-

-

September 5, 2025 at 9:14 am

cnmatu

SubscriberHi,

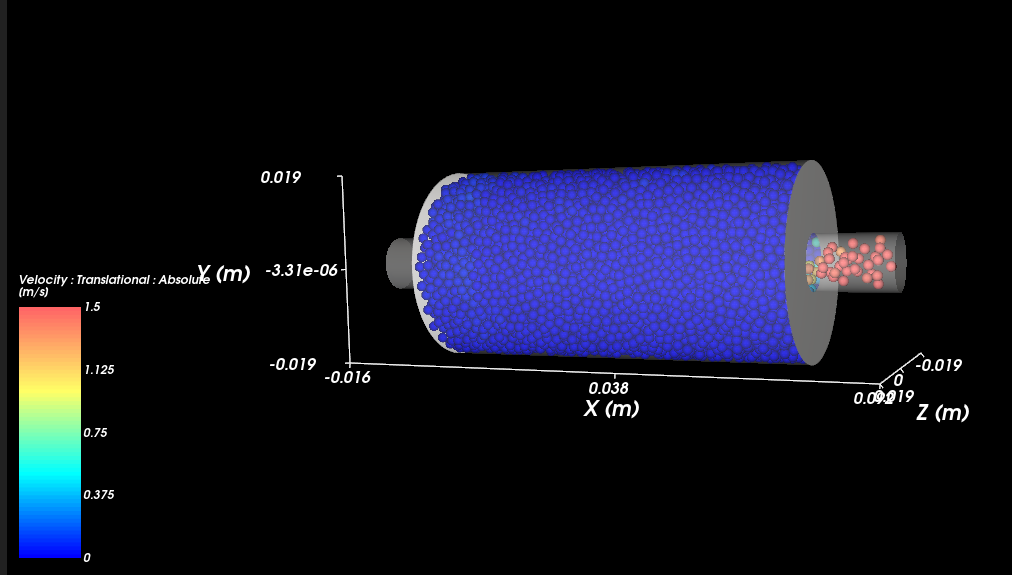

I am running an internal erosion model where particles get eroded and exit out of an aluminium cylindrical mould (image attached). However, the soil particles are cohesive in nature and therefore I have to use the bond model module which I have used but I am wondering the best way to calibrate these bond model parameters (Tangential stiffness per area, Normal stiffness per area, shear stress limit and tensile stress limit)so that I achieve the exact cohesion of my soil so that when I run a one-way or two-way coupled simulation, it simulates the exact experimental result. Any advice on this? Any reading material that could help?

-

September 12, 2025 at 2:18 pm

Jackson Gomes

Ansys EmployeeHI cnmatu

In Rocky, the bond model parameters (normal/tangential stiffness per area, tensile and shear stress limits, bond radius) are user-defined micro-properties. There isn’t a direct formula for soils, they must be calibrated against lab or literature data. The idea is to tune these inputs until the bulk response (cohesion, friction) matches your target soil behavior.

Take a look at script Material Wizard, maybe it can help.

-

- You must be logged in to reply to this topic.

-

5274

-

1860

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.