TAGGED: 2D, elastic, plane-stress, static-pressure, static-structural

-

-

March 21, 2022 at 11:12 am

Puhan

SubscriberDear All

I hope you are doing well.

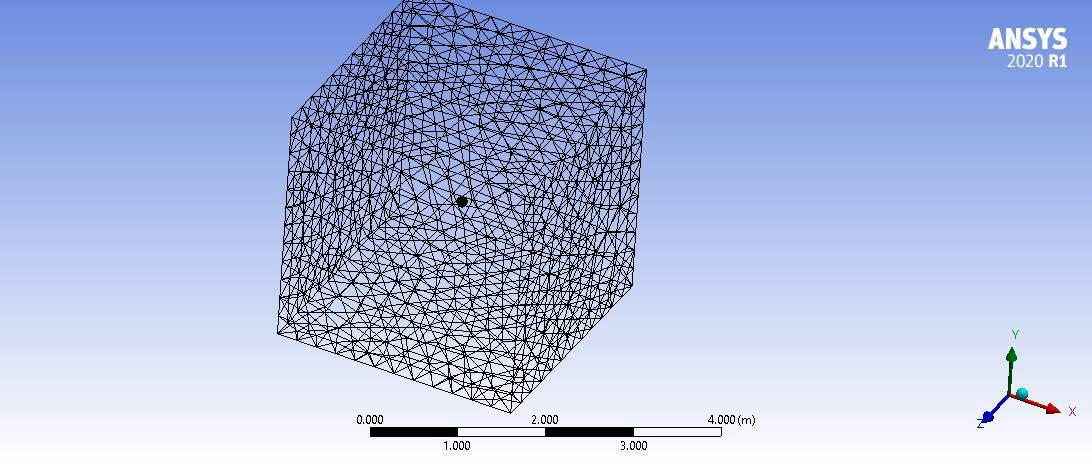

I am having an issue. I was doing an elastic simulation of a system where an inclusion (small object) inside the host (big object) exists as follows with their respective properties.

March 21, 2022 at 11:47 ampeteroznewman

SubscriberAn Axisymmetric model is more likely to give you results similar to a 3D model. They can both simulate a sphere.

A 2D Plane Strain model simulates a long rod, which is a very different shape to a sphere.

March 21, 2022 at 1:03 pmPuhan

SubscriberDear

Thank you very much for the reply.

