-

-

January 23, 2024 at 4:47 pm

javat33489

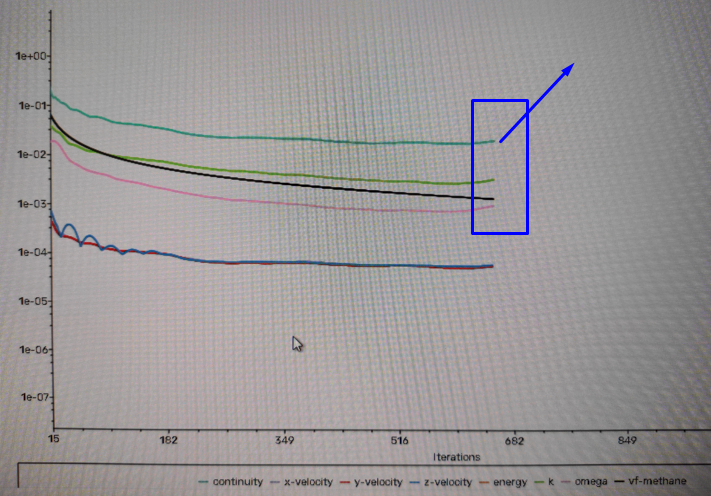

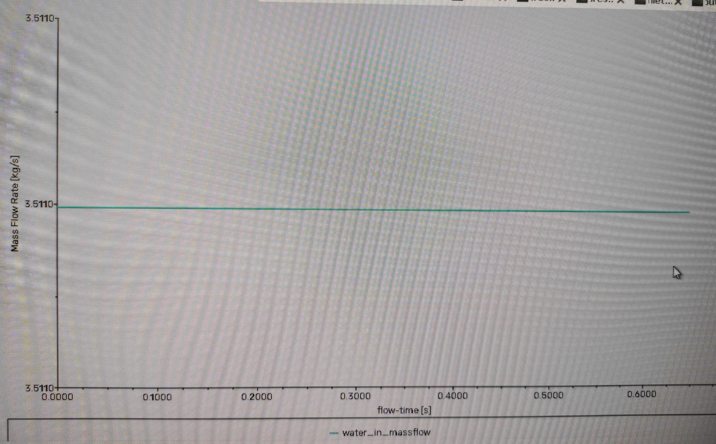

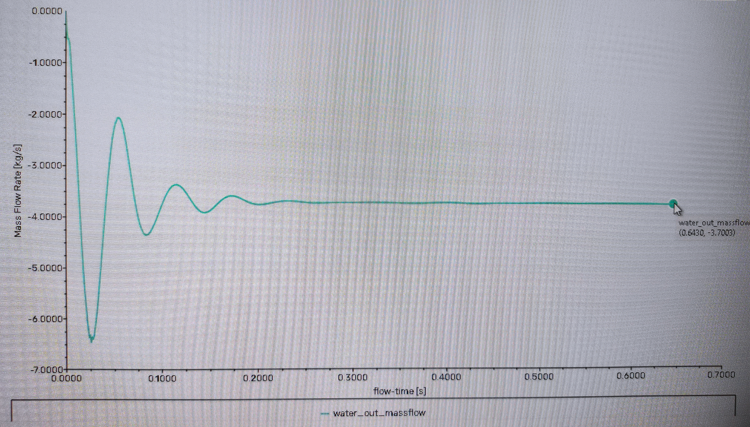

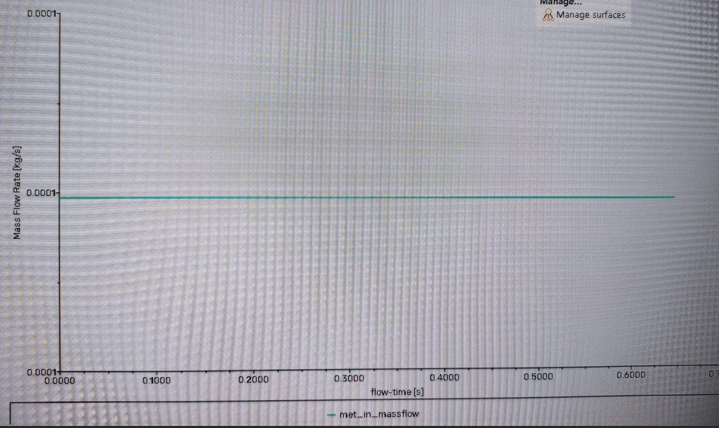

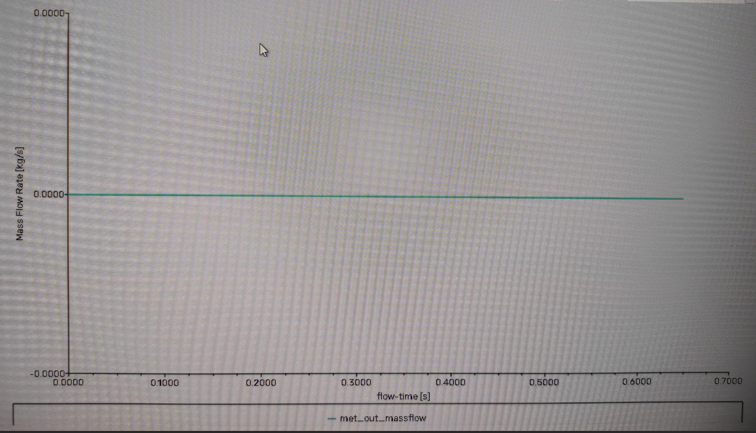

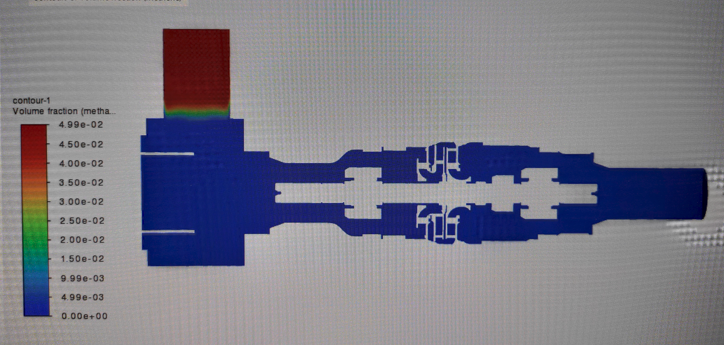

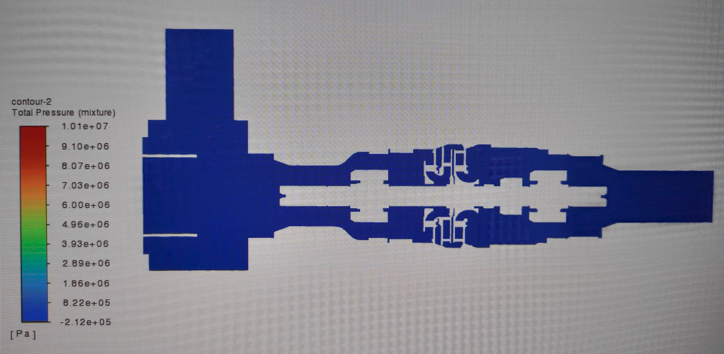

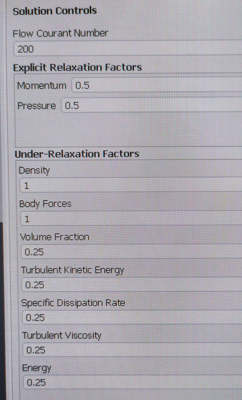

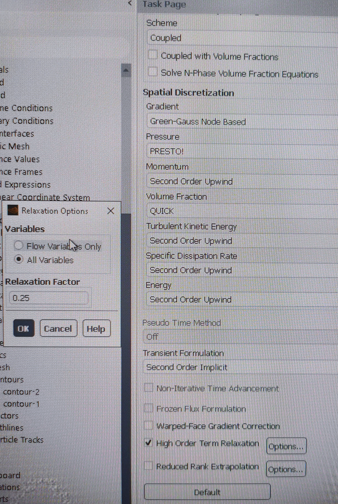

SubscriberHi all.Previously, I calculated a centrifugal pump with water. Everything was perfect.Now I carry out the calculation on the mixture.The mixture is water + 5 percent methane.I use inlet flow and outlet pressure. I determined the outlet pressure from calculations on water.OK. Water consumption is 3.511 kg/s, gas consumption is 0.00013 kg/s.The outlet pressure is 2 atm. Backflow volume fraction = 0.I encountered these problems:1. After 700 iterations, continuity begins to increase, while the input pressure decreases greatly and an error occurs.2. I watch the convergence graphs. After 700 iterations, all the graphs reach a flat line, but I see that the methane output flow rate is 0. Although the methane input flow rate shows 0.0001:After 700 iterations, I looked at the cross-section of volume fraction and pressure, they look like this:It seems that the gas fraction is stuck in the supply pipe and does not go further. Why?I use the coupled method and second orders.I tried to solve the problem like this:- used third orders- turned on high relaxation and indicated all 0.25- I did a strong relaxation to 0.25I ask for your help. Thank you. -

