-

-

February 12, 2020 at 11:07 pm

danielf650

SubscriberHello!

I'm trying to do some transient thermal analysis of a cup holding hot fluid. I need to see how long it will take for the fluid in the cup to cool to a certain temperature. I have the cup design, it was made in solidworks, and I've tried the ansys workbench transient thermal analysis program but my results don't make sense. I was hoping to see if anyone has done something like this before or can steer me in the right direction.

Thank you!

-

February 13, 2020 at 1:29 am

peteroznewman

SubscriberWhat is the fluid in the cup?

What thermal properties did you use?

Where did you get a convective film coefficient for the cup and liquid?

-

February 21, 2020 at 6:24 pm

danielf650

SubscriberThe fluid is coffee. The cup material is HDPE. I'm not sure how to set this up. I'm thinking maybe I should just make the liquid solid and give it the properties of liquid.

-

February 21, 2020 at 6:24 pm

danielf650

SubscriberThe fluid is coffee. The cup material is HDPE. I'm not sure how to set this up. I'm thinking maybe I should just make the liquid solid and give it the properties of liquid.

-

February 21, 2020 at 10:17 pm

peteroznewman

SubscriberYou can have a simple model that will have more error from the experimental data, and you can have a complex model that has less error from the experimental data. The complex model would be done in Fluent and involved the fluid in the cup having convection currents, and the air around the cup having convection currents.

If you have no experimental data, then do the simple model, which would be Transient Thermal in the Mechanical program.

-

February 25, 2020 at 7:36 am

danielf650

SubscriberHow do I go by setting this up in ansys? I only have initial temp of hot liquid, the material of the cup and the ambient temp.

-

February 25, 2020 at 2:37 pm

peteroznewman

SubscriberStart ANSYS Workbench and double click on Transient Thermal in the toolbox on the left. A system will appear in the Project Schematic.

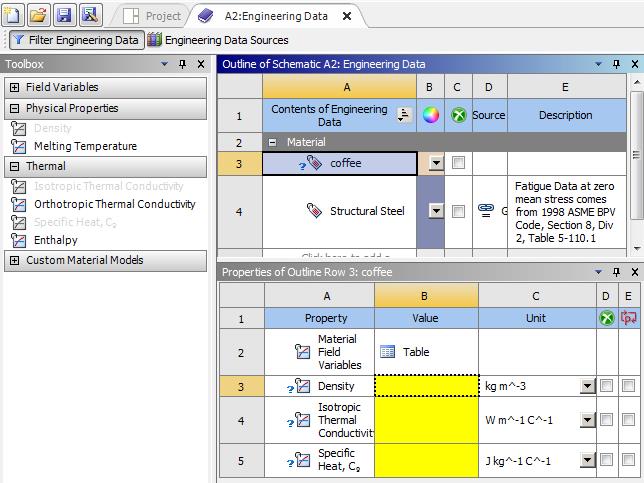

Double click on Engineering Data, a new tab will open in Workbench. Click on the box under Structural Steel and type coffee. The Toolbox on the left has been filtered to only show properties relevant to a Thermal analysis. Drag and drop on the coffee material Density, Isotropic Thermal Conductivity and Specific Heat.

Fill out the values in the correct units in each yellow box.

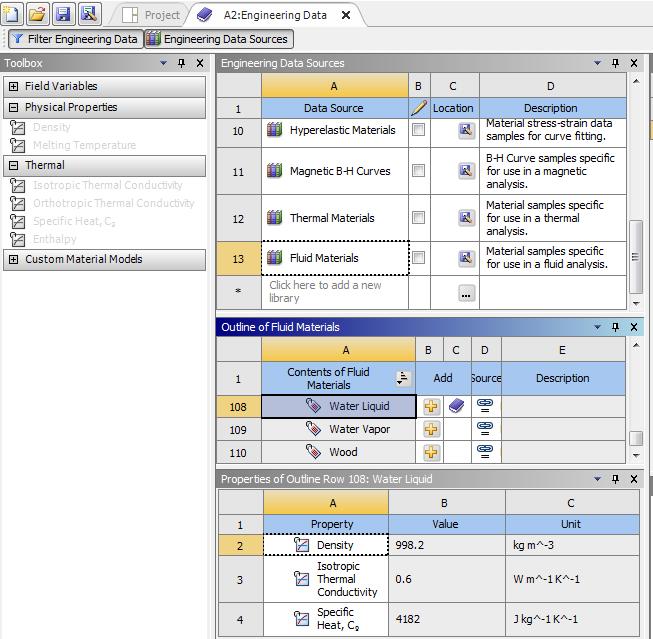

If you don't know those values, click on the Engineering Data Sources button at the top and you can add Water Liquid to the project by clicking on the + button.

