-

-

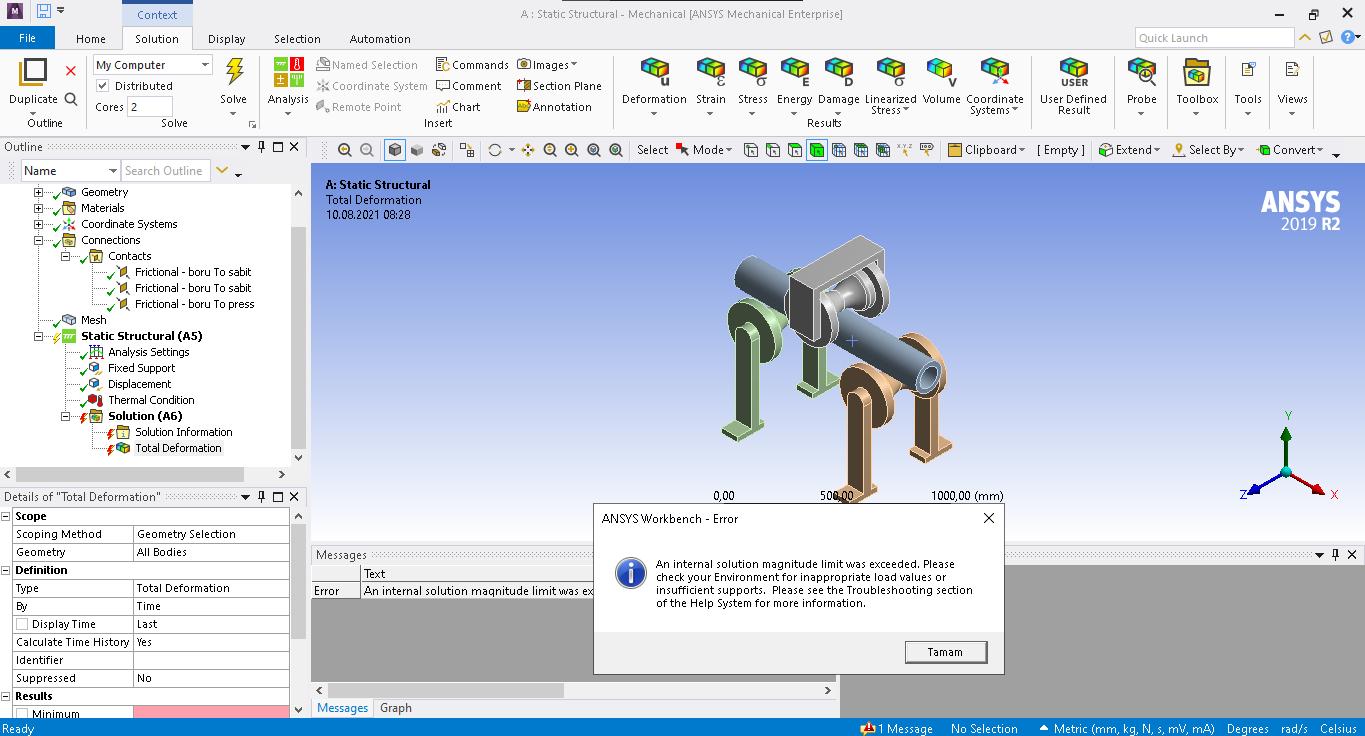

August 10, 2021 at 5:14 am

sonerulger

SubscriberAugust 10, 2021 at 6:45 amsonerulger

SubscriberBy the way I tried every way to solve that I mean I read the discussions in forum which about the same problem but I couldn't solve that error.

August 10, 2021 at 7:14 amAugust 10, 2021 at 1:30 pmpeteroznewman

SubscriberI recommend you take advantage of symmetry to cut your model size in half. Put a vertical plane through the axis of the center roller and cut all the geometry in half and delete or suppress half the bodies.

Apply a symmetry boundary condition on every cut face, which is a Displacement of X=0. This immediately makes the problem more likely to solve because you have controlled 3 out of 6 Degrees of Freedom of the pipe. The cut face can't leave that plane.

You could also repeat that with a vertical plane along the axis of the pipe. Cut everything left in half again and delete another half so you have a quarter model. This now removes more DOF from the pipe and the only freedom left on the vertical line of nodes at the intersection of the two planes is vertical. Note that you have to apply Z = 0 to all the newly cut faces.