January 24, 2024 at 10:59 am

Prashanth

Ansys EmployeeYou need to check why exactlly the dispersed phase is collecting there. For troubleshooting, before mixture model, you can also inject methane bubbles as discrete phase (using DPM) from inlet and gain some insights from their trajectories.

-

January 24, 2024 at 5:08 pm

javat33489

SubscriberThe methane phase not only accumulates, it does not reach the outlet. On the output graph I see 0 kg/s.

I also tried adding surface tension to this mixture and setting the methane phase to the particles, but that didn't help.

I also tried to model flow velocity instead of flow rate, but then my continuity increases and the calculation also fails with an error.

-

January 24, 2024 at 5:10 pm

javat33489

SubscriberTo prevent continuity from growing, I also tried to use standard initialization and set the chime number to 1. This also did not help.

-

January 24, 2024 at 5:15 pm

javat33489

SubscriberCan you write me all your options for debugging this calculation step by step? I'll check them all. I have already used all my options, I tried 50-100 different productions.

-

-

January 24, 2024 at 5:18 pm

Rob

Forum ModeratorThis looks very much like /forum/forums/topic/calculation-of-a-centrifugal-pump-in-fluent-2/

Please do not post multiple times on the same topic. We will get to all threads but it can take time to find the specialists.

-

- The topic ‘Volume fraction problem in fluent’ is closed to new replies.

-

4633

-

1535

-

1386

-

1225

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.