-

-

December 8, 2021 at 6:46 pm

dzaki8598

SubscriberHi,

I am trying to simulate a humid air that enters a room through an inlet, with transient simulation.

I have activated species transport with air and h2o mixture.

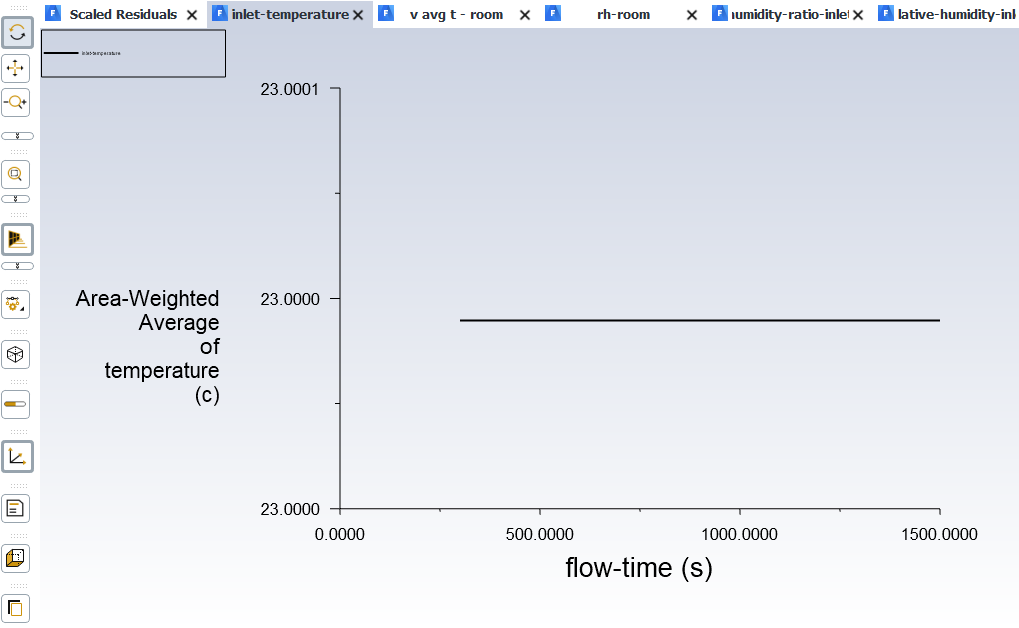

At the inlet boundary condition, I specified the temperature as constant (at 23 C) and the h2o in species (I understand that this should be the humidity ratio value) as constant at 0.0106. And these values are working fine as you can see in these two pictures (I read these values at the inlet with average-weighted-area)

December 9, 2021 at 11:56 amRob

Forum ModeratorAt 23C I think you need around 10g water per kg air to get 60% RH (I Googled RH calculator). You may want to double check the volume fraction of vapour on the inlet. What is the operating pressure?

December 9, 2021 at 3:21 pmdzaki8598

SubscriberHello, Rob. Thank you so much for your reply.

Sorry, so to clarify, the unit of the mass fraction of ANSYS FLUENT is actually gram water per kg air? If so, then I must've made a mistake because I inputted it as kg water per kg dry air.

And I'm sorry, can you clarify about the volume fraction of vapor? Are you referring to the mass fraction of water at the inlet? because I haven't seen settings for the volume fraction.

My operating pressure is 101325 Pascals (by default settings I haven't changed it.)

And lastly, can you tell me what is wrong about the plot of the RH? Because shouldn't it be constant at a value?

Regards

December 9, 2021 at 3:54 pmRob

Forum ModeratorMass fraction is kg/kg Without seeing a convergence plot I can't comment on the RH plot, what is the time step as the curve seems quite facetted.

December 9, 2021 at 6:03 pmAmine Ben Hadj Ali

Ansys EmployeeWrite couple of expressions to deduce required mass fraction from RH input

December 9, 2021 at 6:21 pmDecember 10, 2021 at 11:12 amAmine Ben Hadj Ali

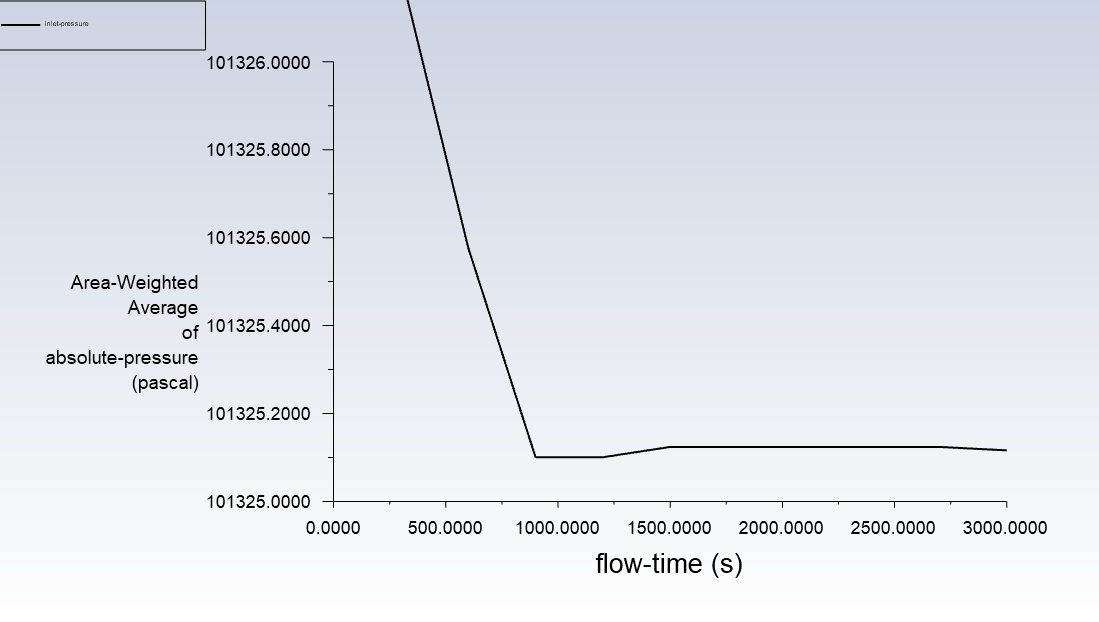

Ansys EmployeeCan you add the area ave of the pressure at your inlet and the temperature? These two will affect the link between RH and Mass Fraction.

