-

-

July 18, 2023 at 9:58 am

sujeesh

SubscriberHello,

I am trying to model a seal with penetration with Ansys Mechanical. I have extensive CFD knowledge, but am somewhat struggling with this FEM problem.I wanted to simulate the seal with small changes in its size by scaling plus minus 10% to check the effects of tolerances. I am able to solve the original size by using penetration and interference modelling to find out contact pressures. When i try to use the same setup for the scaled up version, i notice high element distortion, which only seems to be resolved by reducing the mesh density. This solution, however, is not satisfactory, as there are fewer nodes to detect contact and my model still has penetration.

How should i go about resolving such high amounts of penetration?

Your help is much appreciated :)

-

July 18, 2023 at 11:20 am

Nanda

Ansys EmployeeHello Rohan,

Does your seal has hyperelasticty defined? Kindly refer to this Ansys help video on dealing with element distortion issues:

Let us know it this doesn't help.

Regards,

Nanda.

Guidelines for Posting on Ansys Learning Forum

How to access ANSYS help links

-

July 18, 2023 at 12:11 pm

sujeesh

SubscriberHello Nanda,

thank you for your prompt response. Regarding your question, no I have not modeled the seal as hyperelastic. I understand that it would be more accurate and i would implement it if i had the data at the moment. Nonetheless, if the stress/strain is too much for the seal i have modeled, it would probably break or deform plastically, but the solution should still be converging regardless if i am correct? This issue with too large mesh deformation would still persist I assume.

Thank you for the linked video. I will give it a watch and see if i can find something through that :)

Regards,

Rohan

-

-

July 18, 2023 at 12:48 pm

Akshay Maniyar

Ansys EmployeeHi Rohan,

The video suggested by Nanda will be really helpful for you in solving the distortion issue error.

From your description, it looks like you want to model interference fit. So, make sure that your softer side is your contact side, and the pinball radius you have defined should be more than the interference. I have attached 2 videos that will help you correctly choose the contact and target side, and the other will help you in modeling interference fit properly. Also, use enough number of substeps so that load is applied gradually.

How to Designate the Contact | Ansys Innovation Courses

How to Solve Interference Fit Problems | Ansys Courses

Thanks,

Akshay Maniyar

-

July 18, 2023 at 1:19 pm

sujeesh

SubscriberHi Akshay,

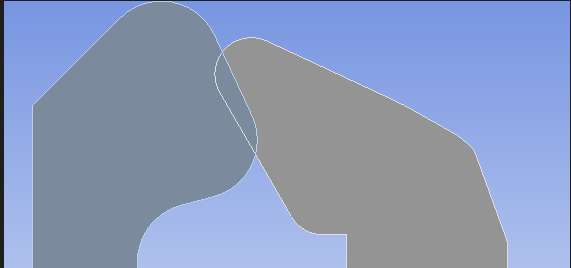

thanks for your reply. As I mentioned before, my setup works well with small penetration. I have watched these videos already and have made sure to choose the contact and targets correctly and have also carefully chosen pinball radii for my model. As you can see in the following image, this is the original fairlead that I have modelled, and i have favourable results (model is 2-D axisymmetric to reduce computational effort).

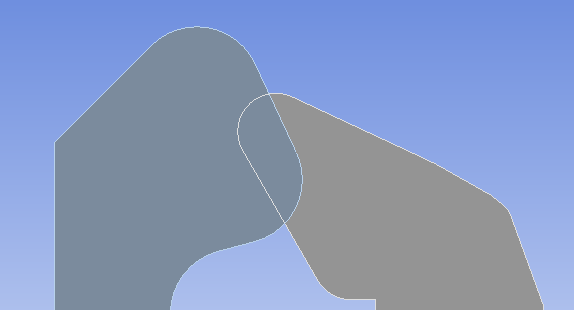

But once i scale the seal to 110% (and adjusted the pinball radii), the solver fails due to high distortion of mesh, and only seems to work if i make the mesh extremely coarse, which seems wrong to me. Have increased loadsteps too, but didnt help. Only reducing mesh density helped.

Thanks,

Rohan

-

July 19, 2023 at 12:53 pm

sujeesh

SubscriberHi all,

it looks like manually making contact stiffness much smaller than the default value helps with high penetration models, and allows for more robust meshing too. It works for me now, thanks for all the help!

Regards,

Rohan

-

-

-

- The topic ‘Problem with high penetration’ is closed to new replies.

-

4597

-

1500

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.