-

-

May 27, 2024 at 7:04 pm

javat33489

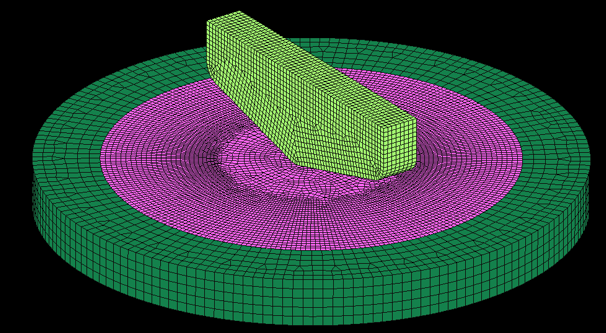

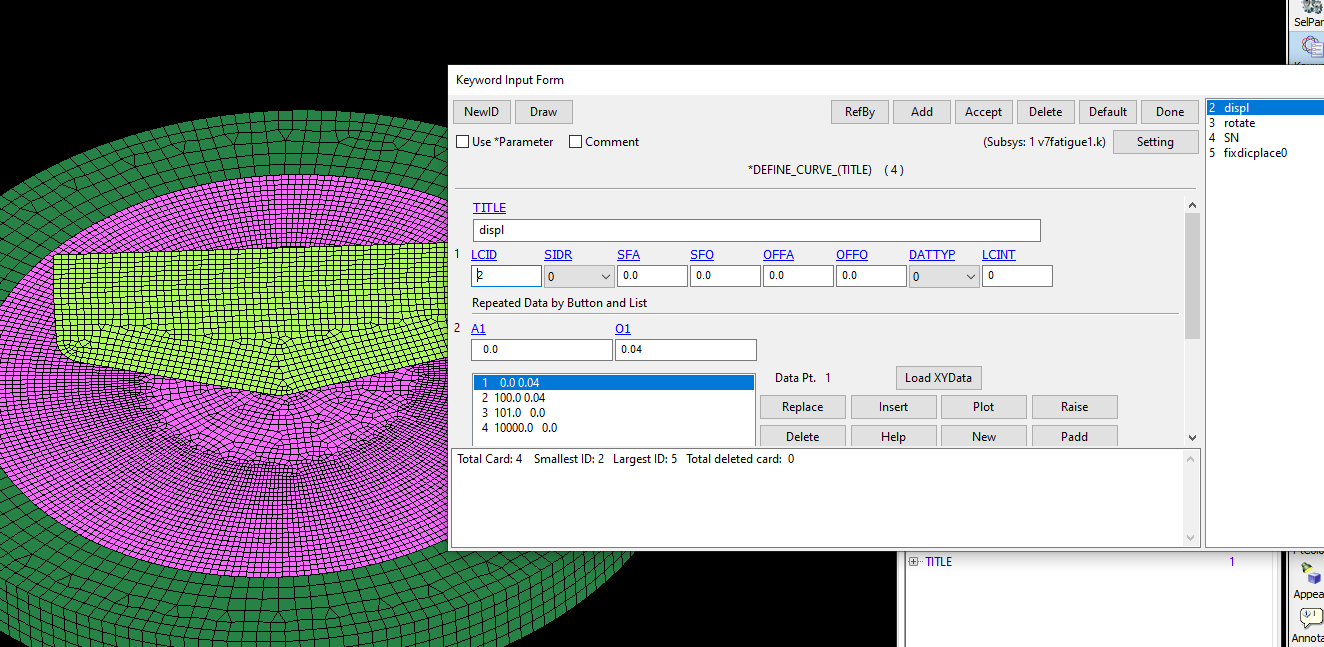

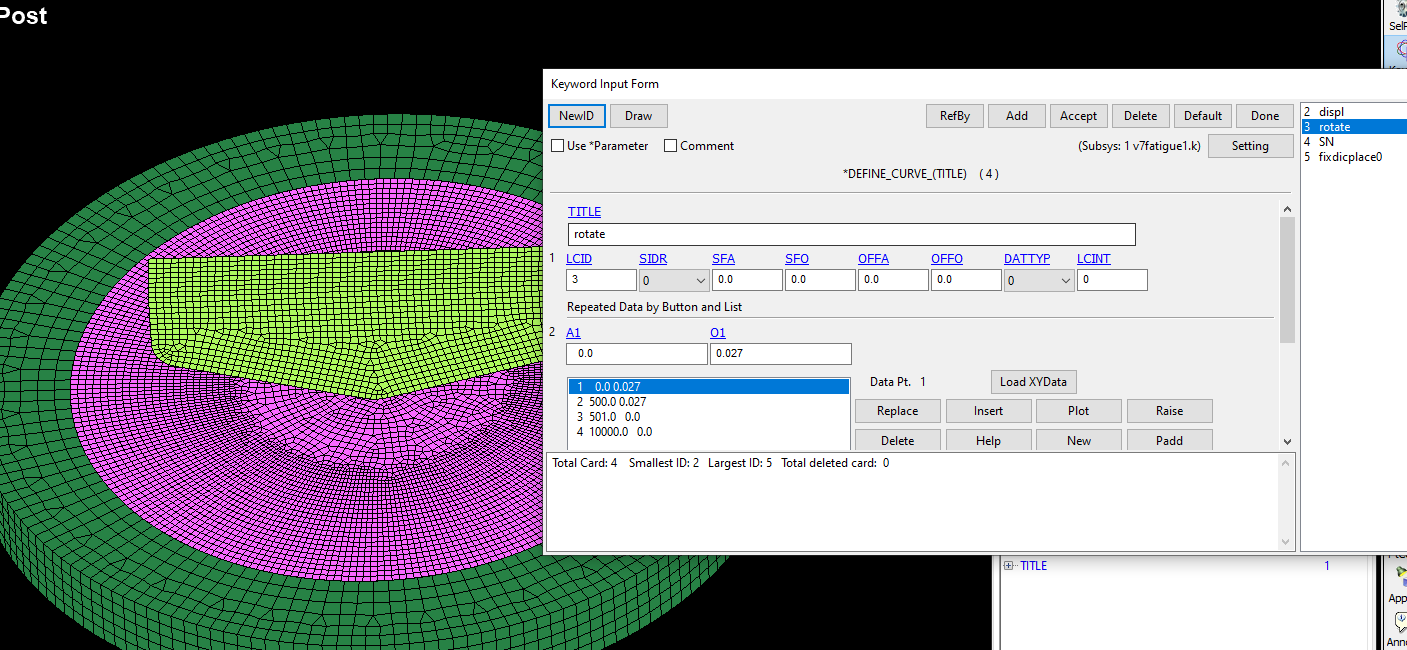

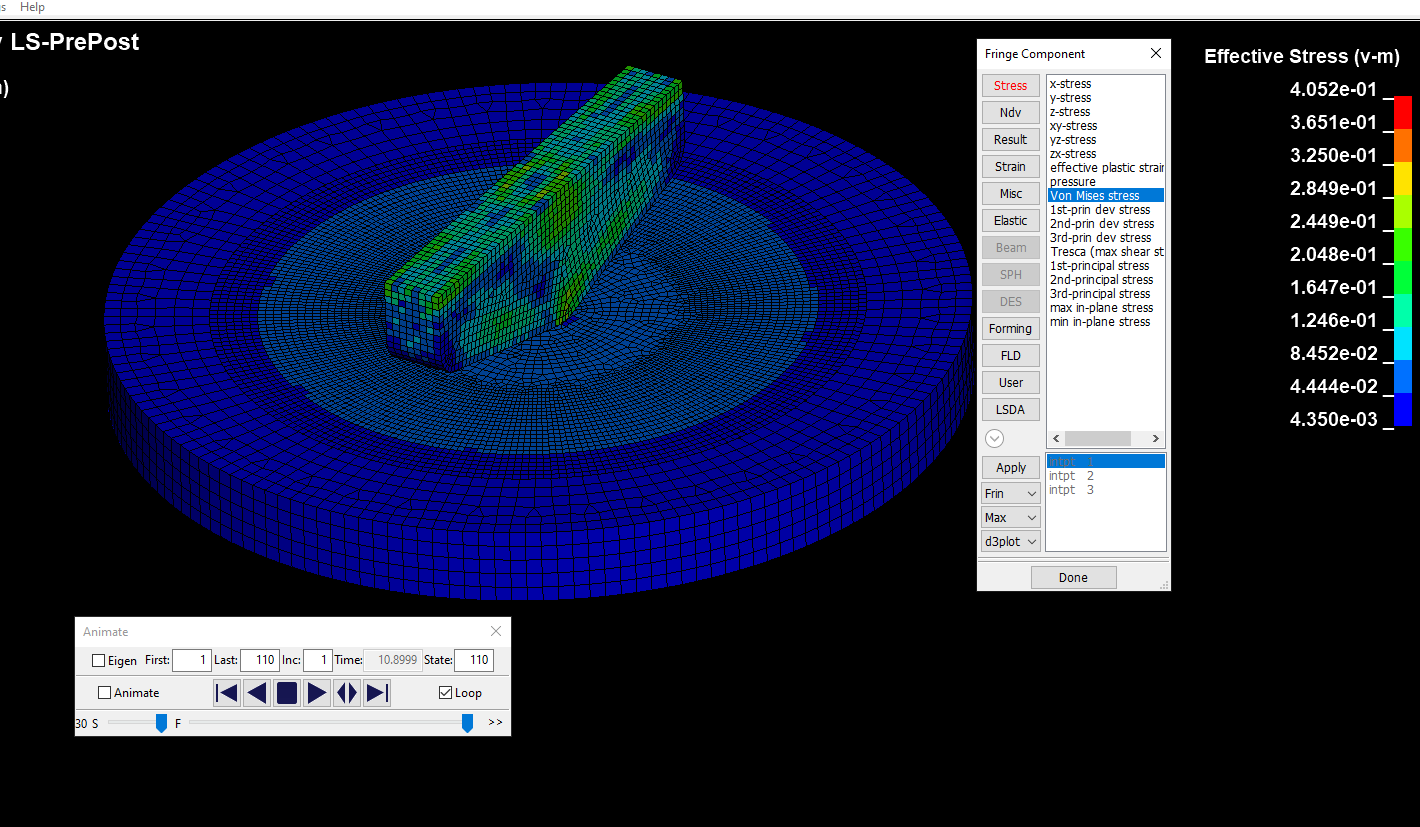

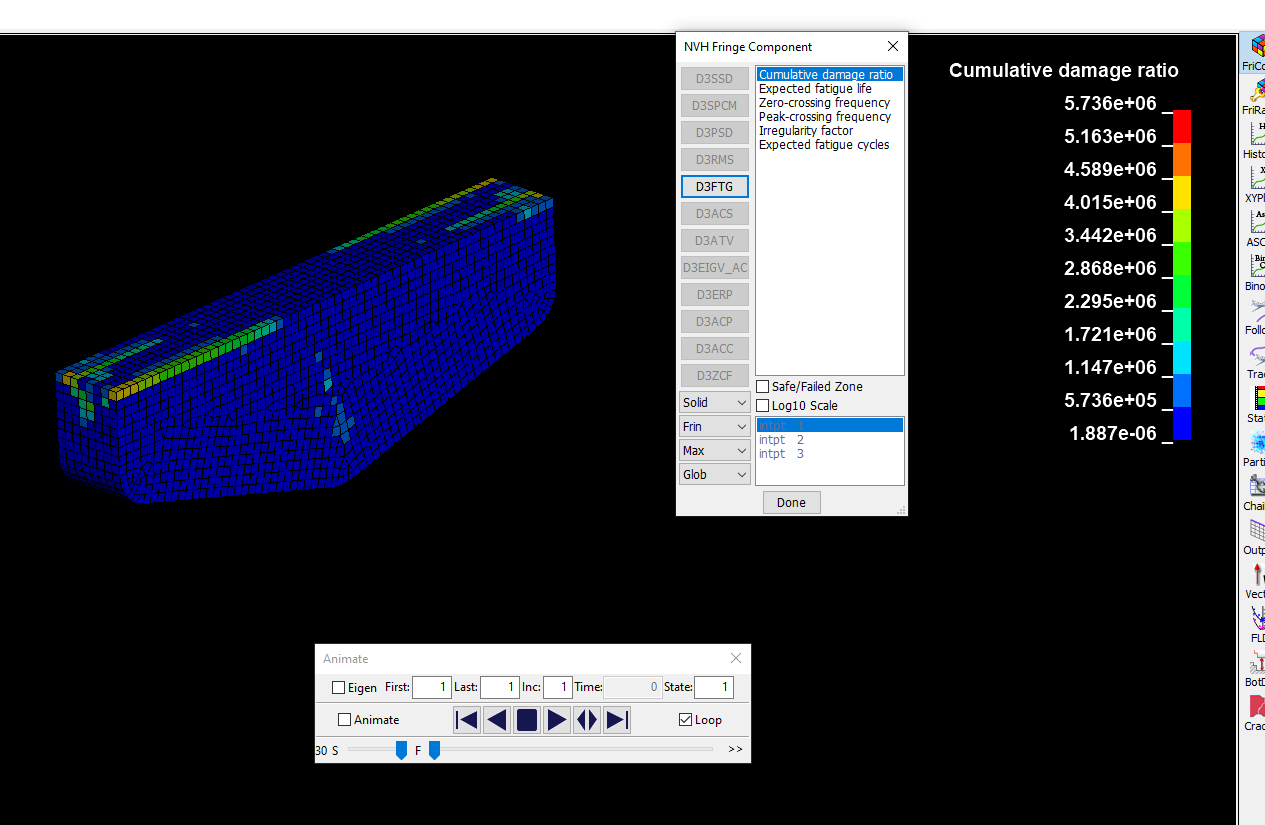

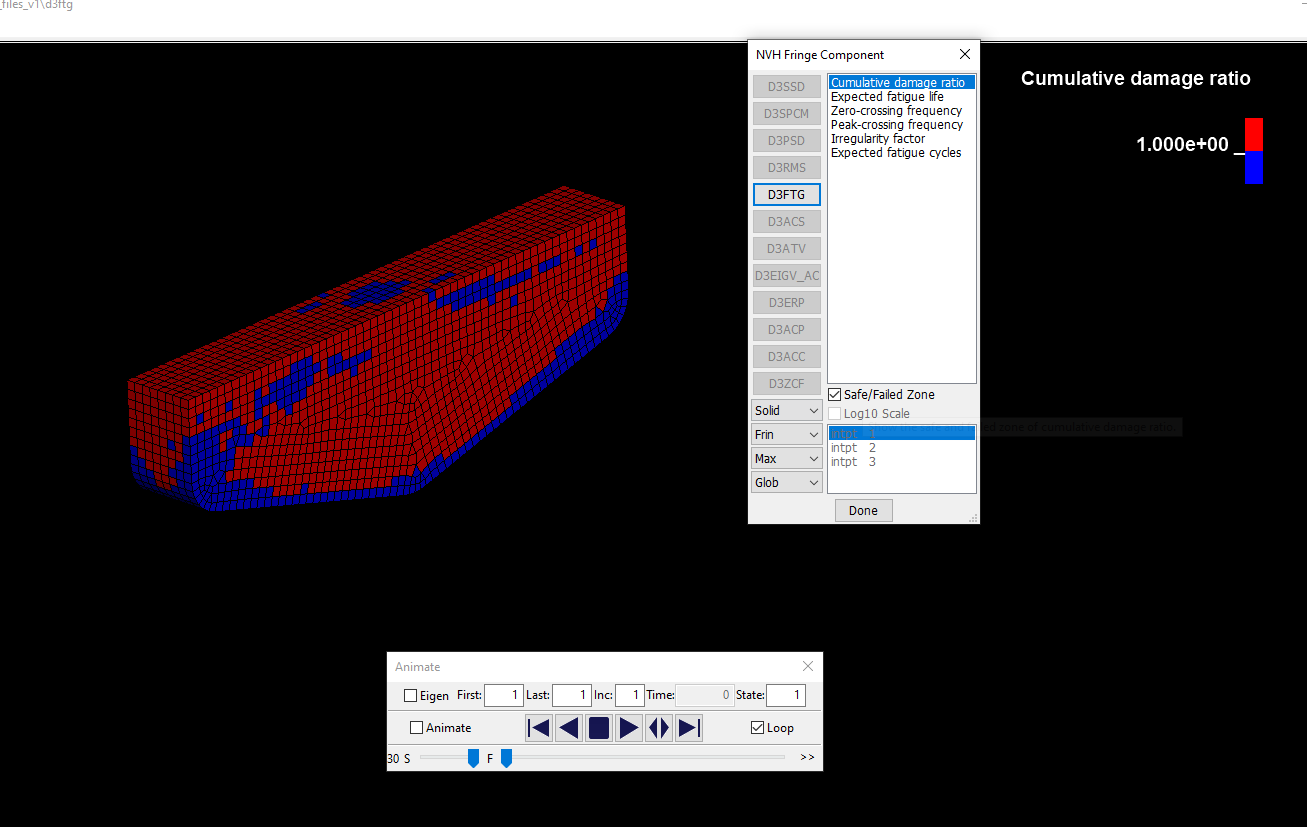

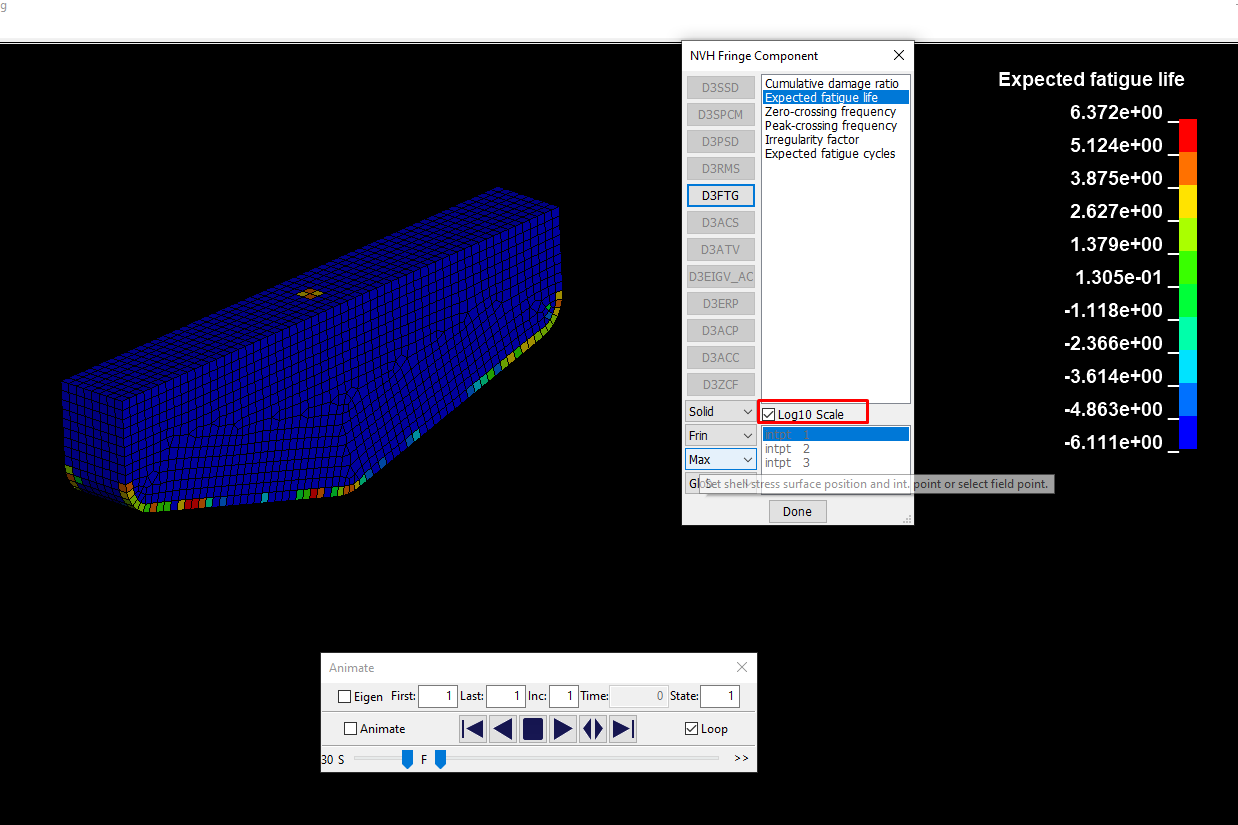

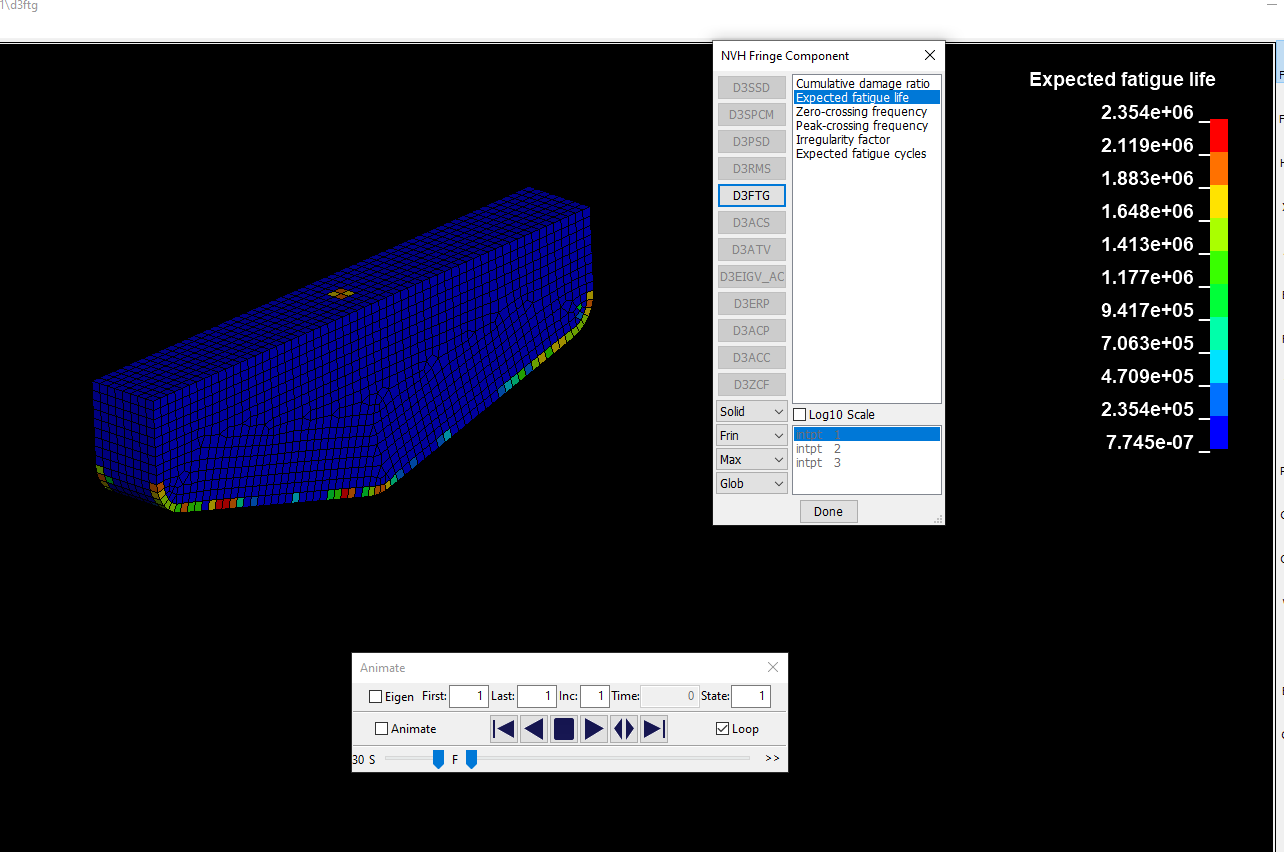

