-

-

December 10, 2023 at 11:46 am

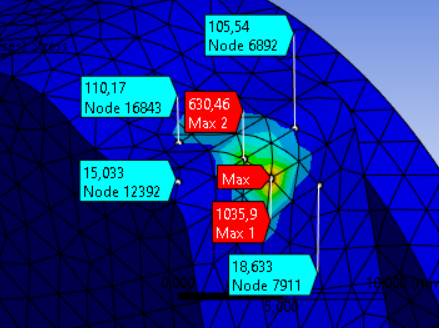

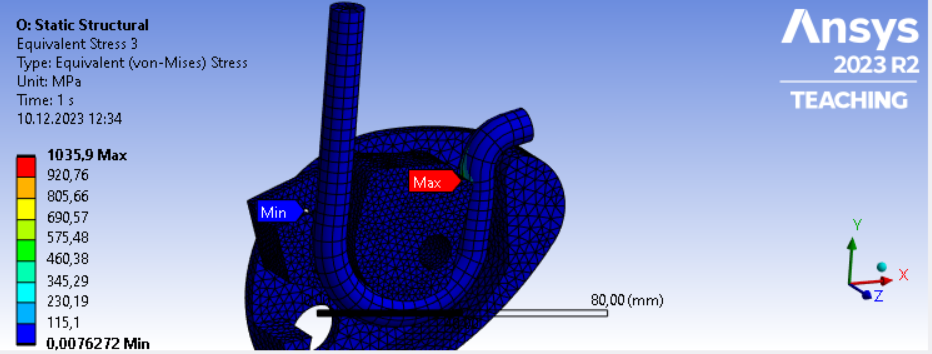

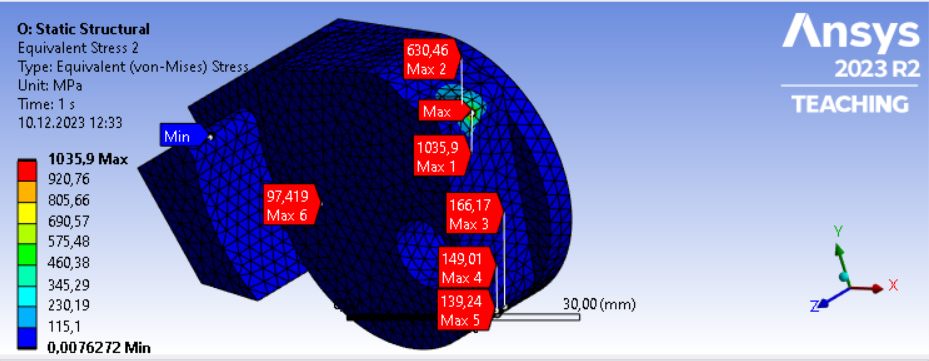

ksoltyk

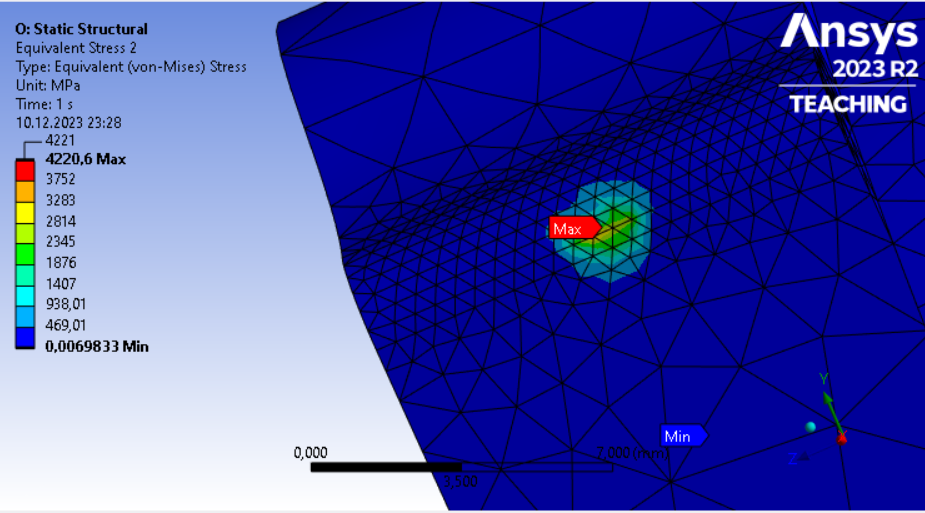

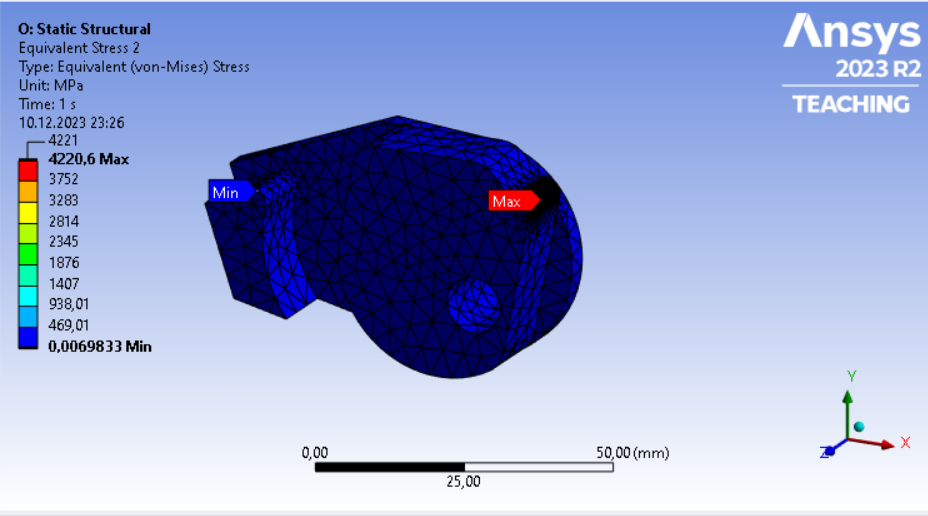

SubscriberHow to get rid of stresses that converge to infinity? I've tried using rounded corners, etc., but it doesn't help. On the website https://medium.com/@nickjstevens/practical-tips-for-dealing-with-stress-singularities-nick-j-stevens-1fe6a57d55a9, I read that one of the ways is to ignore them, and I would like to do that here. My question is, can I remove the maximum stresses so that the graph only shows stresses within the given range? How else can I deal with this? Mesh refinement causes values to increase (to infinity).

