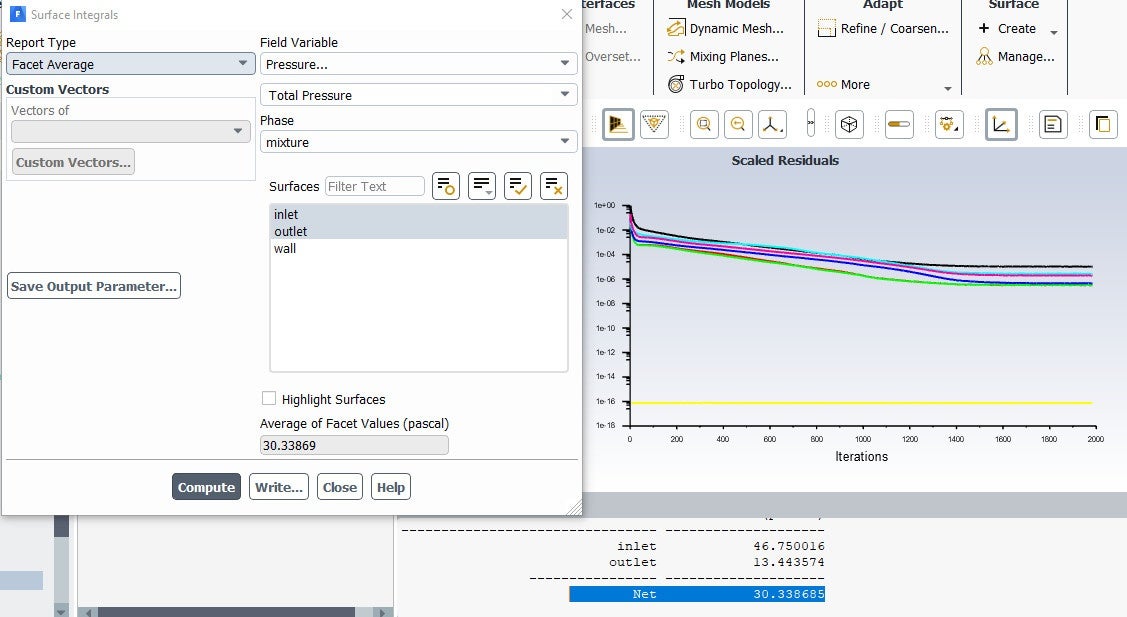

Turbulent channel flow over hydrophobic surface. Even though I changed the contact angle, the result

-

-

November 4, 2021 at 8:46 am

bekir4260

SubscriberNovember 4, 2021 at 10:25 amAmine Ben Hadj Ali

Ansys EmployeePlease insert the pictures in the text. Ansys employees do not download attachements.

November 4, 2021 at 12:07 pmNovember 4, 2021 at 2:11 pmAmine Ben Hadj Ali

Ansys EmployeeI do not understand what do you expect here? Do you have a multiphase case? Are you injecting anything? How are you using the contact angle information to affect the total pressure drop?

November 4, 2021 at 4:19 pmbekir4260

SubscriberI am interested in the plumbing business.

I am looking for ways to reduce the pressure loss in the installation.

I coated the inner surface of the pipe piece with hydrophilic structure with hydrophobic material.

hydrophobic material prevents water from sticking to the surface.

friction on the inner surface of the pipe is reduced.

no slip condition.

I tested it on 3 different surfaces with 3 different hydroobic materials.

Friction and pressure slip were the least in the pipe with the highest contact angle.

now i want to model it with fluent.