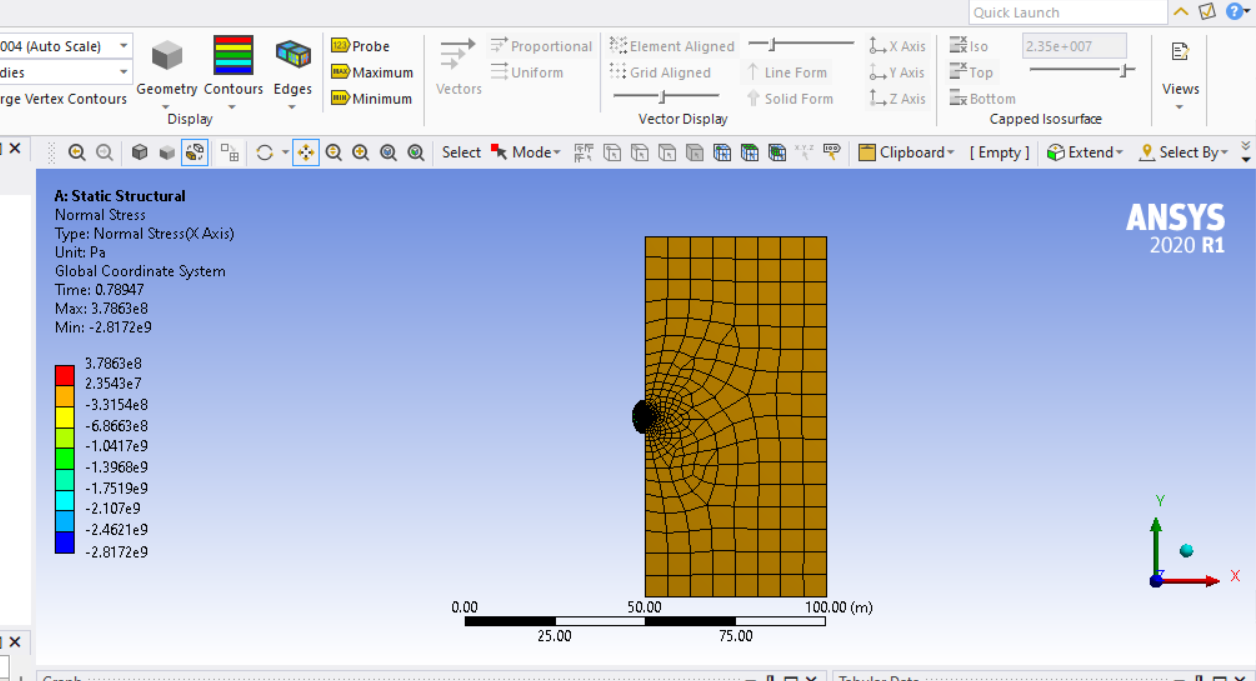

Actually, it was a plane stress model, in-plane strain I am getting even worse results.

According to your recommendation, I did also an Axisymmetric one, but the issue with that is boundary conditions that are not symmetric. I am not sure where to put the Boundary conditions

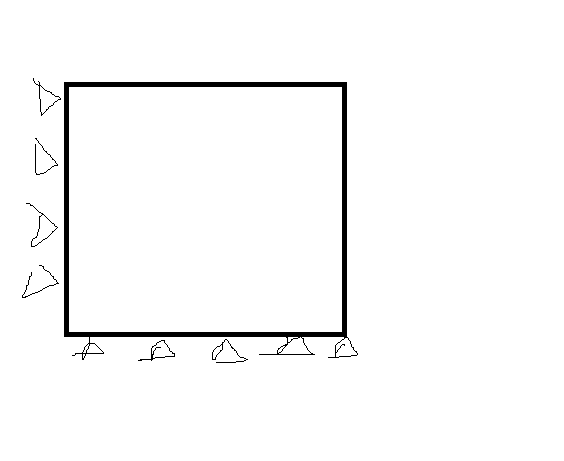

Previously in the 2D model, the BCs were as follows, just displacements zeros in x and y directions.

How to replicate that in the axisymmetric model? Can you please let me know, I am first time doing it?

How to replicate that in the axisymmetric model? Can you please let me know, I am first time doing it?

Regards

Bhanu

March 21, 2022 at 4:58 pmpeteroznewman

SubscriberFor an Axisymmetric model, first translate the solid block and sphere so the sphere is at the global origin.

Cut the bodies with the XY plane and delete the +Z half.

The axis of rotation goes through the center of the sphere, so you have to make a YZ plane cut and keep the +X half of the sphere.

Next use a horizontal XZ plane to cut the bodies a third time and keep the +Y parts. Now all you have is 1/8 of a sphere and block.

Finally, in SpaceClaim, copy and paste the two faces in the XY plane. The center of the sphere will be at the origin of the XY plane.

Then you can apply the X=0 to the Y axis edge and the Y=0 to the X axis edge.

March 21, 2022 at 6:15 pmPuhan

SubscriberThank you very much.

Sorry just the last question, so you are suggesting to get accurate one I have to do axisymmetric which is 3d in nature. Actually I was thinking axisymmetric 2d will give better results. Kindly let me know again.

Thank you very much.

Regards

Bhanu

March 21, 2022 at 8:21 pmpeteroznewman

SubscriberWhat I described above results in 2D geometry. It is two surfaces (or 2 faces on one surface) in the +XY plane, with the corner of a 1/4 circle at the origin. Make sure you set the Analysis Type to 2D on the Geometry cell in Workbench before you open the Model cell and start Mechanical. Once you are in Mechanical, you have to set the Model 2D Type to Axisymmetric. The surfaces will be meshed with Plane elements that have the 3D axisymmetric equations for stress so you will get three normal stresses: Radial, Axial and Tangential or Hoop Stress. This is the output from the 2D Plane elements when they are set to be use in an Axisymmetric analysis.

March 22, 2022 at 1:06 amPuhan

Subscriber

Thank you very much!!! You are absolutely right. For elastic Analysis Axisymmetric analysis gave perfect results.

However, I have to do fracture analysis using xfem. But I think the elements are not supporting for xfem (as elements are axisymmetric), Can you please let me know, how can we do xfem in axisymmetric analysis.

Kindly let me know please.

Thank you again.

Regards

Bhanu

March 22, 2022 at 11:00 ampeteroznewman

SubscriberI don't know about xfem. Try setting the Mesh Element Order to Linear.

ANSYS Help says that PLANE182, a linear element, supports Fracture parameter calculation.

The help for PLANE183, a quadratic element, does not support Fracture parameter calculation.