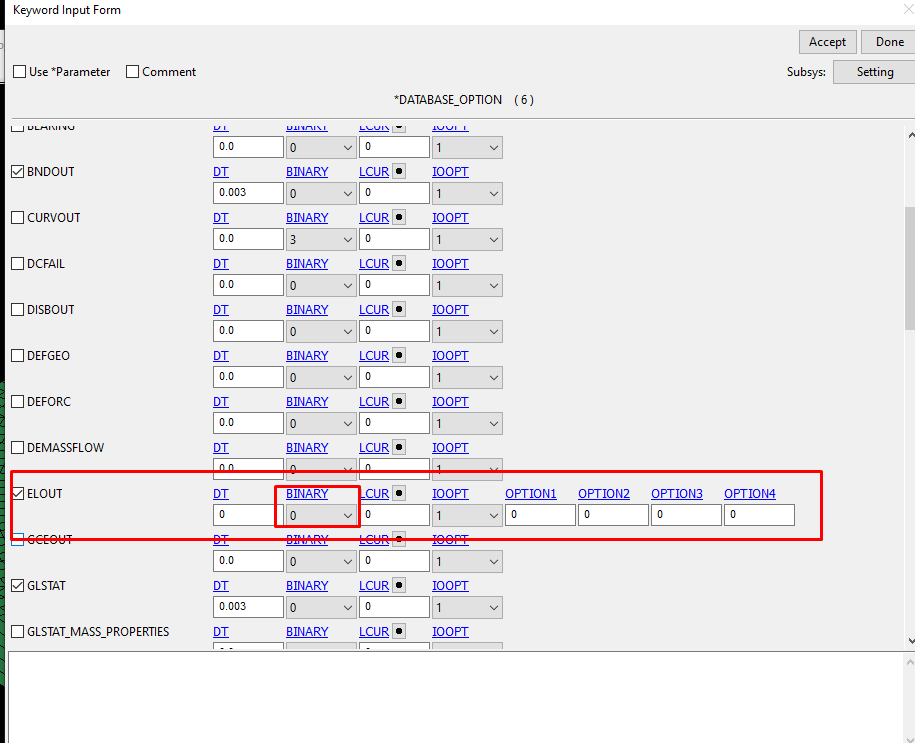

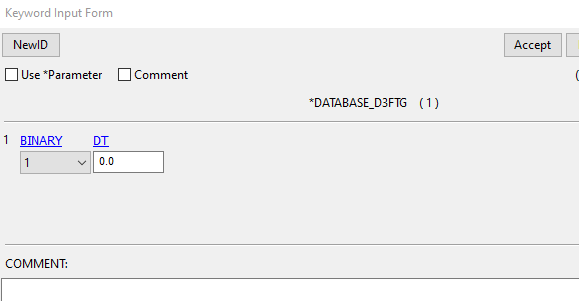

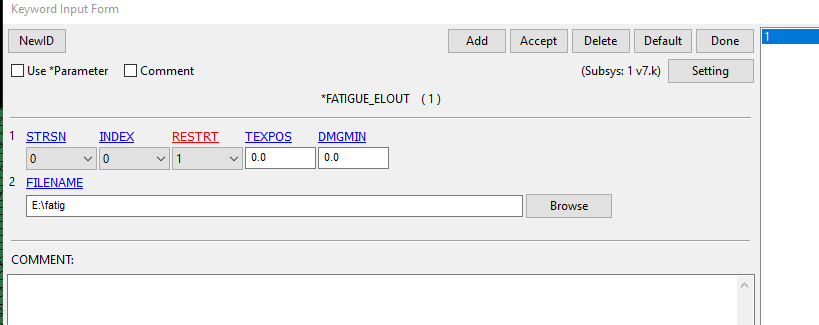

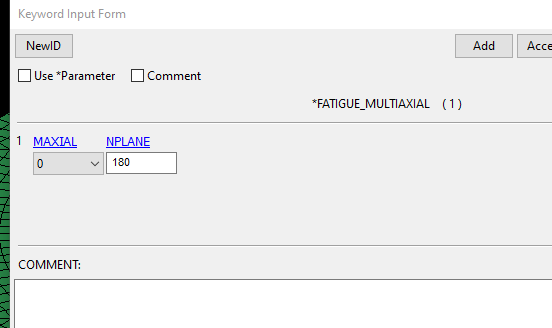

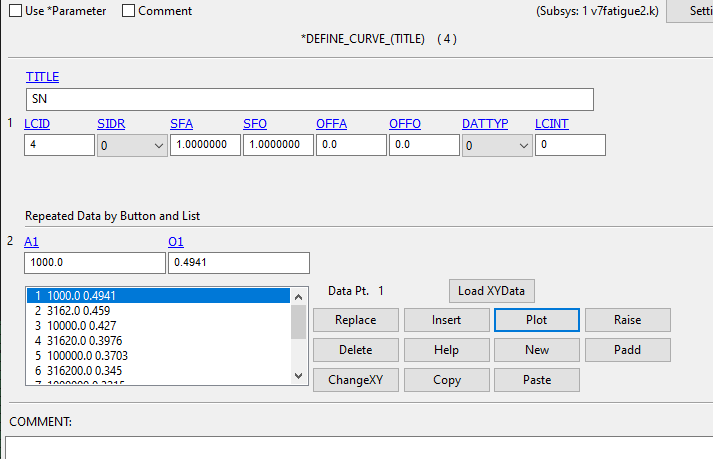

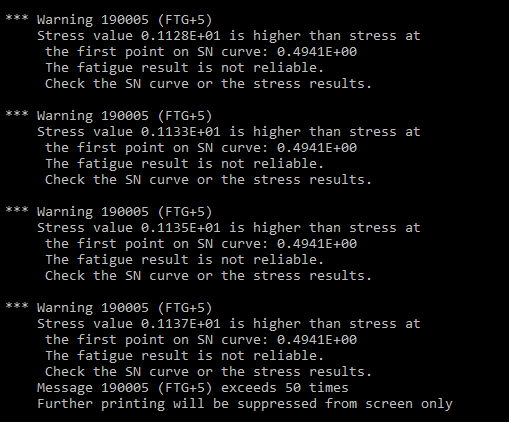

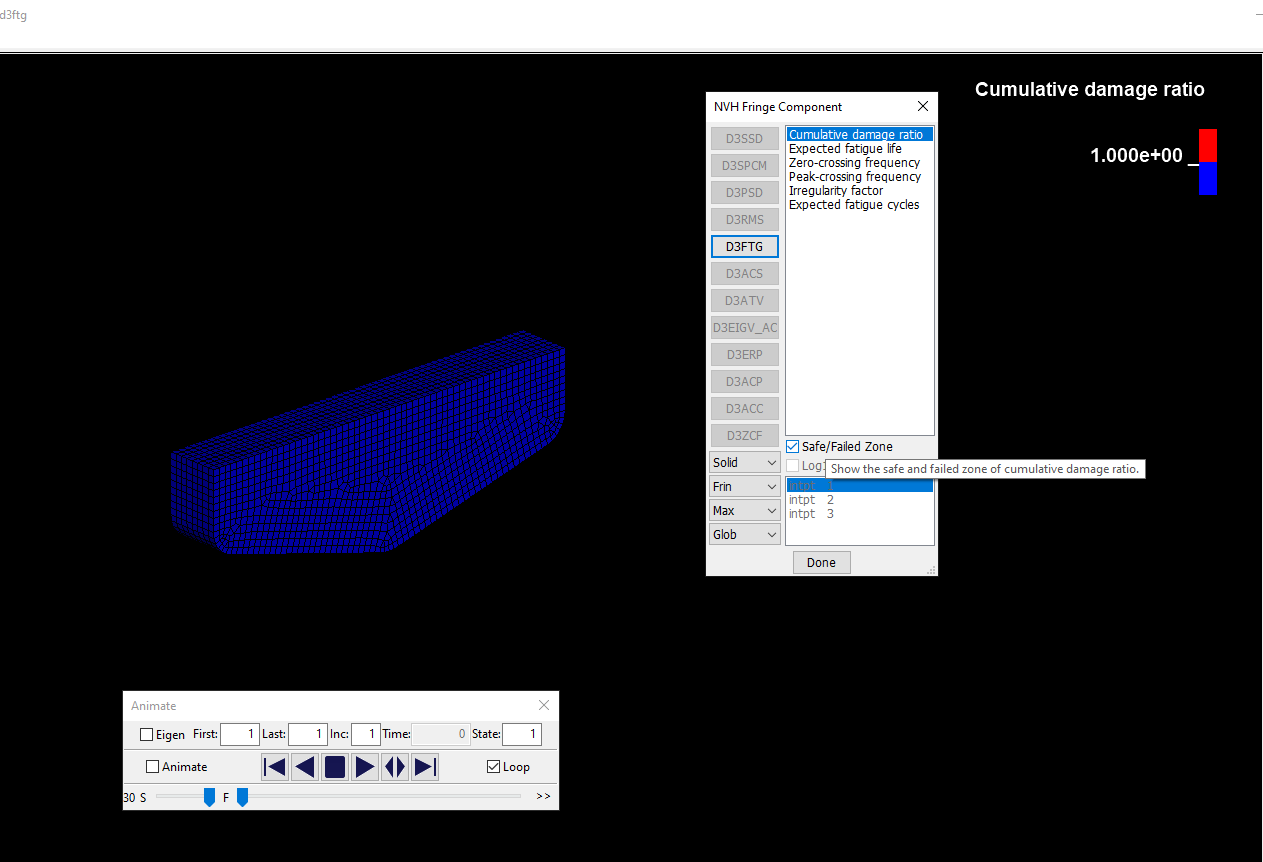

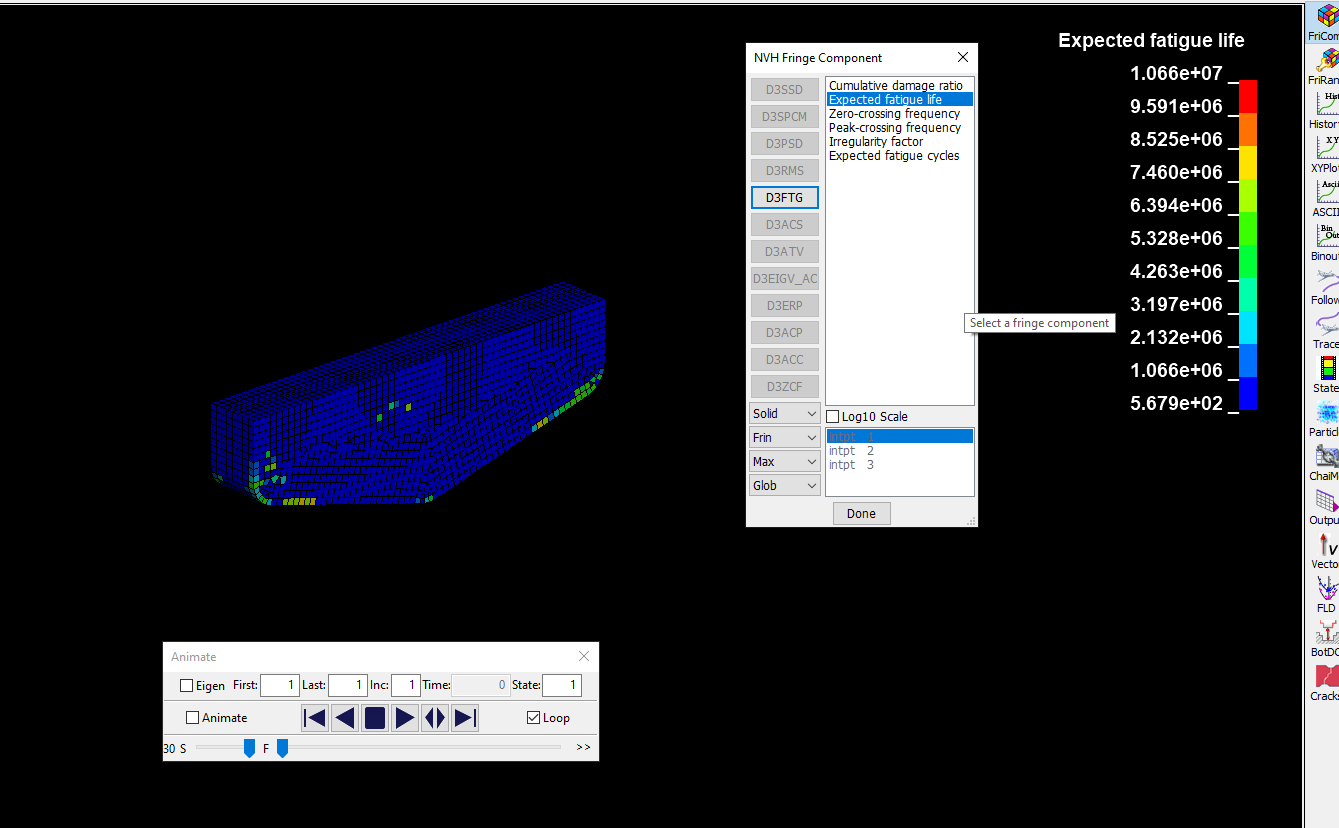

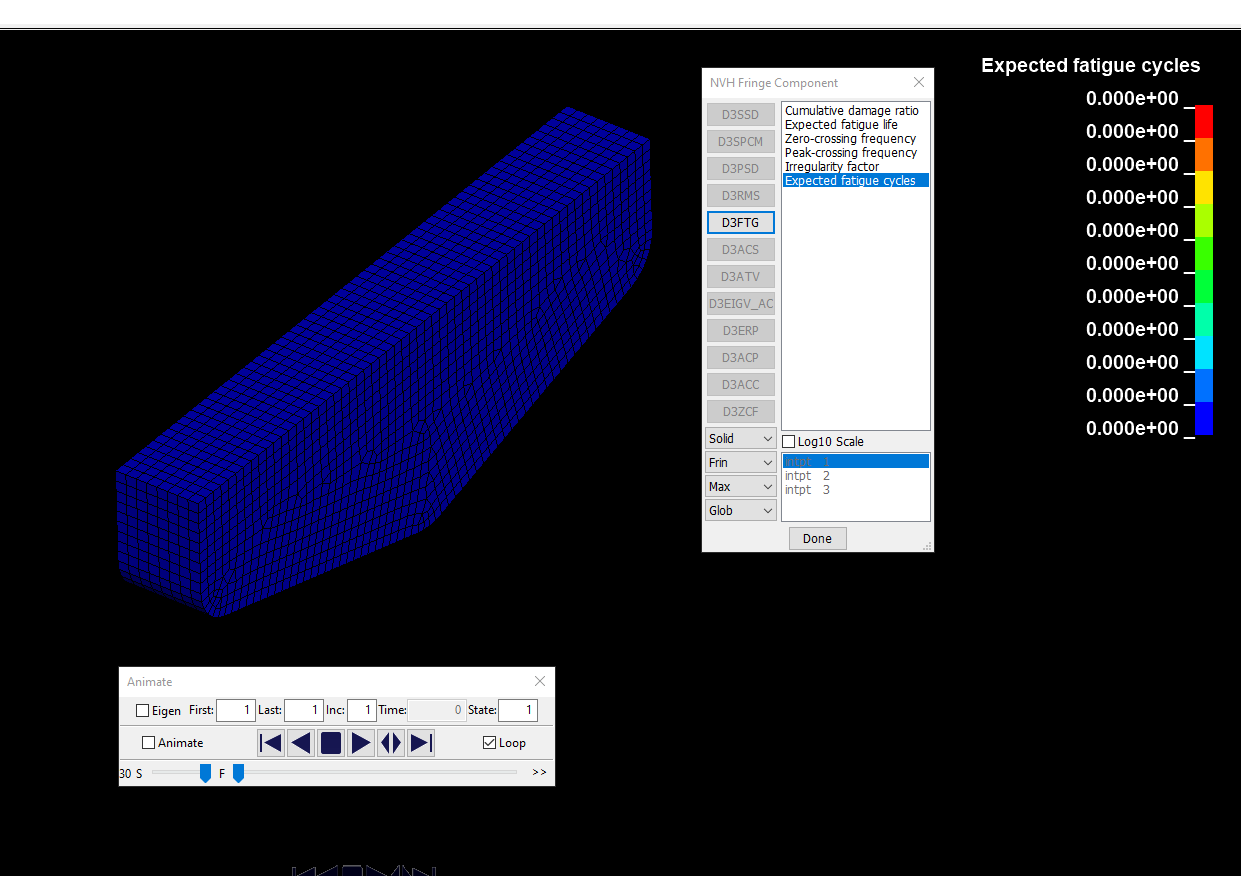

