-

-

October 27, 2024 at 10:48 am

choo.fuhsien

SubscriberHi,

I am a simple static analysis for column with second order shell element. Forces and moments are applied at the top and the bottom end is fixed.

When I displayed the Von Mises stress using Elemental Mean for Top/Bottom surface, the maximum stress of 172.13 MPa is lower than the stress if taken for TOP surface only (255.16 MPa). My understanding is Top/Bottom should display the maximum between the 2 surfaces. For Nodal Average Top/Bottom, it is dislaying the maximum of the 2 surfaces. May I know the reason for this? Is there any option that I need to select to display the maximum stress under Top/Bottom?

-

October 27, 2024 at 11:45 am

peteroznewman

SubscriberThe values of Top/Bottom and Top don't match because the location of the maximum moved. There are settings such as Average Across Bodies that can affect the Elemental Mean stress result.

If you limit the scope to a single face and turn off Average Across Bodies, then values of Top/Bottom and Top will match if the maximum value of stress is on top.

-

October 27, 2024 at 4:43 pm

choo.fuhsien

SubscriberThank for the quick response sir.

Under Element Mean, there is no option for Average Across Bodies. I have separately scoped the top surface for the area with maximum Element Mean stress and the 'Top/Bottom' stress is still lower than the 'Top' stress. Does this mean that the 'Top/Bottom' is unable to capture the maximum stress and I need to check 'Top' and 'Bottom' just to be safe?

-

October 27, 2024 at 6:22 pm

peteroznewman

SubscriberThanks for the reply.

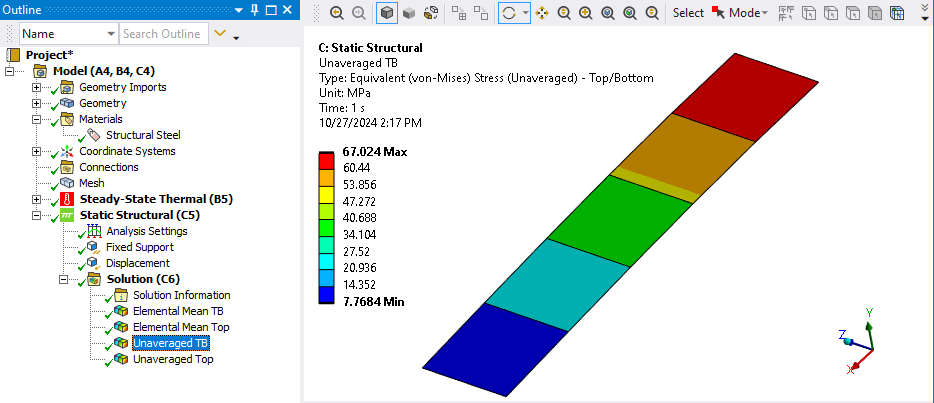

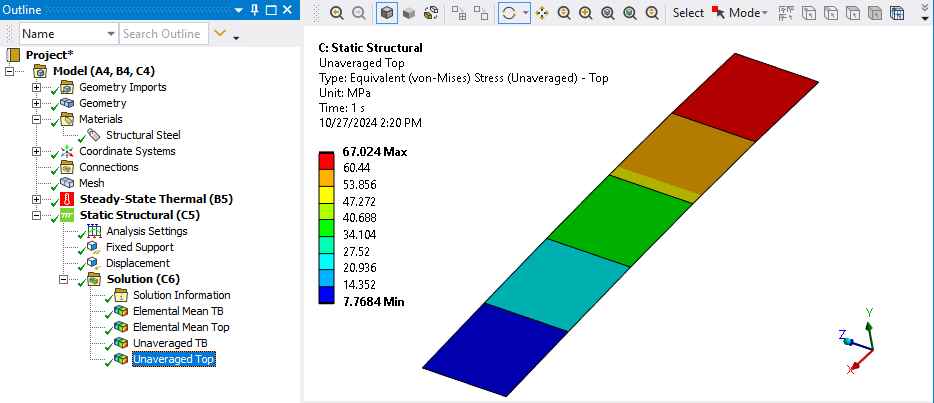

I usually use Unaveraged Stress results, and that is where you get the same results for Top/Bottom and Top.

