-

-

July 26, 2024 at 1:38 pm

andre_costa

SubscriberHi,

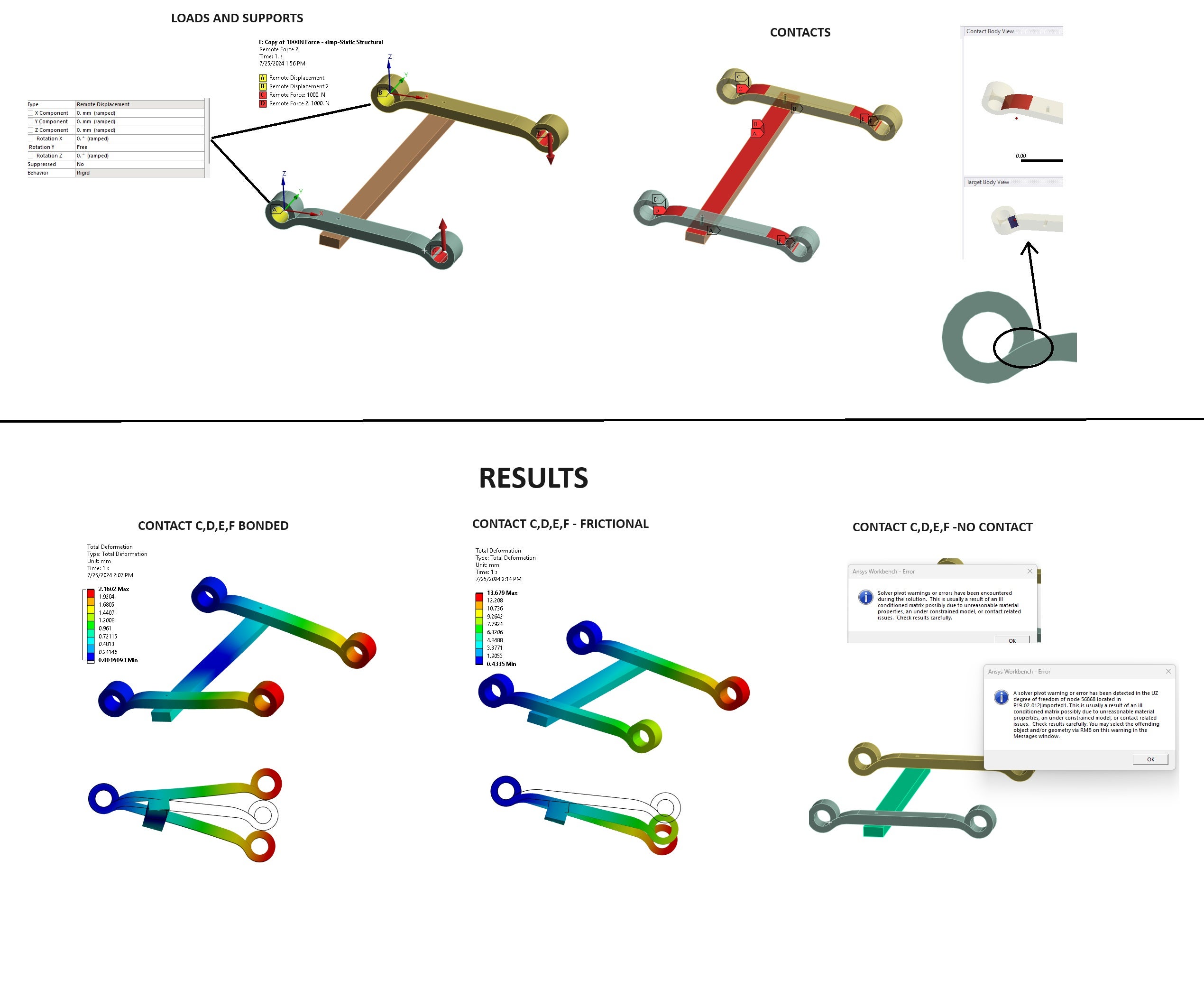

I'm making a stiffness verification of the present swaybar and I'm getting a completely different result in terms of motion when I change the bonded contact to frictional contact. I didn't expected a big diference in terms of the displacement much less in terms of diferent motion. when I supress the contact, (Frictional or Bonded) I get an error related to a node that in presented in the center of the middle bar.

Someone can explain the reason for both scenarios ? -

July 28, 2024 at 3:34 pm

peteroznewman

SubscriberHi Andre,

Bonded contact is a linear contact and can be solved using a linear solution while Frictional contact is nonlinear and requires a nonlinear solution method. That may be the reason for a large difference in results.

You can force the bonded contact to use a nonlinear solution method by turning on the Large Deflection setting under Analysis Settings. Make this change for both the Bonded and the Frictional models and get a fresh Solution for each one. Does that make the results any closer?

It would be good to see the size of the elements being used in this model. There should be at least 2 elements through the thickness of all the bars.

-

- The topic ‘Stiffness Study – Contact problem’ is closed to new replies.

-

4618

-

1530

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.