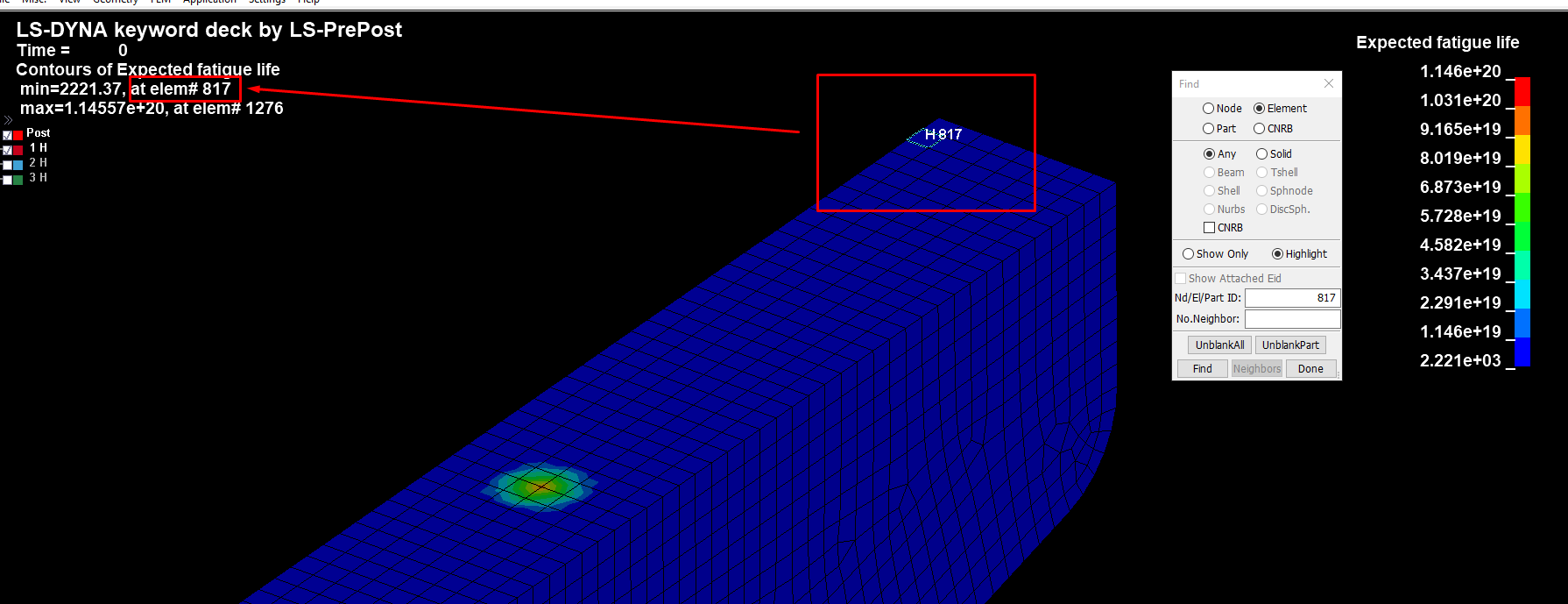

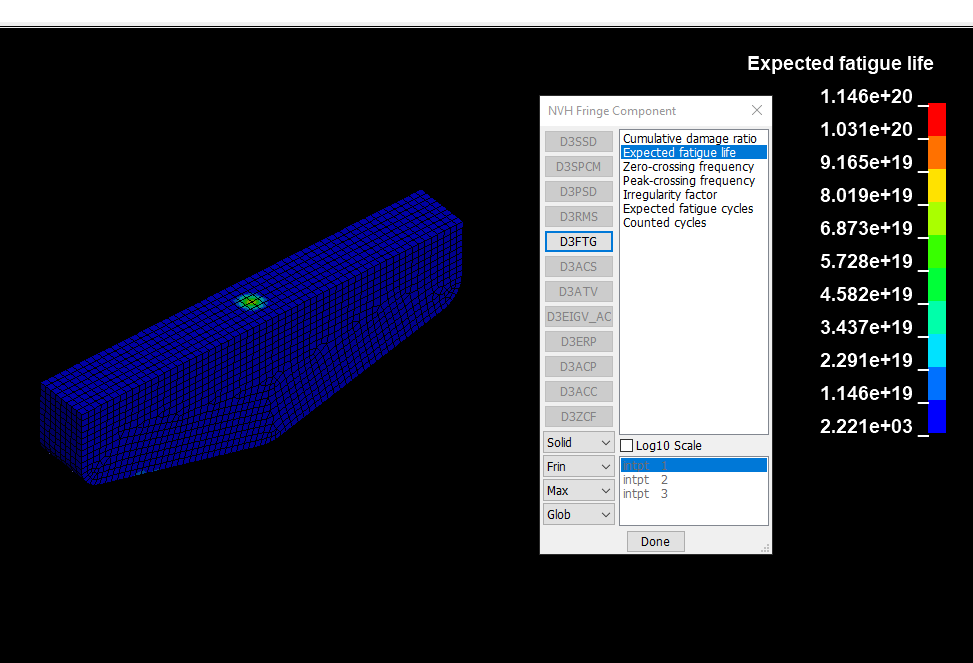

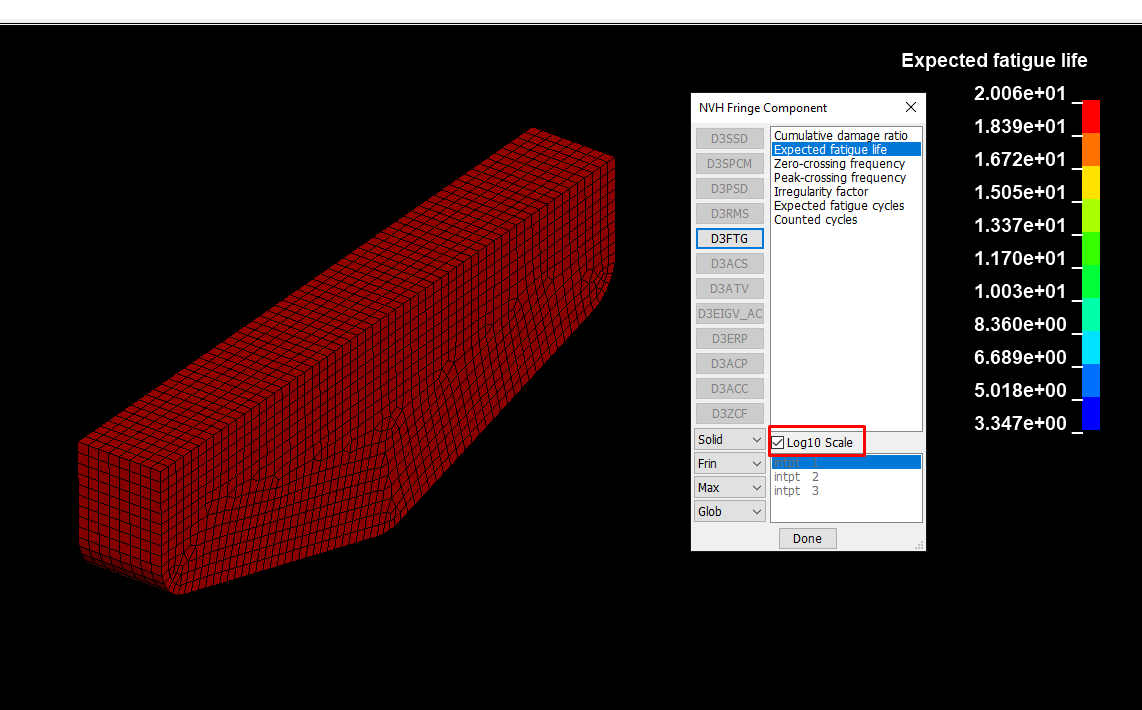

SubscriberHi all.I've done a fatigue test and have questions.I model a tungsten carbide drill tip that drills an SPG die, with a ring of solid body around the die for securing. The material of the die and ring is Mora-Columba concrete.The units I use are: GPa, mm, ms.The rotation of the drill is set at a speed of rad/ms.I did a short calculation (2 hours), the drill rotated about 30 degrees during this time (the total solution to the problem was 60 hours).I checked the d3plot file. Adequate stress:Next, I decided to do a fatigue analysis to check what it would look like.I got inadequate results:1. The cumulative damage ratio is too high.2. Expected Fatigue Life - too small, the elements will only last 235 seconds under load? But they drill with such a drill for many hours or even the whole day. Tungsten carbide is a very durable material with high density.3. Expected fatigue cycles are generally empty. Why?Help me understand the results, what could I have done wrong?I also apply some basic fatigue tinctures:SN curve for drill:I also got this warning when I increased the starting point in the SN curve, I got the following results:The damage has become less, it is gone, but the lifespan is still short.PS. To reduce calculation time, I increased the density of the die, ring and drill by 4e10, can this make a difference?Please, help. Thank you. -

