-

-

October 9, 2018 at 10:17 am

Chad Gouws

Subscriber

"Error: floating point exception

Error Object: #f"

I am simulating a porous-jump turbine with a casing attached to determine the drag and power coefficient using k-epsilon model. If I set the casing to be "interior", the simulation runs "correctly" but then the incompressible gas flows through the casing wall, thereby negating its presence. But when I try to set the casing to be a wall boundary, the error occurs and all but one tiny section of the domain is zero velocity.

I can't seem to understand why the wall function causes errors when the mesh doesn't change but the boundary condition does.

-

October 9, 2018 at 10:55 am

Rob

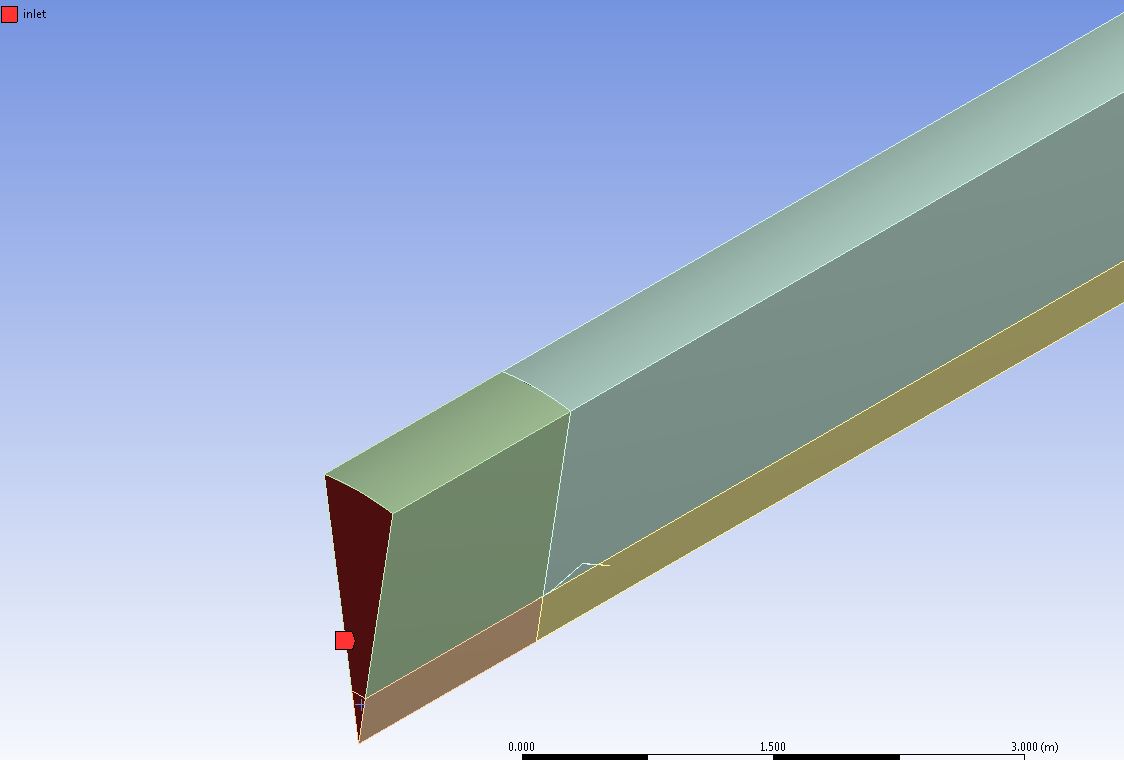

Forum ModeratorPlease can you post some images of the geometry and mesh? Indicate on those the flow speeds etc.

-

October 9, 2018 at 11:19 am

seeta gunti

Ansys EmployeeHelo Chad,

What is the maximum velocity of the domain? Can you please post some pics for more understanding of the issue.