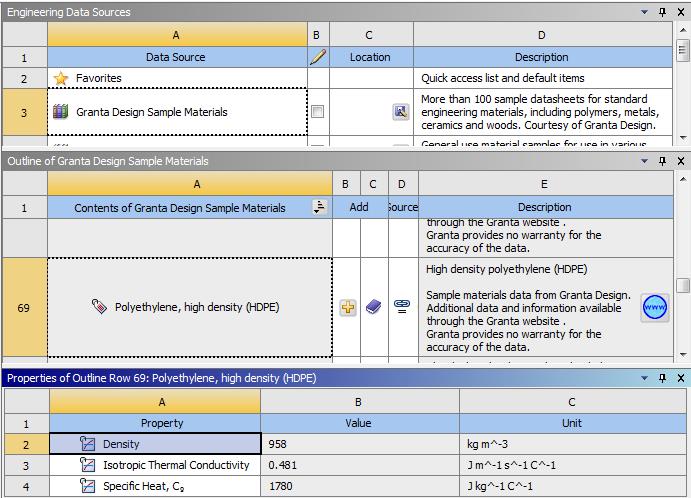

Repeat this for HDPE, which you can find in the Granta Design Sample Materials database.

Click on the Project tab in Workbench.

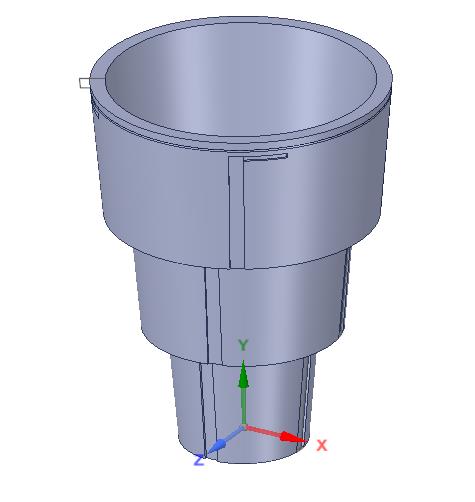

Now you need geometry for the cup and the coffee inside the cup. You can save yourself some time if you create an axisymmetric model.

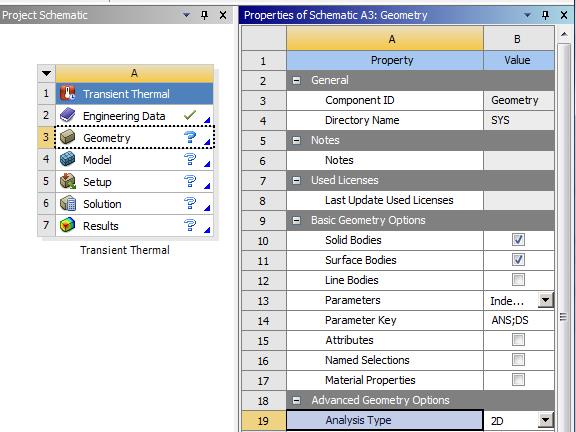

Click on the Geometry cell on line 3 of the Transient Thermal block A. In the Properties window on the right, on line 19 is Analysis Type. Change that to 2D.

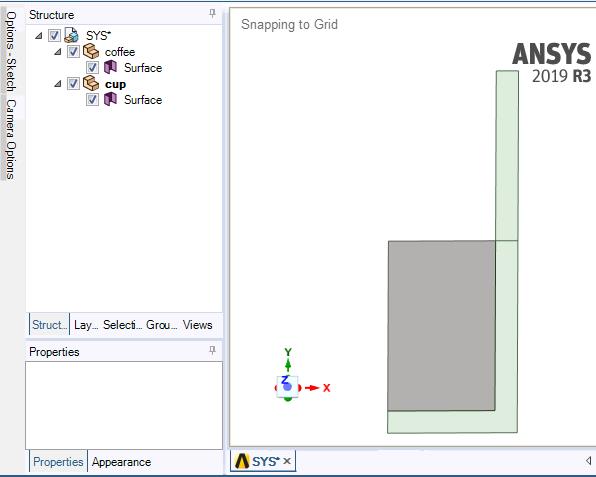

Now double click on Geometry to start SpaceClaim. Sketch a radial slice of the cup on the XY plane on the +X side of the Y axis. Think of the Y axis as the axis of revolution. The surfaces you draw would recreate a solid body if you revolved them 360 degrees about the Y axis. Create a New Component for the cup and draw the L shape. Create a New Component for the coffee and draw a rectangle. My cup is half full. Yours might be half empty : ) Activate the cup Component. Draw a line at the top of the coffee to split the face into two so there can be different boundary conditions.

Close SpaceClaim. In Workbench, click on the Model cell. Mechanical will start.

In Mechanical, click on Geometry and in the Details window, set the 2D Behavior to Axisymmetric.