May 28, 2024 at 5:29 pm

javat33489

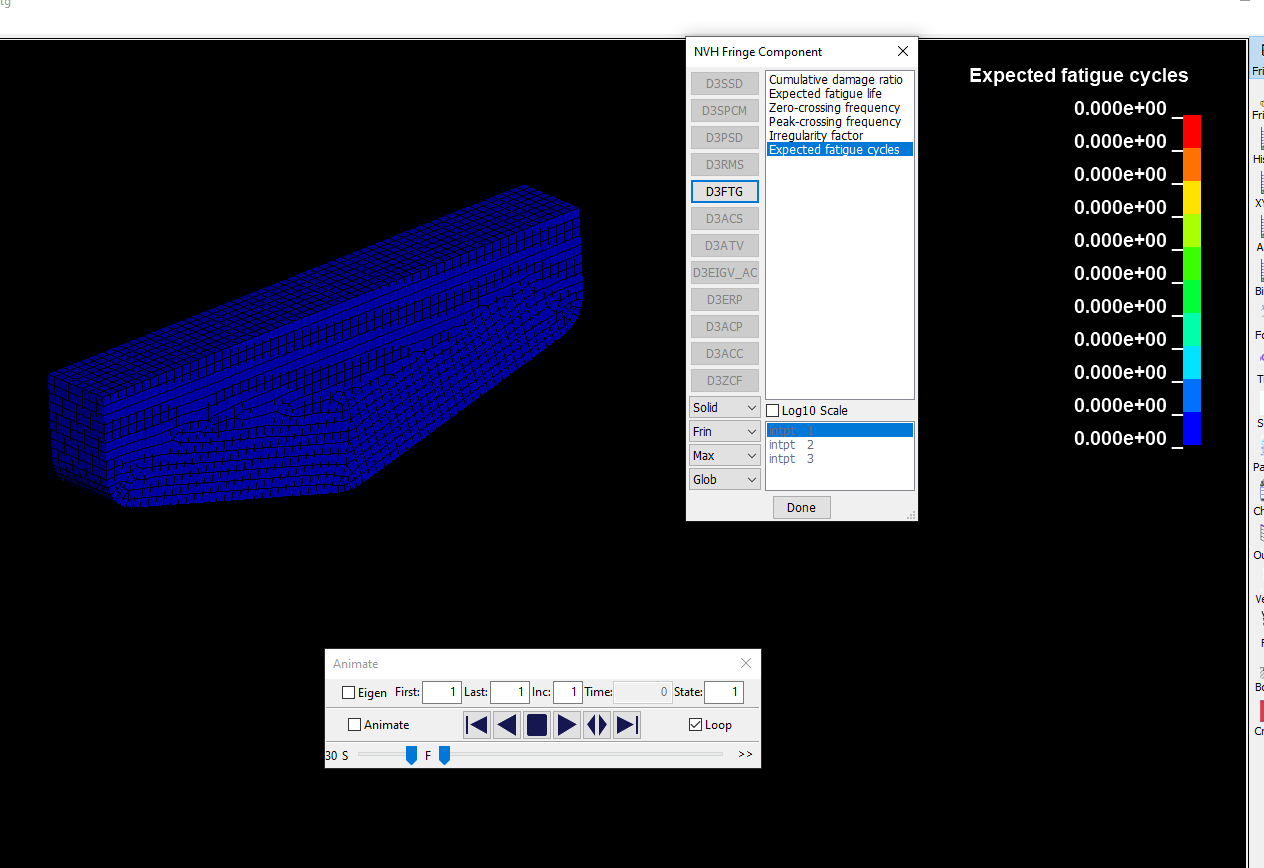

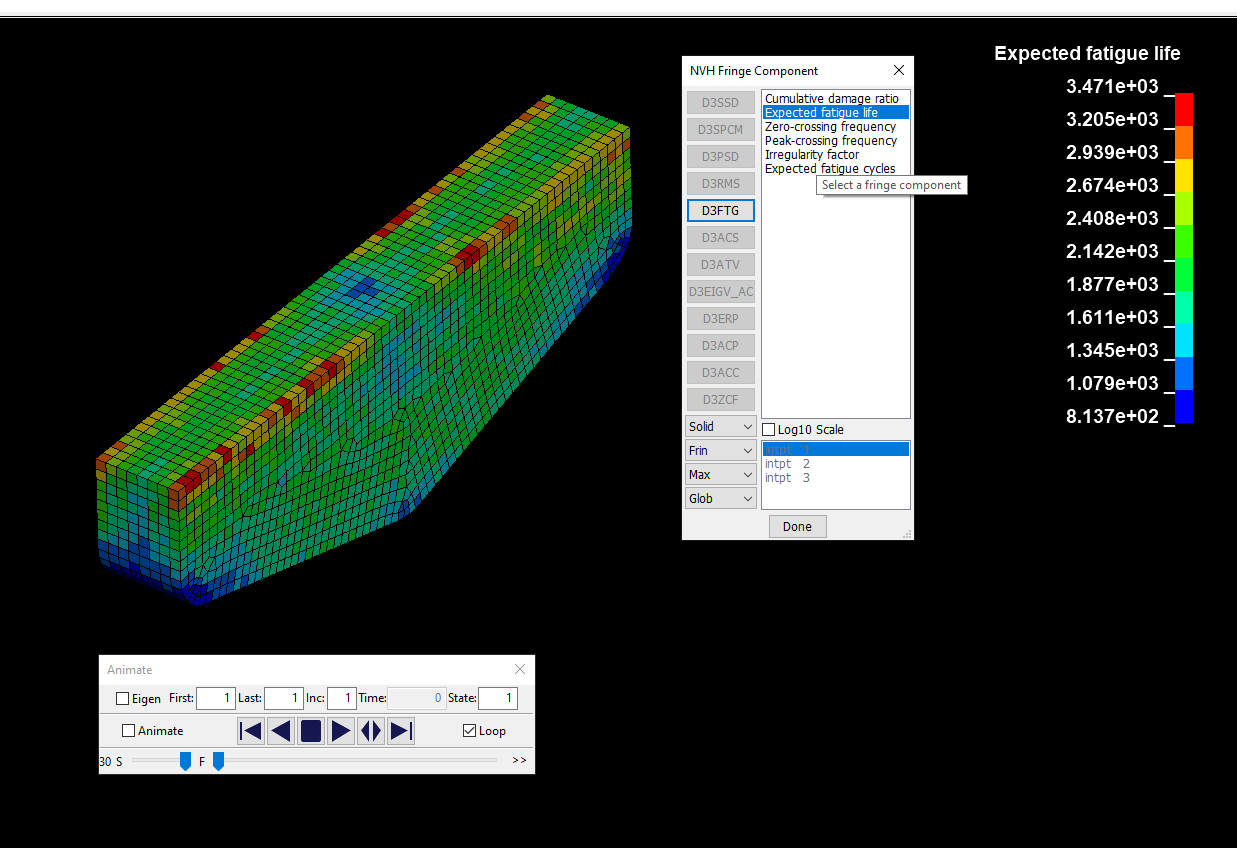

SubscriberColleagues.I figured out one question regarding "1. The cumulative damage ratio is too high". The problem was in the material, I specified the compressive strength and removed the tangential modulus, because... it is unknown and the value was tested in detail.But problems 2 and 3 remain:2.Expected Fatigue Life - too small.3.Expected fatigue cycles are generally empty.Why is Expected Fatigue Life so small? Tungsten carbide is a very durable material. Compressive strength 6 GPa. The maximum stress according to calculations (d3plot) is 1 GPa.There are no Expected fatigue cycles at all, why? Am I missing something?Please, help. -

May 30, 2024 at 6:58 pm

javat33489

SubscriberHELP PLEASE

-

May 31, 2024 at 6:18 pm

javat33489

Subscriber-

June 3, 2024 at 8:46 pm

igandiko

Ansys EmployeeHello, how do the element stress results compare to the S-N curve? Do the elements showing low fatigue life have higher stresses/high damage ratio?

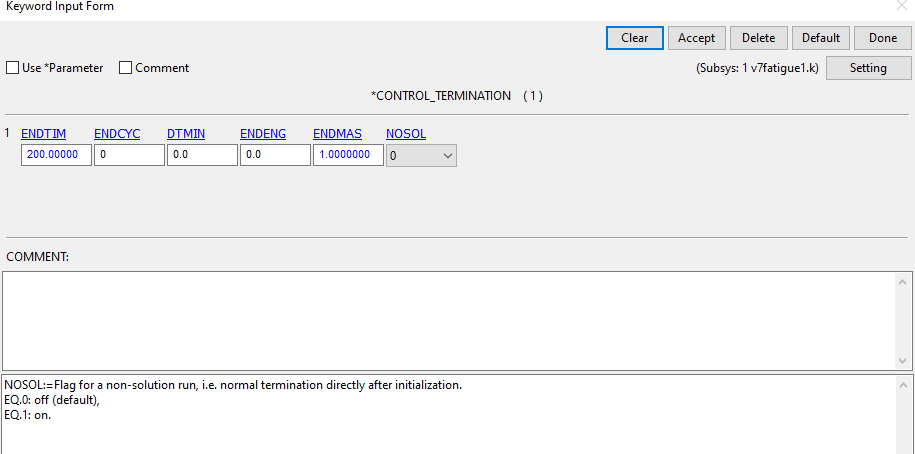

The expected fatigue life is computed as exposure time (in time domain, it is defined by termination time by *CONTROL_TERMINATION, also see texpo paramter) divided by cumulative damage ratio.

