-

-

March 9, 2023 at 6:32 pm

javat33489

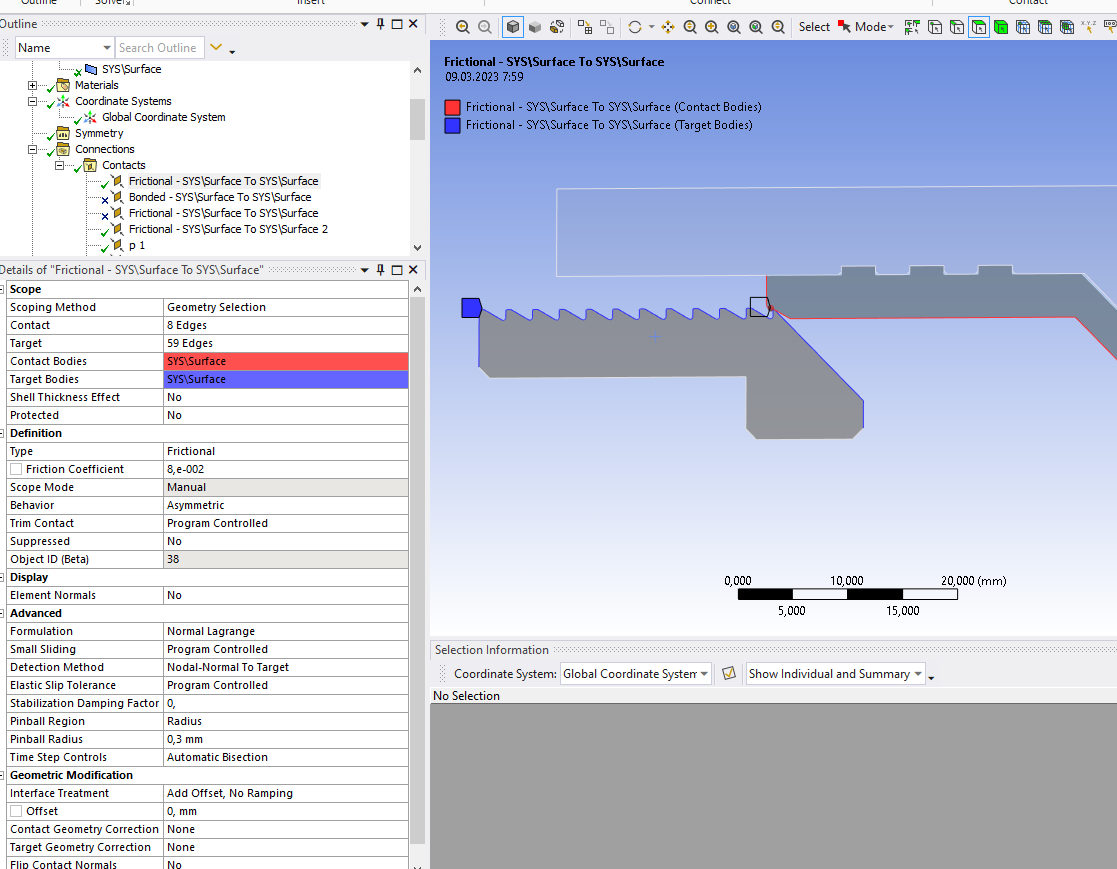

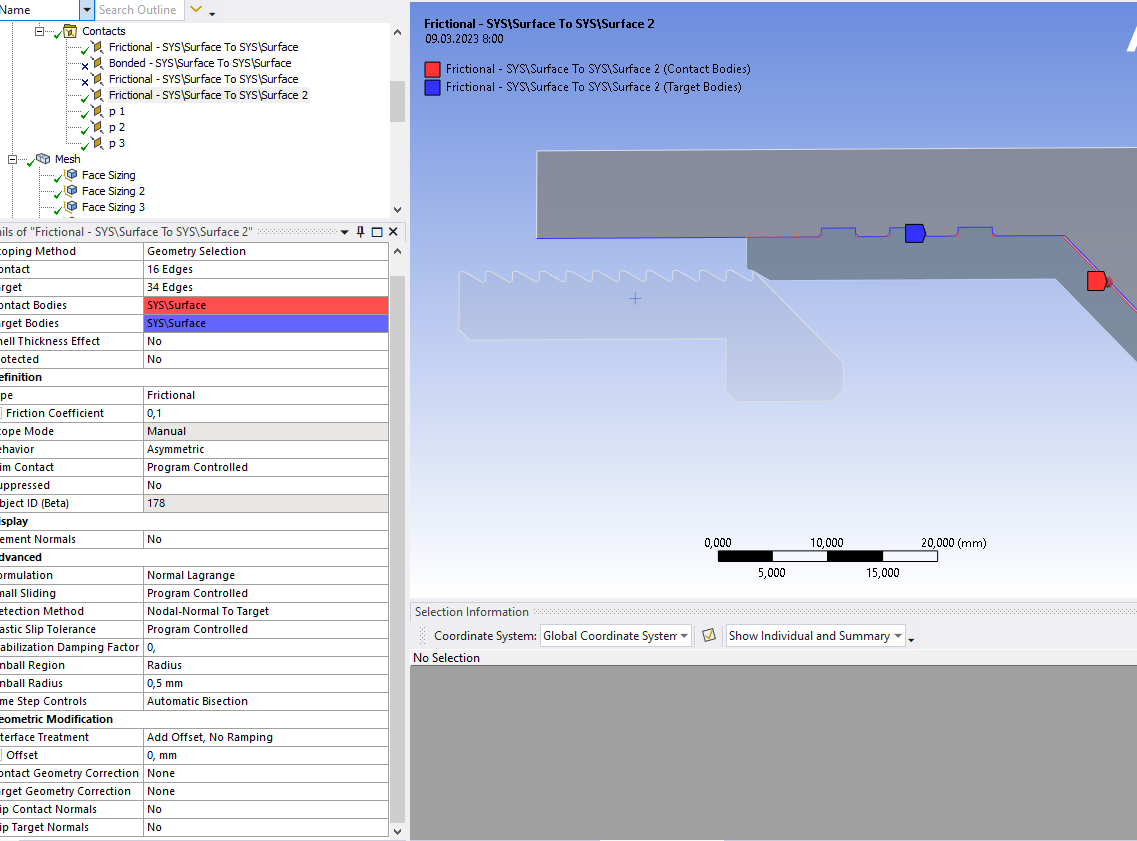

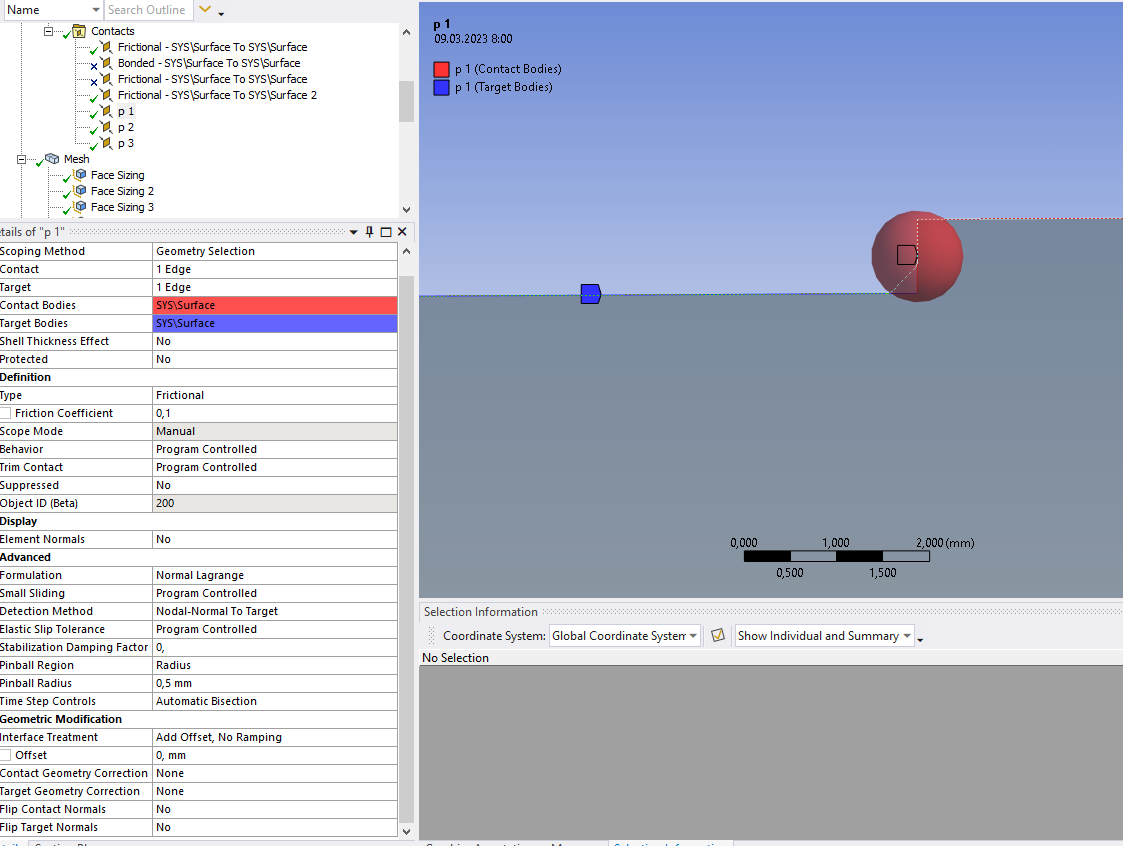

SubscriberI am modeling two teeth that slide over the rubber. I'm using the Ogden model that I made after testing the material. Axisymmetric solution

