-

-

March 13, 2025 at 4:23 pm

javat33489

SubscriberHi all.

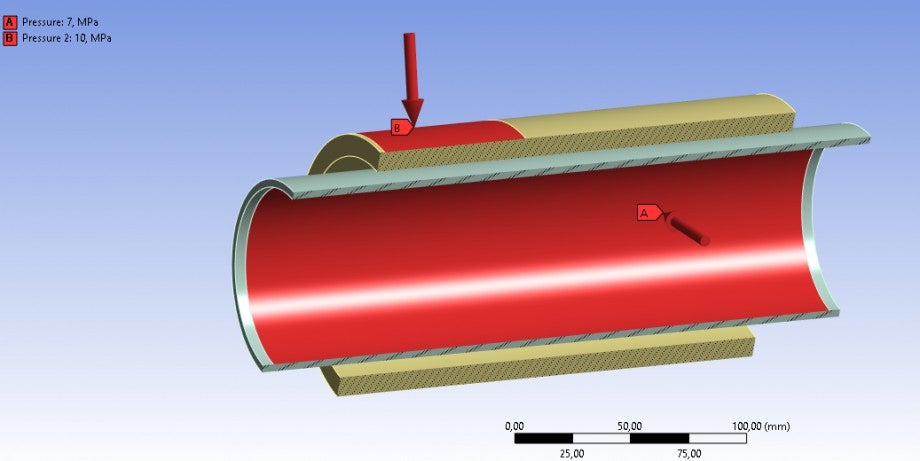

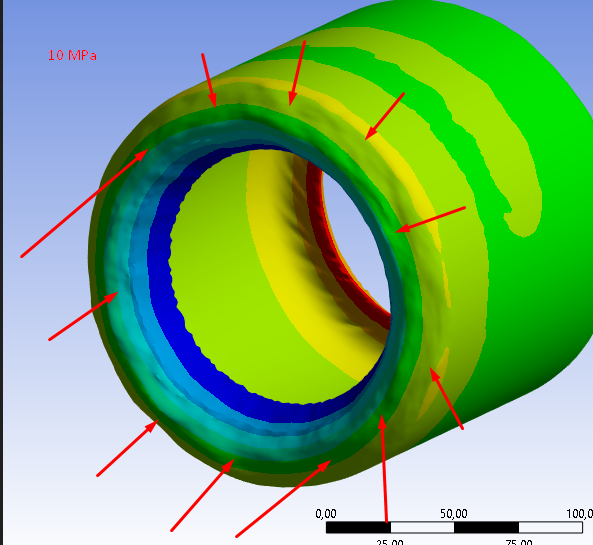

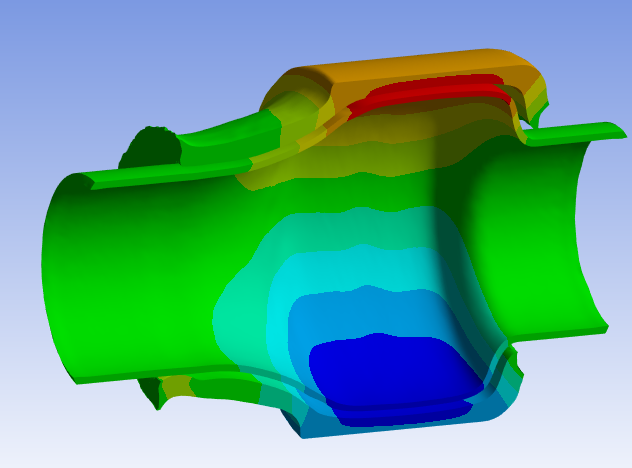

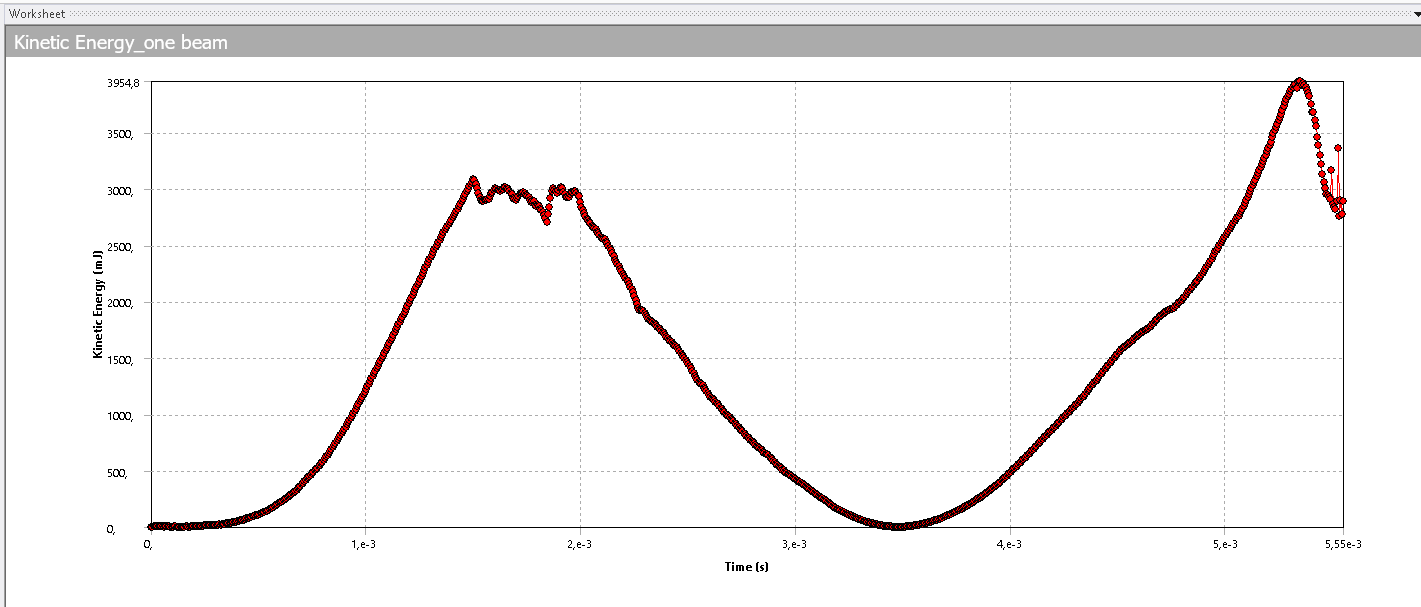

I model two cylindrical rubber and between them beam cables. These two rubber are installed in the pipe (another largest cylinder). One end is a mobile razin so that when bloating it turned out to be an inflatable element.