I will go for lowering the continuity residual be at least 2 or 3 levels of magnitude. If you now just plot the last 40 iterations you will that you are not converging every time step (especially the turb equations). You should also monitor your reports vs iterations so that you can inspect if the monitors are not changing towards the end of the time step.

December 10, 2021 at 11:50 amdzaki8598

SubscriberHello drAmine, seems like I've found a strange problem.

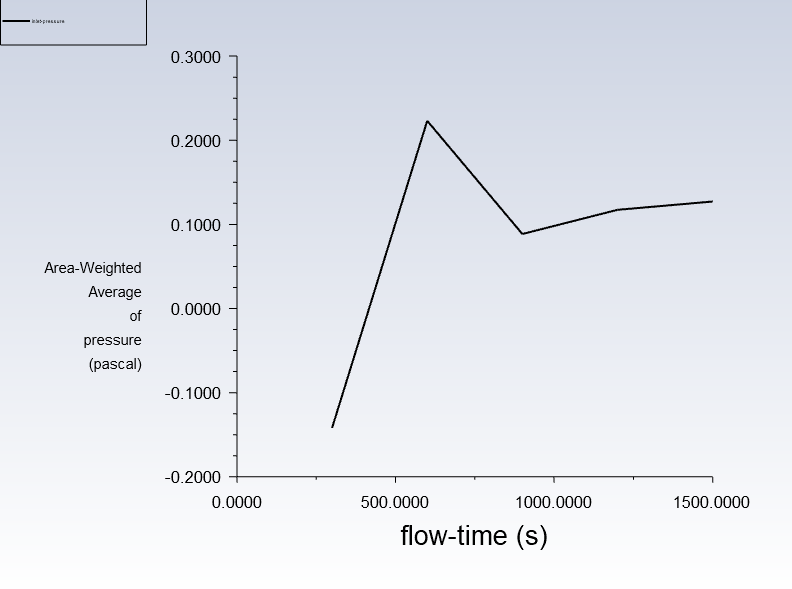

This is the area ave of pressure at the inlet.

I stopped the simulation at that time, since I know the pressure should be constant (with constant velocity inlet), am I correct?

I stopped the simulation at that time, since I know the pressure should be constant (with constant velocity inlet), am I correct?

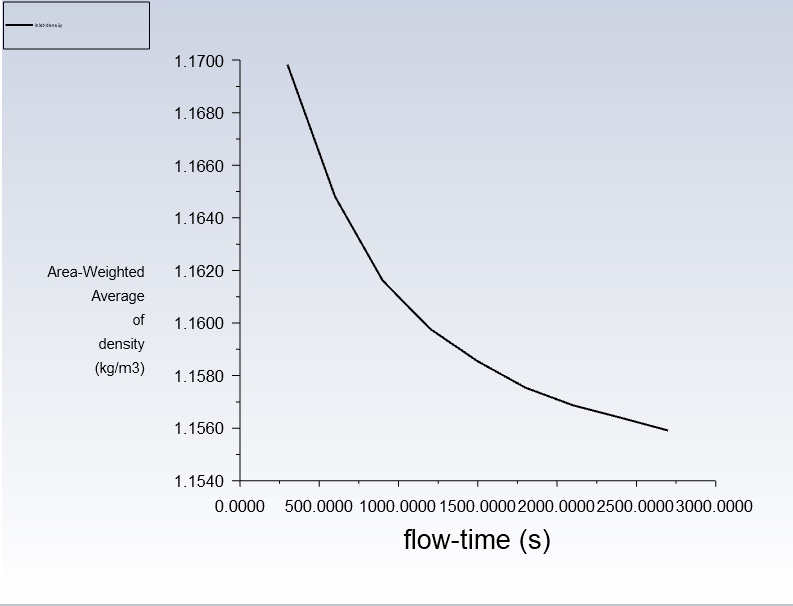

Also, the ave area of inlet density looks like this. It should be constant, right?

(EDIT: I have just found out that the static pressure read in the plot is actually gage pressure).

And I have noticed, that the trendline of the RH is very similar to the trendline of density. So I'm thinking that the density is may be the one that causes the problem?

As for the remainder of DrAmine's reply, I will try to monitor the plot vs iterations. And I would like to ask, so this whole time my results have never converged? I have set the convergence conditions to be timestep convergence.

I also have noticed below that the pressure takes quite amount of time steps to reach a constant value, does this mean the initial timesteps does not give the correct value and should be "sacrificed" ?

December 10, 2021 at 12:08 pmAmine Ben Hadj Ali

Ansys EmployeeOkay so the RH reported by Fluent will depend on that value of pressure and temperature. For that reason I recommend writing a couple of expressions which will translate your RH input into mass fraction given the absolute pressure at the inlet.

Viewing 8 reply threads- The topic ‘Relative Humidity Shows Incorrect Value’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4607

-

1510

-

1386

-

1209

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.