-

-

June 3, 2024 at 1:49 pm

Ans Ahmad

SubscriberHello Everyone!

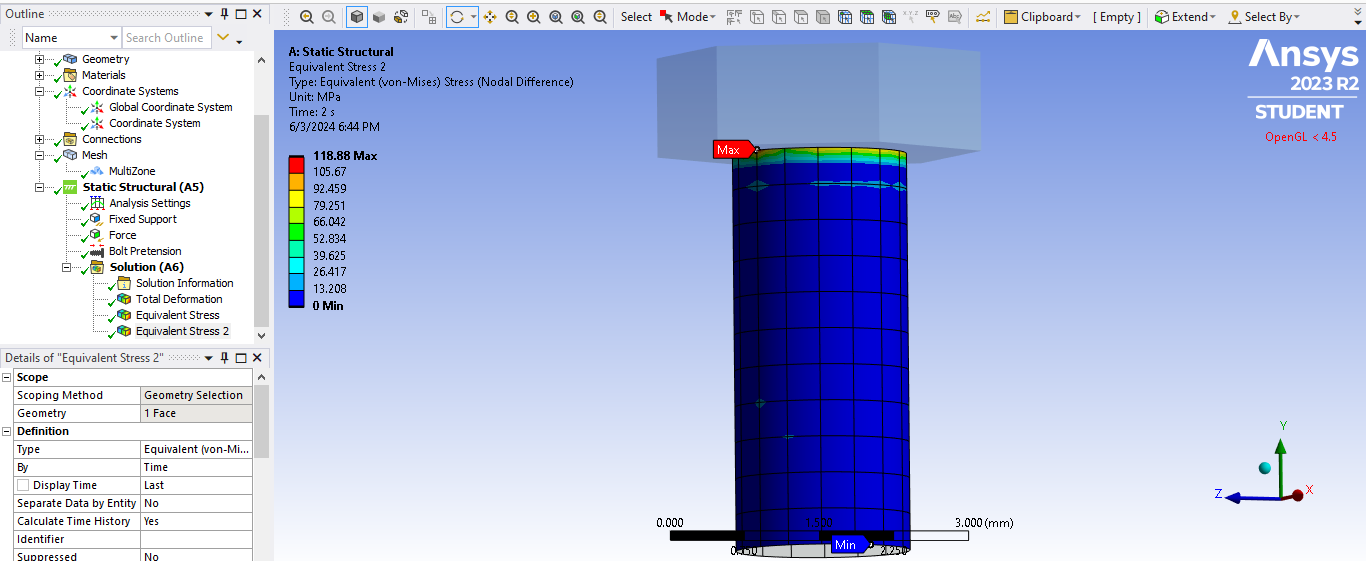

I was practicing a simulation for a simple bolted joint, under shear loading (geometry provided by the Ansys innovation course itself). However, during post-processing I noticed a significant difference b/w the averaged and unaveraged Von-mises stresses.

I tried scoping the stress results on Bolt shank only, but there is still a stress concentration at the location where bolt head and its shank meet (sharing screenshot).

I tried using adaptive mesh convergence as well, but the stresses even increased. Makes me think if this bolt head-to-shank surface is a stress riser or simply a singularity? How should I address that...

-

June 3, 2024 at 3:09 pm

Armin

Ansys EmployeeHi Ans,

Please check the following video where the source of artificially high stresses and how to deal with them are discussed in detail:

Understanding and Dealing with Artificially High Stresses — Lesson 3 - ANSYS Innovation Courses

-

- The topic ‘Capturing accurate stresses in a bolted joint’ is closed to new replies.

-

5054

-

1764

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.