-

-

July 17, 2023 at 1:54 am

Lumisade Snow

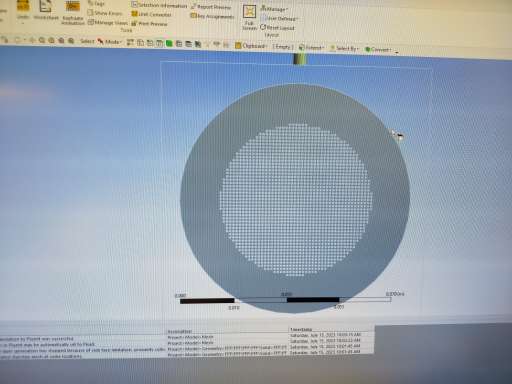

SubscriberHI all, I am trying to model impinging fluid flow on a thin plate with array of holes (both thickness and hole diameter of order 10^-4m), but the meshing and calculation takes way too long, as Im trying to capture fluid structure coupling between the flow and the plate (the plate will vibrate due to fsi). Is there a faster way to run such a simulation? Or better way to mesh it? The fluent simulation takes really long to initialize and when I start to solve it in fluent it gets stuck at 0% and doesnt run, or it gives Received signal sigsegv. My element number is approximately 10 million. Thanks!

-

July 17, 2023 at 9:03 am

Rob

Forum ModeratorAre you modelling a single hole in a plate, or are the holes in the darker grey section? What sort of vibration frequency are you expecting?

-

- The topic ‘Two way fsi – microperforated thin plate’ is closed to new replies.

-

5049

-

1764

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.