I expect maximum stresses of approximately 200 MPa

-

December 10, 2023 at 4:35 pm

peteroznewman

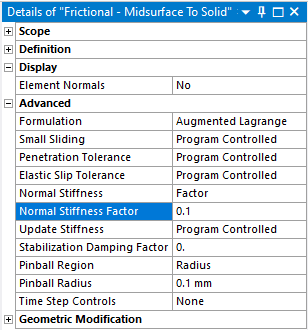

SubscriberKarol,

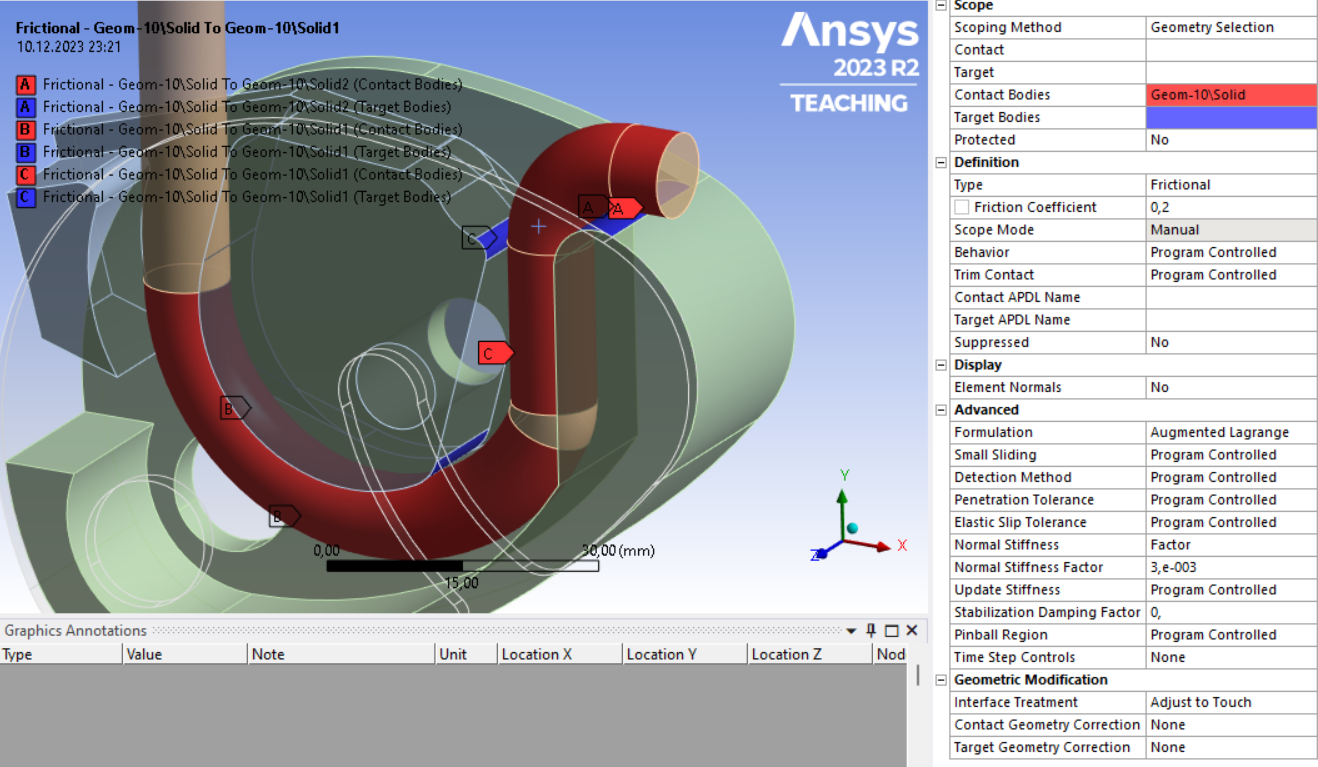

Is there frictional contact defined between two bodies at location where the maximum stress is observed? One method to avoid increasing stress as the mesh is refined in that situation is to soften the contact. Under the Advanced category, change the Normal Stiffness to Factor and enter a Normal Stiffness Factor less than 1. I show 0.1 but you can try 0.01 or even smaller. This will allow the bodies to penetrate slightly, speading the load over several nodes. You do need a fairly fine mesh so that there are nearby nodes to the geometric point of contact to spread the load to. You won't see that with the coarse mesh you are showing. Place a Coordinate System with the origin at the point of contact so you can insert a Mesh Size control on the two bodies of Type: Sphere of Influence so you only create the fine mesh near the point of contact and you can leave the global element size the same.