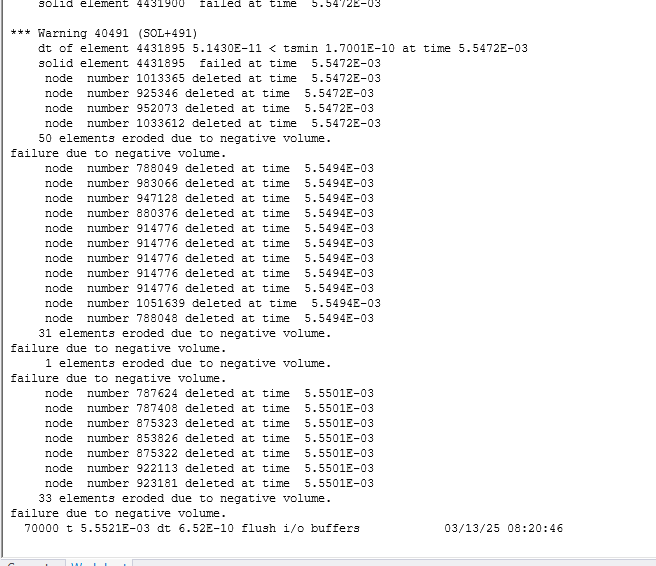

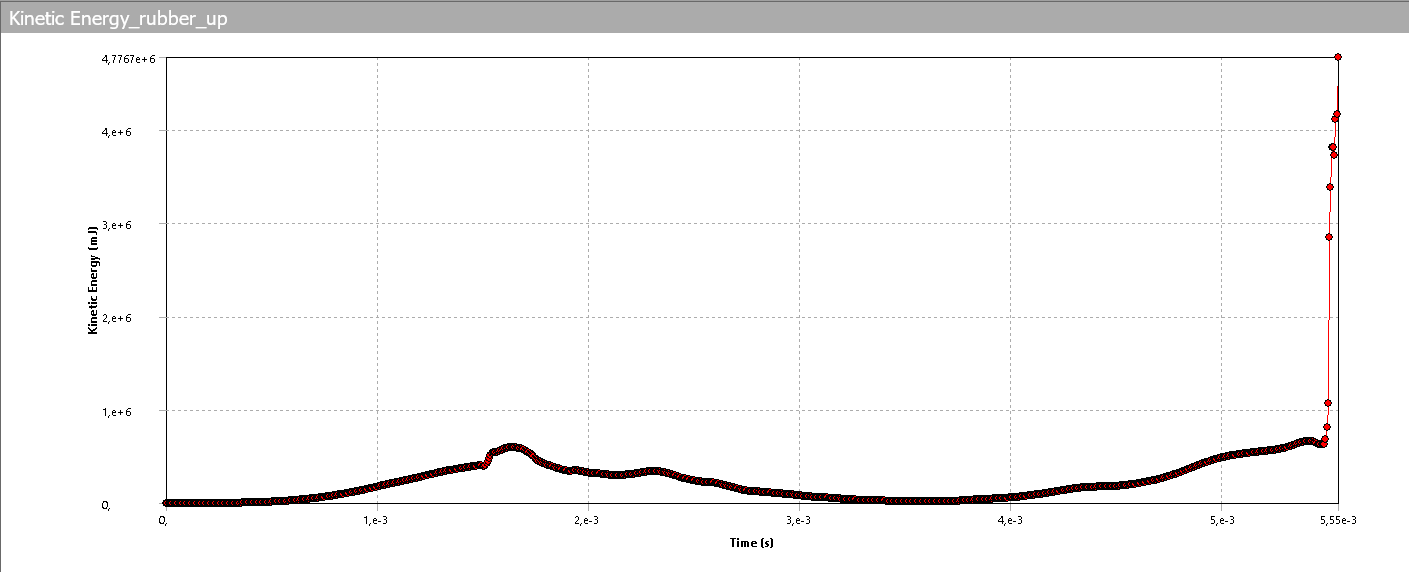

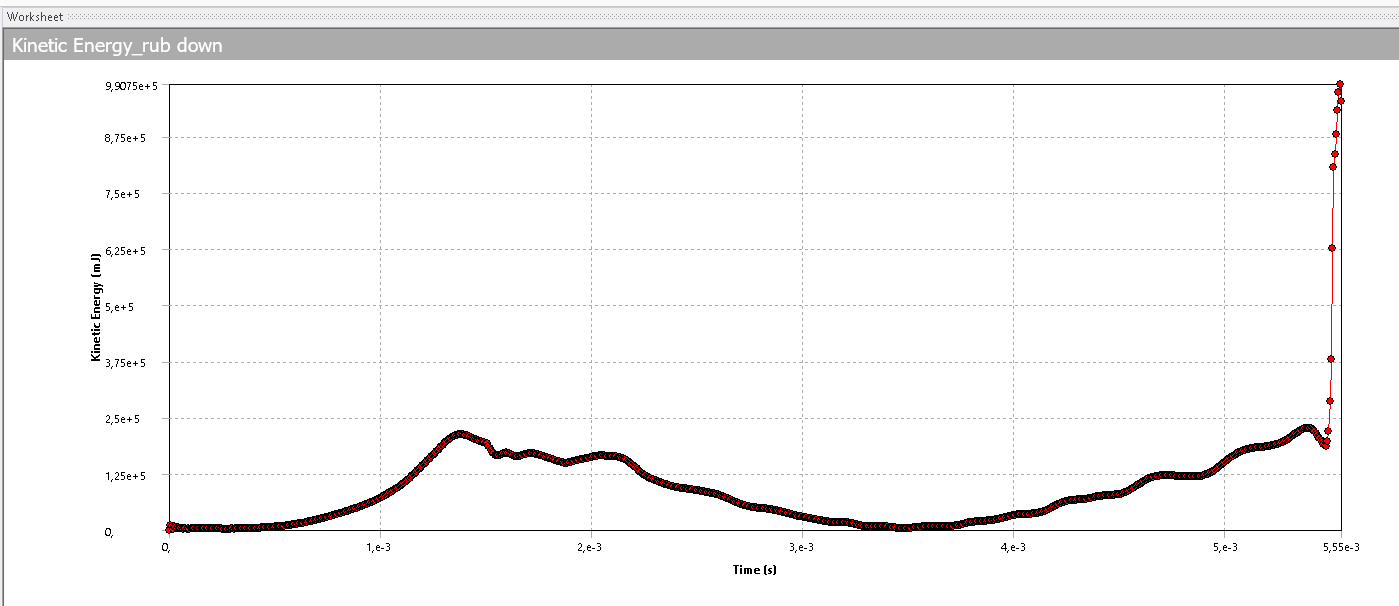

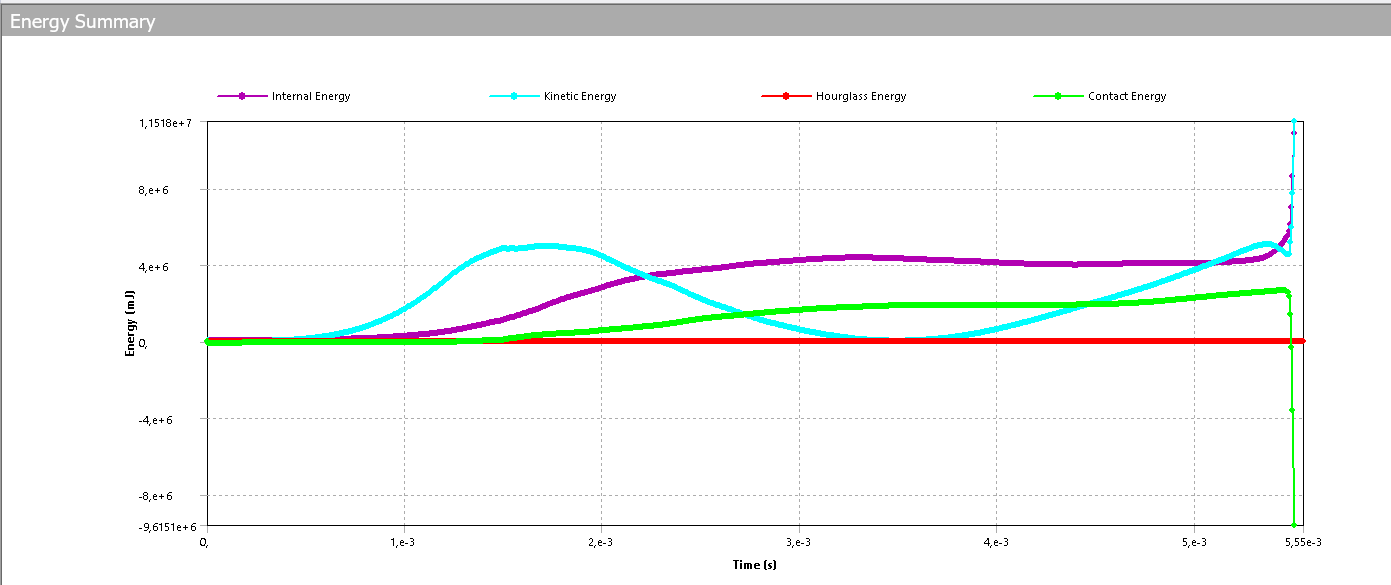

On the inner cylinder, I put a pressure of 7 MPa. After squeezing the rubber, I serve 10 MPa to external rubber, on the edge, so that the rubber is compressed in the other direction and the gap in the pipe becomes sealed.The first stage 7 MPa is excellent. The second stage of 10 MPa for deformed rubber causes errors of the negative volume that leads to a very long solution and a possible error at the end. In total, I have 3.5 million mesh.

Tell me how to improve the result so that at the second pressure there are no mistakes negative volume and eroded? Is it possible to disable this so that the calculation does not increase in time due to these errors? -

March 17, 2025 at 8:56 am

Raman Babu

Ansys EmployeePlease see the link below, which describes the option to overcome negative volume error.

https://www.dynasupport.com/howtos/material/negative-volume-in-soft-materials

Regards,

Raman Babu

-

- You must be logged in to reply to this topic.

-

4863

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.