TAGGED: dpm, fluid-flow, multiphase

-

-

June 4, 2021 at 6:49 pm

pun2000

SubscriberHi all i been really struggling to find the droplet of oil and water. I have been using dpm method. Can any one please help me on how can i find the droplet distribution of multiphase oil and water.

i am happy to discuss please.

June 5, 2021 at 7:25 amAmine Ben Hadj Ali

Ansys EmployeeAdd more details as your description is not clear.

June 7, 2021 at 11:14 ampun2000

SubscriberHi everyone,

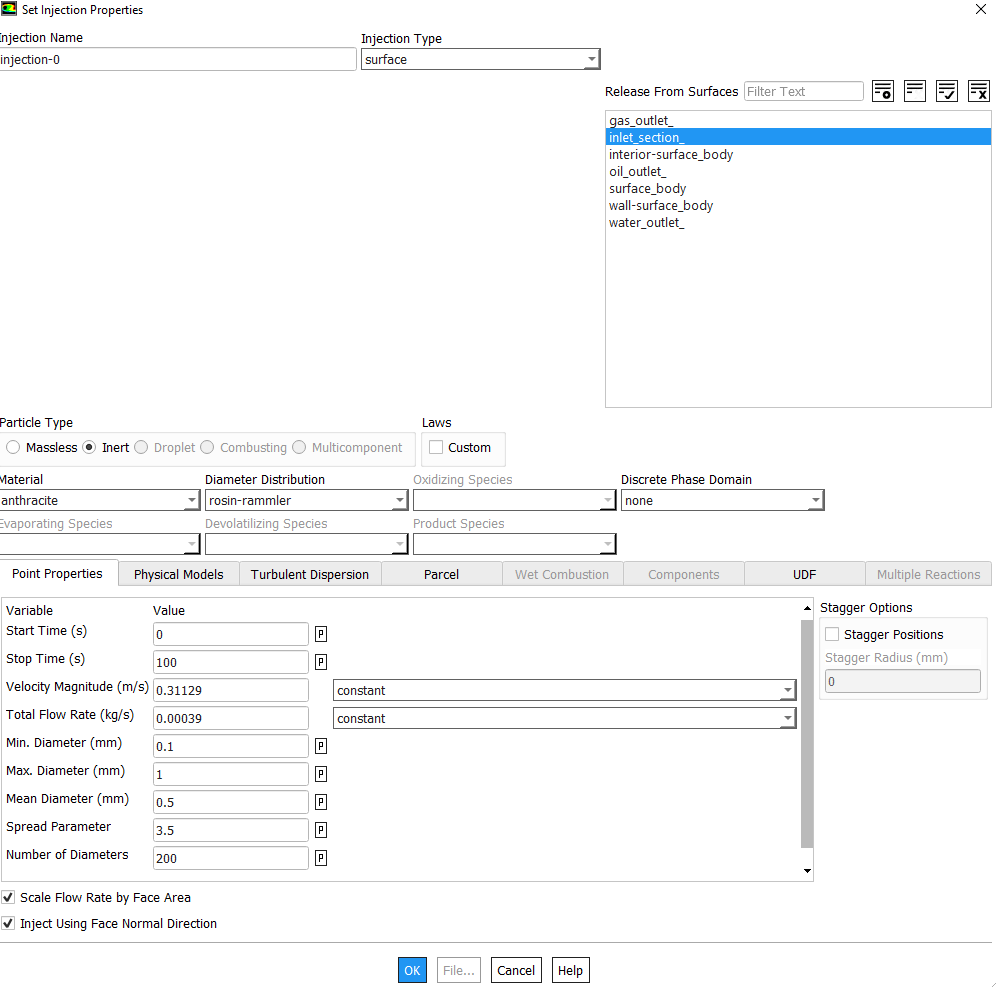

I am using a 2D three-phase model to see the droplet size of oil and water from the inlet section of the separator, with a velocity of 0.31127 m/s for oil and water. Before I simulate with VOF with the k-e model, I use DPM to find the particle where I inject the anthracite with a maximum bubble droplet of 1000 micron, with the minimum droplet size of 100 microns is 500 micron. I may be wrong in injecting the anthracite. Do I have to inject the kerosene or water?

But while I export the result in excel, I found that all value is the same with the average droplet size of 160micron.

Can anyone export please help me to guide the process where I am wrong. I want to find the droplet distribution of water and oil from the inlet section of the separator.

June 7, 2021 at 12:24 pmAmine Ben Hadj Ali

Ansys EmployeeI still do not understand: What are you trying to model? Which Fluid are you injecting?