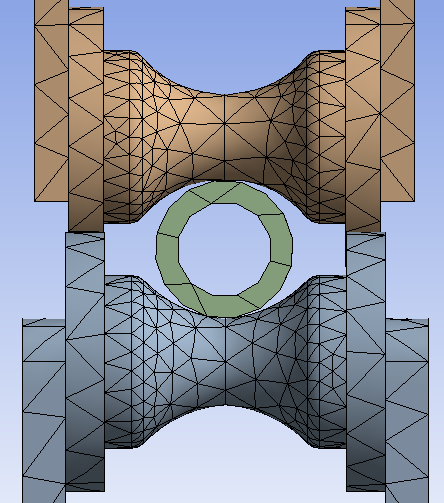

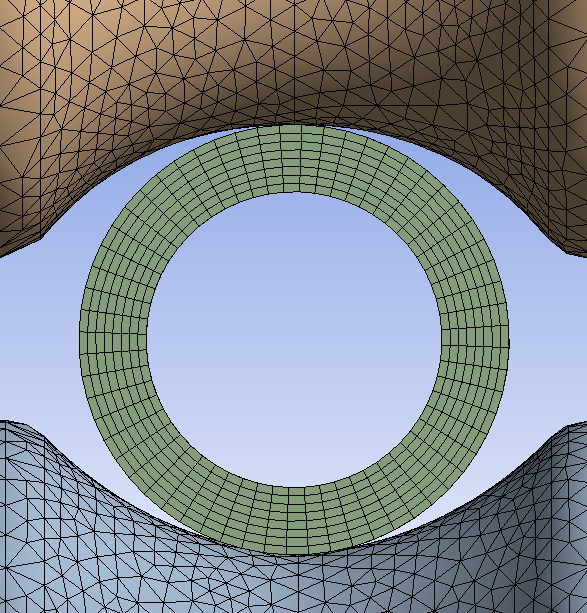

When you mesh the pipe, you need at least 8 linear elements through the thickness. You have one.

You want to set the rollers to Rigid so you don't fill them with elements, you just mesh the surfaces that make contact.

You want to set the rollers to Rigid so you don't fill them with elements, you just mesh the surfaces that make contact.

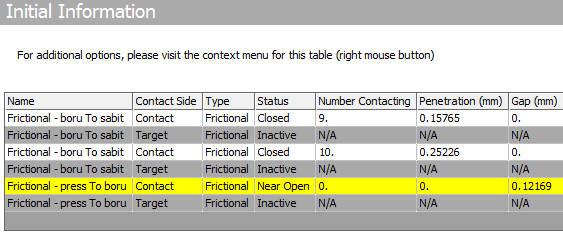

Whenever you do Frictional Contact, you must insert a Contact Tool and make sure all the contacts are closed. In the example below, this will fail to solve.

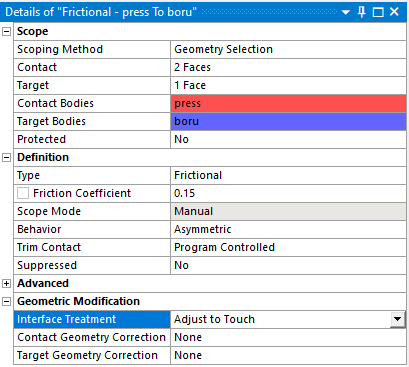

The corrective action is to change the Interface Treatment to Adjust to Touch.

The corrective action is to change the Interface Treatment to Adjust to Touch.

August 11, 2021 at 10:38 am

August 11, 2021 at 10:38 amsonerulger

SubscriberDear Mr. Newman

I changed the design completely. Also revised the parameters as you said. As soon as I get some results, I will leave comment here. Thank you.

Regards.

