Boost Sustainability Through Material Intelligence and a Digital Thread

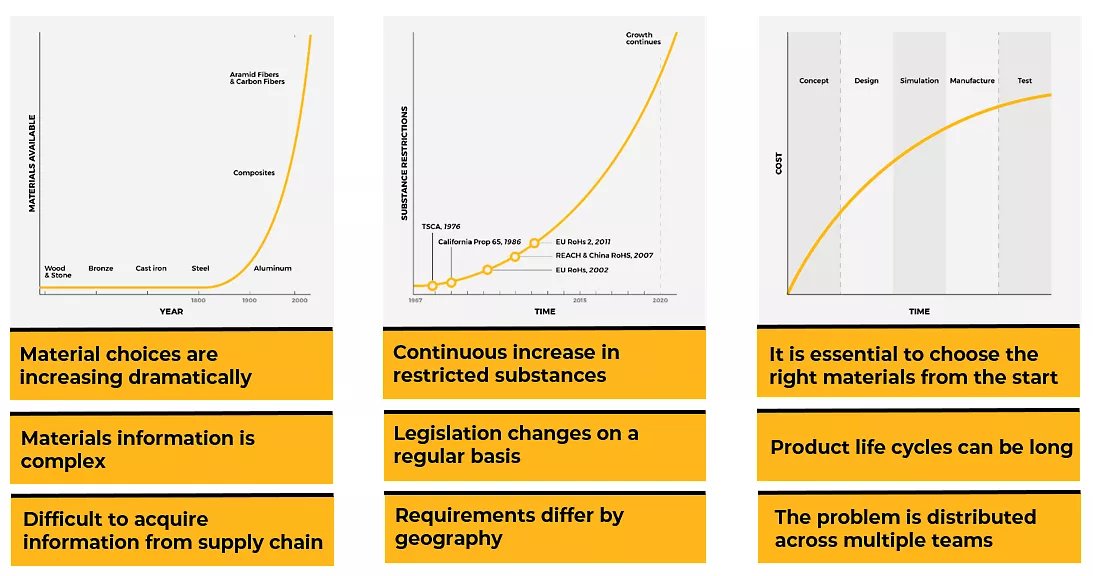

With sustainability concerns impacting industries around the world and demands to meet more rigorous environmental standards, material intelligence is more important than ever. What is material intelligence? In simple terms, it is the data, information and context for the materials being used across a business. This could include information about the properties of materials, including physical, chemical, or mechanical components, or details on the materials testing program. This intelligence enables organizations to understand and select the most suitable, functional, and environmentally compliant materials for their needs. With this knowledge, companies can select more eco-friendly materials, and, in some cases, reduce material usage by making better choices.