-

October 9, 2018 at 1:38 pm

Chad Gouws

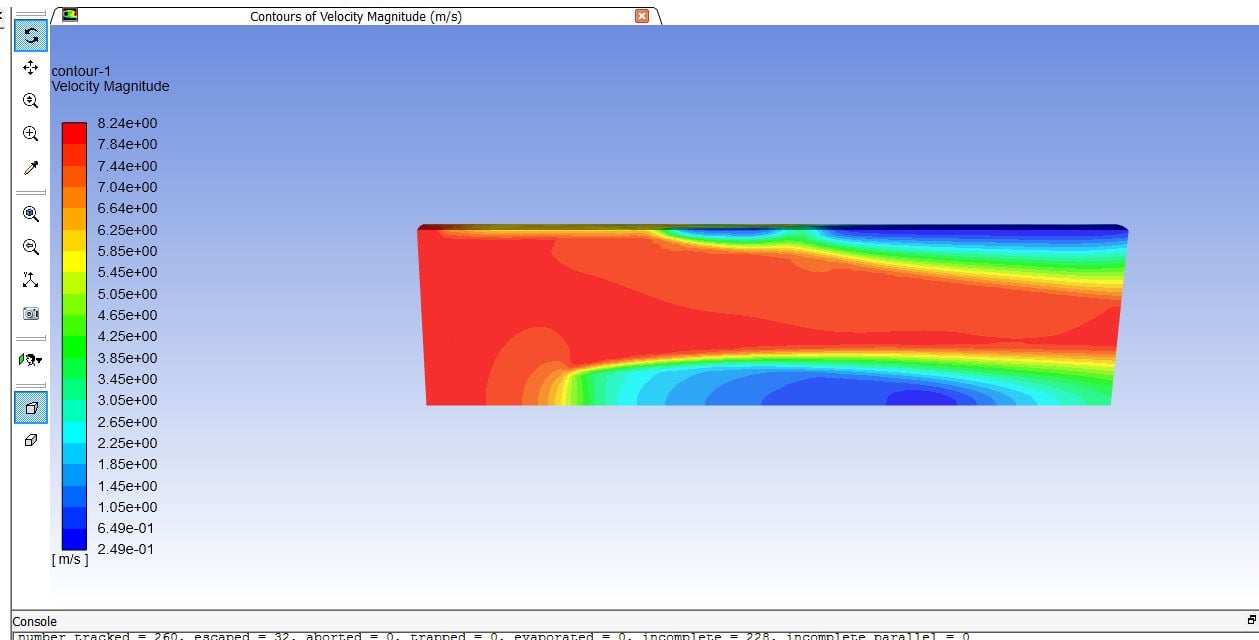

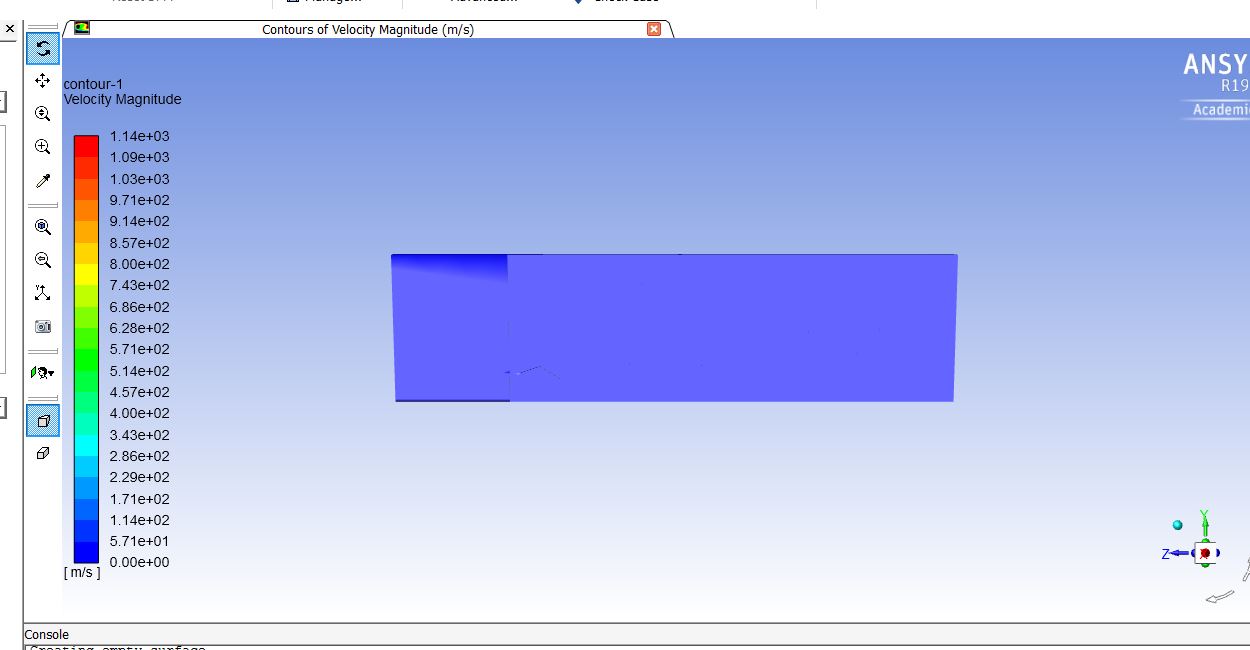

SubscriberThe inlet velocity is 8 m/s, the maximum shown in the simulation is in the order of hundreds of metres per second.

Velocity inlet, pressure outlet, symmetry and porous jump boundaries were used.

