TAGGED: -2d-materials-and-metals

-

-

May 19, 2023 at 1:26 am

radebetb

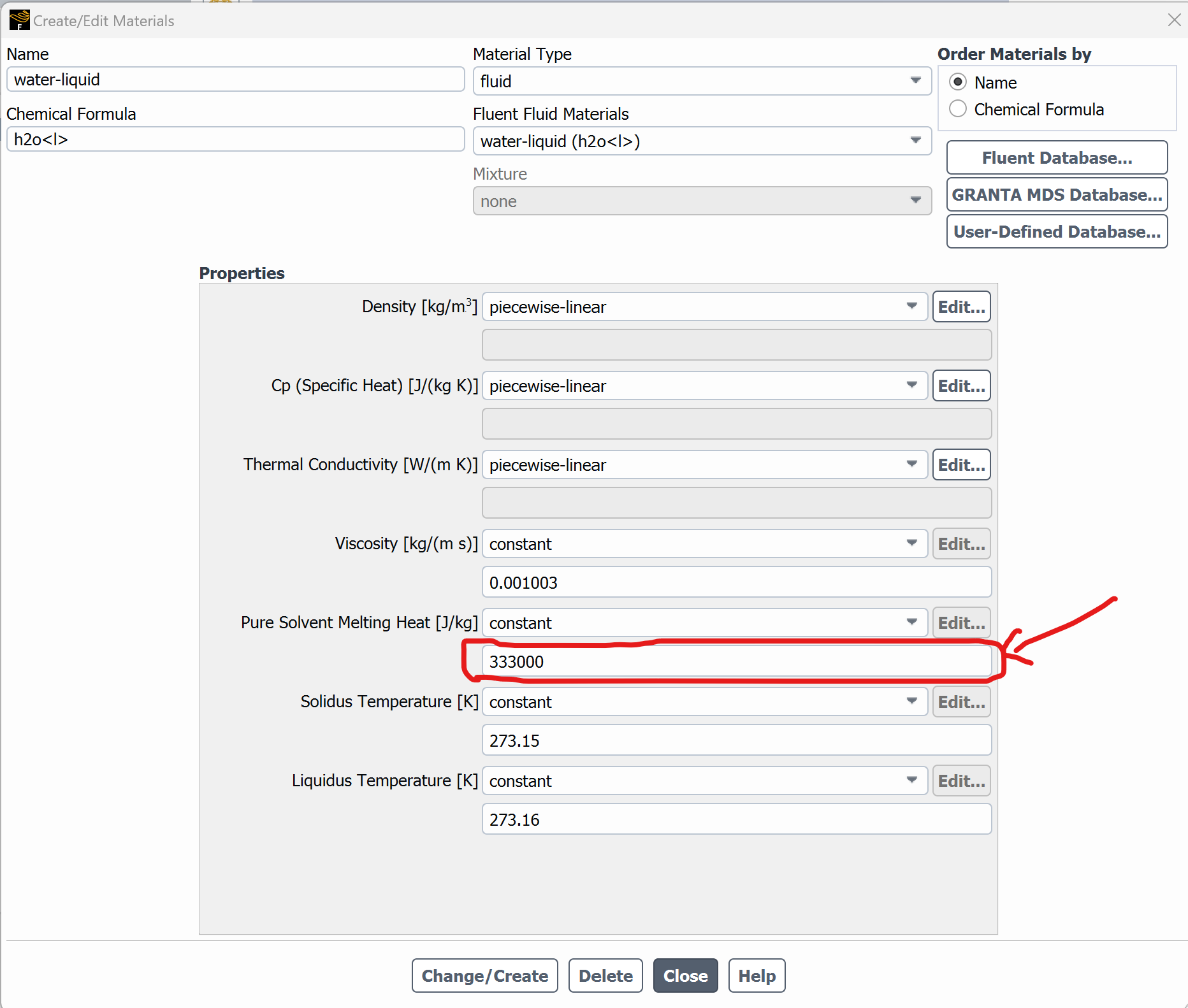

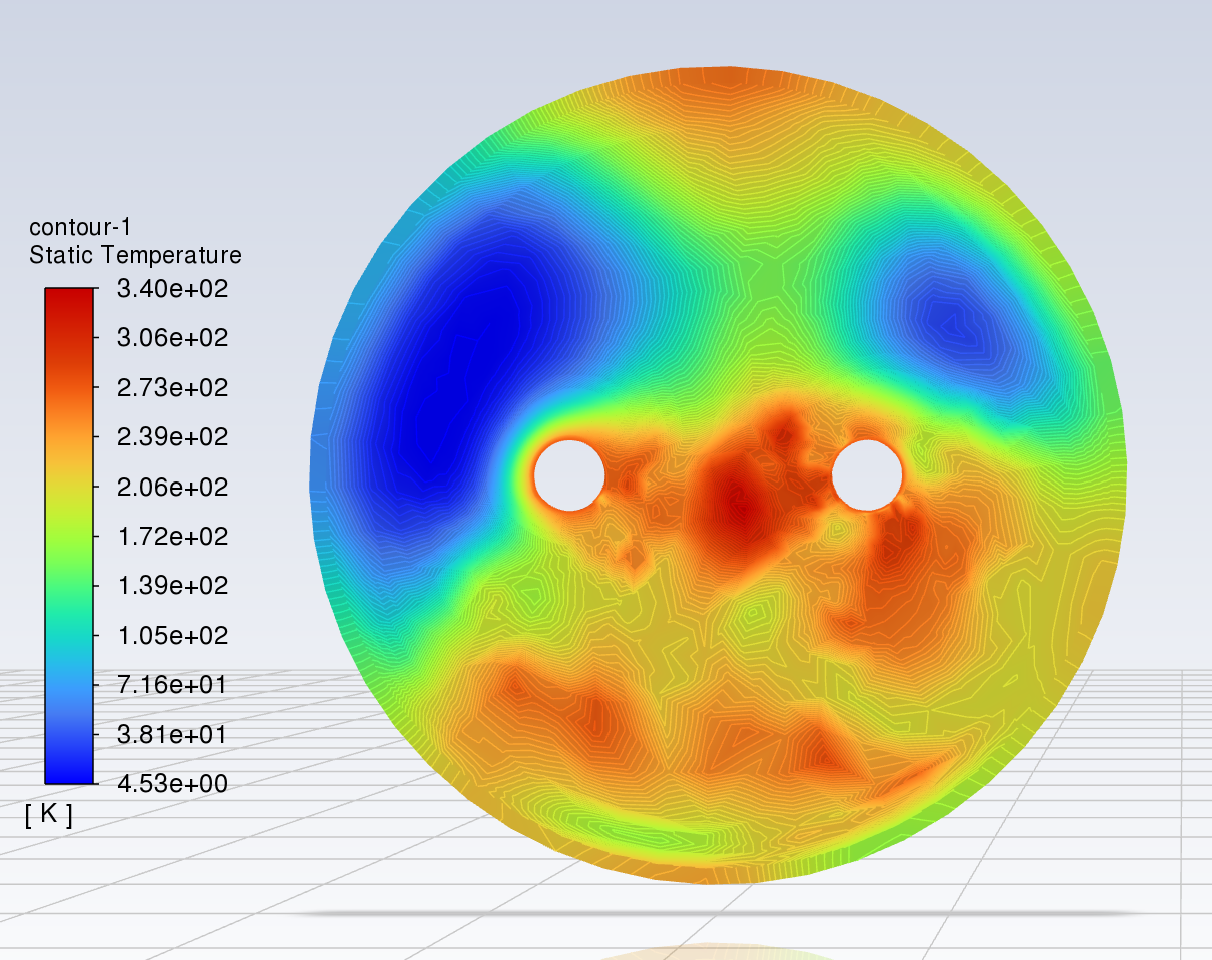

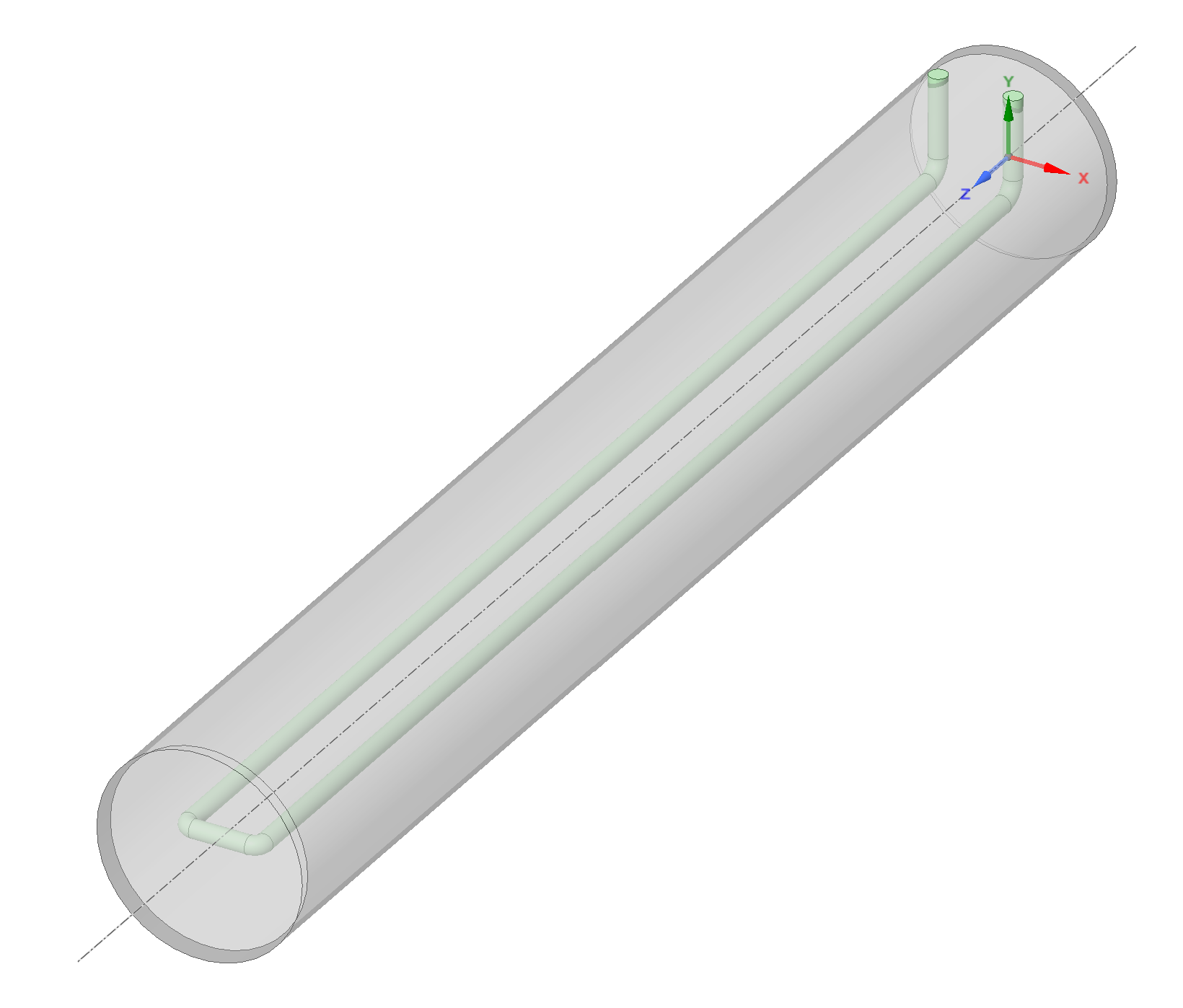

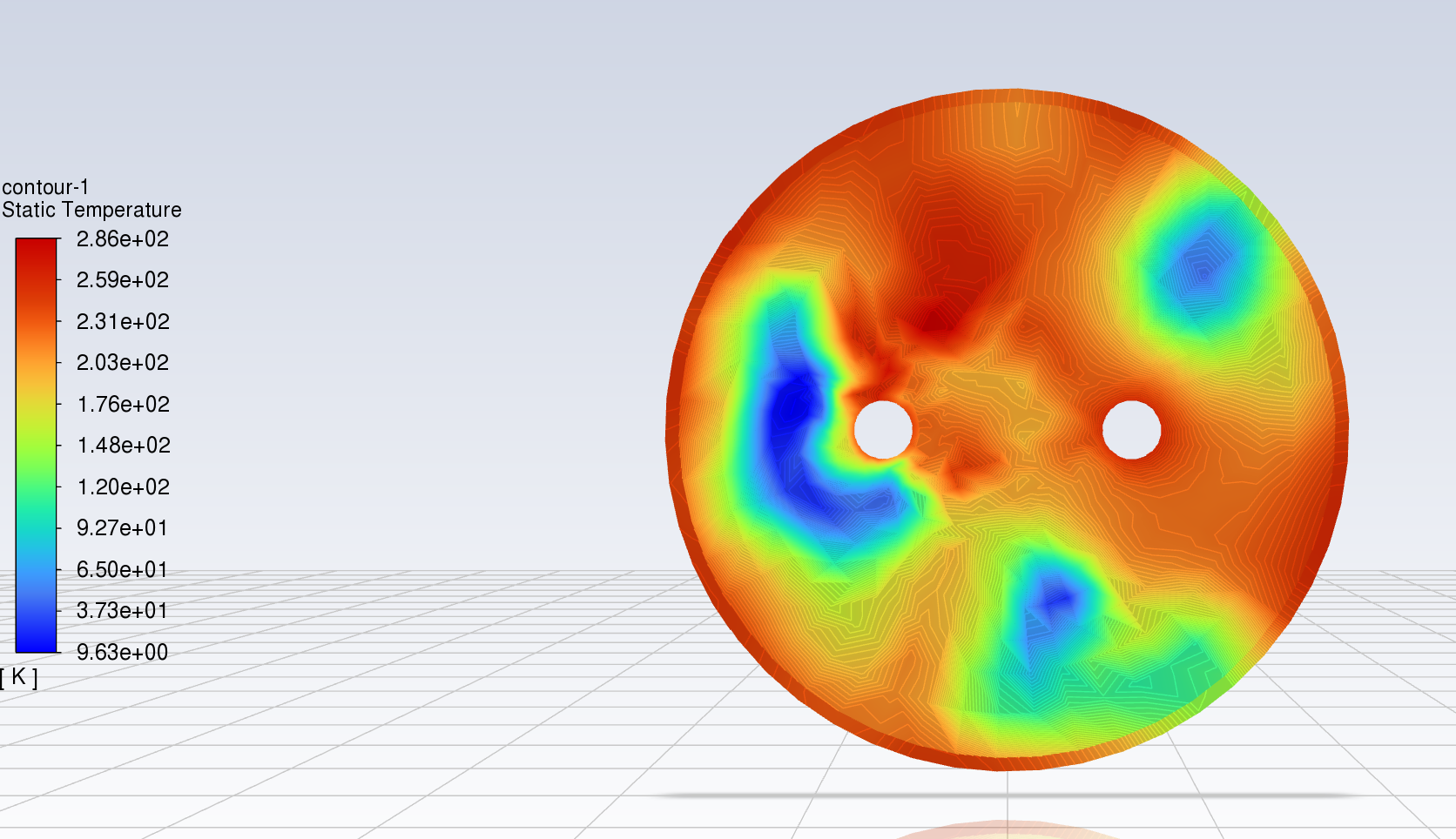

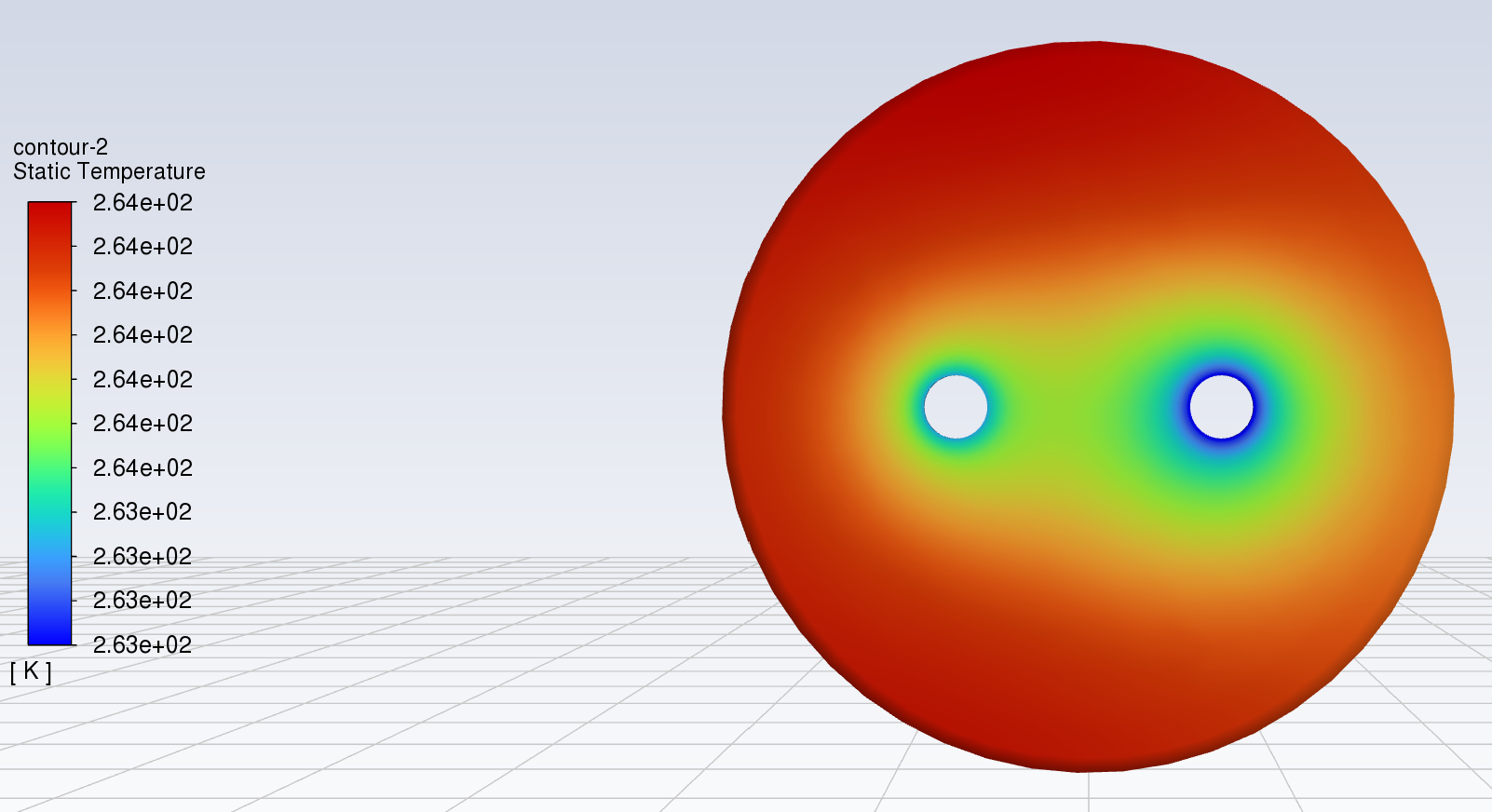

SubscriberGood day Ansys teamI have a problem with my model. I am simulating Water inside an annulus. I was able to reduce my model to a 2D figure as seen in the picture.I need to monitor the behaviour of water as its freezes from 288K to 