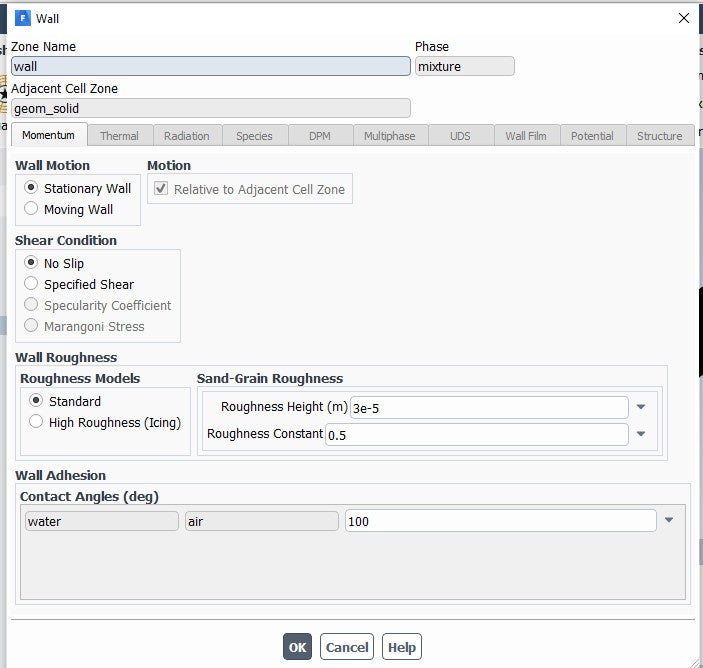

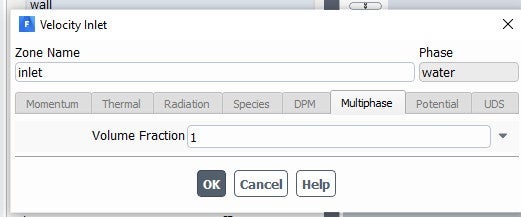

The only place where I can enter the contact angle in the fluent program is the VOF model.

In fact, only water is flowing.

November 4, 2021 at 5:00 pmRob

Forum ModeratorContact angle is set between phases. If there's no meniscus the value is meaningless.

November 5, 2021 at 1:22 pmbekir4260

Subscriber(If there is no meniscus, the value is meaningless.) what did you mean? I do not understand.

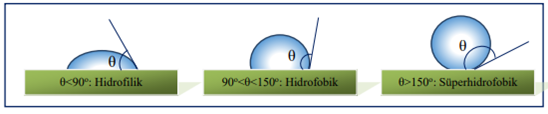

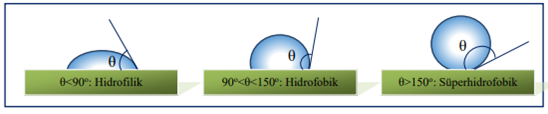

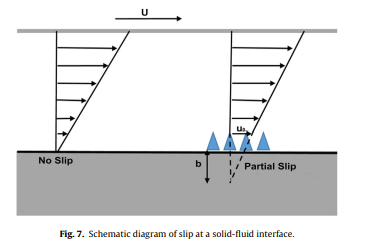

hydrophobic surface means:

the surface is in nano-sized rough structure.

air is trapped in the roughness during the flow of water, so the water does not stick to the surface and the surface does not hold water.

In fact, only water flows on the surface.

Air is trapped in the spaces between the water and the surface.

I am attaching the hydrophobic surface and velocity profile photo.

November 8, 2021 at 9:31 amNovember 8, 2021 at 9:55 am

November 8, 2021 at 9:31 amNovember 8, 2021 at 9:55 amRob

Forum ModeratorCorrect. However, if you read the Fluent manual you'll find we measure contact in the droplet. If the surface is fully wetted there is no free surface to attach the angle to. You'll also see the section explaining how the VOF model works.

November 8, 2021 at 1:16 pmbekir4260

SubscriberI understand.