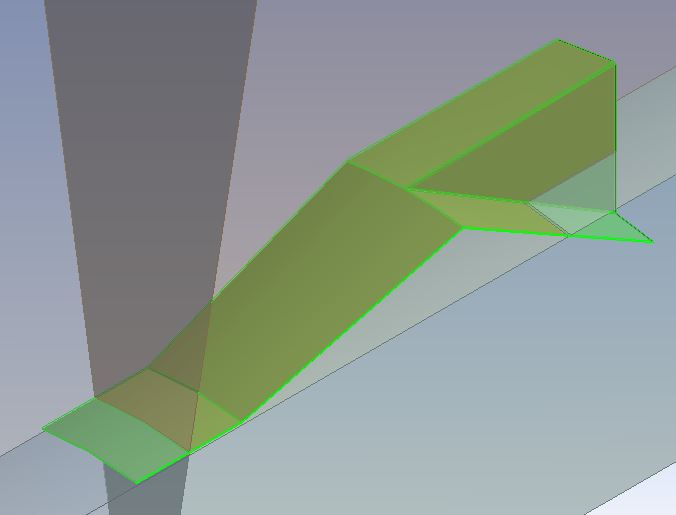

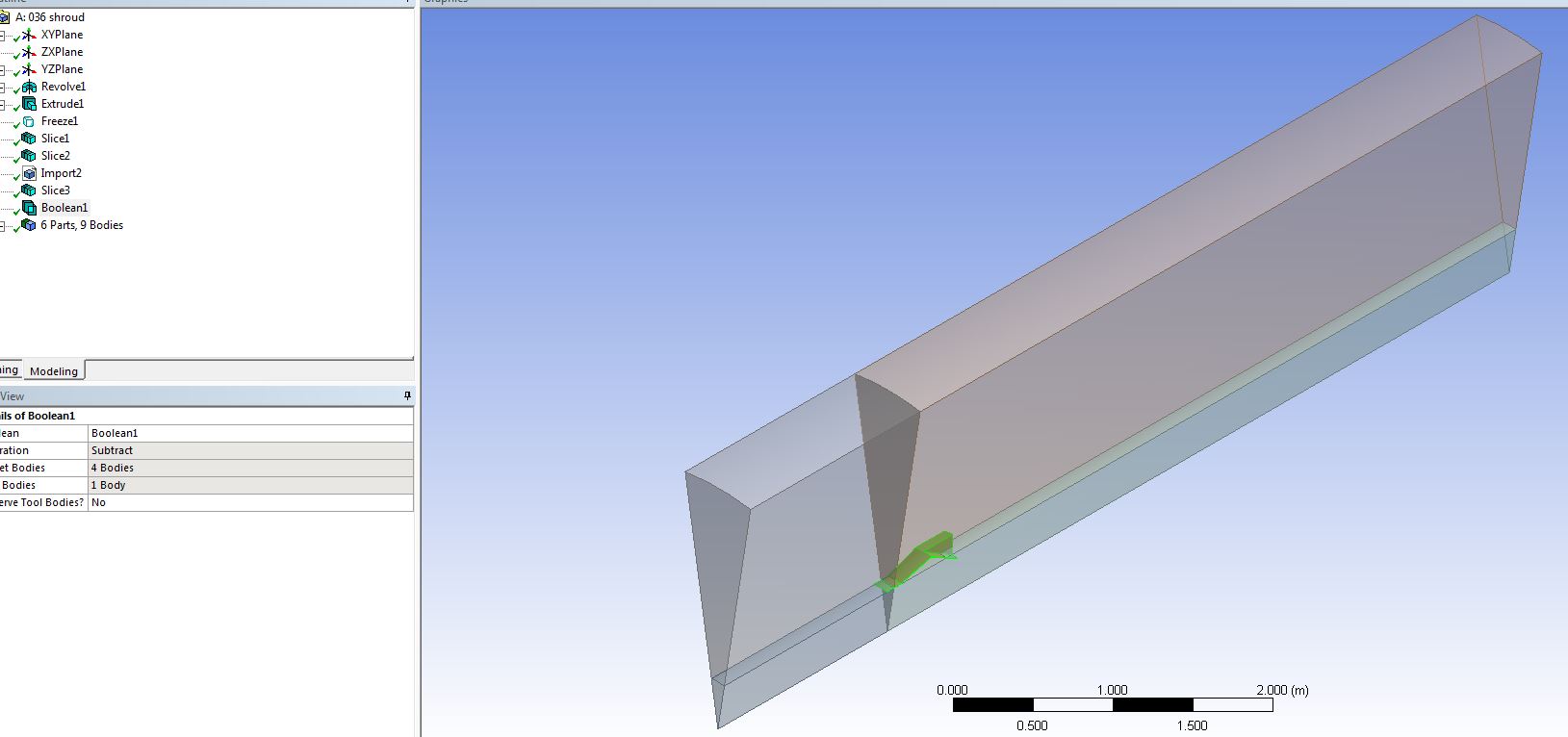

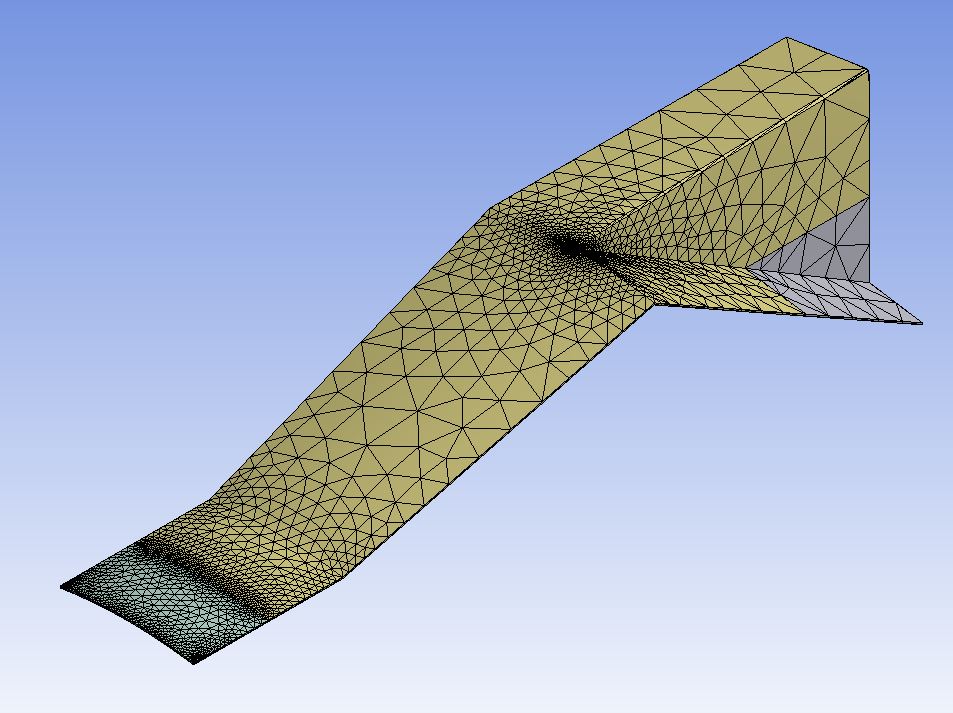

The first image is the porous jump bare turbine, the simulation ran correctly

-

October 9, 2018 at 2:10 pm

Rob

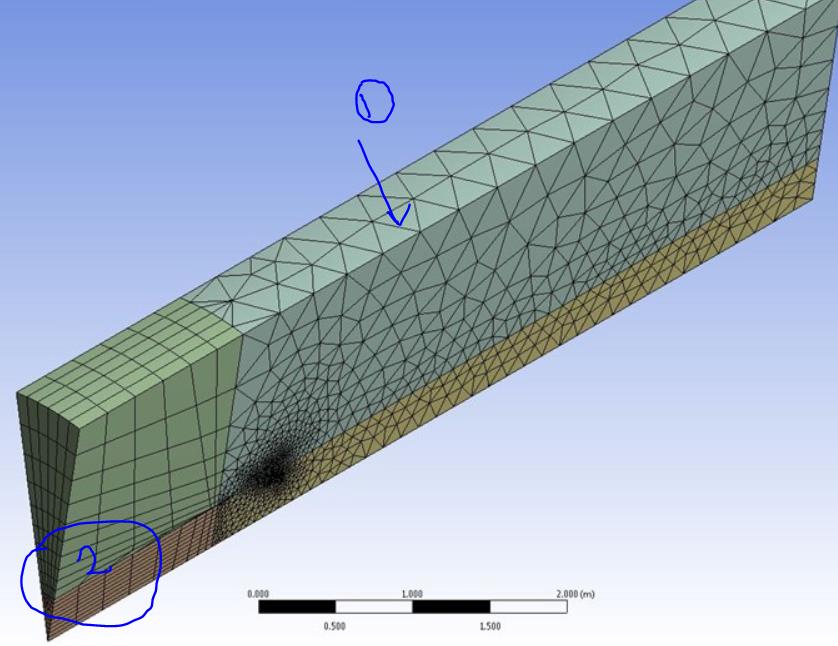

Forum ModeratorPlease check your mesh quality, I think that's causing the problems.

-

October 9, 2018 at 2:20 pm

Chad Gouws

SubscriberWould making it much finer around the casing do the job?

-

October 9, 2018 at 3:41 pm

Rob

Forum ModeratorPossibly, you need to resolve the geometry with enough cells to calculate the flow and also avoid skew cells, big jumps in cell size etc. Have a look in the Meshing tutorials attached to the R19.x help for some pointers.

-

October 10, 2018 at 7:19 am

seeta gunti

Ansys Employee -

October 10, 2018 at 1:53 pm

Chad Gouws

Subscriber

Thank you so much rwoolhou and seeta, I really appreciate the help.

