-

-

December 18, 2023 at 5:34 pm

javat33489

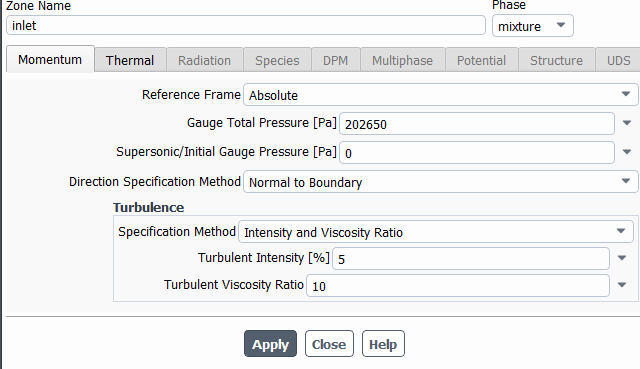

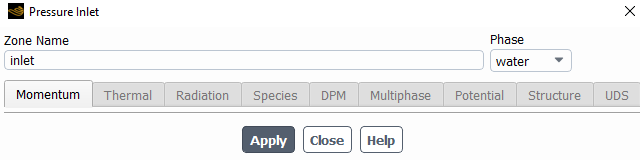

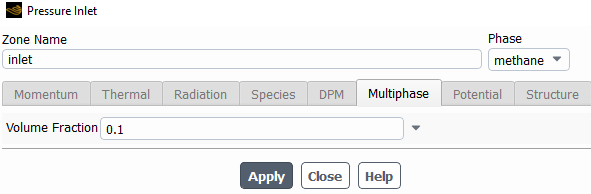

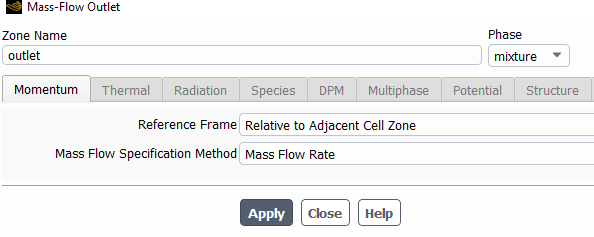

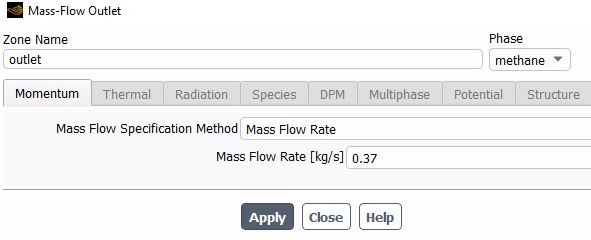

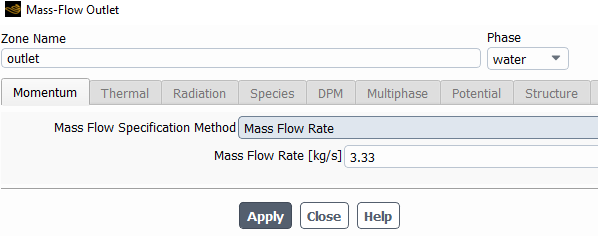

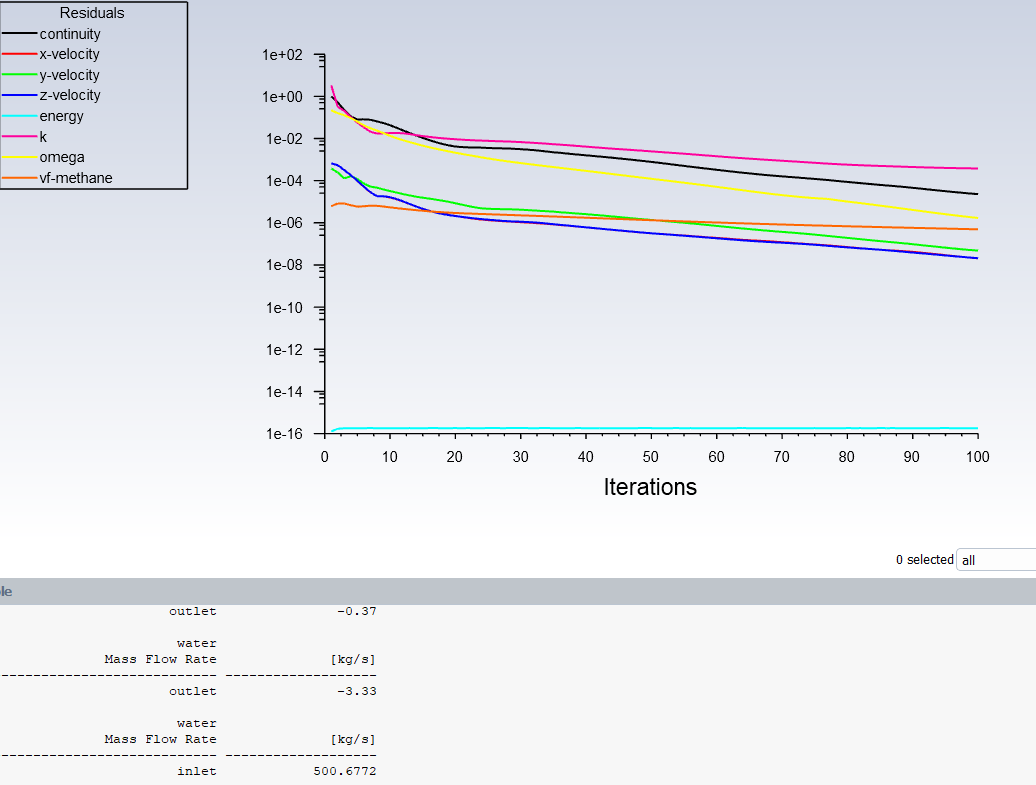

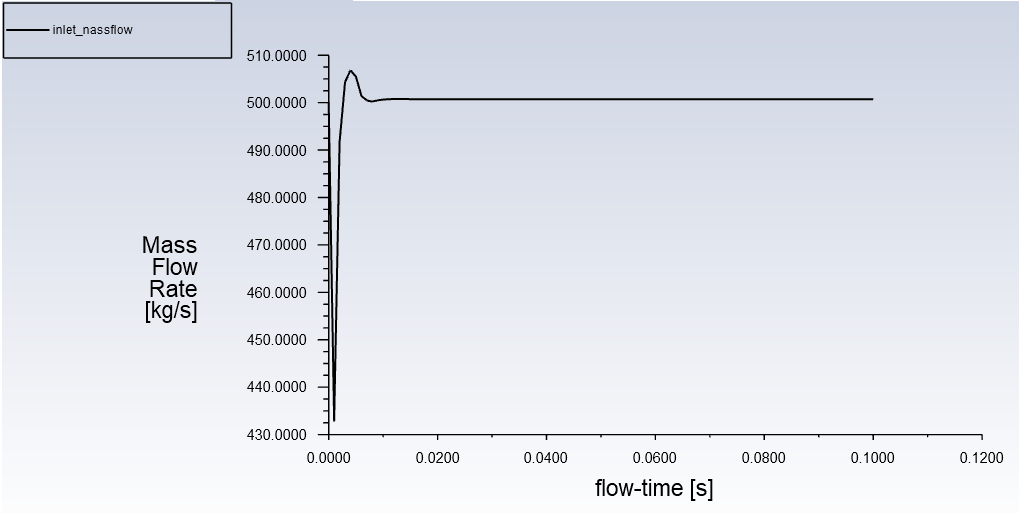

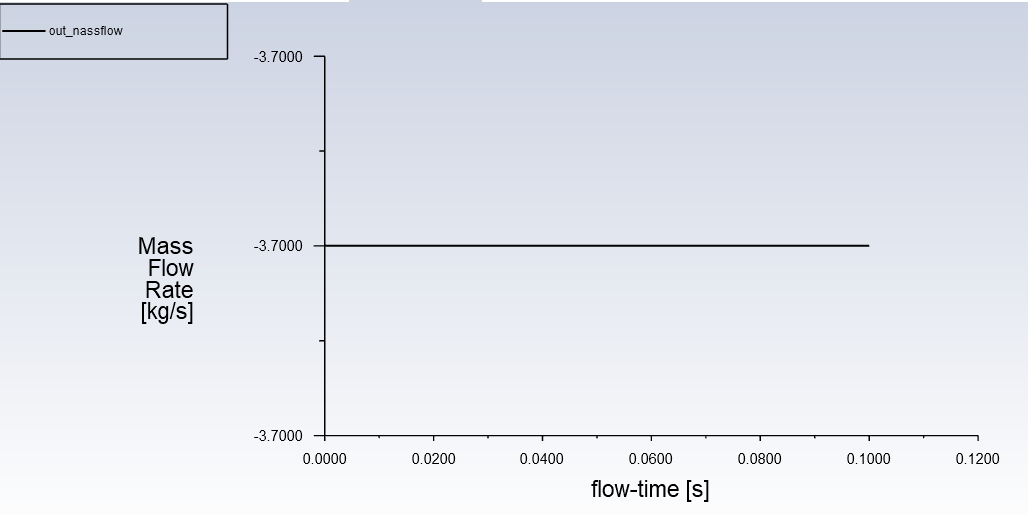

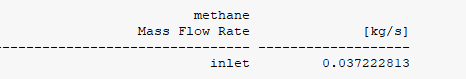

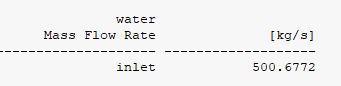

SubscriberHi all. I found a bug in Fluent.I did a simple analysis of a pipe with a diameter of 100 mm and a length of 500 mm.I created a mixture of water and methane. The first phase is water, the second is methane. For both phases the density is constant, they are incompressible.At the entrance to the pipe I set the pressure to 2 atm. The output is mass flow. The problem is that the flow rate for methane cannot be set correctly.-In total, I must pass 3.7 kg/s through the pipe.-At the inlet, the mixture is set to 2 atm, and for methane, the volume fraction is 0.1 (i.e., 10 percent of the total mixture).-At the output, I set the flow rate for water to 3.33 kg/s and 0.37 for methane (10 percent of 3.7).When calculating, I monitor the graphs on the inlet and outlet surfaces and also make measurements on these surfaces after the solution to check how much mixture, methane and water came in and out.The error is that, as a result of the solution, the water input is 500 kg/s, methane is 0.037 kg/s. And there should be 3.33 water and 0.37 methane.

The output is excellent, the mixture is 3.7 kg/s, water 0.33, methane 0.37. WHY?

Thank you.P.S. Screenshots of boundary conditions settings: -

December 20, 2023 at 5:07 pm

javat33489

SubscriberHELP PLEASE

-

December 21, 2023 at 5:56 pm

SRP

Ansys EmployeeHi,

