-

-

April 19, 2024 at 6:52 am

Tadeáš Salcman

SubscriberHello,

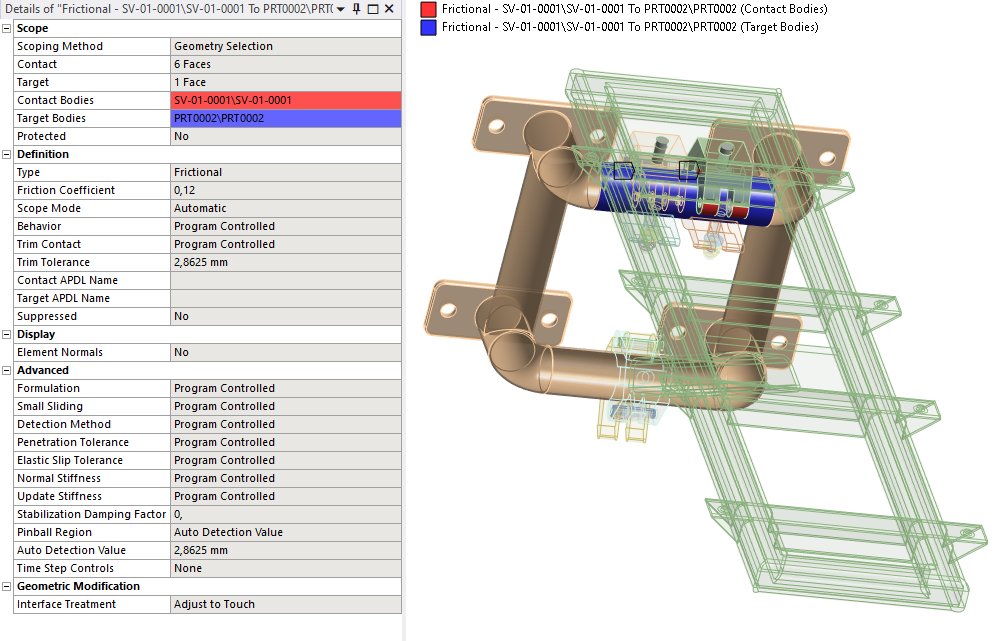

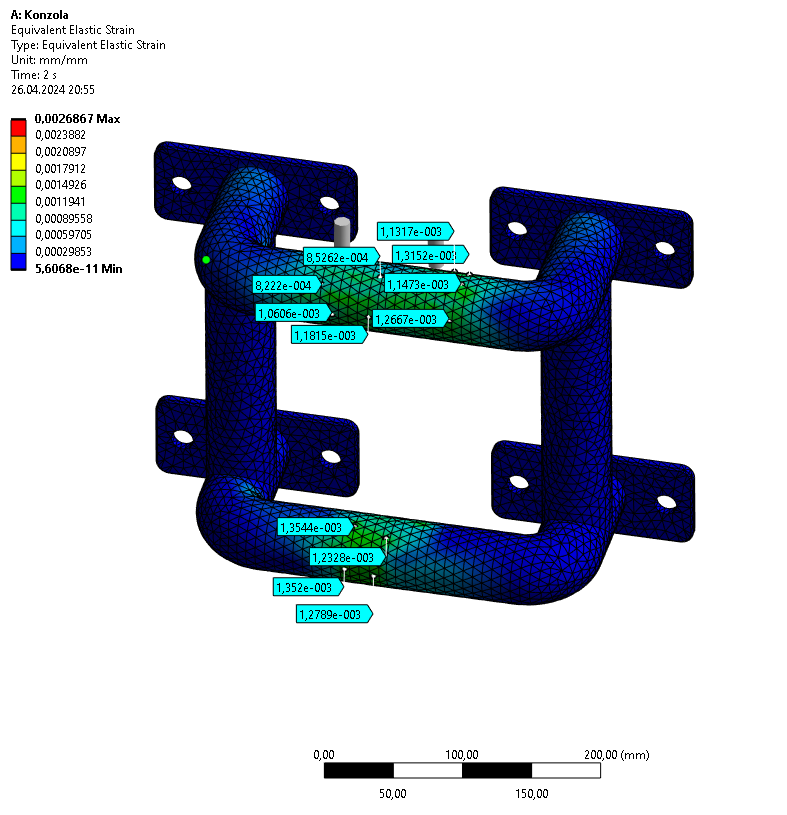

I have encountered a strange problem concerning contact. I am working on a seat attachment rig for a tram and I have been able to get positive results for a first version of the analysis. These are the pictures that document it:

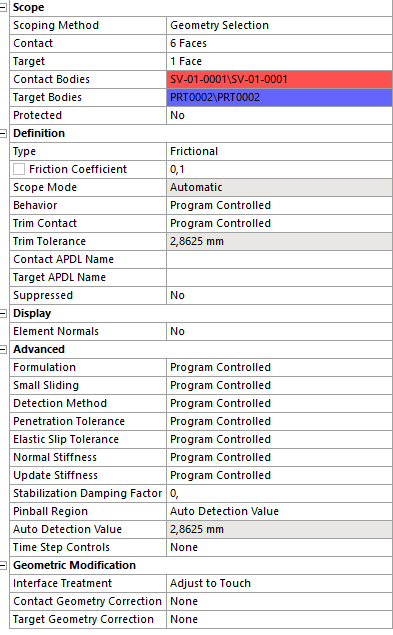

After completion I realised the external loads were too high so I decreased them for about 10 % as well as the friction from 0,12 to 0,1. Then I realised I should add more realistic materials than the Structural steel (yield strength 250 MPa, bilinear isotropic hardening) and Stainless steel (yield strength 250 MPa, bilinear isotropic hardening). So I duplicated the materials and in all of them increased the yield strength (also added bilinear is. hardending).