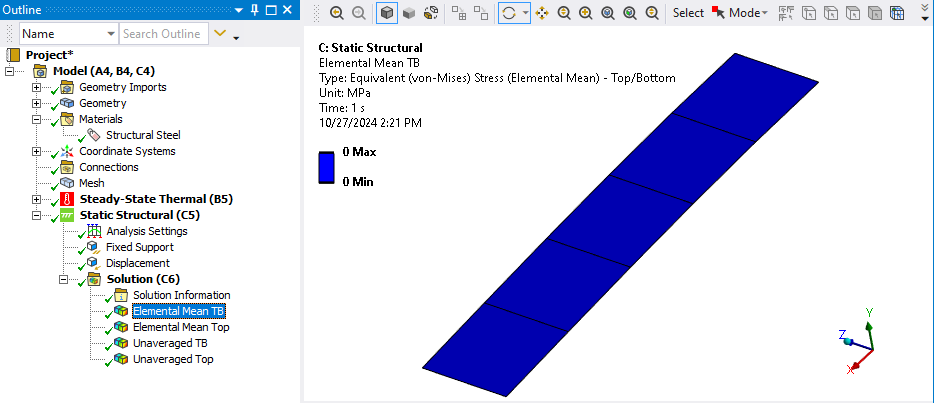

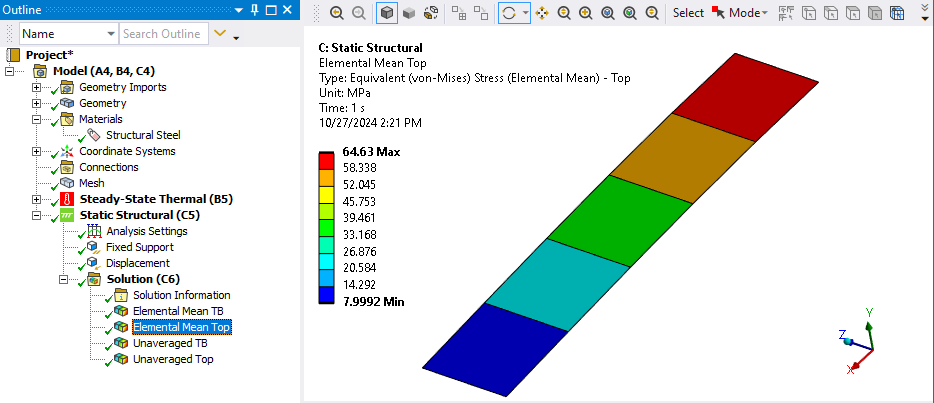

I learned that there is a huge difference for Elemental Mean, which I almost never use.

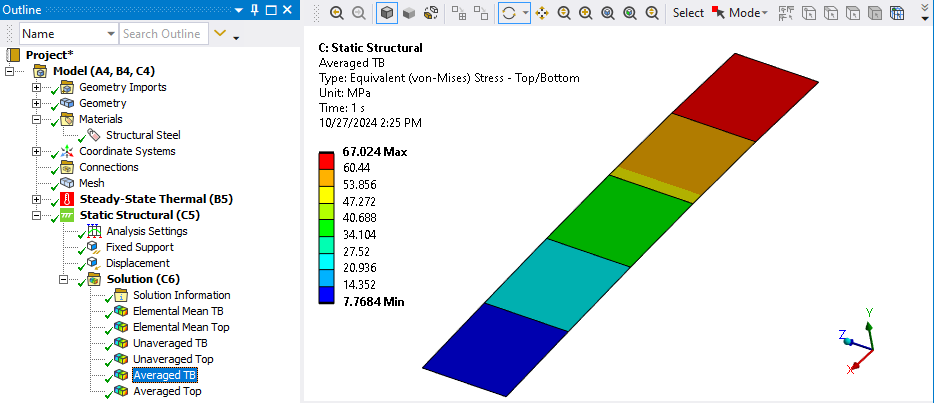

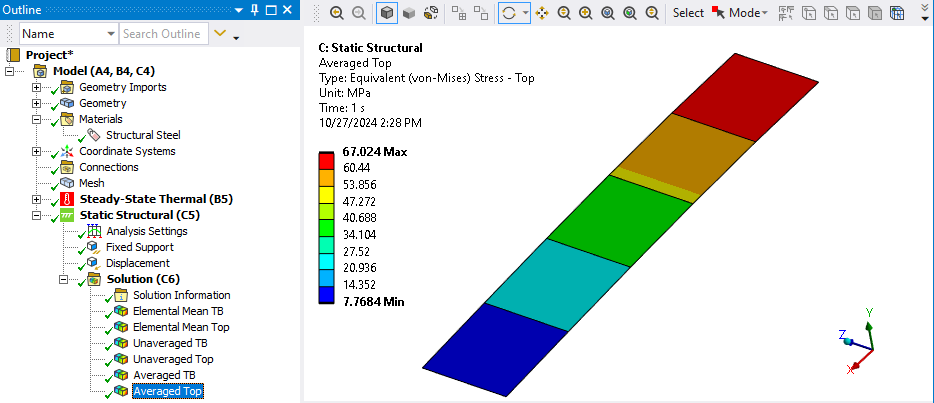

Here are the results of the default setting of Averaged.

I recommend you use either the default Averaged or my favorite Unaveraged stress results so you don’t have to worry about the Top/Bottom distinction.

Note that the stress in the Unaveraged element will approach the Averaged stress as the element size gets smaller.

-

- You must be logged in to reply to this topic.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- BackGround Color

- Contact stiffness too big

- Element Birth and Death

- Python-Script to Export all Children of a Solution Tree

- Which equations and in what form are valid for defining excitations?

-

4597

-

1495

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.