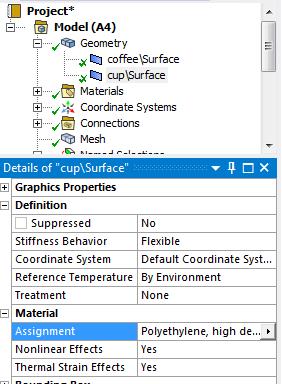

Click on coffeeSurface and assign Water Liquid to the coffee.

Assign HDPE to the cup.

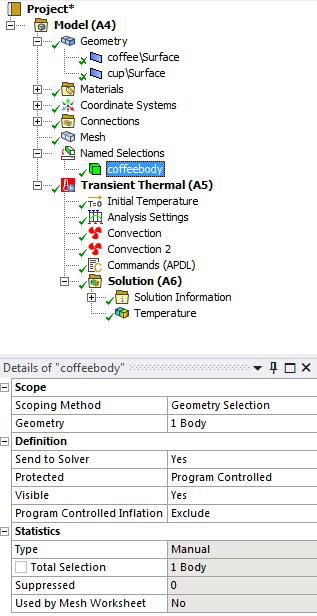

Click on the Body filter and click on the coffee then type N to create a Named Selection named coffeebody

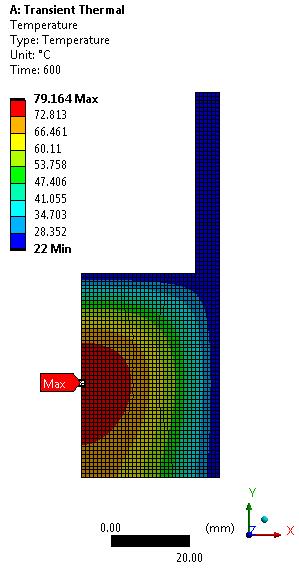

Under Transient Thermal, the Initial Temperature is 22 C. Click on Analysis Settings and choose the Step End Time of 600 seconds.

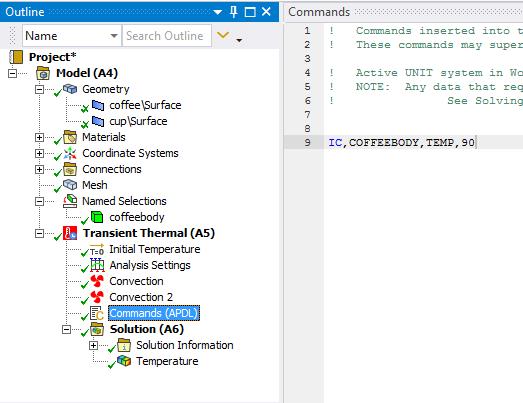

Click on Commands and type in the command shown below: IC,COFFEEBODY,TEMP,90

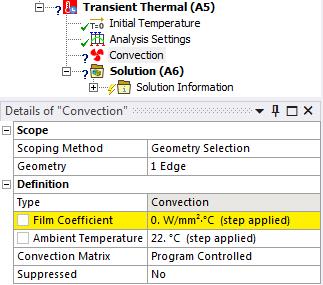

On the Environment tab, pick Convection and pick the top edge of the coffee. Enter a Film Coefficient.

Do the same for the inner top half of the cup, the top and the outer two edges of the cup. Assume the bottom of the cup is insulated. That is the default BC so no action is needed for that edge.

Click on Mesh. I drew 6 mm wall thickness, so I will set the Element Size to 1 mm.

Click on Solution, the click on the Thermal pull down and select Temperature.

Click Solve. Here is a simple estimate of the temperature of the cup after 10 minutes.

This is a very simple model. A more accurate model would be done in Fluent and would include the convective motion of the coffee inside the cup, where there is a flow upward in the center, outward, then downward near the cooler cup body and inward at the bottom. That would allow the system to cool faster than this model predicts, which only accounts for thermal conductivity through the coffee.

An even more accurate model would have the air around the coffee convecting heat away. If you do that, then you don't have to guess at a Film Coefficient. The air flow will carry away the heat.

-

February 25, 2020 at 5:51 pm

-

February 25, 2020 at 8:25 pm

peteroznewman

SubscriberYes, that is possible. Just leave out changing the Analysis Type to 2D. All the other steps are the same. The only problem is there is a 32,000 node or element limit in the free Student version. Even if you don't hit that, you will wait longer for a 3D solution than you will wait for a 2D solution.

To use the solid to make a 2D model, open the SolidWorks file in SpaceClaim. Create a plane on the XY plane and Split Body, discard the +Z half, create a plane on the YZ plane and Split Body, discard the -X half. Now pick the 1/4 face in the XY plane, and Ctrl-C and Ctrl-V. Now you have the radial slice of the cup. Discard the solid.

-

- The topic ‘Transient thermal analysis of a cup that holds hot fluid’ is closed to new replies.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- Issue to compile a UDF in ANSYS Fluent

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

-

4167

-

1487

-

1358

-

1189

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.