So how can I model?

can you help me please

November 8, 2021 at 1:21 pmbekir4260

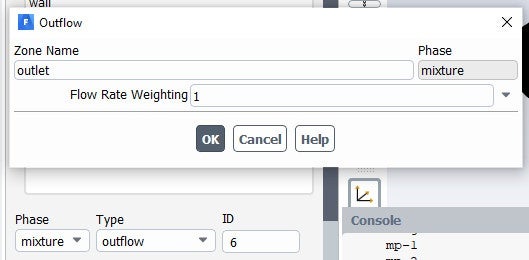

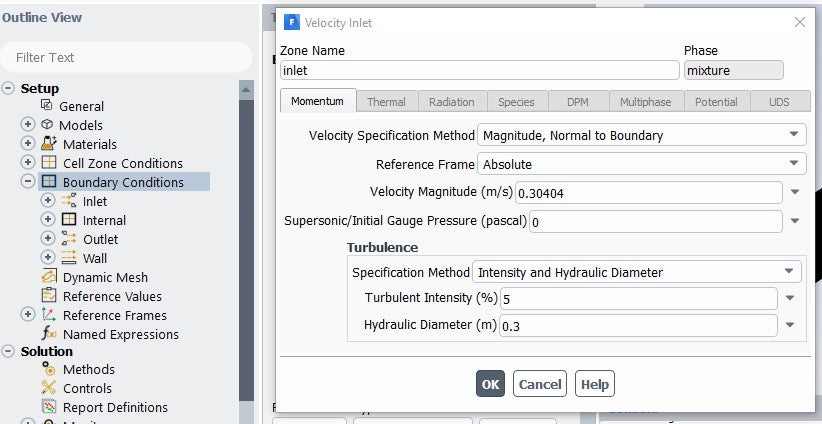

SubscriberThe diameter of the pipe is 0.3m and the length is 10m.

contact angle measured at the surface: 110 degrees , 132 degrees , 148 degrees

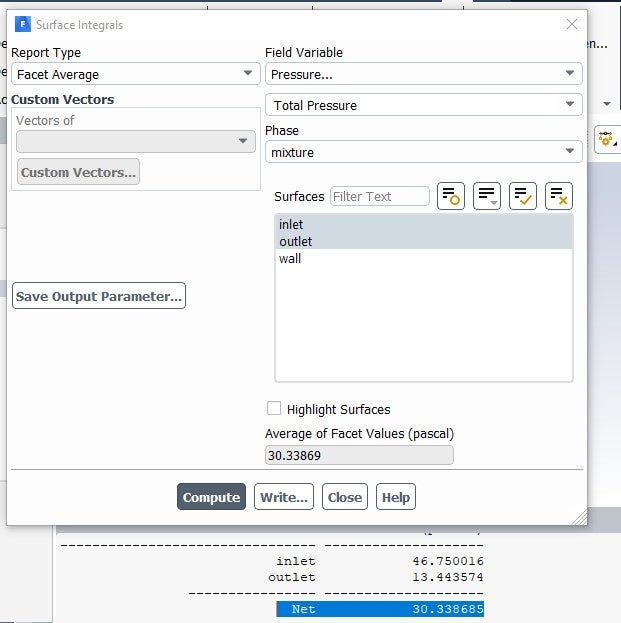

I will calculate the pressure loss due to friction in the pipe.

The flow is continuous and turbulent.

November 8, 2021 at 1:23 pmbekir4260

Subscriberinput speed 0.30404m/s

November 8, 2021 at 3:33 pmRob

Forum ModeratorBest approach is probably to alter the wall shear rates in the boundary condition panel.

November 9, 2021 at 8:06 amNovember 9, 2021 at 1:36 pmRob

Forum ModeratorWall conditions, you'll need to alter the wall Shear Conditions, that may require a UDF or expression. And, no, we don't have the expression, you'll need to figure that out.

November 9, 2021 at 3:55 pmAmine Ben Hadj Ali

Ansys EmployeeYou will rather need to code a wall shear stress to incorporate the effects on the momentum equation instead of using multiphase model for applications where only one phase is present (Navier Slip implementation).

November 10, 2021 at 7:45 ambekir4260

SubscriberThere is only one phase.

If I do as you say, there are contact angles and efficiency values that I have obtained experimentally.

How do I enter these values into the fluent program?