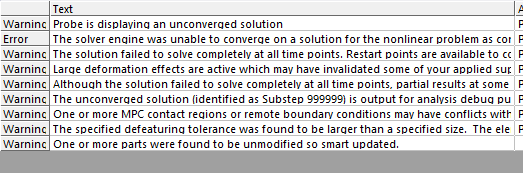

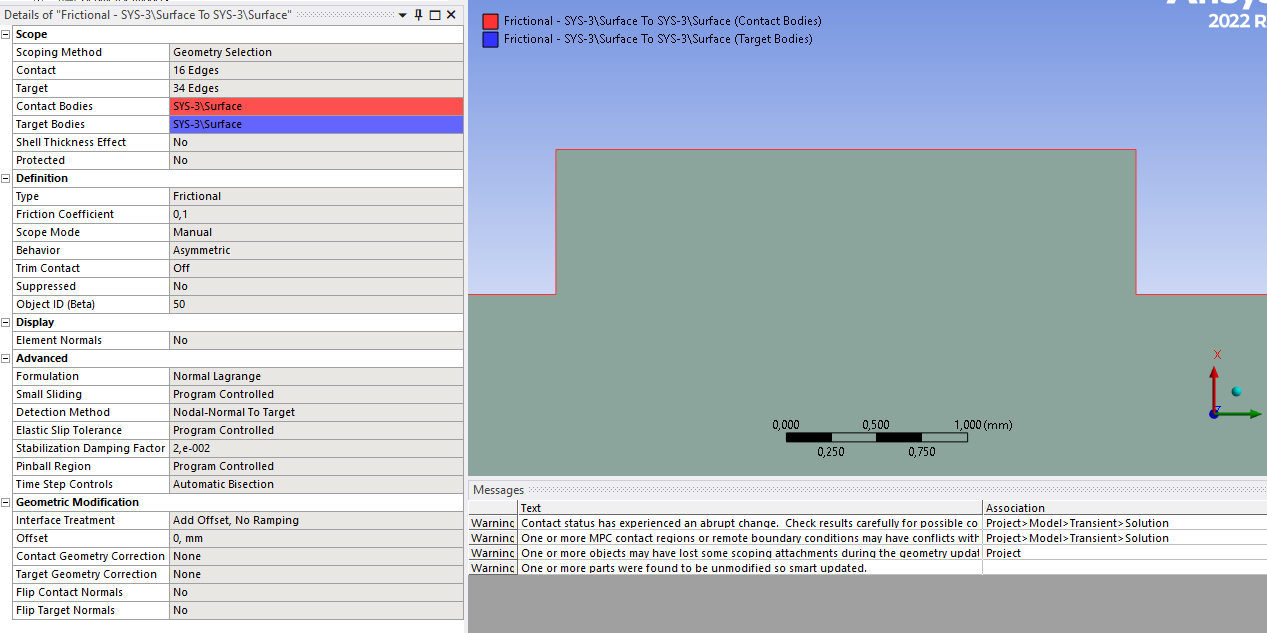

But after a 2 mm pass there is always an error, regardless of any grid, any type of contact, and in general any advanced settings:

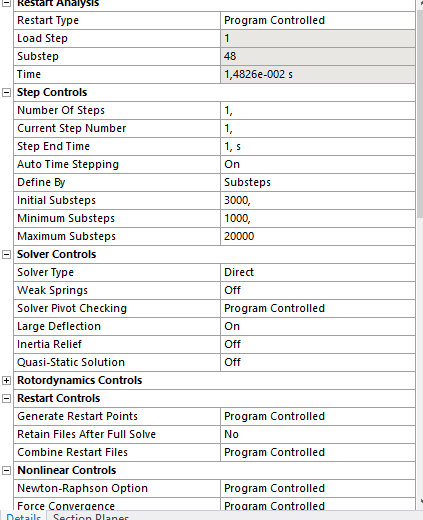

Settings:

Help or advice please? I also tried using NEQIT, 50, as I move my teeth 15mm and simple steps may not be enough, but it didn't help.