259K. The model consists of an outer casing which is Steel, Two temperature boundaries that are set at a temperature of 259K and a PCM which is Water/liquid.I am using a transient state, with a Laminar turbulence model, energy equation and solidification and melting feature. I have 30941 Number of time steps with a time step size of 1.The problem arises when I insert the Pure Solvent Melting Heat as 330 000. The model becomes unstable and I get ridiculous temperatures when I monitor the temperature through the animation. this is seen on the attached pictureWhen I set the Pure Solvent Melting Heat to zero, the model runs well within the specified range, but the liquid fraction remains as 1.Please correct me. -

May 19, 2023 at 10:15 am

Rob

Forum ModeratorHave you reviewed this? https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v231/en/flu_ug/flu_ug_sec_melt_inputs_steps.html

To add, with a 1s time step you could be adding a lot of heat into the model very quickly: how was the convergence looking?

-

May 19, 2023 at 11:46 am

radebetb

SubscriberThank you for the apt response.

- The link you provided requires me to log in using my account, and the current license we are using is the institution's license. on my personal computer, I use the Student Version.

- I am comparing experimental data with simulations. So the experimental data logger records the temperature of the water as it freezes for 9 hours. I then take this data into Ansys fluent via transient table to use as the boundary conditions on the inlet, outlet and surface temperature. So I thought the 1s would be the best. If I lower the simulations will they not take even longer? currently, the model takes 18 hours to run.

- I have exported the simulation results and plotted them against the simulation results. So I inserted the temperature of the experiment as boundary conditions, and then measure them at the same point, which is the middle of the annulus. However, the curves are too far from the experiment data. I was suspecting the Pure Solvent Melting Heat since i set it to zero, instead of 333 000.