Regards,

Peter

-

December 10, 2023 at 10:27 pm

ksoltyk

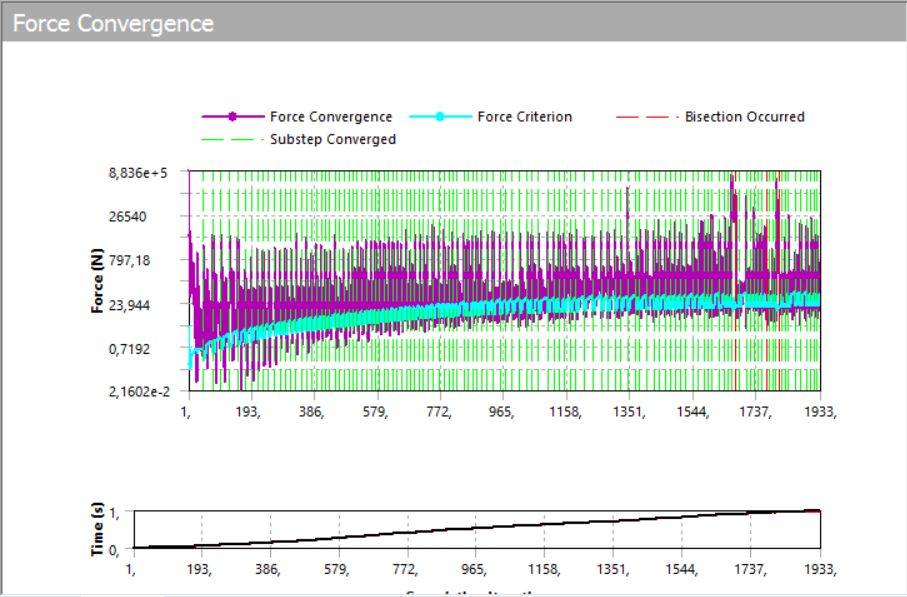

SubscriberI changed the stiffness coefficient to a very low value and densified the mesh, yet the stresses continue to increase to infinity. Is there another way to solve my problem, or would it be a mistake to disregard this result? If it is permissible to overlook the high stresses, what values should I adopt in this situation?Additionally, the program requires a large number of iterations.

-

December 11, 2023 at 10:40 pm

peteroznewman

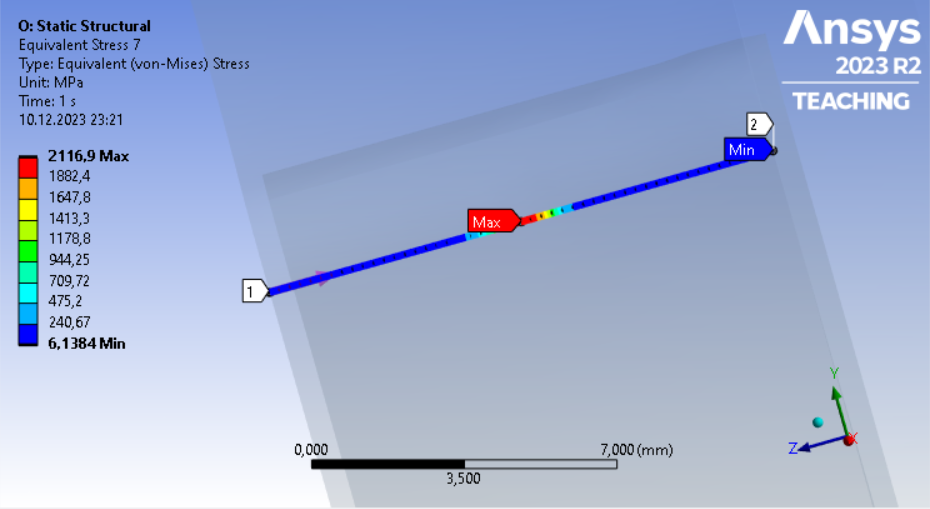

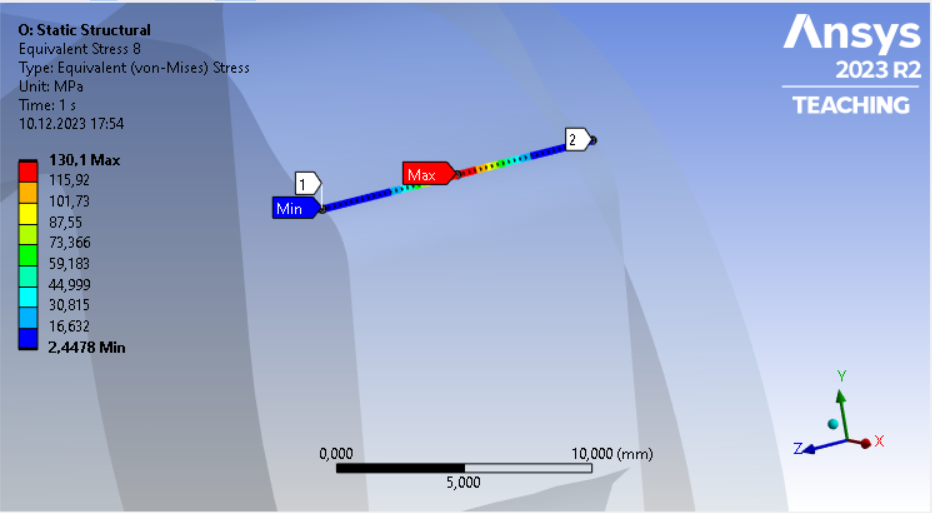

SubscriberYou need a finer mesh on both sides of the contact. The cable mesh is still too coase at the contact point. Apply the same mesh sizing on the cable as you do to the clamp.