You can try with the pressure outlet boundary condition.

Outflow boundary conditions are used to model flow exits where the details of the flow velocity and pressure are not known prior to solution of the flow problem. They are appropriate where the exit flow is close to a fully developed condition, as the outflow bc assumes a zero streamwise gradient for all flow variables except pressure.

You can check ansys user’s guide: 7.4. Boundary Conditions (ansys.com)

-

December 21, 2023 at 6:17 pm

javat33489

SubscriberYes, of course I checked this tutorial.But what should I do if I am calculating a centrifugal pump? There you need to set the flow rate at the outlet and the pressure at the inlet! How should I set the mixture in this case?Can I do it like this:1. The first calculation is to carry out PRESSURE AT INPUT, FLOW AT OUTLET, WITHOUT A MIXTURE ONLY WATER.2. Second calculation. I can take the obtained parameters from the first calculation for the boundary conditions for calculating the mixture (gas + water). For example, I will find out the output speed, and I can set for the mixture: INPUT PRESSURE and OUTLET SPEED. Will this be correct for a centrifugal pump? Tell me your advice: what boundary conditions can be taken from the first calculation and is this correct? -

December 21, 2023 at 6:41 pm

javat33489

SubscriberWhen adding gas to a liquid (creating a mixture), the overall density (relatively speaking) of the mixture will decrease due to the gas. Can I rely on the pump outlet velocity from the first calculation (water only) when calculating the mixture in the second calculation? I plan to change the volumetric content of gas in the liquid (the total volume will not change in both the first and second calculations, only the volume of gas fraction will change). Can the fluid flow rate in a centrifugal pump change when the density of the mixture changes? Can I get an incorrect result in the second mixture calculation using the data from the first calculation (water only)?