June 7, 2021 at 1:10 pmpun2000

SubscriberThank you dr amine, for your reply. I try to find the oil and water bubble distribution. I am using water as the primary phase, and oil will inject from the inlet of the two-phase separator.

June 7, 2021 at 1:55 pmRob

Forum ModeratorWhat is the anthracite for?

June 7, 2021 at 5:32 pmpun2000

SubscriberAnthracite is used To inject the particle.

June 7, 2021 at 5:36 pmpun2000

SubscriberFor oil and water how can i get the droplet distribution ? Or Do i have to inject the kerosene from dpm and use water as primary phase ?

plz i am new to ansys so please any suggest will be helpfull to me.

thanksJune 7, 2021 at 7:03 pmAmine Ben Hadj Ali

Ansys EmployeeSo you want to inject oil and anthracite? Can explain the application?

June 7, 2021 at 7:21 pmpun2000

SubscriberI dont have no idea at the moment i just try with water as primary phase and oil as secondary phase and inject anthracite but i want to inject oil and use water as primary phase. If i apply can i get the oil and water distribution? Sound may be stupid but im new so please forgive me. If you can plz suggest me drJune 7, 2021 at 7:22 pmAmine Ben Hadj Ali

Ansys EmployeeWhy anthracite? Why?

June 8, 2021 at 5:22 ampun2000

SubscriberI have seen most of people have use this materials ? But i dont know why ?

June 8, 2021 at 9:40 amRob

Forum ModeratorAnthracite is the default material as it was added when Fluent DPM was developed to burn coal.

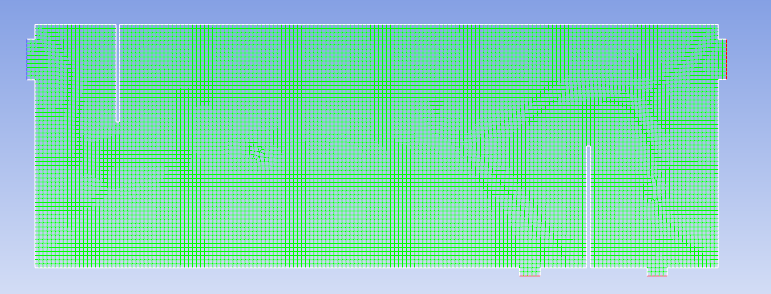

Take a large step away from the computer. Get a sheet of paper and sketch out the geometry you want to model. Add any boundary information you have (inlet, outlet etc) and calculate the Reynolds Number. Post that image on here, and we'll be able to offer advice. Use engineering terms, don't worry about the CFD part. At the moment, you're asking the wrong questions, and it's difficult to help as we're not sure what you are trying to model.

One of the steps to learning to use CFD is to fully understand the physics of the application. Then you can figure out what models are suitable, and even whether you need to use CFD. We often work through problems by sketching out the system and applying a bit of experience. Only then do we switch on the software.

June 8, 2021 at 11:11 amAmine Ben Hadj Ali

Ansys EmployeeI like Rob's post.

June 8, 2021 at 12:03 pmJune 8, 2021 at 1:47 pmRob

Forum ModeratorOil volume fraction? If you have a weir like that is this a 2 or 3 phase separator?

June 8, 2021 at 2:02 pmpun2000

SubscriberAt the moment using this for 2 phase separator only for oil and water with the volume of fraction of .50 and 0.50. BUT in my future I will be using this for three phase with air. I just want to find the droplet distribution for oil and water in the inlet section of the separator.

Thank you so muchJune 8, 2021 at 2:58 pmAmine Ben Hadj Ali

Ansys EmployeeRun standard SST as turbulence model , use Eulerian Multiphase with oil being the secondary phase. With Eulerian you can choose MultiVOF, leave default diameter for the secondary phase: Use that enable Sharp/dispersed use Compressive for VOF Fraction Discretization. I think first of all as beginner you might need to read documentation and some text book and carry out some tutorials.

If you have less volume loading for oil or water one can think about using other models. But for now a "generalized" approach is best.

June 8, 2021 at 3:19 pmpun2000

SubscriberThank you for your suggest but how can I can find the bubble droplet distribution If i default diameter for secondary phase . I am trying to find the droplet distribution. I have read so many literature on Vof-Dpm but they didn't explain about how they find the distribution of oil and water.

i want to know do i have to inject oil from DPM ?

Shall i use water as primary phase and can i inject oil from dpm?

thanks

June 8, 2021 at 3:23 pmAmine Ben Hadj Ali

Ansys EmployeeYou are injecting oil and water from the same inlet using equal volume fraction: Which of the phase is meant to have the continuous morphology? (Forget please for now about VOFtoDPM).