August 11, 2021 at 11:22 amsonerulger

SubscriberDear Mr. Newman

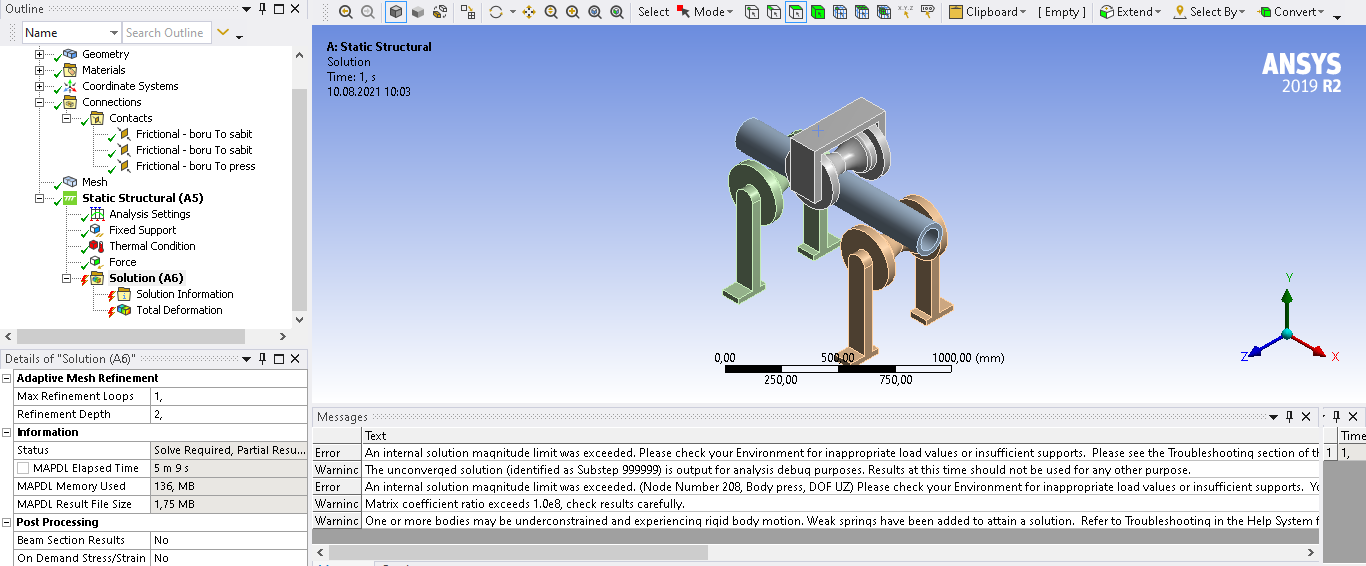

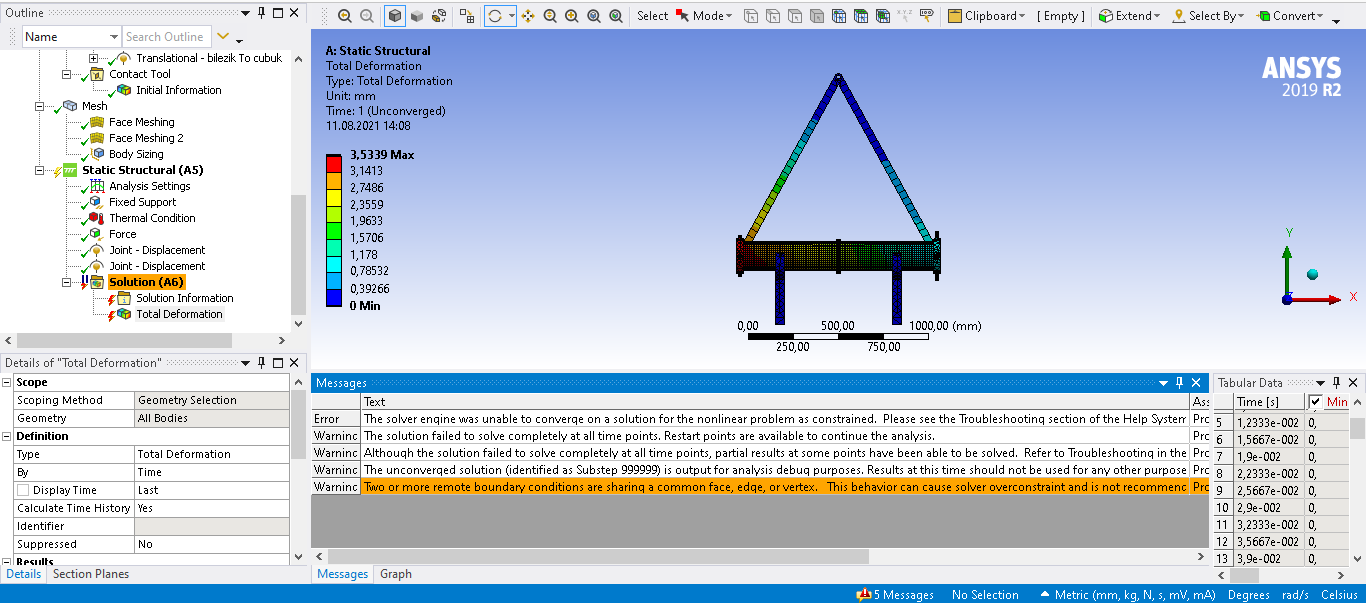

Unfortuntely I got the same error again. I tried to make more basic the design. I need to see the all results of the pipe so I can't seperate the design. But I checked contacts via contact tool to make sure all the contacts are closed as you said. Also I added two rings to the pipe outlets. And added bars to those rings so I can remove them when the end of the process. But as you see I got errors again. This time there is no deformation on the plastic pipe. When you have time maybe you want to look at it. Thank you.

Regards.

Viewing 5 reply threads- The topic ‘Error: An internal solution magnitude limit was exceeded’ is closed to new replies.

Ansys Innovation SpaceTrending discussions- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- How to model a bimodular material in Mechanical

- Meaning of the error

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

Top Contributors-

3882

-

1414

-

1241

-

1118

-

1015

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.