-

-

August 1, 2024 at 12:59 pm

1617836513

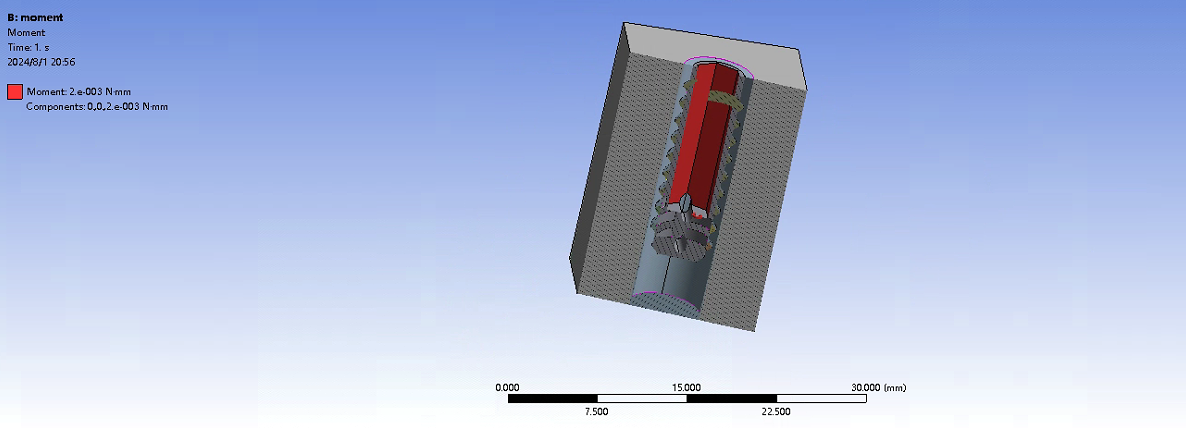

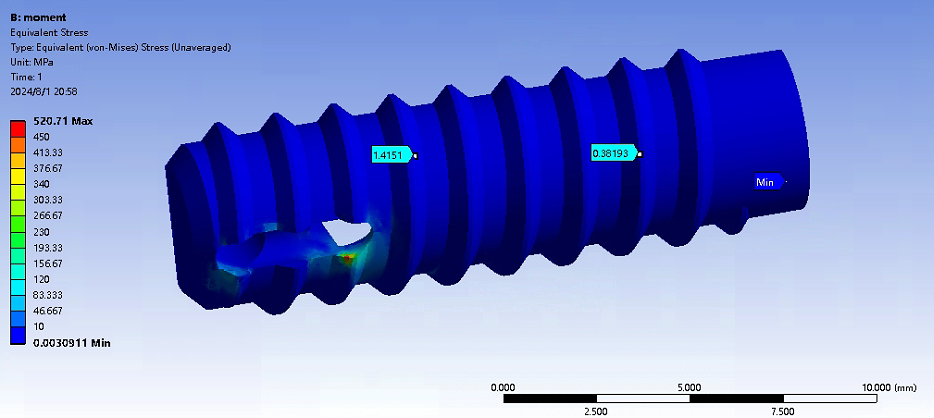

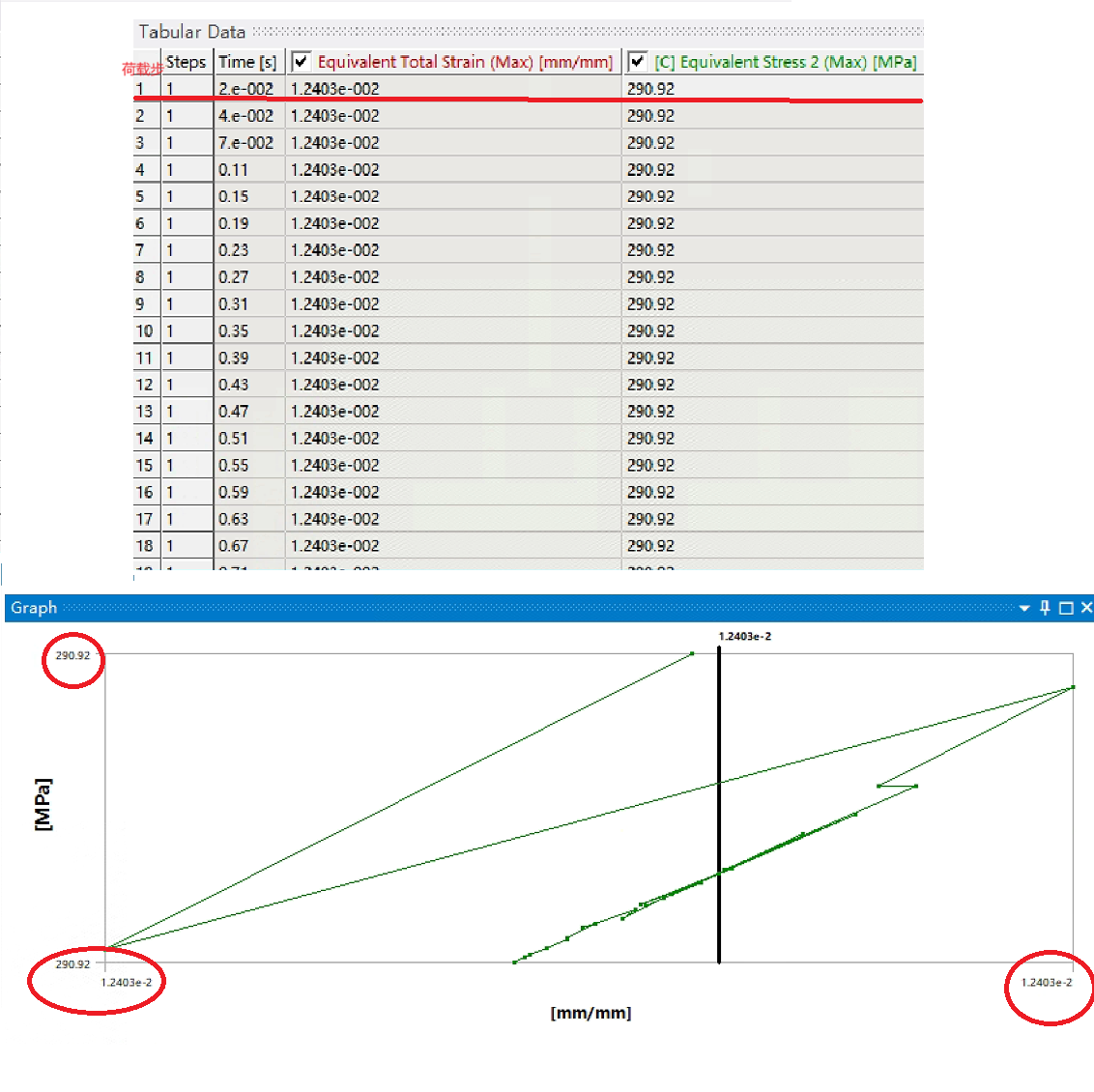

SubscriberI added a torque of 0.002N/mm to the inner six surfaces of the screw that holds the bottom of the square. Why the stress on the threads is only 1 or 2 MPa and 600 MPa near the round hole, what is wrong with this? I selected some points and found that its stress and strain stabilized at the first step of loading and no longer varied with time later, so that the stress-strain curve is drawn as a single point, which is not logical. May I ask why this is so? -

August 1, 2024 at 5:15 pm

Armin

Ansys EmployeeHi Ji,

What is the contact behavior defined between the screw and the block? Is it frictional contact? To me, it looks like that contact occurs at the edge of the hole and it acts as a stress concentrator. That may explain the significantly large stresses you observe at this location. Please consider watching the video below where the topics of artificially large stresses and how to deal with them are discussed.

Understanding and Dealing with Artificially High Stresses — Lesson 3 - ANSYS Innovation Courses-

August 2, 2024 at 5:35 am

1617836513

SubscriberYes, it's frictional contact, what I don't understand is why the stress on the threads is so low, aren't they likely to have stress concentrations as well? And why don't the stresses and strains change as the load step advances?

-

-

August 2, 2024 at 1:43 pm

Armin

Ansys EmployeeThanks Jin. I think the source of stress concentration is the hole. To verify, you can run a model without the hole to compare the results. You can also make a trial run with bonded contact behavior to evaluate the results for a case when all regions of the screw surface are contributing to load transfer.

-

- You must be logged in to reply to this topic.

-

4628

-

1535

-

1386

-

1215

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.