I have also attached the ARCHIVE

-

March 9, 2023 at 7:05 pm

peteroznewman

SubscriberPlease reply with the version of Ansys you are using, Year and R#

-

March 9, 2023 at 7:33 pm

javat33489

Subscriber2022 R2

-

-

March 10, 2023 at 2:33 am

peteroznewman

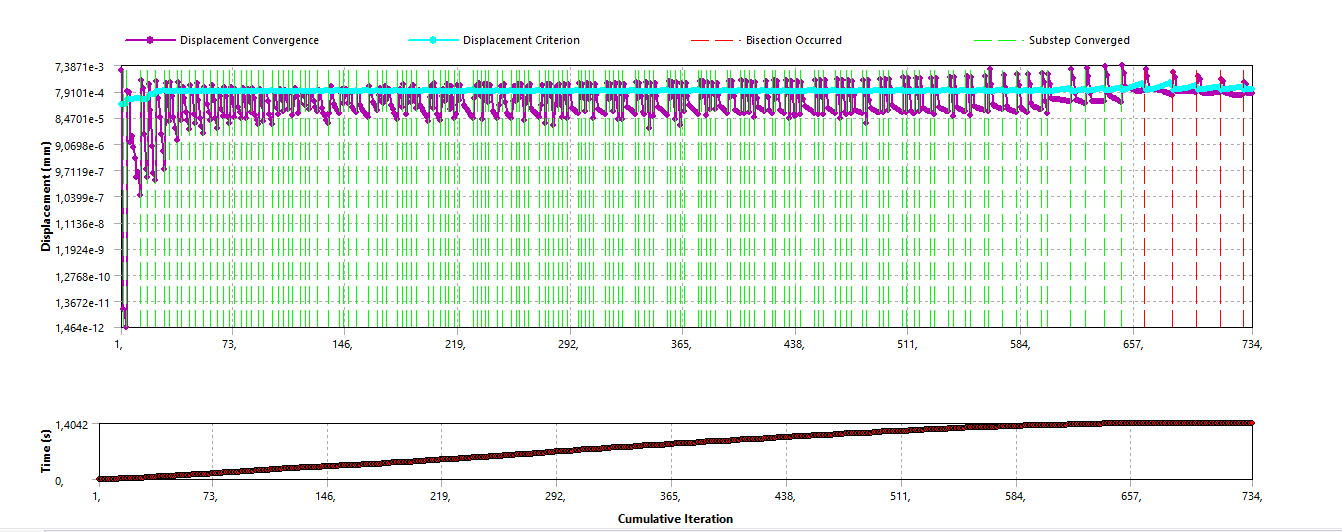

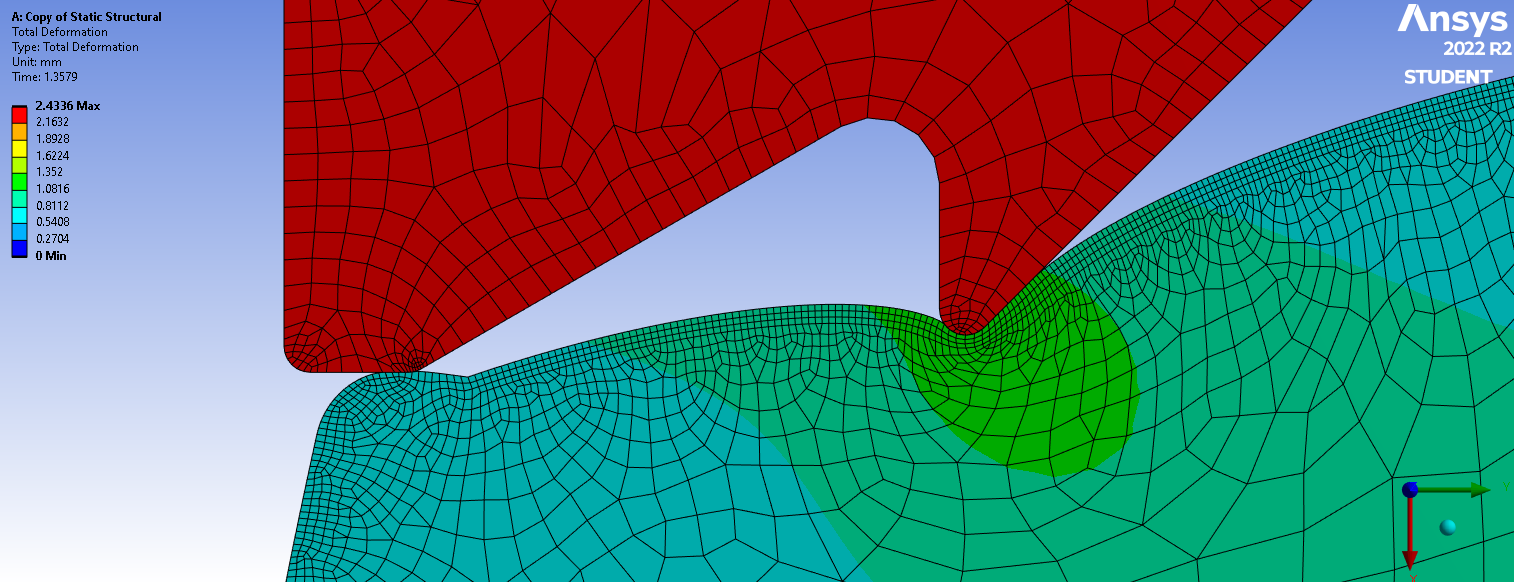

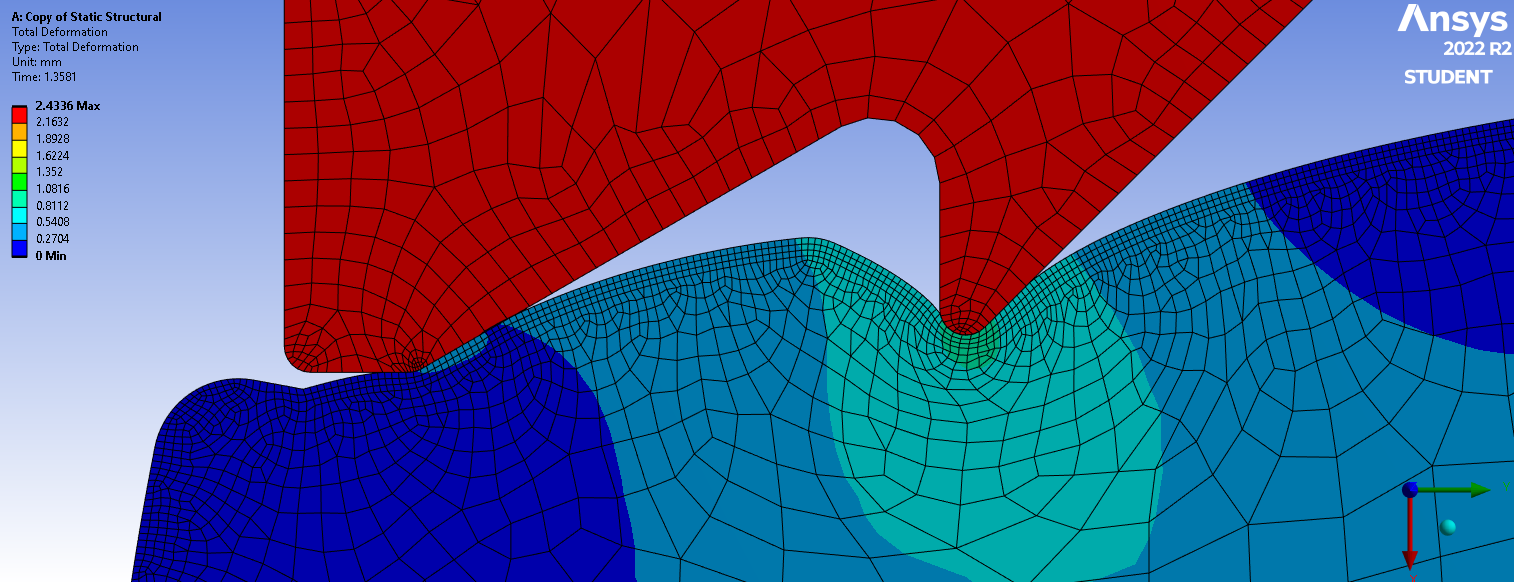

SubscriberI turned on Friction and made some other adjustments, but there is a point in the Static Structural simulation where a dynamic event occurs.

