-

-

October 7, 2019 at 7:26 am

Armand

SubscriberHello

I have been doing the tutorials, called for Modeling Uniform Fluidization in 2D Fluidized Bed.

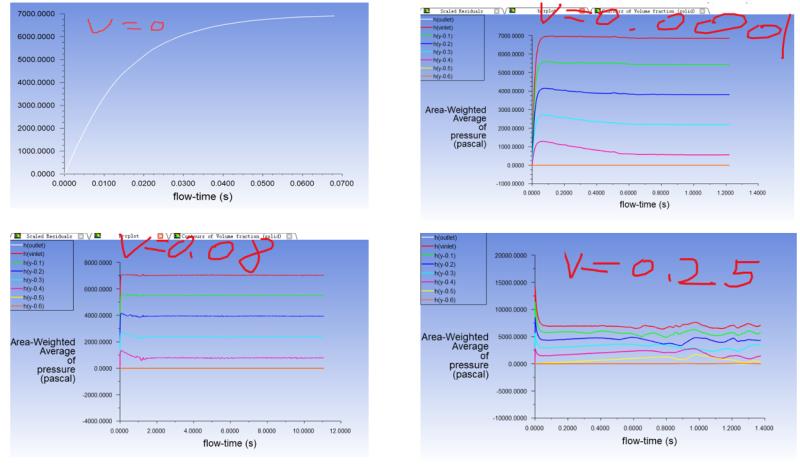

I did this at the beginning and it gives me a constant value equal to the bed's weight (no matter the velocity).

I just wondering if anyone had met the same problem, and what was the way to solve it? Please feel free to reach me via

You answer will be appreciated.

Best Regard

-

October 7, 2019 at 7:40 am

-

October 7, 2019 at 3:38 pm

Rob

Forum ModeratorPlease post images of the bed, ie the mass fraction of phases. Which model are you using?

-

October 7, 2019 at 4:15 pm

Armand

SubscriberHi,

What I were doing is the content of the tutorial, and the tutorial is in the attached files.

I used the multiphasic eulerian model

Best regards,

Armand

-

October 7, 2019 at 4:18 pm

-

October 8, 2019 at 3:14 pm

Rob

Forum ModeratorWhich I am not allowed to open or download. Please post the images I asked for.

-

October 10, 2019 at 2:32 pm

DrAmine

Ansys EmployeeWhat are now your questions? If you type fluent fluized bed tutorial words in Google you will find a Fluent tutorial on that.

-

October 10, 2019 at 2:44 pm

Armand

Subscriberhi,

yes,I can find it, but it gives me a constant value equal to the bed's weight (no matter the velocity).

Best regards,

Armand

-

October 10, 2019 at 2:54 pm

DrAmine

Ansys EmployeeYou need to be much more precise in your communicaiton: what is the constant value? Are you talking about pressure drop? Perhaps you reached the minimum fluidization velocity?

The key feature in capturing bed height and pressure correctly is the spatial and temporal resolution of the simulations. Specifically, for spatial resolution, mesh size should be smaller than 10*dp (particle diameter) (delatx<10dp)

-

October 10, 2019 at 3:03 pm

Armand

SubscriberEven if the gas inlet speed is zero, the bed pressure drop is equal to the weight of the bed material.

Best regards,

Armand

-

October 10, 2019 at 3:12 pm

Armand

SubscriberIn my project, the spatial resolution is what you say.

Best regards,

Armand

-

October 10, 2019 at 3:31 pm

DrAmine

Ansys EmployeePerhaps reporting issue otherwise you won't get different profiles: remove the bed density from pressure via custom field function. I cannot now check what we have done years ago to get to get the well known curve. -

October 10, 2019 at 3:34 pm

DrAmine

Ansys EmployeeHow are u reporting pressure? -

October 10, 2019 at 3:40 pm

Armand

SubscriberIs the meaning of your picture that you can get this curve by refining the grid?

Best regards,

Armand

-

October 10, 2019 at 4:00 pm

DrAmine

Ansys EmployeeStop referring to old posts (my posts) and respond to the comments. For sure the walls have a sustaining effect and you need required resolurion but you can check if the hydro head is spoiling pressure field. We obtained good result for drop curve. -

October 10, 2019 at 4:50 pm

Armand

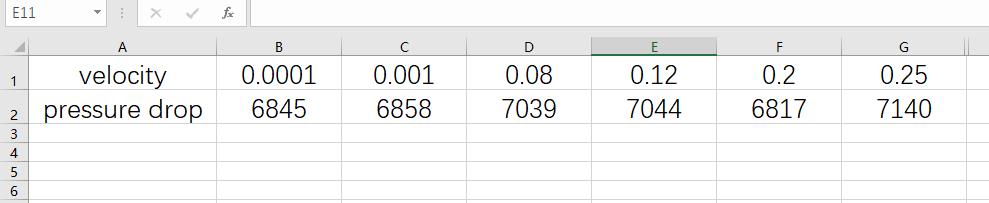

SubscriberI reported the pressure drop by monitoring the total pressure of the air and the static pressure of the mixture.

Best regards,

Armand

-

October 10, 2019 at 4:53 pm

Armand

SubscriberHow can I check if the hydro head is spoiling pressure field?

Best regards,

Armand

-

October 11, 2019 at 12:18 pm

DrAmine

Ansys EmployeeI looked back to my tutorial: I am just evaluating the static pressure @inlet and @outlet (set as outflow). In the tutorial the min. fluid. velocity is about 8 cm/s. I will update later once again.

-

October 11, 2019 at 1:58 pm

Armand

SubscriberThank you very much for your reply. Looking forward to your update.

Best regards,

Armand

-

October 11, 2019 at 2:29 pm

DrAmine

Ansys EmployeeSo I run basically three points far below the expected 8 cm/s

-

October 11, 2019 at 2:29 pm

DrAmine

Ansys Employeeand I definitely can confirm that the pressure difference is increasing.

-

October 11, 2019 at 2:33 pm

Armand

SubscriberCan you tell me in detail about the differences between your settings and the tutorial?

Best regards,

Armand

-

October 11, 2019 at 3:07 pm

Armand

SubscriberWhat you mean is that compared to the tutorial, just change the pressure outlet to outflow.

Best regards,

Armand

-

October 11, 2019 at 3:57 pm

DrAmine

Ansys Employee1 meter height 0.15 m bed width. I used wen drag and enabled Schaeffer friction and frictional pressure after Johnson. Time step size 0.0001 s. One has to be patient to reach steady state pressure level. -

October 11, 2019 at 4:26 pm

Armand

SubscriberHow long does it take to reach steady state?Which type of pressure do you monitor in import?

Thank you very much for your reply. Looking forward to your update.

Best regards,

Armand

-

October 12, 2019 at 5:35 am

DrAmine

Ansys EmployeeBest to monitor pressure differences between in and out. Create two reports based on area average of pressure than a third one for difference and monitor that.

-

- The topic ‘The prediction of pressure drop failed for Modeling Uniform Fluidization in 2D Fluidized Bed’ is closed to new replies.

-

5274

-

1859

-

1398

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.