What is the Young’s Modulus of the cable? Try reducing the Young’s modulus by a factor of 100. That, combined with a finer mesh will allow the clamp to flatten the cable and develop an area of contact instead of a point contact. It is the point contact that is creating the high stress.

Reducing the contact stiffness is another way to get a larger area of contact. You can reduce that by another factor of 100. You can insert a Contact tool into your results and request a Penetration result to check that the clamp is not penetrating the cable by an excessive amount.

Yes, frictional contact often leads to a large number of iterations and hours of computation. This is normal.

-

December 12, 2023 at 12:04 am

ksoltyk

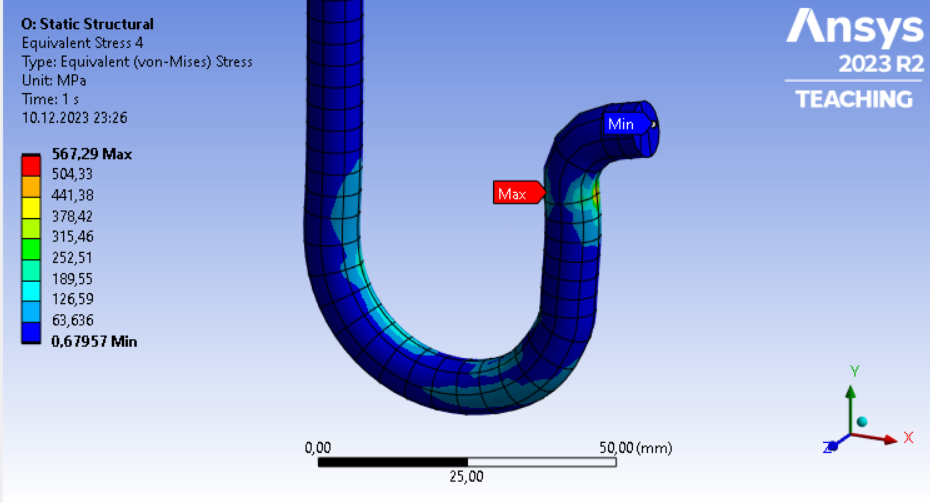

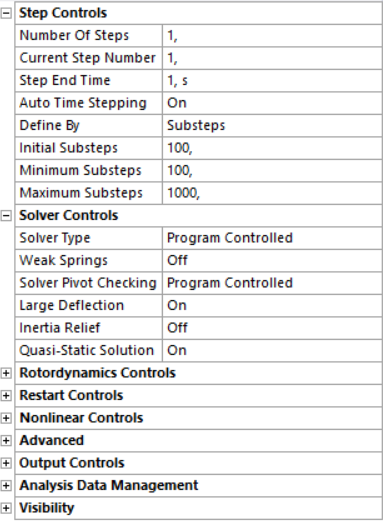

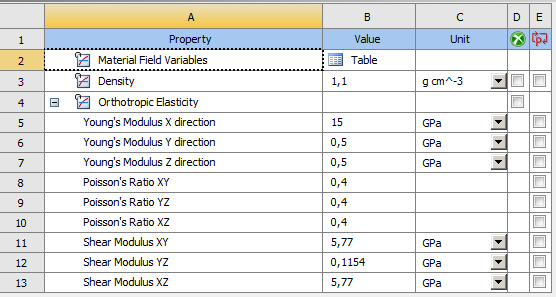

SubscriberI used the parameters shown in the picture. This is a rope used for climbing. I know that a rope should be modeled as a 'cable' with ELEMENT280, but I tried and couldn't achieve satisfactory results. The rope itself is not the focus of my analysis, and it's sufficient if the results are good on the device. Are the parameters adequate to illustrate compression, or should I still make some changes? Should I change the parameters further to make the rope more susceptible to compression?

-

- The topic ‘stress tending to infinity ansys’ is closed to new replies.

-

4833

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.