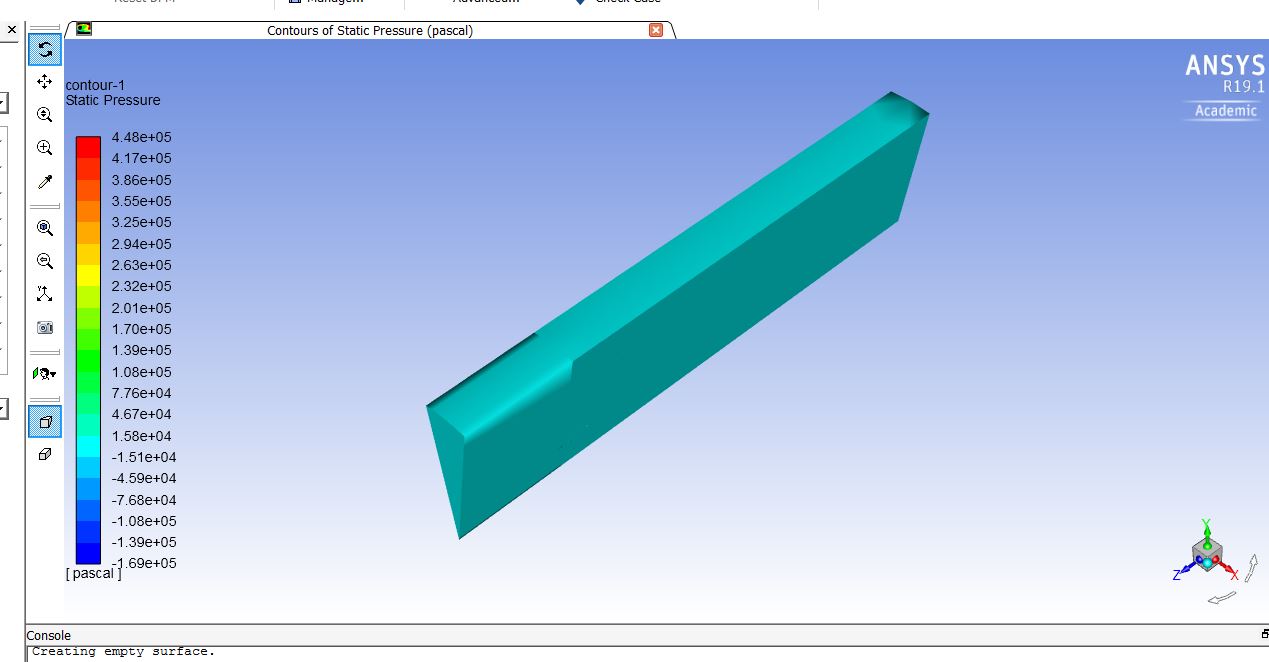

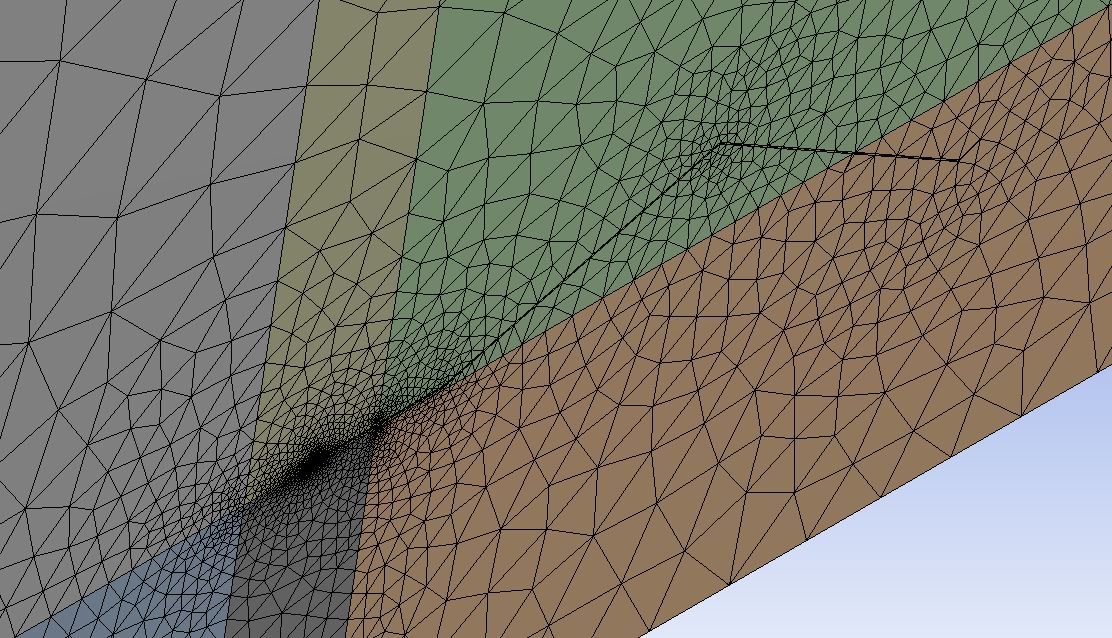

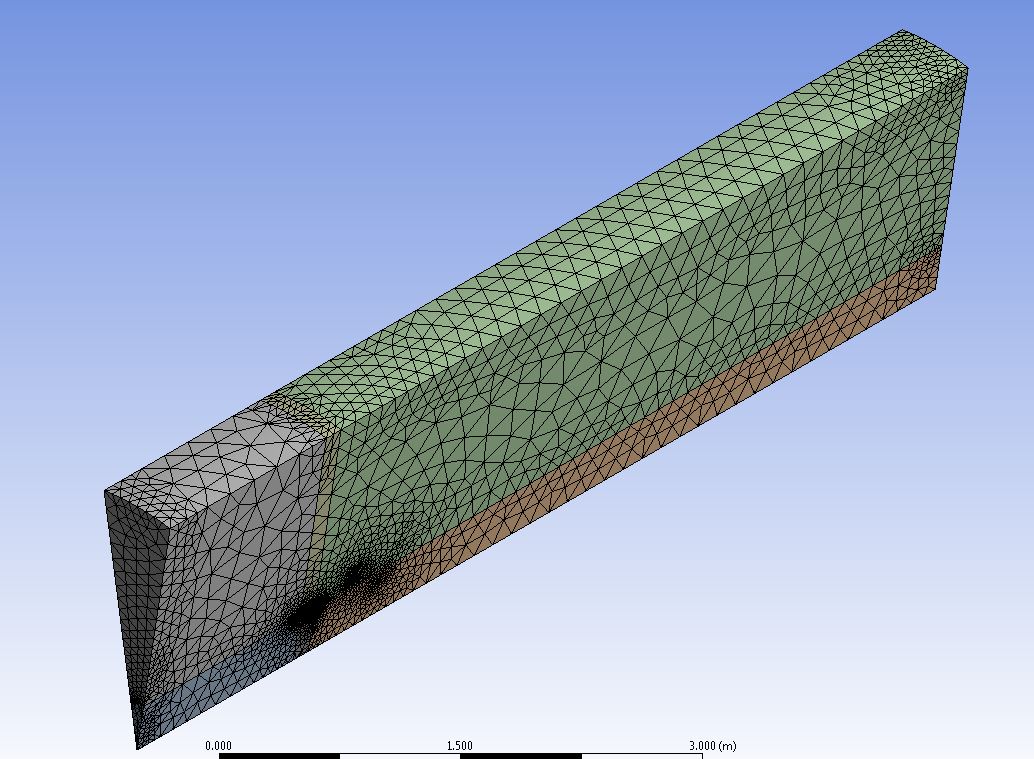

Would this be seen as a better quality mesh? It has been refined right at the casing and the given improvements were made. I did a mesh quality check and ran the mesh improve function. The solution continuity in residuals is now diverging.

-

October 10, 2018 at 4:39 pm

Rob

Forum ModeratorYou're welcome.

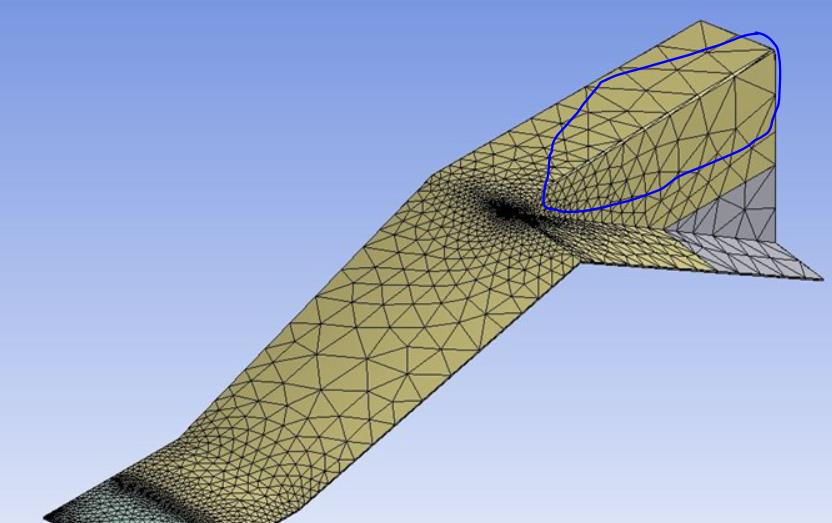

The mesh is better, but I'd check the cells on the yellow surface of the second image. There looks to be a small radius that's skewed the mesh and the area where the 4 surfaces come together may also need some investigation. You may also need to reduce the maximum cell size.

-

October 11, 2018 at 6:09 am

seeta gunti

Ansys Employee

-

- The topic ‘Floating point exception’ is closed to new replies.

-

5014

-

1681

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.