TAGGED: cfd-combustion, fluent, species-transport

-

-

April 20, 2024 at 9:34 pm

J.LoongHee

SubscriberDear Experts,

I am already 1 year into combustion modelling. I think I am getting a better grasp of the concepts.

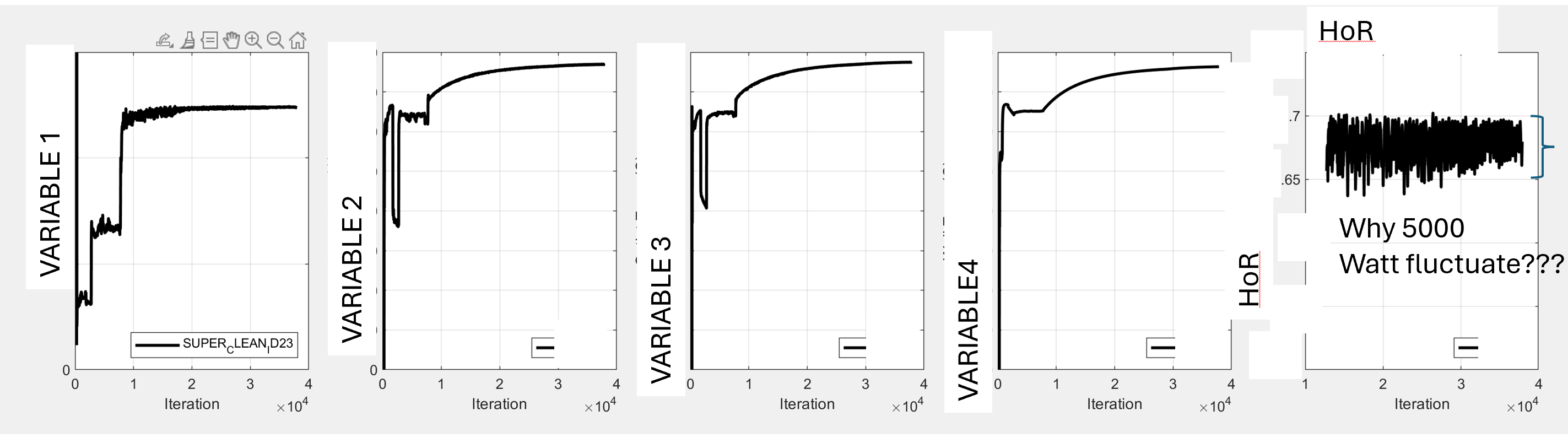

However, it does puzzle me one thing. I did a mesh independency test of a CFD domain (3 meshes). Default numerical scheme, node gradient scheme (as recommended in one of the post). The Heat-of-Reaction Source fluctuate very minimally say around 500W or even less out of XXX,XXX watts. And the solution converged well, energy residual order e-6. the rest at least e-4 or e-5. URF around 0.7 for temperature, DO probably around 0.75. But I can revert back to full default which is 0.75 and 1.0 DO no problem.

I took the medium mesh density and performed subsequent combustion analysis. The outcome of mesh independency is very good. I get a trend and Mesh M2 appeared to be most optimum.

When I am monitoring the convergence, I performed industry best practices which is to monitor various variables. I monitor the fluid zone Heat-of-Reaction for a particular case. This time the Heat-of-Reaction kept fluctuate (probably 5000 Watt in between say 50 iterations). The net result at a particular instance could be 2000 Watt another instance could be -500 Watt. In order words, the net results kept fluctuate but is of course getting down to < 2% regime.

I do view the flow field by exporting images in HPC every 250 iterations. I am quite puzzle why my technique hasn't achieve robustness! I am basically using the same input conditions though. I do aware that different type of combustor geometry could yield different flow stability due to the mixing of fuel & air?

I have been trying to use a smaller and smaller time-scale factor (for steady-state pseudo), I do noticed for some cases the 1 default to 0.5 work well. But when I applied to some combustion cases. This cannot be replicated! I puzzled me why it can be so stable in mesh independency test but not on some actual trials.

The second question I have is:

I do aware that if a preheating of air is used (say XXX Celcius). The above mentioned problem (which is fluctuation of Heat-of-Reaction source) is more likely to occur! Any suggestion what approach I can adopt to better stabilise the flow?

Thanks.

Jee -

May 3, 2024 at 1:06 pm

vinaraya

Ansys EmployeeHi Jee,

May i know your combustion model setup details.

I'm assuming it is Finite Rate model. Are you using reduced or detailed mechanism ? Are you using Stiff chemistry solver or Relax to equillibrium ?

Is it Gaseous fuel or DPM based liquid fuel ?

You could try Coupled solver w/o Pseudo transient option and also could explore combustion (w/o DO model) to begin with and then observe the HoR response.

-

- The topic ‘What could be main reason for Heat-of-Reaction Source to fluctuate (combustion)?’ is closed to new replies.

- JACOBI Convergence Issue in ANSYS AQWA

- Is it able to solve turbomachinery using density-based solver in Fluent?

- Two-way FSI simulation

- Ensight Force_per_unit area_EV

- RIBBON WINDOW DISAPPEARED

- Fluent Meshing Error when .dsco not .stp

- Ansys Fluent for modelling Ocean Wave reactions to Wave Barriers

- Battery Pack cooling

- ISAT ABORT error

- UNASSIGNED INTERFACE ZONE DETECTED FOR INTERFACE…

-

4592

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.