March 22, 2022 at 9:19 pmPuhan

SubscriberDear

Thank you again.

I promise this will be my last question in this thread. The query is a little generalized.

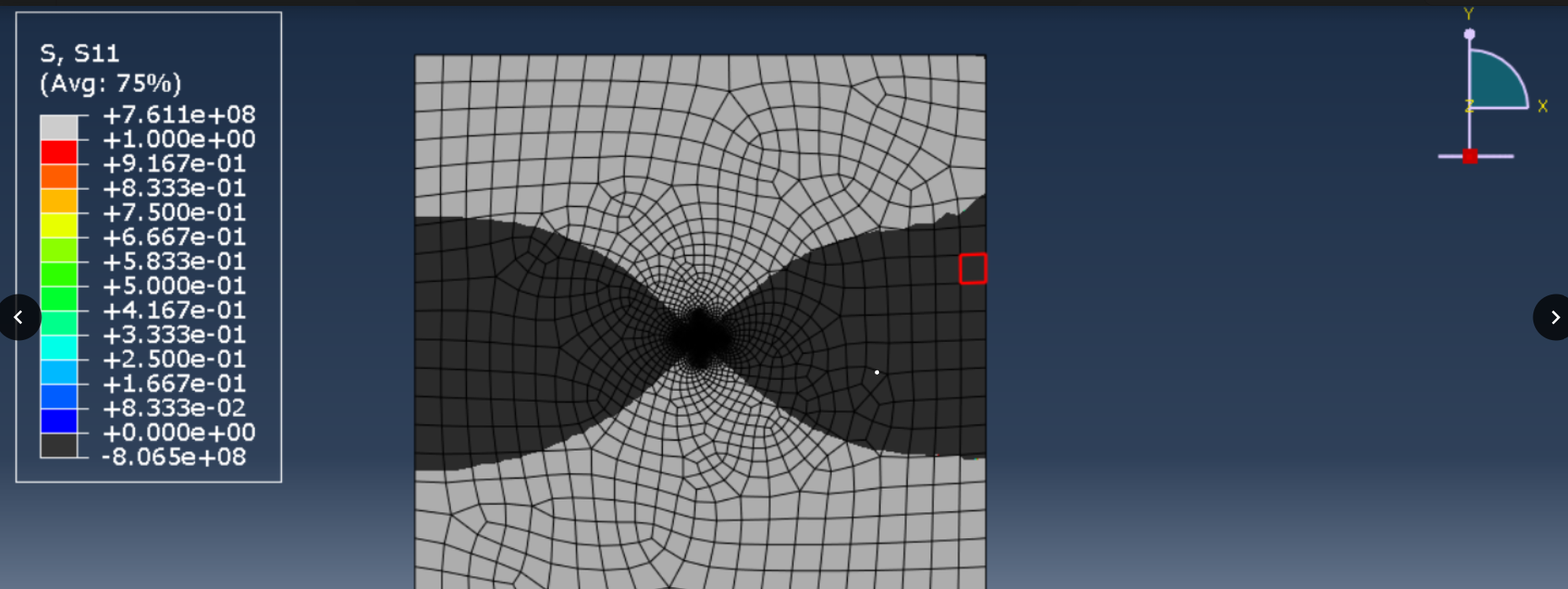

As you know in the 2D model the prestress applied is two-directional (x and y-direction). But I don't understand why the stress gradient we get is like this irrespective of 2D plane stress, 2D axisymmetric, 3D.

S11 (Normal stress in the x-direction)

S22 (Normal stress in the y-direction)

Actually, I am showing here the Abaqus model just because I have this bowtie effect plotted in ABAQUS. I did the same thing in ANSYS also, the result is the same.

Why this bowtie effect is occurring, can you please let me know if it is possible? I will be grateful.

Thank you very much.

Regards

Bhanu

March 23, 2022 at 1:33 ampeteroznewman

SubscriberThe bowtie plot pattern is due to plotting a spherically radial stress pattern on a cartesian plane.

Create a spherical coordinate system and plot the radial component of stress in the spherical coordinate system.

March 23, 2022 at 8:26 amPuhan

SubscriberDear Yes, thank you very much.

But if you look at the plots of S11 for example, it is kind of compressed (negative stress) in one region (black) and tensioned (positive stress) in the other (grey) and vice-versa in S22. I want to understand the reasoning behind it.

Viewing 10 reply threads- The topic ‘Why my 2D elastic isotropic simulation is not matching with my 3D elastic isotropic simulation?’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4673

-

1565

-

1386

-

1231

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.