Regarding your question 3, expected fatigue cycles are computed as "expected fatigue life" times “zero-crossing frequency with positive slope”. For d3ftg generated in a time domain fatigue analysis, only cumulative damage ratio and expected fatigue life are provided. There is no “zero-crossing frequency” so no “expected fatigue cycle” is provided.

-

June 4, 2024 at 4:26 pm

javat33489

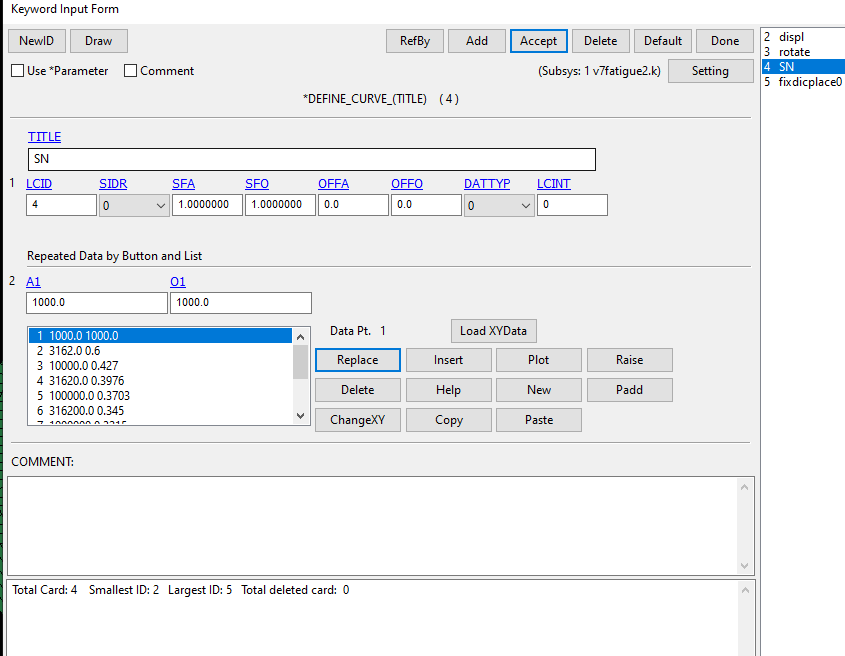

SubscriberHello, how do the element stress results compare to the S-N curve? Do the elements showing low fatigue life have higher stresses/high damage ratio?- Sir, I have modified and simplified the SN curve for the test in this way, from the tensile strength of the material:Mises stress:*CONTROL_TERMINATION, also see texpo parameter- Sir, there is no such parameterRegarding your question 3, expected fatigue cycles are computed as “expected fatigue life” times “zero-crossing frequency with positive slope”. For d3ftg generated in a time domain fatigue analysis, only cumulative damage ratio and expected fatigue life are provided. There is no “zero-crossing frequency” so no “expected fatigue cycle” is provided.- I understand sir, there will be no cycles. How then can I check the load, for example, for a task I will drill 10 mm, but I need to check the strength at 1000, how can I scale this? what maps or settings?___PSMaybe I can upload a K-file here? Can you watch it?

-

-

-

June 3, 2024 at 4:58 pm

javat33489

SubscriberHELP PLEASE!

-

- The topic ‘Problems with fatigue calculations’ is closed to new replies.

-

4592

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.