-

December 22, 2023 at 1:53 am

javat33489

SubscriberI really need your help

-

December 25, 2023 at 6:04 pm

javat33489

SubscriberPLEASE HELP

-

-

December 26, 2023 at 12:17 pm

SRP

Ansys EmployeeHi,

When dealing with gas-liquid mixtures in pump systems, it is critical to consider the variable density and its influence on pump performance. When the fluid composition changes, relying solely on water data may result in incorrect results.

To accurately calculate the fluid flow rate in the second mixture calculation, you should take into account the changed density of the mixture. The change in density can affect the pump performance, and using the initial water-only data may lead to incorrect results.

-

December 26, 2023 at 4:29 pm

javat33489

SubscriberThanks for the answer. I know that adding gas leads to a change in the overall density of the mixture. BUT you don't answer my question. How then to correctly set the boundary conditions for the mixture, for a centrifugal pump? If according to the tutorial it is impossible to set the mass flow rate at the outlet.

-

December 28, 2023 at 6:36 pm

javat33489

SubscriberHELP

-

-

January 4, 2024 at 12:53 pm

SRP

Ansys EmployeeHi,

Sorry for delay in response.

Can you check tutorial on centrifugal pump Chapter 10: Using the Frozen Rotor Method (ansys.com)?

Hope this helps you.

Thank you.

-

January 4, 2024 at 2:02 pm

javat33489

SubscriberYes, I read this tutorial. This does not fit.

-

-

- The topic ‘Volume fraction problem when using fluent mixture’ is closed to new replies.

-

5109

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.