-

May 19, 2023 at 12:54 pm

Rob

Forum ModeratorClick on Help in Fluent and then copy the link into that browser. The solvers give you a token/cookie/biscuit to access the help system.

Inlet temperature using profiles is fine, the outlet shouldn't matter unless you get backflow. However, how does the experiment look regarding getting the liquid out?

-

May 19, 2023 at 1:30 pm

-

May 19, 2023 at 2:15 pm

Rob

Forum ModeratorOK. Have you included buoyancy for the water? As it's a sealed volume you will need to review the options. Setting wall temperatures is sensible, but remember the temperature you know/think you know is inside the tube.

You did add the temperature profile in Kelvin? Profiles and UDFs all assume SI units.

-

May 19, 2023 at 2:32 pm

radebetb

SubscriberI didn't know about the Buoyancy effects. I will research them and were to find them and apply them to the model.

Yes, I did observe the units, so everything is in Kelvin's.

Let me rerun the model with these changes and will update you. Is it still fine if I used the Laminar model

-

May 19, 2023 at 2:39 pm

Rob

Forum ModeratorLaminar ought to be fine: if it's turbulent I'd be very surprised. Unless you use the geologist/medic definition of turbulence......

-

May 23, 2023 at 2:16 am

radebetb

SubscriberI applied the Full Bounancy effects under the K-e turbulence model. But it seems like the model still behaves the same.

The convergence is quick since I set it to 20 iterations, but within 10 iterations the solution converges.

I just want to know what are the implications of not including the Pure Solvent Melting Heat, because it seems to be the one that causes the model to become unstable. When it's set to '0' the model runs well.

is it impractical to leave out the Pure Solvent Melting Heat in this case, since i am freezing a liquid?

-

May 23, 2023 at 2:04 pm

Rob

Forum ModeratorIf you do there's a good chance you're not accounting for the energy for phase change.

-

May 23, 2023 at 2:12 pm

-

May 23, 2023 at 2:31 pm

Rob

Forum ModeratorOK, so the external thermal condition is? You initialise/patch the domain to 295K ? What monitors are you running over the duration of the simulation?

-

May 23, 2023 at 3:13 pm

radebetb

Subscriber- The external thermal conditions are not set in this current model. Reason being i would like to compare the annulus surface temperature with the experimental results.

- I used standard initialization with the temperature of all the domains set to 288K.

- I am monitoring the Static Temperature and the Liquid fraction, to ensure that the water is frozen, and to view which areas freeze quicker.

-

May 23, 2023 at 3:57 pm

Rob

Forum ModeratorSo external bc is adiabatic?

What time step are you using, and does the solver converge well?

-

May 25, 2023 at 12:43 am

radebetb

SubscriberYes

- The surface is exposed to atmospheric air

- I am using a time step of 1

- the solution did converge when i used the Laminar model, however with the k-e model it does not

I have noted that the default value for the latent heat of water in Ansys is 2 263 073 J/kg. Well the known value for water's latent heat is 333 000 J/kg. Is this correct?

I have exhausted all my options. ( I am starting to think that there is a problem with Ansys's back-end coding causing the model's instability)

I would advise other students learning to model solidification and melting to follow this video ANSYS Fluent Tutorial: Analysis of Melting and Solidification of Phase Change Material (PCM).

however, the creators use a steady state, which is not applicable to my model.

-

May 25, 2023 at 10:43 am

Rob

Forum ModeratorYou've compared latent heat of vapourisation with the liquid freezing energy. There's a slight difference.

Having run several freezing models over the years the solver is usually fairly good. What tends to cause problems are mesh resolution, mesh (and cell) quality and material/boundary settings. Time step can also play a part if the frozen region causes flow patterns to change and then the frozen parts to melt as a result of this.

-

May 26, 2023 at 1:57 am

radebetb

SubscriberOw okay, this is the latent heat required to turn it from liquid to steam?

I will keep trying and working on the model.

-

May 26, 2023 at 8:54 am

Rob

Forum ModeratorYes, look in the panel once it's copied over & you have solidification/melting on. For boiling we don't technically use latent heat as it's part of the formation enthalpy: multiphase is OK, reactions are OK, combine the two and it's a little more complicated.

-

- The topic ‘Simulation of water as it freezes’ is closed to new replies.

-

4703

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.