November 10, 2021 at 7:46 ambekir4260

SubscriberAre there any ready made udf codes?

November 10, 2021 at 11:49 amRob

Forum ModeratorNo, but this is where you need to start https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v212/en/flu_udf/flu_udf_sec_define_profile.html

November 10, 2021 at 12:04 pmJSMacdonald

SubscriberI think you've got a really interesting problem but I don't think it's as straightforward to solve as you'd like it to be.

I found this paper which has some pertinent aspects for your problem. https://journals.sagepub.com/doi/full/10.1177/1475090217740470

Specifically, it shows development of a user defined function for "╬▓- the sliding coefficient, which depends on the wall surface properties", used to calculate shear rate.

Also from the discussion section

"There is no straightforward correlation between the CA and the slip length. However, as an example, Ou et al.23reached a slip length of 20ÔÇë╬╝m with a surface having CAÔÇëÔëêÔÇë160┬░. Therefore, it can be expected that the above-mentioned fabrication methods with CAÔÇë>ÔÇë160┬░ are capable of producing slip lengths greater than 20ÔÇë╬╝m."

It sounds to me like there is not an established way to link shear rate with 3-phase contact angle (or surface energy, which would be the more appropriate parameter here).

As I don't work for Ansys I can also say that I think your experimental conclusions sound dodgy

"As the contact angle increased, the friction on the inner surface of the tube decreased." Why is this?

"air is trapped in the roughness during the flow of water, so the water does not stick to the surface and the surface does not hold water." This is for the superhydrophobic regime, however at the contact angles you mention you are in a fully wetted regime.

It would be good to get your thoughts, good luck with the model

November 13, 2021 at 6:44 pmbekir4260

Subscriber (It sounds to me like there is not an established way to link shear rate with 3-phase contact angle (or surface energy, which would be the more appropriate parameter here).

(It sounds to me like there is not an established way to link shear rate with 3-phase contact angle (or surface energy, which would be the more appropriate parameter here).

There are many articles about the relationship between the contact angle and the sliding speed on the surface.

I found many articles in the literature search, but there is no flow modeling on the hydrophobic surface in the FLUENTT program.

I am writing my e-mail address. bekir.dogan@gop.edu.tr

Please I would be very happy if you could help.

If you know the FLUENTT program well, we can work on an article together.

November 15, 2021 at 2:21 pmRob

Forum Moderatorand I've removed the Whatsup number. Normally I'd also remove the email address, but will leave you two to discuss on the condition that you report back in the thread what's decided. Let me know when you've emailed and I'll delete that too.

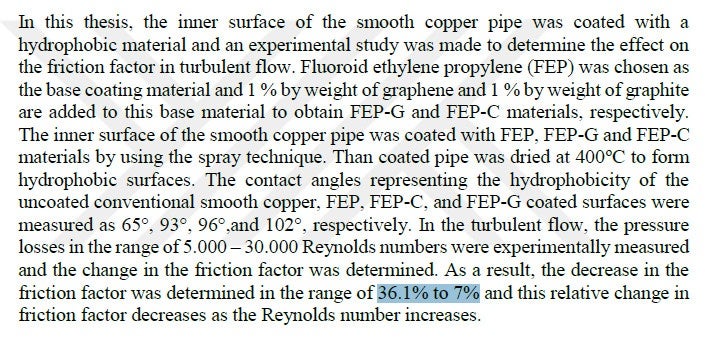

As a comment on the block of text, it doesn't mention if the pressure loss was measured for a moving free surface or a (non)wetted pipe. I can't see a diameter either to see if it's surface tension, gravity or forced flow driven.

November 24, 2021 at 3:23 pmJSMacdonald

Subscriberir - I don't think I'm able to help any further with the interfacial science needed here. I'm afraid I am not an advanced Fluent user either. Good luck

Viewing 22 reply threads- The topic ‘Turbulent channel flow over hydrophobic surface. Even though I changed the contact angle, the result’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3442

-

1057

-

1051

-

917

-

896

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.