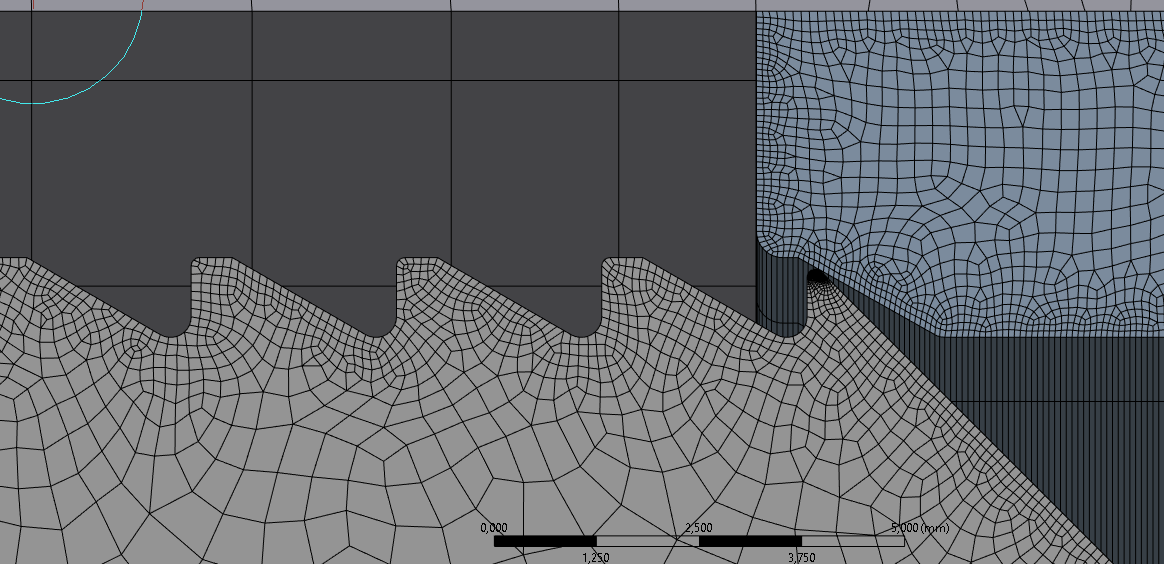

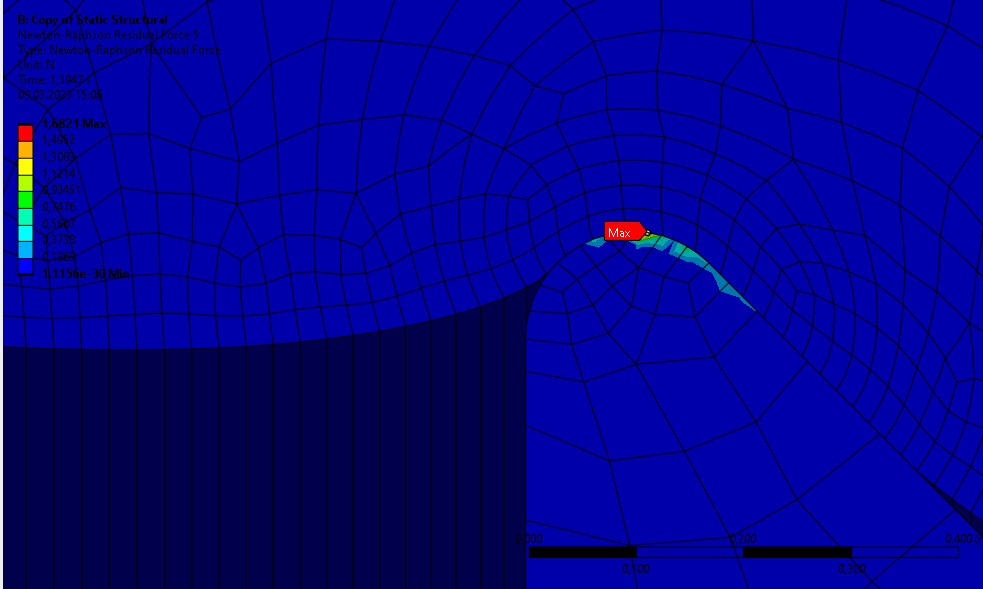

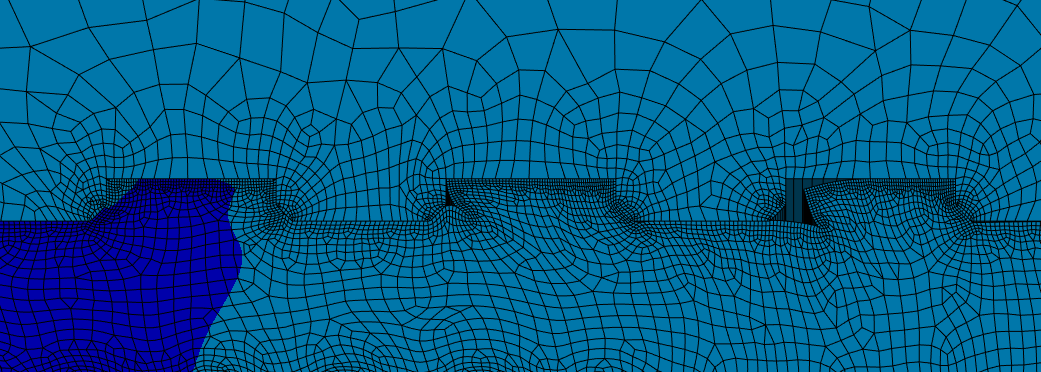

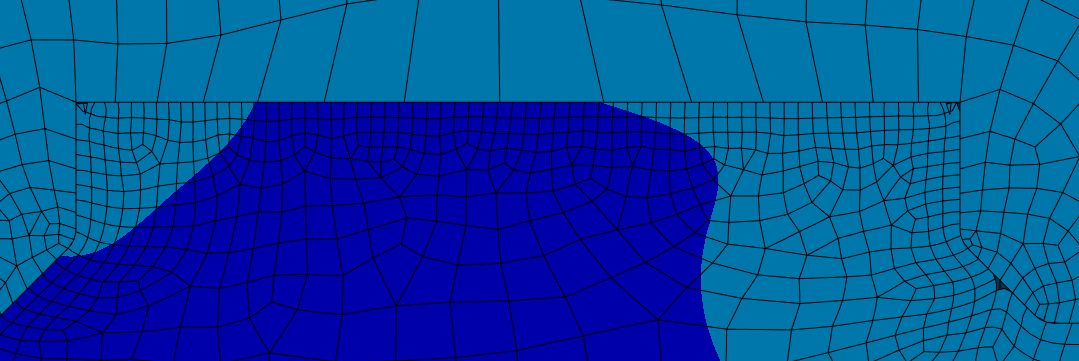

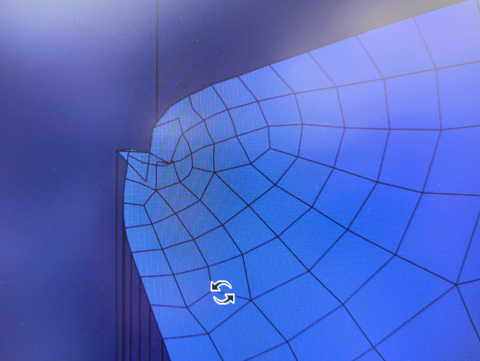

In one increment, the material is here:

In the next increment the rubber has jumped to the left, releasing a lot of strain energy, and the solver cannot find Static Equilibrium again and stops.

