-

-

January 31, 2024 at 4:05 pm

cma6301

SubscriberHello,

I am new in simulation and rocky. I have gone via the tutorial avaliable online. I started my own project on simulating the grinding process in stirred-mill. I encounter some challenges I have not been able to figure out for two weeks now.

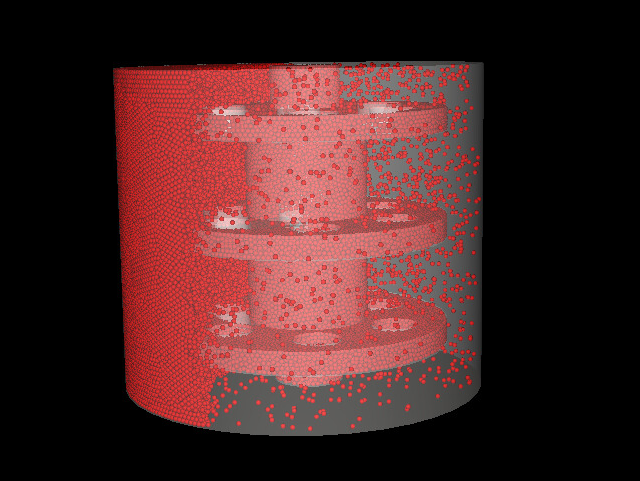

- the particles in the drum settle on the z-axis while the simulation is still on going(see image below)

2. the rotor is not rotating perfectly. I was expecting it to rotate 360 clockwise but what i observed is a kind of dangling motion.

I will be most grateful if anyone could help me figure what could have cause the problem.

Best regards,

Ayuk

-

February 1, 2024 at 1:32 pm

Jackson Gomes

Ansys EmployeeHello Ayuk,

I can give you some suggestion to investigate this issue:

- Take a look at the material interactions parameters, specifically those related to friction between the mill and particles. Make sure the values align with the actual physical properties of the materials involved.

- In the output frequencies, review the simulation time to ensure that the time step is sufficiently small to accurately capture the dynamics of the system.

- Double-check the parameters linked to the rotor’s rotation to confirm that the rotation axis, speed, and direction are accurately defined to ensure optimal performance.

- Verify the gravity settings to confirm if it aligns with the correct axis direction.

I recommend exploring additional information in the User Manual available on Rocky User Manual (ansys.com)

Best regards,

-

February 7, 2024 at 6:29 pm

cma6301

SubscriberHello Jackson,

Thank you so much for your suggestions. The issue of dangling motion was as a result of the rotor not aligning properly with the drum. I have fixed that. Also, gravity was not set in the correct axis. All that is resolved now.

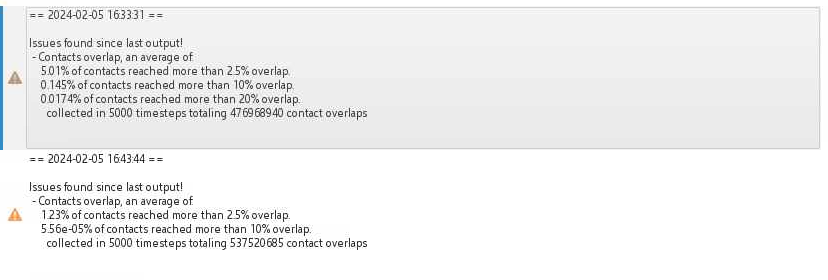

However, during the simulation I got a warning error about contact overlap. My question is what are the carteria for modifying the default warning message level? In case i want to change from the default levels values of 0.025, 0.1 and 0.2?

Best regards,

-

February 8, 2024 at 1:27 pm

Jackson Gomes

Ansys EmployeeI’m glad you managed to solve the rotor’s dangling motion issue!

Monitoring your contacts for overlaps is crucial because Rocky uses the overlap value to calculate collision forces. Therefore, large overlap values can lead to serious stability and accuracy problems in a simulation. In a typical simulation, overlaps of 2.5% may be considered acceptable; however, simulations with overlaps greater than 10-20% probably should not be trusted, as such large values can cause serious instability and accuracy issues.

I recommend exploring additional information in the User Manual available on Rocky User Manual (ansys.com)

Best regards,

-

February 8, 2024 at 2:51 pm

cma6301

SubscriberDear Jackson,

Thank you so much for your response. However, how do I prevent such warning error ?

Best regards,

Ayuk

-

February 9, 2024 at 11:03 am

Jackson Gomes

Ansys EmployeeDear Ayuk,

Try changing the softening factor. All information you need can be found in this tutorial Chapter 4: Tutorial - SAG Mill (ansys.com)

Best regards,

Jackson Gomes

-

February 13, 2024 at 11:11 pm

cma6301

SubscriberDear Jackson,

I hope you are doing well. I have tried playing around with the softening factor but stilling getting the warning message.

However I also what to asked if you know how to cut through my geometry in Rocky inorder to display the inner particles? I tried using plane under particle processes. It just shows the plane not cut the plane. I have gone via the tutorial to see where that is done but to no avail. I hope you could help.

Thank you,

Ayuk

-

February 19, 2024 at 11:43 am

Jackson Gomes

Ansys EmployeeDear Ayuk.

You can create a User Process from the Wall geometry you are interested in visualizing a slice or section. You might do it with a Cube or a Plane by selecting the area of interest with the Coordinates and Dimensions parameters.

-

February 28, 2024 at 4:56 pm

cma6301

SubscriberHello Jackson,

I have tried using but still have challenge on cutting just a slide of the geometry showing some particles.

Also, I want to know if there is a way to extract the raw simulated data from rocky. For example I wish to extract the specific energy data for particles. When I extracted the curves, the data was so small. I need to extract the raw data itself without it being average. So, I can do post analysis using my own code. I need raw simulation data like position, velocity, normal and tangential forces and torque. These parameters i have seen via particle properties. However, when i export say the average position, velocity, and forces and use them for my personal post-processing code, it does not represent my simulation hence why i need to get the raw simulation data.

I wish you can help with this.

Best regards,

Ayuk

-

March 5, 2024 at 9:50 pm

cma6301

SubscriberHello Jackson,

I hope you are doing great.

I want to export raw contact information from my simulation. Please how do I do that?

Best regards,

Ayuk

-

- The topic ‘Studying stirred mill performance’ is closed to new replies.

-

4633

-

1535

-

1386

-

1215

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.