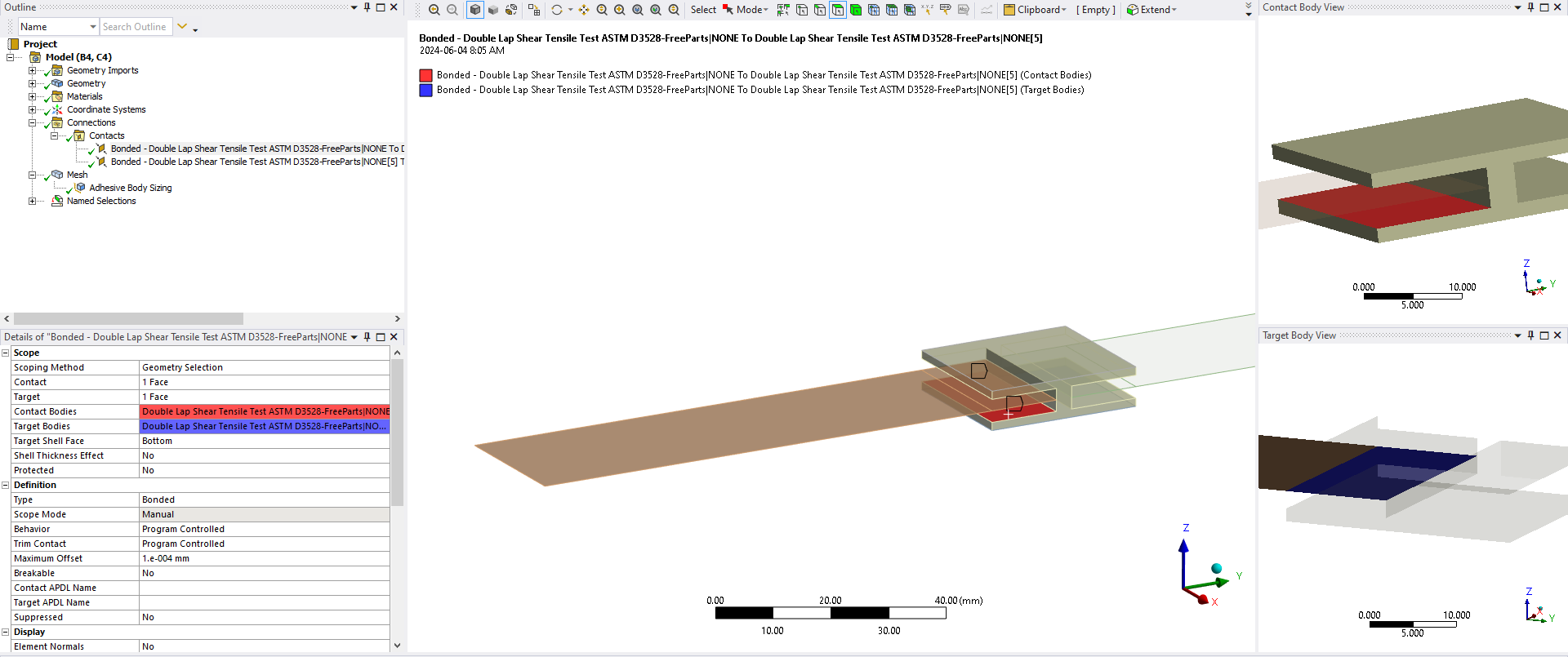

For my bonded interactions, I did this:

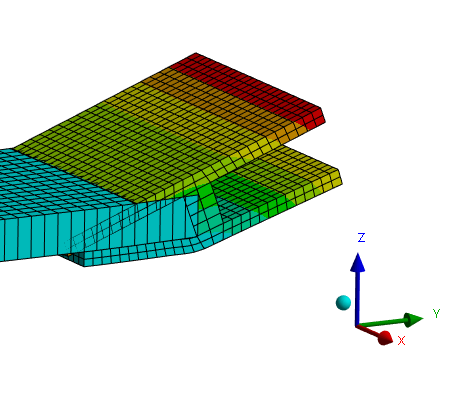

But the premilinary results I get show like if only 1 side of the composite surface is bonded:

I also tried to set the bonded interactions as 1 command, but I get the same results when I use a surface.

Also, if I suppress the side that looks bonded and leave the other side as is, I get the same mirrored results.

I believe is something related with the surfaces because I did the same test with solid bodies (no surfaces) and the premilinary results look more realistic:

Any ideas what I could be doing wrong?

-

June 4, 2024 at 1:47 pm

ErKo

Ansys EmployeeHi

I would suggest to use solsh190 elements (soild shells) instead of only shell elements - see here what solsh190 are and how to mesh with them.

/forum/forums/topic/element-solsh190/

Than it is also much easier to use bonded contact between them since both have a 3D geometry representation.

All the best

Erik

-

June 5, 2024 at 12:36 pm

Andres Mayorga

SubscriberImported composites as solids from ACP and that worked! thanks for your help.

-

- The topic ‘Issues with bonded interactions using a surface’ is closed to new replies.

-

4602

-

1510

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.