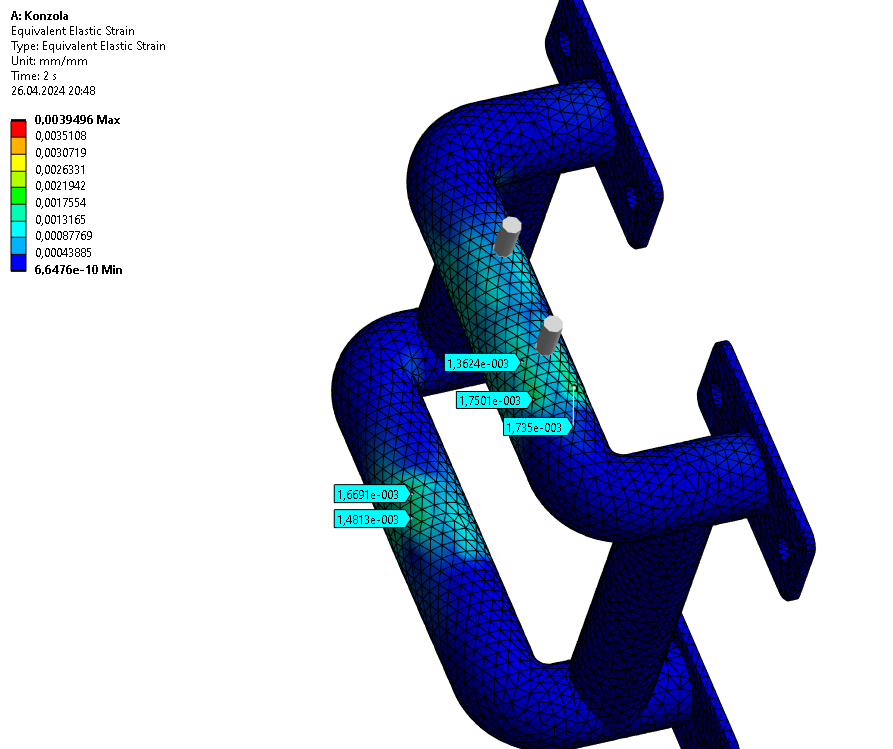

After finishing the update it is clear that the results increased significantly (at some spots for more than 70 MPa). In case of load increase that would be realistic but in a load decrease? Is there a way how to interpret or, better, fix this problem? I haven´t touched anything else, so there is no difference in mesh of the part etc. Thanks for your help!

Best regards,

Tadeáš

-

April 23, 2024 at 12:57 pm

Ashish Khemka

Forum ModeratorHi,

Can you check the deformation? For bilinear hardening after yield point the tangent modulue is lower than the Young's modulus and you may see a difference in deformation and how the structure is behaving when material model is changed.

Regards,

Ashish Khemka

-

April 26, 2024 at 6:58 pm

Tadeáš Salcman

SubscriberHello,

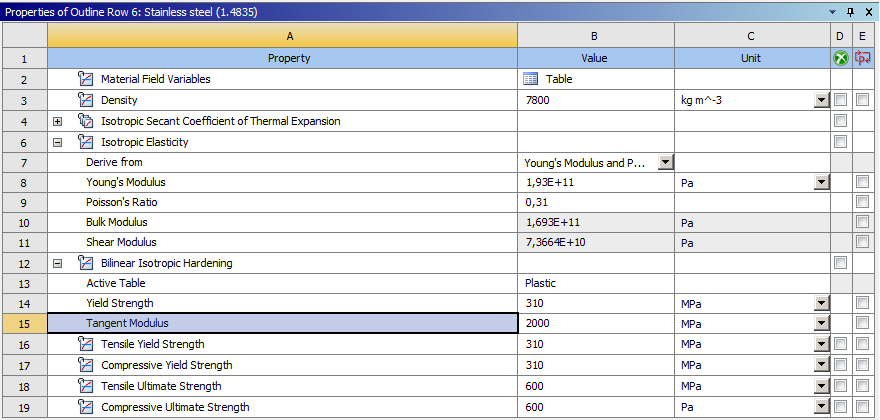

here are the elastic strains (it is visible that the deformation increased which is a bit strange considering the load decrease) and materials documenting the change. I tried to inspect if the target-contact pairs are not reverse, but after I ran the simulation I did get the same results. The value for tangent modulus of 2000 MPa I got from YouTube, is that aproximately correct?

Before I changed the materials and decreased the loads:

After I changed the materials and decreased the loads:

Thanks for your reply!

Best regards,

Tadeáš

-

April 29, 2024 at 7:41 am

Ashish Khemka

Forum ModeratorHi Tadeáš,

It would be difficult for me to comment on the Tangent Modulus as it is a material input requiredfrom user. There is no recommendation from Ansys that what value you should use but you can search the net for generic guidelines.

Regards,

Ashish Khemka

-

- The topic ‘Strange Contact Problem’ is closed to new replies.

-

4678

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.