-

-

March 29, 2021 at 10:16 am

Philippe CLECH

SubscriberGood morning to all

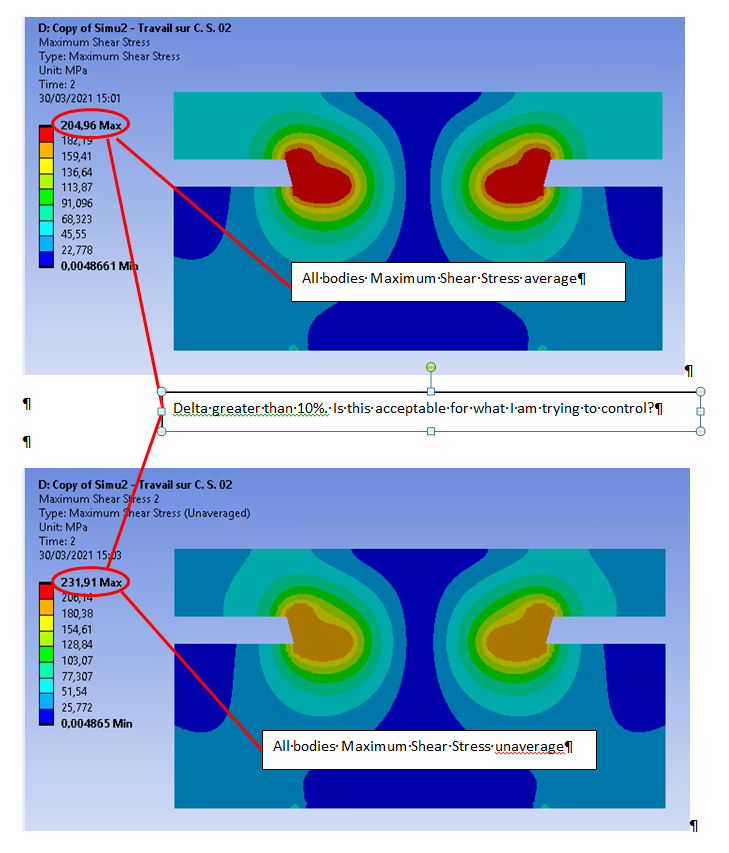

During my training, I was told that in order to obtain a compliant result, the value of the shear stress, for example, should not differ by more than 10% between the averaged and unaveraged result. Is this rule imperative globally or locally?

overall result (Overall model):

March 30, 2021 at 11:01 amAshish Khemka

Forum ModeratornnThere is no rule as such. But when you refine a mesh, the results change. In general, when the change is within say 5% or 10% (based on what may be acceptable by you or design needs) we say that the mesh is converged or the result is acceptable.nnRegards,nAshish KhemkanMarch 30, 2021 at 1:13 pmPhilippe CLECH

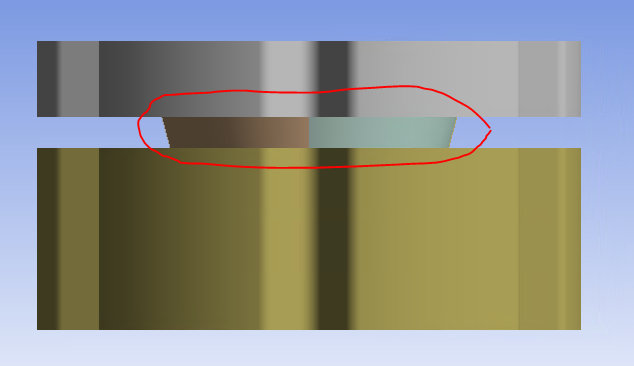

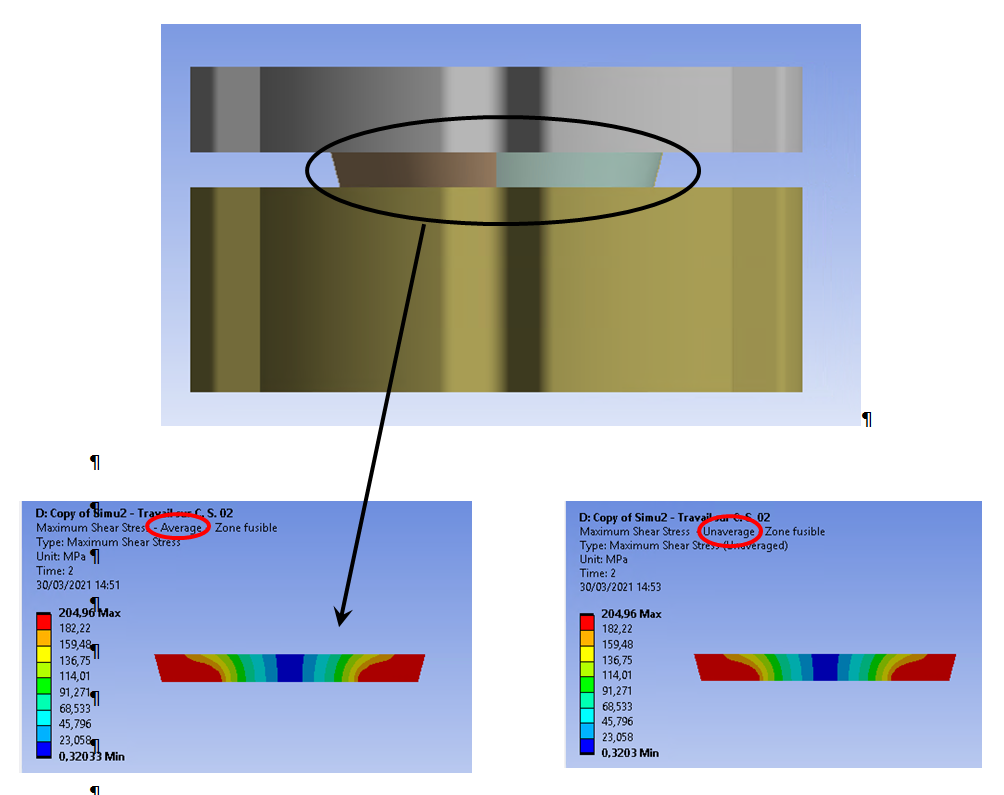

SubscriberHi Ashish.nSo if I go back to my example, I'm trying to validate the sizing of the failure zone.n In this case, for example, the delta of the averaged and unaveraged maximum shear stress result must be 10% less if I am interrogating the bodies in this zone that I am trying to monitor. Is this correct?n

In this case, for example, the delta of the averaged and unaveraged maximum shear stress result must be 10% less if I am interrogating the bodies in this zone that I am trying to monitor. Is this correct?n And it doesn't matter what I'm trying to monitor if in general the 10% rule is not respected. nIs this reasoning acceptable for my case?n

And it doesn't matter what I'm trying to monitor if in general the 10% rule is not respected. nIs this reasoning acceptable for my case?n Best regardsnPhilippen

Viewing 2 reply threads

Best regardsnPhilippen

Viewing 2 reply threads- The topic ‘The 10% rule between averaged and unaveraged results’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3712

-

1313

-

1163

-

1090

-

1014

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.