June 8, 2021 at 3:44 pmpun2000

SubscriberFor the real time both oil and water is used as continuous morphology in real experiment.

i will explain the real time experiment here.

At first water is put in separator with the help of pump and after minute oil is also pump into the separator. when pumping the water and oil lots of small and big bubble are form in the separator. which make lots of different in separation efficiency. this reason why i want to find the droplet distribution of water and oil.

i also attached the youtube video hopefully it will make you more understand.

3 Phase Separator/3PS Demonstration - YouTube

if you have any suggestion it will help me and save my time.

Thanks

June 8, 2021 at 3:55 pmRob

Forum ModeratorThese types of unit don't work well with mixes like that as the weir won't split the phases. Weir based units are generally used with baffles and roughly even gas - liquid mixes with some oil and sand. To look at size separation I'd use multifluid VOF and DPM but be very careful with how I set up and interpreted the results.

From the video, the mixing and bubble/droplet creation is a function of the pump, so you know what sizes to start with. Read up on the Population Balance Model too, but I suggest you start with a very careful think about what you want to see, and how these devices work.

June 8, 2021 at 7:22 pmAmine Ben Hadj Ali

Ansys EmployeeStill recommending multivof in Eulerian. The diameter is just for interfacial momentum. Post processing is used then for psd.

Another way will be using mvof plus population balance or directly deploying GENTOP which includes all of these different modeling strategies.

I recommend to start conservative.

June 9, 2021 at 1:48 pmpun2000

Subscriberthats mean you said to try with vof-dpm. I have already gather the droplet distribution from the separator. I just want to compare result with cfd.

i know how the separator work and this bubble are not created by pump.

i just want to know what kind of method i can implement to compare with my result.

i have try with population balance model and different bins but it takes me lots of time.

thanks for your reply but i didn't get what i want from you.

June 9, 2021 at 1:51 pmpun2000

Subscriberthank you sir for this i will give try. For vof-dpm shall i turn the dpm on ?

i will send you the boundary conditions when i do this. Plz help me to find droplet distribution. Please.

thanks

June 9, 2021 at 2:58 pmAmine Ben Hadj Ali

Ansys EmployeeYes otherwise it won't be called vof-to-dpm :)

I do not think VOFtoDPM is the way to go here at least not for this set of boundary conditions.

June 9, 2021 at 3:27 pmpun2000

Subscriberi cant understand VOF to DPM is the way to go here at least not for this set of boundary conditions ? can you please explain please.

thanks

June 9, 2021 at 3:57 pmRob

Forum ModeratorVOF to DPM is best used when you want to track and see the dispersed phase: atomisation is a good example. In your case you have a mixed flow (we don't know how mixed and you need to define that) which then separates. Using multi-fluid VOF with a reasonable droplet or bubble size will set up the bulk flow. You can then use DPM to see what the separation efficiency is. However, you also need to understand the limitations of this approach.

Otherwise you need PBM and/or GENTOP to sort this out which will be a big compute run. and I have a lot experience in this field, and we approach these problems very carefully as the methodology used depends on a very large number of factors. The runs can also take a fair amount of time or require large amounts of compute. There's a reason a multiphase problem was used for this https://www.ansys.com/news-center/press-releases/07-18-17-ansys-saudi-aramco-kaust-shatter-supercomputing-record

June 9, 2021 at 4:44 pmpun2000

Subscriberi will just try with vof-dpm approach at first this make me little more confidence from your experience and most of researcher use this approach in literature. I will try with this and l definitely put here if I found any result, or any suggest from you will help me.

Thats mean i dont have to activate dpm injection parts in my experiment ? shall i use water as primary and oil as dpm ?

thanks once again.

June 9, 2021 at 6:15 pmAmine Ben Hadj Ali

Ansys EmployeeDpm stands for discrete phase model and is based on Lagrangian Particle Tracking.

So either you start now reading the documentation and doing some exercises to know the definitions and terminologies we are referring or ask your Prof for help.

We recommended from start to rely on the Eulerian MultiVof approach. Try to start simple and add complexities as you gain more experience and confidence.

June 10, 2021 at 9:31 ampun2000

Subscriberthank you i will do this i will start with simple one.

thanks

June 10, 2021 at 1:07 pmAmine Ben Hadj Ali

Ansys EmployeeGreat!

Viewing 31 reply threads- The topic ‘Droplet size distribution’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4678

-

1565

-

1386

-

1242

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-