![]() This learning track covers the comprehensive understanding of Metal Additive Manufacturing (AM), starting from its fundamentals to its application in various sectors. It delves into the significance of manufacturing in the economy, the emergence of additive manufacturing processes, and the shift from mass production to mass customization. The track explores the integral role of Computer-Aided Design (CAD) in additive manufacturing, reducing product lifecycle time significantly. It provides a comprehensive understanding of lasers and their application in metal additive manufacturing. The track also covers the in-depth exploration of the electron beam process and the powder feeding mechanism. It provides a comprehensive understanding of Design for Additive Manufacturing (DfAM), its basic principles, techniques, and application fields. The track also covers the integration of industry 4.0 and IoT in these processes, and the role of on-machine sensing in monitoring and controlling the manufacturing process. It covers the process of fabricating metal matrix composites through additive manufacturing. The track provides a comprehensive understanding of reverse engineering in the context of metal additive manufacturing. It covers the fundamentals of Computer-Aided Design (CAD) and topology optimization, with a special focus on Solidworks software. The track explores the significance of fulfilling the current generation's needs without jeopardizing future generations' necessities in the context of sustainability in metal additive manufacturing. Lastly, it covers the comprehensive aspects of safety measures, hazards, and costing in metal additive manufacturing.

This learning track covers the comprehensive understanding of Metal Additive Manufacturing (AM), starting from its fundamentals to its application in various sectors. It delves into the significance of manufacturing in the economy, the emergence of additive manufacturing processes, and the shift from mass production to mass customization. The track explores the integral role of Computer-Aided Design (CAD) in additive manufacturing, reducing product lifecycle time significantly. It provides a comprehensive understanding of lasers and their application in metal additive manufacturing. The track also covers the in-depth exploration of the electron beam process and the powder feeding mechanism. It provides a comprehensive understanding of Design for Additive Manufacturing (DfAM), its basic principles, techniques, and application fields. The track also covers the integration of industry 4.0 and IoT in these processes, and the role of on-machine sensing in monitoring and controlling the manufacturing process. It covers the process of fabricating metal matrix composites through additive manufacturing. The track provides a comprehensive understanding of reverse engineering in the context of metal additive manufacturing. It covers the fundamentals of Computer-Aided Design (CAD) and topology optimization, with a special focus on Solidworks software. The track explores the significance of fulfilling the current generation's needs without jeopardizing future generations' necessities in the context of sustainability in metal additive manufacturing. Lastly, it covers the comprehensive aspects of safety measures, hazards, and costing in metal additive manufacturing.

These courses have been developed by Prof. Janakranjan Ramkumar, Prof. Amandeep Singh Oberoi from IIT Kanpur for NPTEL. It is now accessible through Ansys Innovation Space courtesy of the partnership between Ansys and NPTEL, under the CC BY-SA license. For more details, visit https://nptel.ac.in/courses/112104312.

Innovation Course

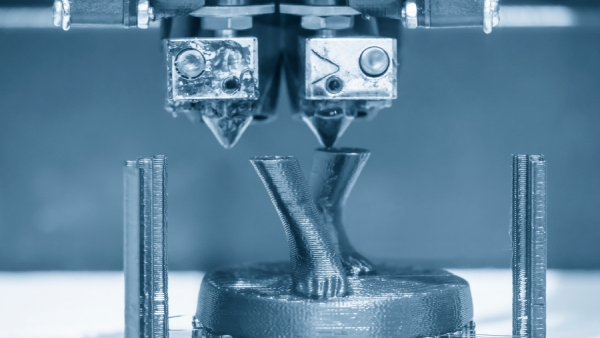

Metal Additive Manufacturing Basics

This course covers the fundamental aspects of Metal Additive Manufacturing, designed to cater to students and professionals from diverse fields. It starts with an introduction to the course and its relevance to various sectors like research, defense, and indust...Read more

Innovation Course

CAD in Additive Manufacturing

This course covers the integral role of Computer-Aided Design (CAD) in additive manufacturing, a technique that significantly reduces product lifecycle time. It explores the importance of CAD in rapid prototyping, discussing topics such as the printing process, CAD f...Read more

Innovation Course

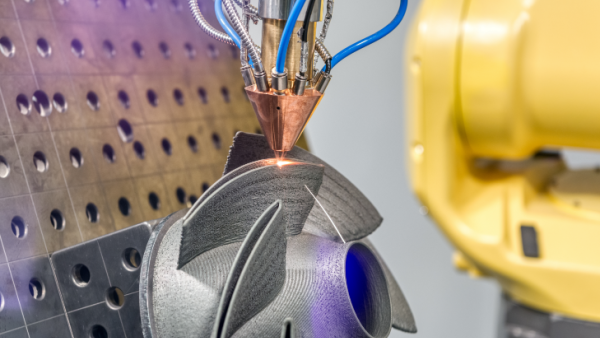

Lasers in Metal Additive Manufacturing

This course covers the comprehensive understanding of lasers and their application in metal additive manufacturing. It starts with the basics of lasers, their types, and properties, and how they are used in different methods of metal additive manufacturing s...Read more