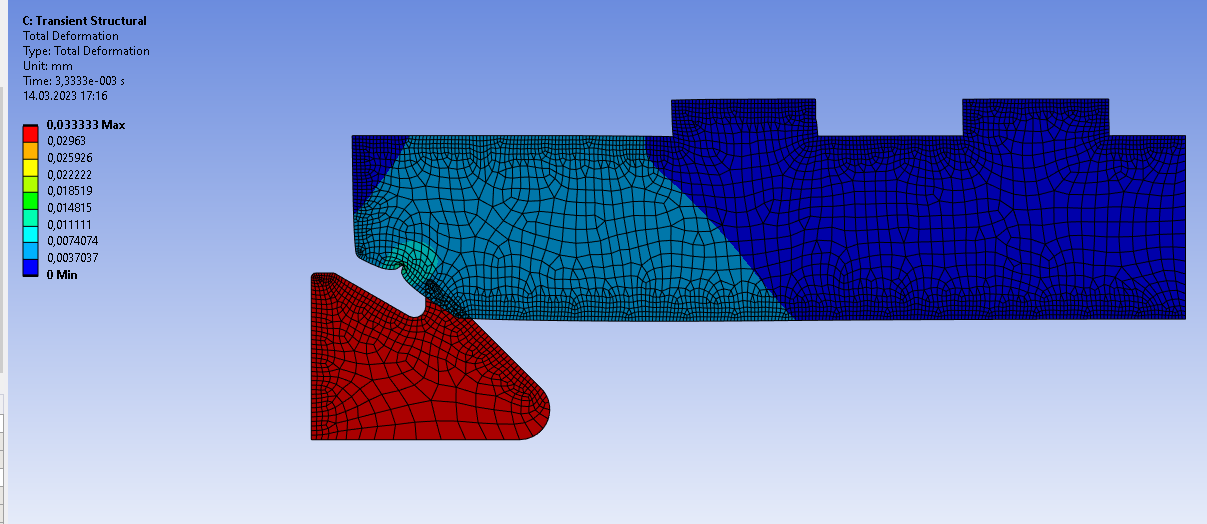

The corrective action is to solve this in a Transient Structural or Explicit Dynamics solver.

There is a method you can enable the Static Structural solver called semi-implicit to automatically switch to the explicit solver to solve the dynamic part of the solution and later to switch back to Static Structural. That might be worth trying here, but note that the material should have a density material property because there must be mass to compute a dynamic solution.

The small cylindrical face on the rubber part at the tip may be contributing to the dynamic event. If the conical surface were to continue all the way to the flat top of the rubber, with a small blend on the corner, that might improve the solution.

-

March 10, 2023 at 5:17 pm

javat33489

SubscriberThanks a lot! I will try!

-

-

March 10, 2023 at 5:36 pm

peteroznewman

SubscriberTry the geometry edit first. I just tried the Semi-Implicit method using defaults for all parameters and it failed to advance the solution.

-

March 10, 2023 at 5:43 pm

javat33489

SubscriberOk, I'll try. I'll let you know the decision here

-

March 10, 2023 at 5:48 pm

javat33489

Subscriber- I will try to solve the problem in Transient Structural.

- I will try Semi-Implicit method in Static Structural.

I'll let you know the decision here.

-

-

March 10, 2023 at 6:04 pm

peteroznewman

SubscriberI tried the geometry edit in Static Structural and it didn't help. It is the stick-slip behavior of the rubber that makes it a Transient solution.

-

March 10, 2023 at 6:33 pm

javat33489

SubscriberOk, thanks a lot! I'll try.

-

-

March 10, 2023 at 10:03 pm

peteroznewman

SubscriberDon't forget to add Damping to the Transient Structural model. I forgot and you can see what happens, lots of high frequency vibration on each stick-slip event.

https://youtu.be/UROc00wP9fk

-

March 11, 2023 at 10:39 am

javat33489

Subscriberwhat damping factor would you recommend? Or find it by testing?

-

March 14, 2023 at 6:59 pm

-

-

March 14, 2023 at 8:51 pm

peteroznewman

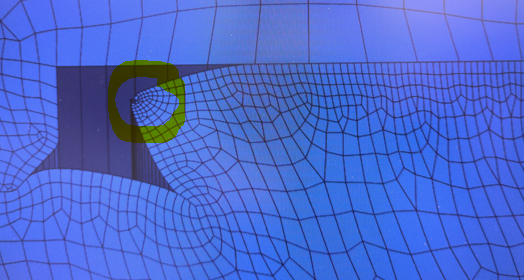

SubscriberIs it possible that the contact has Trim Contact enabled? I would delete the contacts and recreate them from scratch.

You could also try Explicit Dynamics. In the video below, the body-interactions are frictionless. I also removed the frictionless support on the right end of the rubber since that is not present in the full model. After I played this animation, I plotted normal stress in the Z-axis which is Hoop Stress, but did not see a compressive stress building as the rubber moved closer to the axis of revolution, so now I want to investigate why that is. You may want to do a small test for yourself before you spend a lot of time on this solver.

https://youtu.be/8Yt15P--Lsc

-

March 16, 2023 at 3:33 pm

-

March 16, 2023 at 5:28 pm

peteroznewman

SubscriberTry to solve it without the frictionless support on the right end. Does it escape?

