-

-

April 27, 2022 at 9:53 am

henrique.geraissate

SubscriberHello everybody!

First of all, I want to say that I am a beginner in FEA and in ANSYS, and also that I could not find an answer in the forum, and that is why I am posting.

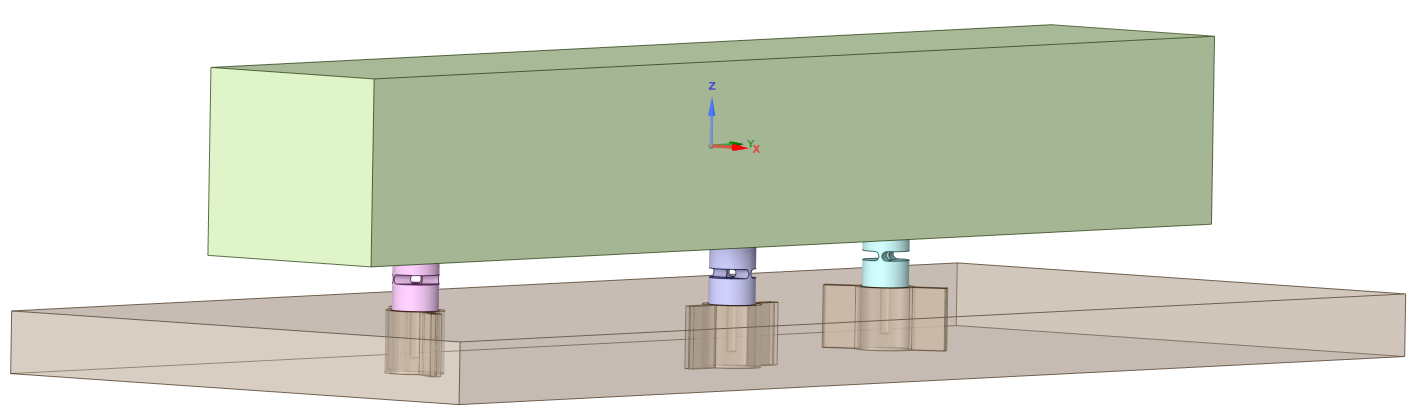

So, I have an assembly which consists in a Silicon block attached to a Aluminum frame with some hinged pads in between. The block is submitted to a Heat Flow that will heat it up, and the frame has flexures in the contact region to accommodate the block expansion (pictures below).

April 27, 2022 at 2:18 pmAshish Khemka

Forum Moderator

Please see if the following video helps you. This may not exactly highlight the model you may be looking for but shows basic guidelines of coupled thermal structural analysis:

ANSYS Tutorial | Thermal Expansion and Stress Analysis | ANSYS Static Structural | ANSYS 2019 R2 - Bing video

Regards Ashish Khemka

April 27, 2022 at 2:40 pmhenrique.geraissate

Subscriberthank you for the answer.

Unfortunately, this video didn't help much, although it does contain useful information. I have seen several videos on how to couple thermal with structural analysis, even reproduced a few of them.

I managed now to represent the free expansion of the silicon block solely, excluding the other parts from the model. So I guess that my error is somehow in the contacts and/or the boundary conditions, but I have tried a few different options here and still no success.

Any ideas?

Kind regards Henrique

April 27, 2022 at 11:25 pmpeteroznewman

SubscriberYou can apply a uniform temperature to the silicon block in a Static Structural analysis, you don't need Steady State Thermal to apply this load, though when you are studying heat flow through the flexures you will want that.

Please show the material properties for the silicon material. What value have you used for the Secant Thermal Expansion coefficient?

From what I can see in the image, there are three hinge flexures. That is not an ideal flexure system to have a practically strain-free expansion of the silicon block, as you will see when you get the Static Structural model working.

April 28, 2022 at 7:18 amhenrique.geraissate

SubscriberThank you for the reply!

Oh, I didn't know that I could apply a thermal condition directly in Static Structural, but now I saw this option indeed. Is there any difference in applying Temperature loads in Static Structural instead of in Steady State Thermal?

And I am so embarrassed now, because I didn't have enter the expansion for the Silicon material, for some reason I thought that Workbench had this information already. I added a tabular data from literature for a quite large range of temperatures now, and the simulation started to behave as I was expecting. I guess now it's a matter of refinement. I am so sorry to bother you guys with such a rookie mistake!

Also, regarding the design, the flexures that are supposed to handle the thermal expansion are those in the Aluminum frame. They won't allow free expansion of the Silicon body, but they are oriented in a way that should keep one specific point in one of the faces in position while the rest of the body deforms. The hinged pads (cylindrical parts) are actually to compensate any machining errors between the parts (and to a certain extent it emulates a spherical joint when combined with the flexures in the frame). But if you have suggestions you would like to make, please feel free to do it.

Thank you again for the help!

Viewing 4 reply threads- The topic ‘Evaluation of Thermal Expansion in connected bodies with different CTE’ is closed to new replies.

Ansys Innovation SpaceTrending discussions- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Real Life Example of a non-symmetric eigenvalue problem

- Nonlinear load cases combinations

- How can the results of Pressures and Motions for all elements be obtained?

Top Contributors-

3977

-

1461

-

1272

-

1124

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.