Innovation Course

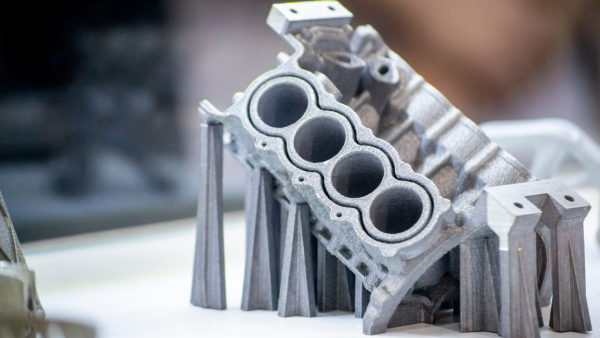

Understanding Metal Additive Manufacturing Processes

This course covers the comprehensive aspects of Metal Additive Manufacturing processes. It starts with an in-depth exploration of the electron beam process and the powder feeding mechanism, highlighting the challenges of handling metal powders ...Read more

Innovation Course

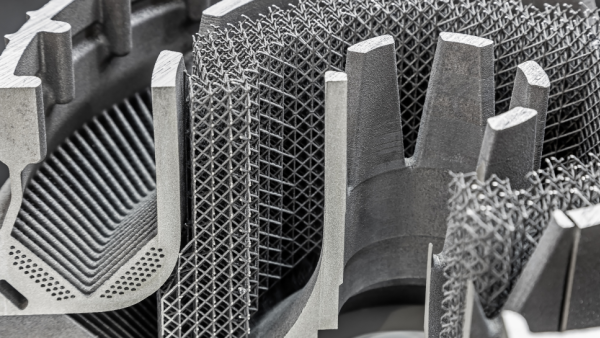

Understanding Metal Additive Manufacturing Techniques

This course covers the comprehensive aspects of Metal Additive Manufacturing (AM), with a focus on the powder bed fusion method. It explores the influence of different process parameters on the machine's output and the properties of the powder...Read more

Innovation Course

Design for Additive Manufacturing Essentials

This course covers the comprehensive understanding of Design for Additive Manufacturing (DfAM). It starts with the basic principles and techniques of DfAM, moving towards its application fields and steps involved. The course provides an in-depth unders...Read more

Innovation Course

Industrial Integration of Metal Additive Manufacturing Processes

This course covers the comprehensive understanding of metal additive manufacturing processes. It provides an in-depth look at the integration of industry 4.0 and IoT in these processes, and the role of on-machine sensing in monitori...Read more

Innovation Course

Additive Manufacturing of Metal Matrix Composites

This course covers the comprehensive process of fabricating metal matrix composites through additive manufacturing. It provides an in-depth understanding of conventional manufacturing techniques, the preparation of composite materials, and the fac...Read more

Innovation Course

Reverse Engineering in Metal Additive Manufacturing

This course covers the comprehensive understanding of reverse engineering in the context of metal additive manufacturing. It provides a deep dive into the various technologies and processes used in additive manufacturing of metals, including sol...Read more

Innovation Course

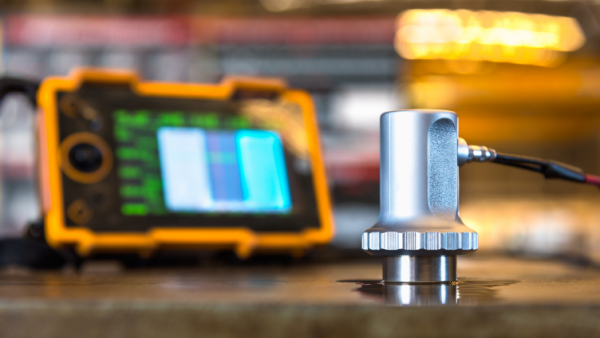

CAD, Topology Optimization and Non-Destructive Testing

This course covers the fundamentals of Computer-Aided Design (CAD) and topology optimization, with a special focus on Solidworks software. It provides a comprehensive understanding of various CAD software available in the market, their unique ...Read more

Innovation Course

Sustainability in Metal Additive Manufacturing

This course covers the comprehensive understanding of sustainability in metal additive manufacturing. It explores the significance of fulfilling the current generation's needs without jeopardizing future generations' necessities. For instance, the co...Read more

Innovation Course

Understanding Costing and Safety in Metal Additive Manufacturing

This course covers the comprehensive aspects of safety measures, hazards, and costing in metal additive manufacturing. It begins with an exploration of potential risks such as high energy density sources, high voltage sources, chemi...Read more

There is no badge available for this learning track.

Please visit Guided Learning Paths to browse through our selection of other learning tracks.