The animation looks better if you color the elements by Body Color, in my opinion.

-

March 16, 2023 at 6:42 pm

javat33489

SubscriberTry to solve it without the frictionless support on the right end. Does it escape?

In life, there is just an emphasis for her so that she does not run away. If you remove it, I think it will run away. I'll try, the calculation time was 10 hours.

The animation looks better if you color the elements by Body Color, in my opinion.

Yes, I was in a hurry. If there is time I will do the color of the bodies. Thanks for the help!

-

-

March 16, 2023 at 8:10 pm

peteroznewman

Subscriber-

March 17, 2023 at 6:13 pm

javat33489

SubscriberI have not been able to solve it completely yet, after a long time solving the grid error 99999999, I am working on it

-

March 24, 2023 at 8:14 pm

-

April 11, 2023 at 6:44 pm

-

-

April 12, 2023 at 11:22 am

peteroznewman

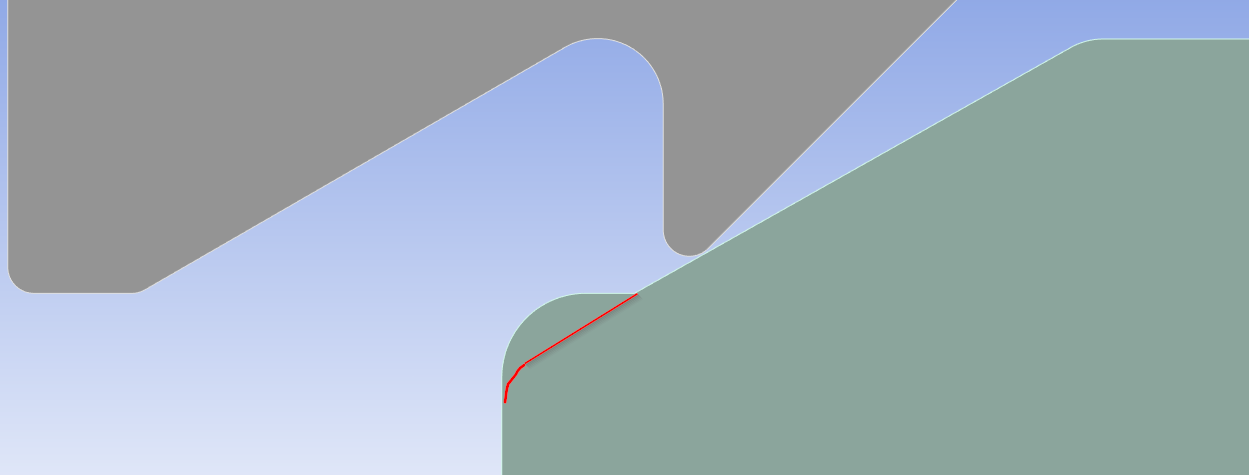

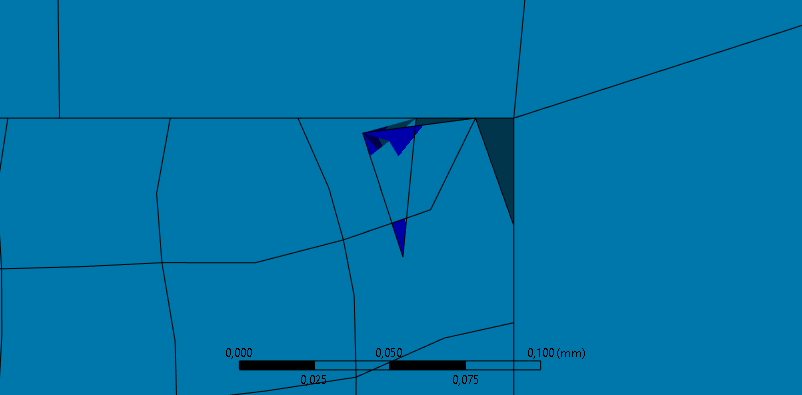

SubscriberAdding a small blend radius to that corner might help prevent the corner element from turning inside out, becuase there will no longer be a corner element!

-

April 12, 2023 at 5:02 pm

javat33489

SubscriberThanks for your reply! I didn't fully understand you. Need to increase the radius of the geometry? Or are you talking about some sort of grid tool?

-

-

April 12, 2023 at 6:29 pm

peteroznewman

SubscriberI am talking about the geometry. There is a sharp corner where the element turns inside out.

In SpaceClaim, edit the geometry by using the Pull tool to pull that point into a blend radius.

Now when you mesh that geometry, there will be no sharp corner. If you put at least 4 elements on the circular edge, there will be no elements on a corner.

-

April 12, 2023 at 6:47 pm

javat33489

SubscriberThe screen is hard to see. There already is a radius, the problem is what happens to the radius. Maybe increase it until the problem goes away?

-

-

April 12, 2023 at 11:14 pm

peteroznewman

SubscriberAh, okay, yes, I bigger radius. Also mesh with Linear Elements.

-

- The topic ‘The problem with hyperelasticity’ is closed to new replies.

-

4613

-

1515

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.