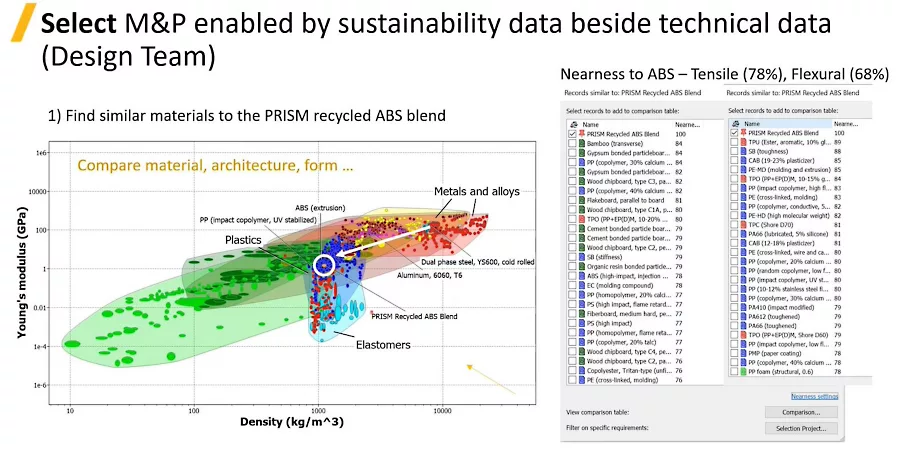

Turning Recycling Waste Into Automotive Components Using Simulation

Plastics are everywhere, including places we would rather not see them — like our oceans. According to National Geographic, “Every year, about 8 million tons of plastic waste escapes into the oceans from coastal nations. That’s the equivalent of setting five garbage bags full of trash on every foot of coastline around the world.”1 Recycling is an obvious solution, but most of us have a naïve understanding of recycling. You may think that plastics, for instance, arrive at a recycling center ready to be melted down and formed into new raw materials, which can then be used to make new plastic components. In reality, there is a lot of sorting and chopping involved to make the plastic pieces small enough to flow in a mixer, and there are chemical additives used as binders or flow enablers to enhance the properties of the resulting material.

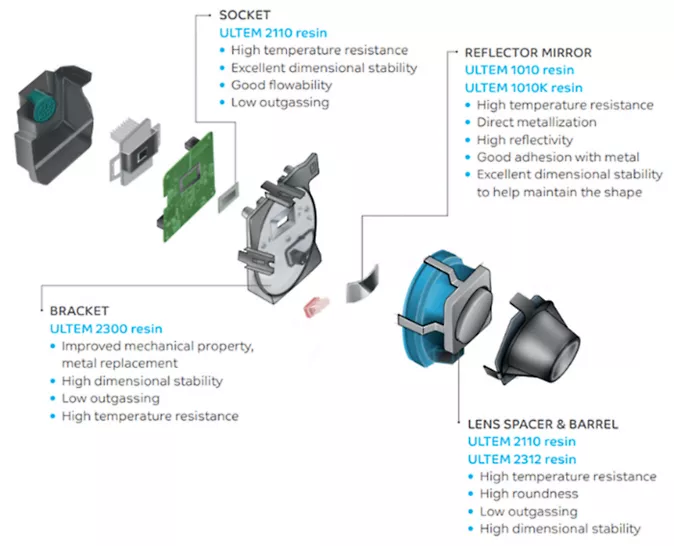

Lighting the Path Ahead with New Materials

Finding cleaner and smarter materials for automotive headlight design has never been easier. With Ansys Granta MI materials data management software, you have access to comprehensive data, such as MaterialUniverse™ dataset, which includes technical, economic, and environmental materials for thousands of engineering materials, and the advanced Global Polymers library with in-depth information on over 100,000 polymer grades, including polymers from SABIC. SABIC is a leading petrochemicals manufacturer globally which creates high-performance polymers that are well-equipped for headlamp applications. By using Granta and Ansys multiphysics simulation tools, material selection is seamless throughout the design process for automotive projects and more. SABIC produces a wide range of materials solutions, including ULTEM™ resin family of high heat solutions, LNP™ compounds and PC Copolymer resins, NORYL™ resins, etc. The data for these materials is available in the materials libraries of Granta MI Enterprise and Ansys Granta Selector, and can be easily exported into a wide range of Ansys simulation platforms.

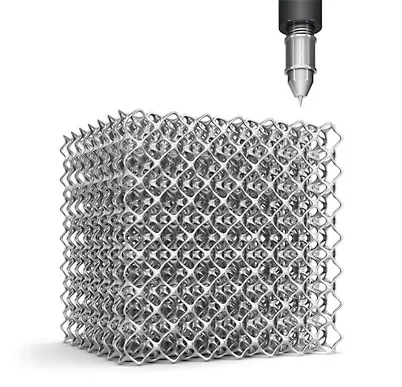

Selecting the Right Materials for Aerospace Additive Manufacturing

Additive manufacturing has become a popular tool to produce limited runs and complex parts. While this technique was originally used with polymers, material compatibility has expanded to metals, fibers and even biological matter. This increase of material options has led to additive manufacturing becoming popular in many industries. For instance, metal printing has caught the eye of many in the aerospace industry. Aerospace engineers design solutions that need to work in extreme environments — from the weather experienced by an airplane to the vacuum experienced by space vehicles.